* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

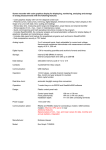

Download SCADAPack ES Hardware Manual

Resistive opto-isolator wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Oscilloscope types wikipedia , lookup

Power electronics wikipedia , lookup

Scattering parameters wikipedia , lookup

Power over Ethernet wikipedia , lookup

Buck converter wikipedia , lookup

Two-port network wikipedia , lookup

Mains electricity wikipedia , lookup

Power dividers and directional couplers wikipedia , lookup

Immunity-aware programming wikipedia , lookup