* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Technician Handbook For Huurre WIC With Petrol Genset

Variable-frequency drive wikipedia , lookup

Buck converter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power over Ethernet wikipedia , lookup

Electric power system wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electrical substation wikipedia , lookup

Power engineering wikipedia , lookup

Control system wikipedia , lookup

Electrification wikipedia , lookup

Distribution management system wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Earthing system wikipedia , lookup

Rectiverter wikipedia , lookup

Mains electricity wikipedia , lookup

Fault tolerance wikipedia , lookup

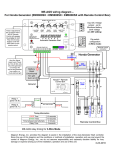

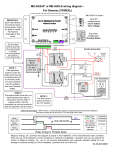

‘huurre’ Cold-room Technicians’ Hand Book 1 HUURRE WALK-IN-COLD-ROOM CONTENTS: Page No. 1. General Information 3 2. Diagrams: Lay-out Control Unit (Part - 1) Control Unit (Part - 2) Cooling Units Alarm System Temperature Recorder 5 5 5 6 7 8 3. Description Of Main Components 8 4. Initial Starting & Normal Operation 10 5. Trouble – Shooting 14 6. Sequence of operating of relays in control unit 17 2 ‘HUURRE’ WALK IN COLD ROOM GENRAL INFORMATION: The Cold – Room: One of The Most Important Links In the Cold-chain is Walk-InCold-Room. This Is Used For Buck Storage Of Vaccines At +4 To 8 c At State Level Or Regional Storages. This insulated room is kept cold by two nos. of cooling-units, mounted on its walls. The working of the cooling-units are controlled by their thermostats, which switch-on and switch-off the compressors, depending upon the inside temperature. The thermostats of the units are so adjusted that one unit works when the inside temperature is about +5c and goes off at about +4 c and the other works when the temperature is about +7 c and goes off at about +6 c. This way, when the temperature is around +5 c, only one unit works. But, if Due to door opening, storage of new vaccines, higher ambient temperature, power failure etc. The temperature of the cold-room rises above +7 c, both the units work. When the temperature comes down to about +6 c, the 2nd unit stops and only the 1st unit work and maintain the vaccines at the lower temperature. The evaporator-fans of the cooling-units (inside the cold-room) blow the cold air from the units and circulate the air inside the cold-room. They run continually. The condenser-fans of the units (out-side the cold-room) cool the condenser coils and they run only when the compressors works. Power- supply: The cooling-units run from 400 v, 3-phase, 50 Hz. AC power supply, normally from the network (Mains). Stand-by Generator & Control Unit: To keep the cooling-units running on the event of network (mains) power failure, a stand-by generator is provided. In case of power failure, the generator can be started either “manually” or “automatically”. In case of Automatic selection, the control-unit sense the power failure and sends signal automatically to start the generator. If the generator could not start on the 1st starting signal, the control unit sends 2 more start to the generator at intervals. Even then, if the Generator could not start, Generator failure alarm is given. (This can be put off by bringing ‘hand/Auto drive’ selectors switch to ‘hand’ position. once). If generator starts and run the power from the generator is connected, with a delay, to only one of the cooling-units (to be selected by a selector switch), to continue the cooling. When network power returns, the generator power supply cutoff and the generator are stopped and also the network power is reconnected to the units (with a delay) automatically by the control-unit. Whenever generator runs, the 3 ‘Drive memory’ lamp glows and remains, indicating that the generator was working. This lamp can be put off by pressing the ‘Reset’ button once. NOTE: Also in the cases of single phasing, phase reversal etc. in the network supply, the same is disconnected and the generator starts and run connect generator power to the selected unit automatically. IMPORTANT: The 12 V car battery on the generator is not only for starting the engine, but also for supply of 12 V DC to the control-unit and alarm-system. So if the battery voltage is low or the battery is discharged they, will not function properly in case of power failure and the generator will not start (or can be started manually). Alarm System: The alarm system provided monitors the cold room temperature and actuates audio and visual alarm, immediately, in case of the temperature reaching +2c or with a present delay, when the temperature rises to about +10c. In alarm condition, the audio alarm can be stopped by pressing a button, but visual alarm will continue till the alarm condition prevails or the switch of the alarm system is put off. The alarm also actuates in case of 12 VDC Failure. There is also a test button, provided to test the functioning of the alarm system. Temprature Recorder: The temperature recorder records the cold-room temperature continually on a circular chart. Normally the recorder is set to turn the chart one complete round in 7 days. So the charities to be changed each week. DEFROSTING: The moistures in the air inside the cols-room get frozen and form frost on the evaporator coils of the units. For better cooling efficiency, they are to be melted, time-to-time. Defrosting is done automatically, by the defrost timers in the cooling units, which puts off the units for a present time, twice in 24 Hrs., at an interval, allows the frost to melt and drain out. 4 5 6 7 DESCRIPTION OF MAIN COMPONENTS CONTROL UNIT F1 = Circuit Breaker, 10 A, (K1 Circuit) F2 = Circuit Breaker, 16 A, (Generator Power Circuit) F11 = Circuit Breaker, 16 A, (Cooling Unit I) F12 = Circuit Breaker, 16 A, (Cooling Unit II) F13 = Circuit Breaker, 16 A, (Room-Light & 3.4 V Rectifier) FB1 = Transformer for 3.4 V Rectifier H1 = Signal Light (Red) (Engine Failure Indication) H2 = Signal Light (Yellow), (Drive Memory) K1 = Contactor (Network Power) K2 = Contactor (Generator Power) K11 = Sequence Relay (Network Power) K12 = Time Delay Relay (Network Power) K13 = Relay (Network Power Sensing) K21 = Sequence Relay (Generator Power) K22 = Time Delay Relay (Generator Power) K23 = Relay (Drive Memory), 12 V DC. 8 KAP3 = Circuit Card (Generator Control) KAP4 = 3.4 V. Rectifier Circuit Card For Recorder Power Supply S1 = Main Switch (Network Power & 12 V DC Inputs) S11 = Selector Switch UNIT I / UNIT II (For Generator Supply) S12 = Press Button, Reset (Drive memory) S13 = Press Button, Stop (Generator) S14 = Press Button, Start (Generator) S15 = Selector Switch, HAND / AUTODRIVE (Generator) X1 = Plug X2 = Terminal Strip X3 = Junction Box XA= Terminal Strip (KAP3) XB = Terminal Strip (KAP3) COOLING UNITS C1 = Capacitor (Evaporator Fan Motor) C2 = Capacitor (Condenser Fan Motor) F1 = Circuit Breaker H1 = Signal Light, Green (Main Supply Indication) H2 = Signal Light, Yellow (Defrosting Indication) K1 = Contactor (Power Input to Compressor Motor) M1 = Compressor Motor, 400 V 3Ø M2 = Condenser Fan Motor, 220V 1 Ø M3 = Evaporator Fan Motor, 220V 1 Ø P1 = Defrost Timer R7 = Varistor (K1 Circuit) S1 = ON/OFF Switch, Power S2 = Thermostat (Compressor Motor Control Circuit) S3 = Pressostat (Compressor Motor Control Circuit) S4 = Pressostat (Condenser Fan Motor Circuit) ALARM SYSTEM A2 = Alarm Center A11 = Alarm Device G1 = Battery, (8 * 1.5 v), (Internal) H1 = Signal Light, Green, (Network Voltage) H2 = Signal Light, Red, Alarm K1 = Alarm Relay, 12 V DC (Temp. Too High) K2 = Alarm Relay, 12 V DC, (12 V DC Failure) P1 = Delay Timer (K1 Relay) S1 = Main Switch for Alarm-Center S2 = Test Button (Alarm Operation) S3 = Alarm Thermostat (Temp. Too Low) S4 = Alarm Thermostat (Temp. Too High) 9 Temperature Recorder A3 = Recorder Unit G1 = Lithium Battery, 3.4 V, Size-AA/IEC, R6 (Internal) K1 = Change- Over Relay (Internal /External Power) INITIAL STARTING & NORMAL OPERATION Before power supply from the network is switched on, keep the Selector switch in ‘HAND’ Position and the main-switch in ‘O’ position in the control-unit. When supply is made available to the control-unit (Incoming at terminals L1, L2 & L3) and the main switch on the control unit is put to ‘I’ position, Sequence-relay K 11 should operate. Operated condition of this type of relay can be observed from the glow of the red pilot-lamp (LED) on the same. How, after a pre-set delay period (approx. 30 secs.) relay K 12 will operate, which in turn will operate relay k 1 which will extend the network power-supply to the cooling-units HU I and HU II. HU I & HU II can be operated by switching ‘ON’ the circuit-breakers and the switches on them. 10 On switching on the units the Green (mains ON) indicator lamps on them will glow. Now shift the selector-switch on the control-unit to ‘Auto Drive’ position. In the cooling-units, the evaporator fans are always in operating condition so long the power-supply 10 there in the units. But the running of the compressors will be controlled by the thermostats. The thermostats are so set that they will make the compressors to operate whenever the cold-room temperature rises above the preset value on the thermostats and stop the compressors whenever the cold-room temperature falls to the pre-set values. The condenser fans will run only when the pressure in the condensers exceeds the pre-set values and goes off when the pressure falls normal. When the units are put on defrosting automatically by their ‘Defrosting-timers’, which is indicated by the glow the yellow indicating lamps, only the evaporator fans will be running in this condition. ‘ALARM’ CONDITION Whenever, due to any reason, the temperature insides the cold-room falls to the minimum set limit (+2 c). For alarm, the alarm comes immediately. On the other hand, when temperature inside the cold-room rises above the pre-set value (10 c), the delay timer for alarm is actuated and if the temperature remains above this value for more than the present time, (30 mins.) Alarm is given. In ‘Alarm’ condition, acknowledge by pressing the ‘Red’ button on the indicator unit. This will stop the audio signal only, but the blinking of the indicator lamp (LED) will continue till the alarm condition is over or alarm-unit is put off. Now, acceleration the temperature-recorder or from the temperature-recorder or from the dials of the thermostats on the cooling-units (which will be indicated by the black hand on the dial). (a) If the temperature in the cold-room has gone below +2 c observe which of the cooling-unit is running its compressor. Note it and put ‘off’ this unit immediately. (This may be due to defect in the thermostats in this unit, which may have to be replaced, if required.) Also open the cold-room door till the temperature rises to above 2 c and the alarm conditions is over and then close it. (b) If the temperature in the cold-room is observed to be higher then +10 c examines the cooling units if they are working. Temperature may rise sometimes in spite of both the cooling-units working normally in case a fresh lot of vaccine of considerable quantity is put into the cold-rooms when the ambient temperature is considerably high in such cases there is no other alternative but to wait and keep the units under observation. If you feel, you can keep the alarm circuit ‘OFF’ by its switch until required temperature is reached. If it is observed that the alarm is for high temperature but cooling units are not working than there may be some trouble in the electrical system. Trouble-shooting for this condition is given separately in the following pages. 11 IMPORTANT NOTES (1) The normal 12 V supply to the alarm unit is coming from the 12 V car battery mounted on & for the generating-set through the fuse in the generator terminal-box and then the control-unit. Therefore, any break in this 12 V supply circuit, blowing-off of the above fuse or removal of the above battery/ its terminals (for maintenance etc.) will actuate the alarm circuit and give alarm operating from the batteries contained in the unit. In such case, the switch of the alarm unit may be kept ‘OFF’ till the fault in the 12 V supply circuit is removed or the battery on the generating-set is replaced/ reconnected. (2) Healthy operative condition of the alarm-unit may be tested by pressing the red test-button of the same. When both audio and visual alarm will be obtained as long the button is kept pressed. (3) Apart from the above, faulty alarm may come in one or both the thermostatic switch inside the norm-unit becomes defective. In this case, faulty thermostat/o1o/are to be replaced and reset for connects temperature limits. TEMPERATURE RECORDER There are 3 position on the chart-speed selector switch, viz. ‘OFF’ – ‘1’ – ‘7’. Normally it is to be kept at ‘7’ position, which enable to record temperature for 7 days on a single card. In case of power failure the recorder operates from the built-in batteries and recording of temperature is not interrupted. For changing of chart, battery etc. the company’s hand-book may be consulted where the same are explained in details. TEMPERATURE FAILURE CONDITION As moistened earlier when power supply from the network is present, in to all the 3 phase are healthy and are in required sequence, relays K 11, K 12, & K 1 will be in operated condition and the unites will be running from the network supply. In Case Of Network Failure, the Above Relays Drop Off (A) If the selector-switch on the control-unit is in ‘HAND’ position, the generating set will not start automatically but can be started and stopped by pressing the corresponding START (Green) and STOP (Red) press-button given on the control-unit. (B) But, if the selector-switch is in ‘AUTODRIVE’ position then ‘START’ signal is given to the generating-sot automatically (after a pre-set delay, if any) and the generating-set will start. Then the engine will pick-up the start signal is withdrawn automatically and the generating-set continue to run. 12 Now, the sequence-relay K 21 will operate emerging relay K 22. Relay K22 will operate after the pre-set delay (approx. 30 sec.) which in turn will operate K2 which will now extend the power-supply to other cooling unit HU I or HU II depending upon the position of the ‘cooling-unit’ selector-switch. When supply is made available from generating-set only one cooling-unit operates. HU I will operate if selector switch position is at ‘1’ and HU II will operate if it is at ‘2’. As soon as the power supply in the network come back, the generating set will be made to stop automatically by the control-unit and relays K 21, K 22 & K 2 will **** to operate. Now relays K11, K12, & K1 will operate again (as described earlier in P.1) after the pre-set delay times and operate the cooling-units from network supply. ENGINE FAILURE: When ‘Hand-Auto drives’ selector-switch is in ‘AUTODRIVE’ position and the network supply fails, start signal in given by the control-unit automatically to the generating-set and starter cranks the engine. The solenoid for choke will also operate as they are automatically coupled together. After a present time the start signal is withdrawn automatically. But, if due to some reason the generating-set did not start on the first try, the start signal is sent, automatically for two more times, at intervals. But if even in spite of the 3 trials of above the generating set could not be operated, then no further start signal is sent but now the ‘ENGINE FAILURE’ indicator-lamp will light up and remain. Some of the probable reasons of engine not taking start in spite of cracking may be: (a) no fuel in the tank. (b) Fuel value closed. (c) Choke is not working. (d) Fuel overflow in the carburetor. (e) Dirty spark plug, etc. problems as (a), (b), (c) etc. may be checked up easily but for other assistance of experienced technician will be necessary. IMPORTANT NOTE: 1) Whenever the generating-set operates, the yellow ‘Drive Memory’ lamp on the control-unit lights up, and remain glowing to put It OFF press the red ‘RESET’ button on the control-unit. 2) The ‘ENGINE FAILURE’ lamp can be put off by turning the selector from ‘AUTODRIVE’ to ‘HAND’ Position 13 TROUBLE SHOOTING NOTE: In case of electrical troubles – always check the FUSES and CIRCUIT BREAKERS first. Circuit-breakers trip off/ fuses blow off when there is an over-load in the circuit in which they are incorporated. In such cases, reset (put CN) the circuit breaker/ replace the blown off fuse with one of the same capacity and observe if the same trips off / blows off again. But, this will mean that there is permanent fault persistence in the circuit. Assistance from experienced technicians will be necessary to rectify the same. (1) NO GENERAL POWER-FAILURE. BUT GENERATING-SET IS RUNNING. Blowing-off of fuse in the main-switch of the power supply network, or any other stage of the network. Signal-phasing etc. may also actuate the generating-set. In such cases, put the network main-switch OFF and as certain and locate the fault (if required through local PWD/SEB/PHE electrical technicians) and rectify it. After rectification, put the network main-switch ON again. IMPORTANT NOTE: While testing the 3 phase of power always use a Voltmeter (or Millimeter) with 0-500 volts A.C. range and test the voltage between the phase or with a neon-tester may mislead. (2) NO GENERAL POWER-FAILURE, ALL IN THE NETWORK SUPPLY IS PRESENT UP TO TERMINAL POINTS L1 L2 L3 BUT GENERATING-SET IS RUNNING. Examine If Relay K11 Is Operating: (a) If operating, then the fault may be beyond relay K11 in the control unit – notify maintenance technicians. (b) If not operating : this may be due to (i) Phase-Reversal: Put OFF the network main-switch and interchange 2 phases of the incoming network supply (at the main-switch or controlunit terminals L1, L2, L3) and put the main-switch ON again and observe. If the trouble was due to phase-reversal, now relay K11 should operate and restore the network-supply to the units. (ii) Defective K11: If K11 does not operate after operation as (i) above, K11 may be defective and may have to be replaced. First, change the interchanged connections to their original positions. Replace K11 with a similar spare relay (in absence of a spare relay the test may be done by stopping the generating-set and removing K21 from its position and fitting the same in K11 position).if even then, K11 does not operate – notify maintenance technicians. 14 NOTE: In Case (1) and (2) above, if the generating-set is not running due to enginefailure or some other reasons, the cooling-units will also stop running. (3) IN CASE OF NETWORK FAILURE, GENERATING-SET IS RUNNING BUT COOLING-UNITS ARE NOT WORKING Examine If Relay K21 Is Operating: (a) If operating, then the fault may be beyond relay K21 in The control-unit – Notify Maintenance Technicians. (b) If Not Operating this may be due to (i) Phase Reversal: As certain if the original connections of the power supply from generating-set to control-unit (14, 15.16) are not changed by any chance, either at generating-set terminalbox or at terminal 14, 15, and 16 of the control-unit. If found to be altered , then stop the generating set, interchange 2 phases of the incoming supply from the generating-set, start the generating set again and observe. If the trouble was due to phase-reversal. Now relay K21 should operate and restore the power supply from the generating-set. (ii) Defective K21: if K21 does not operate after as (i) above, K21 may be defective and may have to be replaced. Replace K21 with a similar spare relay. In absence of a spare relay, the test may be done by putting ‘OFF’ the main-switch of network and removing K11 from its position and fitting the same in K21 position. If even then K21 does not operate notify maintenance technicians. (4) THE GENERATING-SET DOES NOT START AUTOMATICALLY IN CASE OF NETWORK FAILURE BUT CAN BE STARTED MANUALLY. (i) (ii) Put the generating-set ‘OFF’ if it is running. (And also keep the network main-switch ‘OFF’ during testing as below). Check the continually of the control-cable between generating-set terminal box and the circuit-card. (Take care to remove both ends of the cable to XA: 10 because it is coming from ignition-coil of generating-set and carries high voltage). If there is no defect in the cable, then the circuit-card, (KAP3) may be defective. Changes the circuit-card KAP3 (before disconnecting the different wires connected to the card note & mark the wire numbers carefully). (5) THE GENERATING-SET DOES NOT START BOTH AUTOMATICALLY AND MANUALLY IN CASE OF NETWORK FAILURE 15 (i) Check the condition of the battery. A hydrometer may be used to as certain its charge condition. Also check the electrolyte level, terminal-ends, their contacts to the battery pole and the battery voltage (should be about 11 to 12 8 Volts D. C.) Check the polarity of battery also (i.e. whether the positive terminal is connected to the positive pole of the battery and the negative terminal is connected to the negative pole of the battery or not). Take corrective measure to remove any defective observed as above. (ii) If the above is found to be in satisfactory condition, then measure the DC voltage supply to the circuit-card at the circuit-card terminals across XA:1 (-) and XA:2 (+) This voltage should be almost same as the battery voltage (i.e. 11 to 12 8 Volts DC). (iii) If the above is also found to be satisfactory. Then the circuitcard (before disconnecting the different wire connected to the Card note and marks the wire numbers carefully). (6) CORRECT NETWORK-SUPPLY / SUPPLY FROM THE GENERATING-SET IS PRESENT BUT COOLING –UNITS NOT WORKING Examine if power-supply is present at terminals 7, 8. 9 (for cooling-unit I) and 11, 12, 13 (For cooling-unit II) in the control-unit. If power-supply is present at these points it will mean that the defect is in the cooling-unit/s. absence of power-supply at these points indicate in the control-unit. For rectifying the defect – notify maintenance technicians. 16 17 18