* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download module 4–headlamps - Northwest Technology Center

Fault tolerance wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

Electrification wikipedia , lookup

Opto-isolator wikipedia , lookup

History of electric power transmission wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Light switch wikipedia , lookup

Electrical ballast wikipedia , lookup

Safety lamp wikipedia , lookup

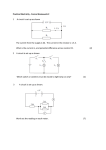

MODULE 4–HEADLAMPS Topic A. Exterior And Interior Lamps Turn Signal Lamp And Hazard Lamp Headlamps Cornering Lamp Underhood Lamp Side Marker Lamps And Parking Lamps Fog Lamp Side Marker Lamp A-2 There are many different types of exterior lamps found on the front of the vehicle. Exterior lamps in the front of the vehicle include: headlamps. Headlamps are white lights that are on when the headlamp switch is turned ON or they may use a sensor to automatically turn ON. fog lamps. Fog lamps are white or amber lights that are on when the fog lamp switch is turned ON. driving lamps. Driving lamps are white lights that are on when the driving lamp switch is turned ON. turn signal lamps. Turn signal lamps are amber lights that are on when the turn signal switch is turned ON. Additional turn signal lamps may be located in the side mirrors or along the fenders. The turn signal lamp may be the same lamp as the parking lamp. Multiple turn signal lamps located on the same side of the vehicle may alternately flash. cornering lamps. Cornering lamps are white lights that are on when the corresponding turn signal is turned ON. parking lamps. Parking lamps are amber lights that are on when the headlamp switch is in the PARK position and when the headlamps are ON. side marker lamps. Side marker lamps are amber lights that are on when the parking lamps or headlamps are ON. Side marker lamps may be separate from the parking lamps. additional marker lamps. Additional marker lamps include the lights above the windshield in exterior visors or on the roof of a truck. Additional marker lamps are on when the standard parking lamps are ON. hazard lamps. Hazard lamps are amber lights that are on when the hazard lamp switch is ON. Hazard lamps may use the same bulb as turn signal lamps, therefore the hazards may also alternately flash. underhood lamps. The underhood lamp is a white light that is on when the hood is open. Underhood lamps may use a mercury switch or a button to turn them OFF when the hood is closed. Many mercury switches in vehicles are being replaced with different types of switches for environmental reasons. High-Mount Stop Lamps Stop Lamps Additional Turn Signal Lamp License Plate Lamps Side Marker Lamps And Parking Lamps Back-Up Lamp Turn Signal Lamp And Hazard Lamp Additional Marker Lamps Cargo Lamp A-3 There are many different types of exterior lamps found on the rear of the vehicle. Exterior lamps located in the rear of the vehicle include: Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair stop lamps. The stop lamps are red lights that are on when the brakes are applied. The stop lamps may use the same bulb as parking lamps, but brighter. Switches for the stop lamps are located on the brake pedal arm or on the master cylinder. 67 high-mount stop lamps. High-mount stop lamps are red lights that are on when the brakes are applied. High-mount stop lamps may be mounted in the rear closure panel, in a spoiler, above the backlite, at the top of the backlite, or on the interior rear shelf. parking lamps. Parking lamps are red lights that are on when the parking lamps or headlamps are ON. side marker lamps. The side marker lamps are red lights that are on when the parking lamps or headlamps are ON. additional marker lamps. Additional marker lamps include the lamps in the rear fenders of six-wheel trucks, along the tailgate of some heavyduty trucks, along the running boards, and along the sides of conversion vans. Additional marker lamps are on when the standard parking lamps are ON. license plate lamps. The license plate lamps are white lights that are on when the parking lamps or headlamps are ON. turn signal lamps. Turn signal lamps may be red or amber lights that are on when the turn signal switch is ON. Turn signal lamps may be the same bulb as the stop or parking lamp except that they flash. Multiple turn signal lamps may alternately flash. hazard lamps. Hazard lamps are red or amber lights that are on when the hazard lamp switch is ON. Hazard lamps typically use the same bulb as signal lamps, therefore the hazards may also alternately flash. back-up lamps. Back-up lamps are white lights that are on when the transmission is in REVERSE. trunk lamps. The trunk lamp is a white light that is on when the trunk is open. cargo lamps. The cargo lamp is a white light that is on when the cargo lamp switch is ON. The cargo lamp lights the bed of the truck. Vanity Mirror Lamps Dome Lamp Courtesy Lamps Map Lamps Instrument Panel Lamps A-4 There are many different types of interior lamps. Interior lamps are white lights including: Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair the dome lamp. courtesy lamps. vanity mirror lamps. map lamps. instrument panel lamps. accessory lamps. 68 Topic B. Headlamps B-2 Standard sealed beam headlamps are typically found on older vehicles. B-1 High-intensity discharge and projector headlamps are two different types of headlamps. Standard sealed beam headlamps: Headlamp types include: standard sealed beam. halogen sealed beam. composite. high-intensity discharge (HID). projector. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair may be the two-headlamp style. may be the four-headlamp style. The high beam and the low beam are separate lamps. must stay sealed for the bulb to light and stay lit. 69 Vented Headlamp B-3 Sealed beam halogen headlamps are typically a rectangular shape. Sealed beam halogen headlamps: light and remain lit even if the housing is broken or cracked. A damaged housing does not prevent the bulb from lighting, but may cause poor light quality depending on the location of the damage. require the bulb and the housing to be replaced if the bulb is burned out. B-4 Vented composite headlamps may have a filter that is covered by a drain tube. Composite headlamps: Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair use a replaceable halogen bulb. Therefore if the bulb is burned out, only the bulb requires replacement, not the entire assembly. may be vented. Condensation in a vented composite headlamp does not damage the bulb initially, but excessive moisture may cause the socket to corrode. may be nonvented. Condensation in a nonvented composite headlamp requires replacement of the assembly. Condensation may cause damage to the bulb or distort the light. 70 HID Bulb B-5 An HID headlamp bulb may be replaced separately or as part of the headlamp assembly. B-6 A projector headlamp is easy to distinguish from the other types of headlamps. Projector headlamps: High-intensity discharge headlamps or HID headlamps: may have a bluer hue compared to traditional headlamps. may also be called xenon headlamps. use an electronic control unit (ECU) or HID ballast unit that changes DC volts to AC volts and provides 25,000 volts and 20 amps to light the HID capsule. create a focused beam of light. are typically used for the low beam headlamps. may also be used for fog lamps. Use caution when working with these types of headlamps. High amounts of electricity are used to light this type of headlamp, so serious injury may occur when working on a malfunctioning system. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair 71 Topic C. Headlamp Removal And Replacement C-2 The code on the bulb should match the code on the base of the lamp assembly. When selecting a replacement lamp: C-1 The bumper cover and grille may require removal to access the headlamp assembly fasteners. When removing and replacing headlamps: identify if the bulb has to be replaced, or if the entire assembly requires replacement. If the assembly requires replacement, determine if the bulbs are supplied with the assembly. parts such as the bumper require removal to gain access. a variety of different hardware is available depending on the vehicle make and model. Damaged adjusters also require replacement. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair use the standard trade number located on the lamp housing for identification. choose the same type and style. HEADLAMP REMOVAL Refer to screen C-3v of your CD-ROM for a video on different types of headlamp hardware and attachment methods. 72 Topic D. Aiming Headlamps C-4 Minor damage to a lamp such as a chip may be repairable using a product designed to fix lenses. Types of headlamp lens damage that may be repaired includes small: chips that can be repaired using special plastic repair product. Check local and provincial laws for lamp repairability standards. Red and yellow products are also available for colored lenses. scuffs that can be polished using special products. D-1 There are several equipment makers that specialize in headlamp aiming equipment. Types of headlamp aiming equipment includes: LENS REPAIR PRODUCTS Select the Demonstration Icon found on screen C-4 of your CD-ROM for examples of lens repair products. manual using a screen or chart. the type that is already built into the headlamp assembly. the suction cup type. the computerized type. the light-sensitive type. MANUAL HEADLAMP AIMING Select the Demonstration Icon found on screen D-1 of your CD-ROM for an example of manual headlamp aiming instructions. LENS REPAIR Refer to screen C-5v of your CD-ROM for a video on repairing a chip in a tail lamp lens and polishing a hazy headlamp lens. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair 73 D-2 A bubble level may be built into the headlamp for aiming purposes. D-3 Only headlamps that have protruding pegs can be aimed using suction cup type aiming equipment. Built-in headlamp aimers may: The suction cup type aiming equipment: be a dual bubble level. automatically adjust. be controlled from inside the vehicle. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair uses protruding pegs built into the headlamp lens. Headlamps without these pegs cannot be aimed using this type of equipment. requires the lens to be smooth. The suction cup will not attach to a lens with raised letters. physically levels the headlamp assembly. This type of headlamp aiming equipment is for the type of headlamp that adjusts the assembly, not just the beam of light. Some headlamp assemblies adjust the beam of light inside the headlamp, the exterior part of the assembly does not move with the adjustment. 74 D-4 Computerized aiming equipment can be used to aim any type of headlamp. D-5 This headlamp aiming equipment uses heat intensity to determine where the headlamps are aimed. Computerized headlamp aiming equipment: Light-sensitive aiming equipment: may use a mark on the headlamp lens. This mark indicates the center of the beam of light. uses the beam of light to aim the headlamp assembly. This type of equipment may be used on any type of headlamp. uses the hottest spot of the light beam for adjustment. uses the beam of light to aim the headlamp. The headlamps are coded for the shape of light that is projected. uses a color-changing method to indicate heat intensity. Deflated Tire D-6 A deflated tire may cause the vehicle to be unlevel. Before aiming headlamps: Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair install parts that affect ride height such as the hood. remove materials that affect ride heights such as excessive snow or mud. verify that tires are properly inflated. 75 Low Beam Left And Right High Beam Up And Down High Beam Left And Right Low Beam Up And Down D-7 Several adjusters may be located on the headlamp assembly. Headlamp aiming hardware: may use a screw or a knob to adjust the position of the headlamp beam of light. includes vertical or up-and-down adjustments. All headlamps have vertical adjustments. may include horizontal or left-and-right adjustments. Some headlamps have vertical and horizontal adjustments. D-8 An instruction manual is typically provided with the aiming equipment. When aiming headlamps, follow all federal, state, provincial, and local laws and the headlamp aiming equipment maker’s instructions. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair HEADLAMP AIMING Refer to screen D-9v of your CD-ROM for a video on different product makers’ headlamp aiming equipment. 76 Topic E. Lighting Circuit E-2 Start the troubleshooting process by defining the problem and verifying that the switch is operational. E-1 All lamps should be checked to verify that they are operational. When problem-solving lighting failures with no vehiclespecific troubleshooting flowchart, follow the I-CAR Five Step Troubleshooting Flowchart. The steps in this flowchart require: defining the problem. knowing the system. finding the cause. making the repair. testing the system. If a lamp does not work, begin the troubleshooting process by asking questions such as: Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair what else does not work? Try other switches that control the same load. Try switches and loads that might be related. Isolate the problem or group of problems as much as possible. is the circuit trying to work, but cannot? Listen for a motor humming or relay clicking. These can be signs of too much resistance. Try jiggling the switch lightly or positioning it between settings to see if it makes a difference. 77 When using a service manual to troubleshoot a problem, determine if it has a diagnostic chart for the problem. However, when using service manuals to diagnose electrical problems, note that most are NOT written from a collision repair standpoint. This may require some modification of the flowchart steps. General circuit information may be found in an owner’s manual. It may be referenced in a general sense if a service manual is not available. Use the collision advantage to troubleshoot a damaged system. The collision advantage is the concept of inspecting the: E-3 Know the system by referencing manuals for specific vehicle electrical systems. Learn how the circuit works by reading the system description and using a wiring diagram. The system description is used to verify if the part is working correctly or incorrectly. A wiring diagram is necessary unless the circuit is very simple and its operation obvious. A wiring diagram is used: area of direct impact for damaged parts before inspecting all parts of the vehicle. parts of the vehicle that were replaced or removed during the repair. to find the ground and power distribution. If there are several different loads not working, a common ground or circuit protector should be inspected for damage. if one load, or set of closely related loads are not working properly, start where the power comes into the circuit protector. to determine if the key must be in RUN or ACC for the circuit to work or if the circuit is normally closed. to determine the type of circuit protector and its amperage rating. to determine the current flow through the switch, load, and to ground. to determine the current flow when the switch is moved to different positions. to determine where current is flowing when the switches are in the normal, or at rest, position. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair 78 E-4 A loose ground may be the cause of an improperly operating lighting circuit. E-5 A pinched wiring harness may be the cause of an improperly operating lighting circuit. Start with the simplest solutions. There may be some obvious signs of faults that allow the problem to be solved quickly. These fault “quick checks” include: If none of these are obvious, closer inspection is required. Check for: tracing the circuit back to the fuse, doing voltage checks until voltage is present. This process is typically performed when voltage is not getting to the load because of an open in the hot side of the circuit. checking for an open ground. This is indicated by the load not working, full supply voltage getting to the load, and power on both sides of the load. checking the load itself for proper operation. replacing a fuse and having it blow immediately after replacement or after a period of time. This can be caused by a short to ground between the fuse and the load. checking if the load is not connected to the circuit, dropping out the main source of resistance in the circuit. making sure that the fuse is the proper size. loose or damaged connectors. bare spots in the insulation, especially where a wire passes through a body panel or metal clip. This could cause a wire to rub against a metal surface, cut the insulation, and cause a short. signs of pinched wires. signs of stretched wires. signs of discoloration in connectors or harnesses. signs of spilled battery acid or corrosion. any harness clips or brackets not fastened correctly. Check wiring under brackets or clips by performing a voltage-drop check. To perform a voltage-drop check: 1. Connect the DVOM from the load to the nearest ground. 2. Wiggle the wire. 3. If the DVOM changes readings, there is likely a hidden short. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair 79 E-6 Follow the vehicle maker’s guidelines when repairing damaged wires. E-8 Splice locations should be staggered, which typically requires cutting the new replacement wires. Once the problem has been identified: Connector replacement kits: repair or replace damaged wiring harnesses. replace damaged parts. test the circuit before reassembling or reinstalling parts. are partial wiring harnesses with the connector. These kits are available from the vehicle maker for some vehicles and applications. replace the damaged connectors and the wiring near the connector. CONNECTOR REPLACEMENT Refer to screen E-9v of your CD-ROM for a video on replacing a headlamp connector using one vehicle maker’s repair kit. E-7 A scan tool can be used to retrieve some electrical circuit information. Some lighting circuit problems may be identified using a scan tool. Do NOT use a test light to test lighting circuits unless recommended by the vehicle maker. Some circuits include computers that may be damaged by a test light. Use a DVOM unless a test light is recommended by the vehicle maker. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair 80 Topic F. Switches F-2 License plate lamps should light with the rest of the parking lamps. F-1 There are several different types of headlamp switches. The PARK position of the headlamp switch supplies power to the: The headlamp switch is typically powered all of the time. The headlamp switch may be: mounted on the instrument panel. part of the multifunctional switch on the steering column. a rotary switch. a push-button switch. side marker lamps in the front and the rear of the vehicle. license plate lamps. instrument panel lamps. HEADLAMP PARK OFF F-3 Symbols are typically used instead of words to identify the positions on the switch. The HEADLAMP position of the headlamp switch supplies power to the headlamps and the lamps lit by the PARK circuit. Each headlamp may be fused separately. This allows each headlamp to operate separately if a lamp is burned out. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair 81 Dimmer Switch F-4 Late model vehicles use the multifunctional switch to dim the headlamps. F-6 An automatic lighting system sensor may be located on the instrument panel. The headlamp dimmer switch: An automatic lighting system: switches the headlamps from high beam to low beam and vise versa. is controlled by either pushing or pulling the multifunctional switch on the steering column. uses a light-sensitive photocell sensor or amplifier to turn the headlamps ON and OFF. This sensor is in the upper part of the instrument panel near the windshield. is overridden by the headlamp switch. The headlamps may be manually turned ON and OFF or the AUTO setting may be used. F-5 The multifunctional switch typically controls the flash-to-pass function. Flash-to-pass: switches on the high beam headlamps with the headlamp switch in ON, OFF, or PARK. The high beams are only on for as long as the switch is held. is controlled by the headlamp dimmer switch. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair 82 F-7 The automatic headlamp dimmer sensor may be attached to the base of the rearview mirror. An automatic headlamp dimmer switch: switches the headlamps from high beam to low beam. uses a photocell or image-sensing technology. A photocell is activated by the light from the environment, approaching headlamps, or tail lamps. Image-sensing technology uses a camera-on-achip. may have a switch used to control the sensitivity of the photocell. F-8 Headlamps may stay on for a specified length of time. Headlamps may be delayed: Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair to stay on for a specific period of time after the ignition switch is turned off. for a length of time that is controlled by a switch. Some delay timers are built-in and cannot be adjusted. 83 F-9 Daytime running lamps may use an amber bulb. F-10 Daytime running lamps may use a headlamp bulb. Daytime running lamps are: Daytime running lamps may: on when the vehicle is running or in gear depending on the make and model vehicle. deactivated by the parking brake and headlamp switch. Daytime running lamps automatically turn OFF when the headlamps are ON or when the parking brake is applied. required by Canadian law for safety. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair be a separate light. use the high beam headlamps at a reduced voltage. use the turn signal lamps. use the low beam headlamps. 84 Topic G. Retractable Headlamps Topic H. Review REVIEW Refer to screens H-1 and H-2 of your CD-ROM for review questions on headlamps. G-1 Retractable headlamps are found on a limited number of late-model vehicles. Retractable headlamps: are controlled by electric or vacuum motors. may also be referred to as concealed or pop-up headlamps. Lighting, Starting, And Charging Systems Program 1 v.5.1–Module 4 © 2003 Inter-Industry Conference On Auto Collision Repair 85