* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download AT-B420L

Audio power wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Ground (electricity) wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Electrical ballast wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrification wikipedia , lookup

Electrical substation wikipedia , lookup

Power inverter wikipedia , lookup

Pulse-width modulation wikipedia , lookup

History of electric power transmission wikipedia , lookup

Earthing system wikipedia , lookup

Power engineering wikipedia , lookup

Voltage regulator wikipedia , lookup

Stray voltage wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Current source wikipedia , lookup

Surge protector wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power electronics wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Buck converter wikipedia , lookup

Opto-isolator wikipedia , lookup

Mains electricity wikipedia , lookup

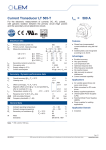

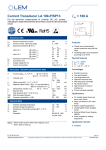

AC Current transducer AT-B420L AC Current transducer AT-B420L Split-core transducer the electronic measurement of ACofwaveform Split-core for transducer for the electronic measurement AC waveform currents, withcurrents, galvanic between thethe primary (power) withisolation galvanic isolation between primary circuit circuit (power) and the and the secondary circuit (measurement). 4-20current mA output current output to secondary circuit (measurement). 4-20mA proportional thethe RMS valuevalue of the primary current. current. proportional to RMS of the primary IIPN 150AA == 5 5 .... 150 PN Electrical data Primary nominal current rms IPN (A.t.Rms) Electrical data Output current IOUT (mA) Features Type 5 4-20 10 4-20 20 4-20 Primary nominal Output current Type 50 4-20 current rms 100 4-20 ISplit-core (A.t.Rms) IOUT (mA) transducer for150 the electronic measurement 4-20 of AC waveform PN AC Current transducer AT-B420L AT AT AT AT AT AT • RMS output Features • Loop-powered 4-20mA current output 5 B420L 10 B420L 20 B420L 50 B420L 100 B420L 150 B420L • Split-core type ●● RMS output • Ø 16 mm sensing aperture for non●● Loop-powered 4-20mA current contact measurement output • Terminal output ●● Split-core type • Isolated plastic case recognized ●● Ø 16 mm sensing aperture for according to UL 94-V0. non-contact measurement ●● Terminal output Advantages ●● Isolated plastic case recognized • High isolationtobetween primary and according UL 94-V0. IPN = 5 .. 150 A between the primary and 1) the currents, 5 with galvanic 4-20 AT 5 B420L R L isolation Load resistance, with Vcircuit = +(power) 24 V DC C secondary circuit (measurement). 4-20mA current output proportional to Supply voltage (loop-powered) the RMS 10value ofVCthe primary 4-20 AT 10 B420L current. ISL Output current 20 4-20limitation AT 20 B420L ÎP Overload capability - continuous 50 4-20 AT 50 B420L - 1 min 100 4-20 AT 100 B420L 150 4-20 AT 150 B420L Performance data < 600 W + 20 .. 30 V DC < 30 mA 120 % of IPN 150 % of IPN secondary circuits 1) data RL Electrical Load resistance, with VC =@+ I24, TV =DC < 600 W X Accuracy 25°C (excluding offset) < ± 2 % of IPN Advantages A • Compact case Primary nominal current rms Output current PN Type Features VC Supply voltage (loop-powered) + 20 .. 30 < ± 0.5 V DC % Linearity I (A.t.Rms) ε L I (mA)error • Cost-effective solution • RMS output4 ± 0.2mA mA ISL Output current limitation < 30 IOE Electrical offset current, TA =AT25°C ●● High isolation between primary 5 4-20 5 B420L • Easy installation • Loop-powered 4-20mA current output 10 10 B420L t r capability Response time to 90% of IAT step <% 100of IPN m s ÎP Overload -4-20 continuous 120 and secondary circuits P 20 4-20 AT 20 B420L • Split-core type BW Frequency bandwidth 50/60 50 -4-20 1 min 150 % of IPN Hz AT 50 B420L • Ø 16 mm sensing aperture for non-●● Compact case PN OUT 100 150 AT 100 B420L AT 150 B420L 4-20 General 4-20 data Performance data Load resistance, with V X e RL VC ISL ÎP L = + 24 V DC 1) < 600 W C TA Ambient operating temperature Supply voltage (loop-powered) + 20 .. 30 V DC TS Ambient storage temperature< 30 Output current limitation mA Accuracy @ IPN , TA = 25°C (excluding offset) Overload -Mass continuous 120 % of IPN mcapability LinearityIPxx error -Protection 1 min 150 % of IPN degree IOE Electrical offset current, TA = 25°C Performance data t r Response time to 90% of IPN step X Accuracy @ IPN, 1)TA = 25°CLoad (excluding offset) < ± 2Voltage % of IPN Note: Max. Resistance vs. Supply BW Frequency bandwidth ε Linearity error < ± 0.5 % L IOE tr BW Electrical offset current, 35TA = 25°C Response time to 90% of IP step Frequency bandwidth General data 4 ± 0.2 < 100 50/60 mA ms Hz Applications contact measurement • Terminal output • Isolated plastic recognized - 20case .. + 60 °C according to- UL 20 94-V0. .. + 85 °C ●● Cost-effective solution • ●Automation and Supervision ● Easy installation Current measurement for process Applications regulation by distributed PLCs or < ± 1.5 % of IPN 90 g remote control (e.g. SCADA < ±Advantages 0.5 % of I PN IP40 ●● Automation and Supervision 4 ±• High 0.2isolation between mAprimary and software) Current measurement for process • Security and Condition Monitoring < 100 secondary circuits ms regulation by distributed PLCs Load monitoring for protection • Compact case 50/60 Hz or remote control (e.g. SCADA systems and predictive software) maintenance (e.g. conveyers, • Cost-effective solution • Easy installation Supply Voltage (V) 30 Supply Voltage (V) ●● Safety and Condition pumps or HVAC motors) Monitoring • Energy management General data TA Ambient operating temperature - 20 .. + 60 °C • Automation and Supervision Load monitoring for protection Convenient connection to power Ambient storage operating temperature - 20 .. + 60 °C - 20 .. + 85 25 TSTA Ambient temperature °C for process systems and predictive Current measurement TS Ambient storage temperature - 20 .. + 85 °C consumption sub-meters regulation by distributed m m Mass g PLCs or Mass 90 g 90 maintenance (e.g. conveyers, remote control (e.g. SCADA 20 IPxx Protection degree IP40 IPxx Protection degree IP40 pumps or HVAC motors) software) Application domain • Security and Condition Monitoring●● Energy management 15 Load monitoring for protection • Energy and Automation Note: 1)1)Max. Max. Load Resistance vs. Supply Note: Load Resistance vs.Voltage Supply Voltage700 Convenient connection to power 400 500 600 800 900 1000 systems and predictive 35 consumption sub-meters Max. Load Resistance (Ohm) maintenance (e.g. conveyers, 30 pumps or HVAC motors) Application domain LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice. • Energy management 071115/4 Convenient connection to power consumption sub-meters 25 20 www.lem.com ●● Energy and Automation 500 600 700 800 900 1000 • Energy and Automation Max. Load Resistance (Ohm) 090609/6 071115/4 Page 1/3 Application domain 15 400 Applications Page 1/3 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice. LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice. www.lem.com Page 1/3 www.lem.com Current Transducer AT-B420L Isolation characteristics Vb Vd dCp dCl CTI Rated isolation voltage rms 2) with IEC 61010-1 standards and following conditions: - Reinforced isolation - Over voltage category CAT III - Pollution degree PD2 - Heterogeneous field Rms voltage for AC isolation test 3), 50Hz, 1min. Creepage distance Clearance distance Comparative tracking index (Group I) 300 V 3.5 6 6 600 kV mm mm Notes:2)If insulated cable is used for the primary circuit, the voltage category could be improved according to the primary cable insulation category (please refer to the cable manufacturer’s indications) 3)between primary (completely filling the hole) and secondary. Safety and warning notes In order to guarantee safe operation of the transducer and to be able to make proper use of all features and functions, please read these instructions thoroughly! Safe operation can only be guaranteed if the transducer is used for the purpose it has been designed for and within the limits of the technical specifications. Ensure you get up-to-date technical information that can be found in the latest associated datasheet under www.lem.com. Caution! Risk of danger Ignoring the warnings can lead to serious injury and/or cause damage! The electric measuring transducer may only be installed and put into operation by qualified personnel that have rceived an appropriate training. The corresponding national regulations shall be observed during installation and operation of the transducer and any electrical conductor. The transducer shall be used in electric/electronic equipment with respect to applicable standards and safety rquirements and in accordance with all the related systems and components manufacturers’ operating instructions. Caution! Risk of electrical shock When operating the transducer, certain parts of the module may carry hazardous live voltage (e.g. primary conductor, power supply). The user shall ensure to take all measures necessary to protect against electrical shock. The transducer is a built-in device containing conducting parts that shall not be accessible after installation. A protective enclosure or additional insulation barrier may be necessary. The transducer shall not be put into operation if the jaw opening is open (split core version) or the installation is not completed. Installation and maintenance shall be done with the main power supply disconnected except if there are no hazardous live parts in or in close proximity to the system and if the applicable national regulations are fully observed. Safe and trouble-free operation of this transducer can only be guaranteed if transport, storage and installation are carried out correctly and operation and maintenance are carried out with care. Page 2/3 090609/6 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice. www.lem.com Dimensions AT-B420L (in mm. 1 mm = 0.0394 inch) Dimensions AT-B420L (in mm. 1 mm = 0.0394 inch) Bottom view Back view 18 18 16 Dimensions AT-B420L (in mm. 1 mm = 0.0394 inch) 23.5 16 4 4 16 40.5 + 28.5 4 + 4 1.5 23.5 31.5 51 (OUT) (+V) 22 K L N.P 18 18 51 28.5 1.5 31.5 16 + 40.5 2.5 + (OUT) (+V) 2-M3 terminal with cover 22 K L N.P Top view 2.5 2-M3 terminal with cover Remark Mechanical characteristics •Mechanical ATTENTION: characteristics contact areas (air gap) must be kept clean • Remarks General tolerance ± 1 mm • Primary aperture ∅ 16 mm ●Mechanical ● ATTENTION: contact areas (air gap) must be kept clean characteristics • Fastening Cable tie (particle free) to ensure proper performance ●● General tolerance ± 1 mm Remark ●● Primary aperture Ø 16 mm • ATTENTION: contact areas (air gap) must be kept clean ●● Fastening Cable tie (particle free) to ensure proper performance (particle free) to ensure proper performance • General tolerance • Primary aperture • Fastening Connections •Connections Wires up to 2 mm ∅ ± 1 mm ∅ 16 mm Cable tie Connections (+V)(OUT) ●● Wires up to 2 •mm Ø up to 2 mm ∅(+) (-) Wires (+V)(OUT) (+) (-) K K 24 VDC Power 24 VDC Power (+) (+) (-) (-) (+) Ip (-) (-) (+) Load (+) Ip L (+) OUT OUTIs (-) (-) GND +24VDC GND (Controller, meter etc) LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice. 071115/4 Is L Load 090609/6 +24VDC (Controller, meter LEM reserves the right etc) to carry out modifications on its transducers, in order to improve them, without prior notice. Page 3/3 www.lem.com Page 3/3 www.lem.com Page 3/3 071115/4 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice. www.lem.com