* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download implemetation of an automatic protection for a

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Solar car racing wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Control system wikipedia , lookup

Lumped element model wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Thermal runaway wikipedia , lookup

IMPLEMETATION OF AN

AUTOMATIC

PROTECTION FOR A

SOLAR WALL

CONTROL OF AN ELECTRICAL SHUTTER

Xavier de Sanz Cosialls

2010-2011

Project at:

BETHUNE IUT

Dpt GEII

1230 rue de l’université

62400 BETHUNE

FRANCE

Tutor: Dr Patrick FAVIER

Implementation of an automatic

protection for a solar wall

Contents

I. Acknowledgements ............................................................................................... 3

II. Presentation of the project and objectives ............................................................ 4

II.1 Solar wall...................................................................................................................4

II.2 Protections needs for solar wall .................................................................................5

III. Elements of the project ........................................................................................ 7

III.1 Structure of the electronic controller .........................................................................7

III.2 Light sensor ..............................................................................................................8

III.3 Temperature sensors ................................................................................................9

III.3.1 Thermistor ................................................................................................................................ 9

III.3.2 Tiny Serial Digital Thermal Sensor TC74.................................................................................. 10

III.4 Model of card with micro-chip PIC16F877 with relay ................................................ 11

III.4.1 Micro-chip PIC16F877 ............................................................................................................. 11

III.4.2 relation of inputs and outputs of the PCB .............................................................................. 14

III.5 solar heater ............................................................................................................ 16

IV. Implementation of the system ........................................................................... 17

VI.1 Study and realization of sensors .............................................................................. 17

VI.1.1 Light sensor ............................................................................................................................. 17

VI.1.2 Temperature sensor ............................................................................................................... 19

VI.2 Study of relay and thermal safety system ................................................................ 23

VI.2.1 Relay ....................................................................................................................................... 23

VI.2.2 Safety temperature system with thermal contact.................................................................. 24

IV.3 Realization of the prototype ................................................................................... 26

IV.4 Model of power supply ........................................................................................... 28

IV.5 Program of the simulator ........................................................................................ 29

IV.5.1 Structure of the program ........................................................................................................ 29

IV.5.2 Program trancription .............................................................................................................. 32

IV.6 Tests ...................................................................................................................... 36

IV.7 Execution of source boxes ....................................................................................... 38

V. Areas of improvement ........................................................................................ 39

VI. Conclusion ......................................................................................................... 40

2

Implementation of an automatic

protection for a solar wall

I. Acknowledgements

We want to thank all the pedagogic and administrative team of the technological

university college of Béthune (IUT) and of the university of Artois.

We want to thank specially the team of the Electric Engineering Department of the IUT:

Mr Favier Patrick

Maxime Guyot

Mr Cresson Pierre-Yves

Mr Leroy

Borrega Xavier

N'diougas m'baye

3

Implementation of an automatic

protection for a solar wall

II. Presentation of the project and objectives

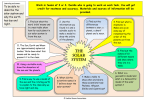

II.1 Solar wall

The department of research of Civil Engineering from the University of Artois

has installed, in two houses in the department of Pas-de-Calais, two prototypes of a wall

able to transfer the energy from the sun into special brick able to store the thermal

energy.

electrical shutter

HOT AIR FOR

HEATING

Int.

Ext.

electrical gate

bricks

COLD AIR

Fig 1 : Graphic of the wall

The bricks of wall get warmer when they receive the energy of sun. The system

get warmer, so the hot air, with the premise of convection, flows up and it will go to

warm the house. To prevent a circulation of air in the opposite sense, there's an

electrical gate in the intake of cold air that only less get inside in one way. This solution

avoids losing energy during periods of no sun conditions.

However the bricks are made with a plastic envelopment, which melts if the

temperature of the wall it's too high. To prevent this problem, the engineers installed to

the wall an electric shutter. The aim of this project is to set up an automatic control of

the shutter

Objectives of the project:

Design and realization of an automatic system to control the shutter.

Improve the performances of the system, taking more variables than the

temperature of the system to control it and make it more efficient.

4

Implementation of an automatic

protection for a solar wall

II.2 Protections needs for solar wall

To protect the solar wall and make it efficiently, we have to take to variables:

•

1)Temperature

How explained before, the bricks have a temperature limit of working. Taking

this variable we are able to protect the bricks against over warming situations and keep

the system working at the appropriated temperature.

•

2)Light

Not only is the temperature the only element that we have to think, also the light

received for the solar wall is very important to make more efficient our system. We will

use this variable in two cases:

First of all during the night period when there’s no sun and the solar wall only

give energy to the receptor and it doesn’t stores new ones. Is in this moment when we

have to keep down the shutter to save the stored energy.

The other case where we have to work in function of the light is during the day.

When we have a cloudy weather, without in off sun to warm efficiently the solar wall

also we have to put down the shutter to keep the stored energy.

Fig 2: Graphic of hystereis of the variables

5

Implementation of an automatic

protection for a solar wall

The graphic of the fig 2 show us our needs of light and temperature. How we can

see, the shutter only will be open if the conditions are ok. This means: there’s in off

light to work and the brick’s temperature not too hot.

Another really important think that we can see in the graphic is the hysteresis

zone that we put to operate the shutter. The output depends in part on the internal state

of system and not only on its input. Using this system we avoid the problem of constant

mouvement up and down of the shutter if temperature or light range during a periond in

the same working zone.

For exemple when temperature arrives to a too hot temperature, we put down the

shutter. But instead of put it high when it arrives again to the too hot threshold

(too_hot), we put up the shutter in a lower threshold (hot) .

In the light case we use the hysteresis to avoid the constant up and down

mouvement in the case of variable or not so strong clouds.

In the histeresis zone the system doesn’t do anything and it’s like that how we

give memory to our system and we make it capable of work in a imperfect contitions of

work.

To control the LEDS, that show us the light or temperature level, we don’t need

hysteresis because they only tell us the variable state. To see the light state we use two

LEDS: one for high level and the other for the low level. In the temperature case we use

three LEDS: one for too hot temperature, another for hot temperature and finally one for

no hot temperature.

In the following graphic we can see the light and temperature LED range of

working:

Fig 3: Graphic LEDS range working

6

Implementation of an automatic

protection for a solar wall

III. Elements of the project

III.1 Structure of the electronic controller

Our system is composed by different elements. In the following block diagram

we can see the different parts of our system:

Fig 4: Block diagran of the system

How we can see the PIC16F877’s supply comes from the electrical network

(230V AC) and finally the microcontroller receive a voltage of 5V DC.

The PIC receives and processes the data from the sensors (light and

temperature). In function of our needs the microcontroller will control the relay. This

one commands the electrical shutter that will go up or down depending of the situation.

To protect the solar wall against over temperatures we installed a safety thermal

contact system that will close the shutter if the temperature is too high.

7

Implementation of an automatic

protection for a solar wall

III.2 Light sensor

The light sensor is composed of a photo-pile and one resistance of 22Ώ. The

photo-pile give us an image of current from the sunshine, that means that value of

output current in the photo-pile is proportional to the sunshine received.

The circuits of micro-chips are controlled with voltage. To have an image of

voltage from the sunshine received we added a resistance in the terminals of the photopile.

Fig 5: Photopile

8

Implementation of an automatic

protection for a solar wall

III.3 Temperature sensors

III.3.1 Thermistor

The temperature sensor that we utilise is a thermistor whose resistance varies

significantly with temperature. Its operating system is based on the variation of the

resistance who presents a semiconductor with the temperature. The word is a ensemble

of thermal and resistor. Thermistors can be classified into two types, depending on the

sign of the coefficient of temperature:

•

•

NTC (Negative Temperature Coefficient) – negative temperature coefficient

PTC (Positive Temperature Coefficient) – positive temperature coefficient

The sensor works because of the raising of temperature, a semiconductor

increases the number of electrons able to move about and carry charge. It promotes

them into the conduction band. More charge carriers that are available, more current a

material can conduct. If the resistance decreases with increasing temperature, the device

is called a negative temperature coefficient (NTC) thermistor. And if the resistance

increases with increasing temperature, the device is called a positive (PTC) thermistor.

The difference between a thermistor and a resistive thermal devices (RTD) is

that the variation of the resistance in function of temperature is not linear. With that

characteristic we are able to have a huge variation of resistance with a little variation of

temperature.

In the followings graphics we show the relation R(T) of both types of

thermistors.

Fig 6: Different graphics of thermistor characteristic

For our application we've chosen a thermistor type NTC. Utilising that type, for

low temperatures we will have a high value of resistance. And for high temperatures we

will have a low value of resistance. If we look the graphic, we can see that the

temperature which we are working (50ºC) is inside of the zone of big variation of

temperature. This characteristic is perfect for our needs.

9

Implementation of an automatic

protection for a solar wall

III.3.2 Tiny Serial Digital Thermal Sensor TC74

The TC74 is a serially accessible, digital temperature sensor particularly suited

for low cost and small form factor applications. Temperature data is converted from the

onboard thermal sensing element and made available as an 8-bit digital word.

Communication with the TC74 is accomplished via a 2- wire SMBus/I2C

compatible serial port. This bus also can be used to implement multi-drop/multi-zone

monitoring. The SHDN bit in the CONFIG register can be used to activate the low

power Standby mode.

Temperature resolution is 1°C. Conversion rate is a nominal 8 samples/sec.

During normal operation, the quiescent current is 200 µA (typ). During standby

operation, the quiescent current is 5 µA (typ). Small size, low installed cost and ease of

use make the TC74 an ideal choice for implementing thermal management in a variety

of systems.

Features

• Digital Temperature Sensing in SOT-23-5 or TO-220 Packages

• Outputs Temperature as an 8-Bit Digital Word

• Simple SMBus/I2C™ Serial Port Interface

• Solid-State Temperature Sensing: - ±2°C (max.) Accuracy from +25°C to

+85°C ±3°C (max.) Accuracy from 0°C to +125°C

• Supply Voltage of 2.7V to 5.5V

• Low Power: - 200 µA (typ.) Operating Current - 5 µA (typ.) Standby Mode

Current

Applications

• Thermal Protection for Hard Disk Drives and other PC Peripherals

• PC Card Devices for Notebook Computers

• Low Cost Thermostat Controls

• Power Supplies

• Thermistor Replacement

Fig 7: Fonctional block diagram

10

Implementation of an automatic

protection for a solar wall

III.4 Model of card with micro-chip PIC16F877 with relay

To control the relay we utilise a card already designed. That relay is controlled

by a micro-chip PIC16F877.

III.4.1 Micro-chip PIC16F877

The microcontroller PIC16F877 from Microchip® belongs to a big family of

microcontrollers PIC (Peripheral Interface Controller) of 8 bits.

They have an improved memory of program type EEPROM flash, this makes

easier to program it using computer software of PIC. This characteristic makes much

easier to design the projects and reduce the time used in the programming of

microcontrollers.

Main features:

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

High performance RISC CPU

Only 35 single word instructions to learn

All single cycle instructions except for program branches which are two

cycle

Operating speed: DC - 20 MHz clock input DC - 200 ns instruction cycle

Up to 8K x 14 words of FLASH Program Memory,

Up to 368 x 8 bytes of Data Memory (RAM)

Up to 256 x 8 bytes of EEPROM Data Memory

Pinout compatible to the PIC16C73B/74B/76/77

Interrupt capability (up to 14 sources)

Eight level deep hardware stack

Direct, indirect and relative addressing modes

Power-on Reset (POR)

Power-up Timer (PWRT) and Oscillator Start-up Timer (OST)

Watchdog Timer (WDT) with its own on-chip RC oscillator for reliable

operation

Programmable code protection

Power saving SLEEP mode

Selectable oscillator options

Low power, high speed CMOS FLASH/EEPROM technology

Fully static design

In-Circuit Serial Programming (ICSP) via two pins

Single 5V In-Circuit Serial Programming capability

In-Circuit Debugging via two pins

Processor read/write access to program memory

Wide operating voltage range: 2.0V to 5.5V

High Sink/Source Current: 25 mA

Commercial, Industrial and Extended temperatura ranges

Low-power consumption:

- < 0.6 mA typical @ 3V, 4 MHz

- 20 µA typical @ 3V, 32 kHz

- < 1 µA typical standby current

11

Implementation of an automatic

protection for a solar wall

The combination of these features gives to the microcontroller a high efficiency

in the use of data memory and program.

program. So also we will have an efficiency speed of

execution.

Microchip® divides the microcontrollers in three big subfamilies according with

the number of bits of the instruction bus:

subfamilies

instructions

name

Base - Line 33

instructions of 12 bits

PIC12XXX and PIC14XXX

Mid – Range 35

instructions of 14 bits

PIC16XXX

High - End 58

instructions of 16 bits

PIC17XXX and PIC18XXX

Fig 8:: Subfamilies microcontroller PIC

We can find different types of packages: PDIP (Plastic Dual In Line Package),

PLCC (Plastic Leaded Chip Carrier), QFP (Quad Flat Package) y SOIC (Small Outline

I.C.). In thee following figure we can see the different type of packages:

Fig 9: Packages PIC

12

Implementation of an automatic

protection for a solar wall

The package that we use is a PDIP. In the following ping diagram we can see

with more detail the microcontroller used:

Fig 10: Ping diagram PIC16F877

13

Implementation of an automatic

protection for a solar wall

III.4.2 relation of inputs and outputs of the PCB

In the following table we can see de relation of inputs and outputs that we used:

OUTPUT/INPUT

USE

A1 Analog. Input

Light

C3 Input

I2C Serial clock

C4 Input

I2C Serial data

B2 Input

Switch 1

B3 Input

Switch 2

D3 Output

Relay

D4 Output

Green led 02

D5 Output

Orange led 02

E0 Output

Green led 01

E1 Output

Orange led 01

E2 Output

Red led 01

Fig 11: Table relation outputs/inputs

14

Implementation of an automatic

protection for a solar wall

Power

contacts for

the shutter

control

E0,E1,E2

B2,B3

POWER

SUPPLY

12V DC

RELAY

DEBBUGING

CONNECTOR

Safety

system

contacts

PIC16F877

ANALOGIC

INPUT

A0

I2C

CONNECTOR

E0,E1,E2

Fig 12: PCB with outputs/inputs

15

Implementation of an automatic

protection for a solar wall

III.5 solar heater

The solar heater has been made by french students during the year 2009/2010.

It's an autonomous system of solar heating that captures the thermal energy from the

sun. This converted energy is sent in form of hot air to the place where it is needed.

When the glass of the heater is exposed in front of the sun light, the black

aluminium surface absorbs the energy and in the same time gets warmer the air

contained inside the box. With an automatic system, controlled by a PIC micro

controller, our system drives a variable speed fan and an electrical gate. With the fan

and a little door opened by the engine, we can manage the thermal energy flowing in the

hot air.

The internal program of this application is not utilized in our project. To get

more information of this project consult the inform (web).

Fig 13: Solar heater

16

Implementation of an automatic

protection for a solar wall

IV. Implementation of the system

VI.1 Study and realization of sensors

The first part of the project, from September to October, we looked for the datasheets of the different sensors used. The aim was to understand the way of working of

the sensors. That part of my work is connected to the projects of Mr Borrega Xavier and

Mr M'baye N'diougas.

VI.1.1 Light sensor

How we explained before, the light sensor is a photo-pile that gives us an image

of current, so we have to add a resistance to the terminals. The current value that we

checked for the standard value of irradiance (1000W/m²) is 54mA.

We dimensioned the resistance (22Ω) to get a voltage of 1,2V in the output of

the sensor.

In the following schema we can see the light sensor equivalent circuit:

Fig 15: Light sensor equivalent circuit

Fig 14: Light sensor schema

17

Implementation of an automatic

protection for a solar wall

The last step of the light sensor study was to realize the characteristic curve of

the photo-pile. The two variables that we needed for our application were output voltage

in function of the irradiance received from the sun.

In the following graphic we can see the photo-pile characteristic`s curve:

1,6

y = 0,0011x + 0,0386

R² = 0,9962

1,4

1,2

V(V)

1

0,8

0,6

0,4

0,2

0

0

200

400

600

800

1000

1200

1400

E(W/m²)

Fig 16: Graphic output voltage in function irradiance received

In the graphic we see that the curve that we found is a linear equation, so with

the equation that excel give us we can calculate all the voltage value for each value of

irradiance. With the information that the graphic gives us, we are able to calculate the

different thresholds that after we will us in the program to control our shutter.

18

Implementation of an automatic

protection for a solar wall

VI.1.2 Temperature sensor

VI.1.2.1 Thermal sensor MOXIE

After the research of the reference and datasheet of thermal sensor, offered to us

by the IUT, we found that our thermistor was a Thermal sensor MOXIE TS3 B3 (NTC).

Fig 17: Reponse characteristic thermal sensor TS 3-57

For our application we've chosen this thermistor type NTC. Utilising that type,

for low temperatures we will have a high value of resistance. And for high temperatures

we will have a low value of resistance. If we look the graphic, we can see that the

temperature which we are working (50ºC) is inside of the zone of big variation of

temperature. This characteristic is perfect for our needs.

19

Implementation of an automatic

protection for a solar wall

VI.1.2.1 Thermal Sensor TC74

The TC74 acquires and converts temperature information from its onboard solidstate sensor with a resolution of ±1°C. It stores the data in an internal register which is

then read through the serial port. The system interface is a slave SMBus/I2C port,

through which temperature data can be read at any time. Eight SMBus/I2C addresses

are programmable for the TC74, which allows for a multi-sensor configuration. Also,

there is low power Standby mode when temperature acquisition is suspended.

To use our sensor we must create a subroutine to write, to read and to receive the

data of the sensor. In the following table we can see the SMBus/I2C Protocols that we

followed to create the routines:

Fig 18: SMBus/I2C Protocols

The TC74 is internally programmed to have a default SMBus/I2C address value

of 1001 101b. Seven other addresses are available. In our case, after searching in the

datasheet we found the table with the address of our sensor.

SOT-23(V)

Address

Code

SOT-23 (V)

Address

TC74A0-3.3VCT

1001 000

V0

TC74A0-5.0VCT

1001 000

TC74A1-3.3VCT

1001 001

V1

TC74A1-5.0VCT

1001 001

TC74A2-3.3VCT

1001 010

V2

TC74A2-5.0VCT

1001 010

TC74A3-3.3VCT

1001 011

V3

TC74A3-5.0VCT

1001 011

TC74A4-3.3VCT

1001 100

V4

TC74A4-5.0VCT

1001 100

TC74A5-3.3VCT

1001 101*

V5

TC74A5-5.0VCT

1001 101*

TC74A6-3.3VCT

1001 110

V6

TC74A6-5.0VCT

TC74A7-3.3VCT

1001 111

V7

TC74A7-5.0VCT

Code

U0

U1

U2

U3

U4

U5

1001 110

U6

1001 111

U7

Fig 19: TC74 adress table

20

Implementation of an automatic

protection for a solar wall

Our sensor is the model TC74A3-5.0VCT, so our address will be 1001 011 in

binary.

In the following image we will see the connections schema of the Tiny Serial

Digital Thermal Sensor TC74 with the components of the PCB and the PIC ports:

Fig 20: TC74 connections schema

21

Implementation of an automatic

protection for a solar wall

VI.1.2.3 Choose of the temperature sensor

After study both sensors. We chose the Tiny Serial Digital Thermal Sensor

TC74. We chose the digital sensor because with the other we hadn’t the precision that

this one give us.

With the thermistor the threshold changes all the time and never we can know

certainly at which temperature the system will work. We have to think that the digital

sensor always give us the exactly temperature with a precision of one degree.

The other advantage of the digital sensor is that we can introduce directly the

temperature’s value in Celsius. In the thermistor’s case first we have to predict the

voltage value in certain temperature. After to introduce the value to the program we

have convert it to a decimal number.

Fig 21: MOXIE TS3 B3 (NTC)

and

Tiny Serial Digital Thermal Sensor TC74

22

Implementation of an automatic

protection for a solar wall

VI.2 Study of relay and thermal safety system

VI.2.1 Relay

To operate the shutter we use a relay as a switch. The realy used is a FINDER 40.52.8.24.

Fig 22: Relay Finder 40.52

Our relay works in 230V AC because the shutter uses that voltage to work. Also

we have to remember that we need to ways of movement to put up or down the shutter.

For that reason our relay it’s a type DPDT (Double Pole Double Throw). These have

two rows of change-over terminals. Equivalent to two SPDT (Single Pole Double

Throw) switches or relays actuated by a single coil. Our relay has eight terminals,

including the coil.

In the following symbol circuit we can see the relay’s structure:

Fig 23: Relay symbol circuit

How we can see in the graphic, using that type of relay with double throw we are

able to have a double way of movement.

Another important aspect of the relay connection is the security. How we have

said the relay circuit works in a higher level of voltage (230V AC) than the other part of

the PCB (5V DC). This forces us to separate both voltages to protect the 5V DC circuit

and also the microcontroller.

23

Implementation of an automatic

protection for a solar wall

VI.2.2 Safety temperature system with thermal contact

If inside the solar wall, temperature’s the too high and the program fails during

the protection action. We installed a thermal switch to protect our system against over

temperatures.

The thermal switch that we chose is a MICROTHERM 05N1034(55/M). With a

configuration SPST (single pole single throw) is a simple on-off switch NC with reset

pin. When it arrives to 55ºC, it opens himself automatically. When the thermal contact

is opened the shutter goes down.

When we want to close the switch we have to press the reset pin. But the

problem is that the shutter is down and the only way to open it’s doing a short circuit

around it. We installed a push- button, which will produce a short circuit at the thermal

switch. Using this PB we can open the shutter and reset the thermal contact.

In the followings images we can see the thermal contact and its pin

configuration SPST:

Fig 24: MICROTHERM 05N1034(55/M)

Fig 25: thermo contact SPST

pin diagran

24

Implementation of an automatic

protection for a solar wall

In the following schema we can see the relay’s connections with both voltages

that we use and the thermal contact safety system:

Fig 26: Relay and safety thermal contact schema

25

Implementation of an automatic

protection for a solar wall

IV.3 Realization of the prototype

In the beginning of the project, our prototype only was the old project made by

others student. One very important part of our project was to modify the old frame and

put it ready for ours needs.

The prototype is composed of a solar heater mounted on a frame with an electric

shutter and the electronic board that commands the shuttle and the different sensors.

Mr Leroy realized for us the frame for the solar heater. We placed the solar

heater into the frame and we assembled it using a transversal axe enabling the rotation

of the solar heater into the frame, to incline it in respect the solar inclination angle for

maximum energy capture. This capacity of movement it’s made for the application of

autonomous solar air heater, but also we used that rotation to warm faster the

temperature inside the prototype. We have to remember that our system it’s made to

work in a vertical position.

Then we placed the sensors of temperature and light into the system. After we

designed and realized the 12V DC supply.

Fig 27: Solar heater before modification

26

Implementation of an automatic

protection for a solar wall

Fig 28: Sensors in the prototype

Fig 29: Ensemble PCB power supply

27

Implementation of an automatic

protection for a solar wall

IV.4 Model of power supply

The card of control utilise the types of tensions:

•

•

230V AC voltage to drive the shutter

12V DC voltage to supply the PIC electronic board.

To protect the AC circuit against short circuits or over current, we put a magneto

thermical breaker type C6 ref. Legrand 6392.

The power supply is composed of a P2 diodes rectifier placed at the output of a

transformer with a ratio of 230V-15V. Two capacitors of high value filter the signal. A

special 7812 regulator give us at the output a constant 12V DC voltage. The green led

display us the presence of voltage at the output.

Fig 31: Equivalent circuit power supply

Fig 30: Power supply

The following schema show us the equivalent circuit of our power supply:

Fig 32: Equivalent circuit power supply

28

Implementation of an automatic

protection for a solar wall

IV.5 Program of the simulator

When we finished our PCB, we started the design of the PIC's program to

control the system.

IV.5.1 Structure of the program

The program’s structured in different structures called subroutines. These

routines are small programs that we execute during the sequence of our main program.

This use gives to our program a clearly structure.

Main subroutines of the program:

•

1) Normal function

If the switch is in position 1,0 the system will work normally.

The magnitudes that we control, are analogical (light) and digital

(temperature).

With two subroutines of the program (cadlum and actemp) we

receive and process the data of our sensors. Finally this information is

used to control the shutter in function of our needs.

•

2) Test function

If the switch is in the position 0,0 or 0,1 the shutter

will go up or down depending of the position of the switch .

With this mode we can test if the shutter works or not

and also opened it if we need to make some reparation.

How we can see in the normal function flowchart, which we find in the next

page, we used a variable in form of bit to store the light and temperature. This means

that when the temperature is too hot or there’s enough light ours bits MEMLI and

MEMTE are 1 and the bits will be zero in the opposite case.

Using this system we are sure that, when we arrive to a threshold, the program

will work according to ours needs without the dangerous of doing a wrong action if the

light or the temperature range weirdly.

In the next pages we can see the different flowcharts, which explain the way of

working of our program. The three flowcharts are the main subroutines of the program.

29

Implementation of an automatic

protection for a solar wall

•

Main flowchart

•

Test function flowchart

30

Implementation of an automatic

protection for a solar wall

•

Normal function flowchart

Legend:

•

•

•

•

THLH: Thresholds Light High

THTH:Thresholds Temperature High

MEMLI: Light bit

MEMTE: Temperature bit

31

Implementation of an automatic

protection for a solar wall

IV.5.2 Program trancription

#include "C:\Borrega\Xavi D\TEST\I2C\testi2C03.h"

#include <stdio.h>

#ZERO_RAM

//---------- application variables -------------#define LEDV1 PIN_E0

//define LED'S

#define LEDO1 PIN_E1

#define LEDR1 PIN_E2

#define LEDV2 PIN_D5

#define LEDO2 PIN_D4

#define LEDR2 PIN_C7

#define SHUT PIN_D3

//define shutter

#define switch_01 PIN_B3 //define switch

#define switch_02 PIN_B2

//---------- variables declaration -----------------signed int temp;

int1 ack;

//bit to store the acknowledge

int8 light=0;

//to store the light value after

conversion

int1 MEMTE=0;

//bit to store temperature condition

int1 MEMLI=0;

//bit to store light condition

const

const

const

const

const

int

int

int

int

int

too_hot=50; //constant threshold of temperature

hot=45;

//

no_hot=30; //

THLH=25;

//constant threshold of light

THLD=13;

50°C

45°C

30°C

//---------- funtions declaration -----------------void cadlum(void);

//subroutine for AD conversion of the

light

void actemp(void);

//subroutine of temperature data

capture to bus I2C

void norm (void);

//subroutine of normal function

void test (void);

//subroutine of test function

//---------- main program -----------------------void main()

{

setup_adc_ports(AN0);

setup_adc(ADC_CLOCK_DIV_2);

setup_psp(PSP_DISABLED);

setup_timer_0(RTCC_INTERNAL|RTCC_DIV_1);

setup_timer_1(T1_DISABLED);

setup_timer_2(T2_DISABLED,0,1);

set_tris_E(0x00);//port E as output

set_tris_D(0x00);//port D as output

i2c_start();

ack=0;

ack=i2c_write(0x9A);

while(ack);

ack=0;

ack=i2c_write(0x01);

32

Implementation of an automatic

protection for a solar wall

while(ack)

ack=0;

ack=i2c_write(0x00);

while(ack);

ack=0;

i2c_stop();

//----------------------------- MAIN boucle --------while(1)

{

if (input(switch_01)==1)

{test();}

else

{cadlum();

light

actemp();

to bus I2C

norm();}

//switch_01 in position 1

//=> function test

//subroutine for AD conversion of the

//subroutine of temperature data capture

//subroutine function normal

}

}

//------- end of MAIN bucle -------//----------------------subroutines-----------------------//-----------------subroutine normal function

void norm(void)

{

if (light>THLH)

{(MEMLI=1);}

//light ok

if (light<THLD)

{(MEMLI=0);}

//light low

if (temp>too_hot)

{(MEMTE=1);}

//indoor temperature too hot

if (temp<hot)

{(MEMTE=0);}

//indoor temperature ok

if (MEMLI==1)

//light ok

{

if (MEMTE==1)

{

output_low(SHUT);

}

if (MEMTE==0)

{output_high(SHUT);

}

if (MEMTE==1)

//indoor temperature too hot

//=> shutter down

//indoor temperature ok

//=> shutter up

//indoor temperature too hot

33

Implementation of an automatic

protection for a solar wall

{

output_high(LEDR1);

//=>switch on red LED01

output_low(LEDO1);

output_low(LEDV1);

output_low(LEDO2);

}

if ((temp>=no_hot)&&(temp<too_hot))//temperature between

too hot and ok

{

output_high(LEDO1);

output_low(LEDV1);

output_low(LEDR1);

output_low(LEDO2);

}

if (temp<=no_hot)

{

output_high(LEDV1);

output_low(LEDR1);

output_low(LEDO1);

output_low(LEDO2);

}

//=> switch on orange LED01

//indoor temperature low

//=> switch on green LED01

}

if (MEMLI==0)

{

output_low(SHUT);

}

//light low

//=>shutter down

if (light<THLH)

{

output_high(LEDO2);

output_low(LEDV2);

output_low(LEDR2);

}

//light lower than THLH

if (light>=THLH)

//light ok

{

output_high(LEDV2);

delay_ms(40);

output_low(LEDV2);

output_low(LEDR2);

output_low(LEDO2);

}

//=> switch on orange LED02

//=>switch on green LED02

}

//--------------subroutine test function

void test(void)

{

{output_high(LEDR1)&output_high(LEDV1)&output_high(LEDO1);

output_high(LEDV2)&output_high(LEDO2)&output_high(LEDR2);

delay_ms(100);

output_low(LEDR1)&output_low(LEDV1)&output_low(LEDO1);

output_low(LEDV2)&output_low(LEDO2)&output_low(LEDO2);

delay_ms(100);}

34

Implementation of an automatic

protection for a solar wall

if(input(switch_02)==1)

{output_low(SHUT);}

//switch_02 in position 1

//=> shutter down

else

{output_high(SHUT);}

}

//switch_02 in position 0

//=> shutter up

//--------------routine function light conversion

void cadlum(void)

{

set_adc_channel(0);//Selection of port to conversion AN0

light = read_ADC(ADC_START_AND_READ);

}

//-------------//subroutine of temperature data capture to

bus I2C

void actemp(void)

{

i2c_start();

ack=0;

ack=i2c_write(0x9A);

while(ack);

ack=0;

ack=i2c_write(0x00);

while(ack)

ack=0;

delay_ms(100);

i2c_start();

ack=0;

ack=i2c_write(0x9B);

while(ack);

ack=0;

temp=i2c_read(0);

i2c_stop();

}

//------------ subroutines end ---------------------------------

35

Implementation of an automatic

protection for a solar wall

IV.6 Tests

•

Light test:

To test the light system we used a potentiometer o simulate the sun variation. In

the graphic we can see a normal function example.

We start the test without light and we go up until a standard irradiation level

(1,2V -> 1000W/m²). Then we test the hysteresis mode where we can see that the output

high temperature level of the shutter is higher than the down threshold.

To see the shutters state we use the relay voltage. When there’s high level means

that the shutter’s high. And the opposite with low voltage level.

V relay

V photo-pile

Fig 33: Light test

36

Implementation of an automatic

protection for a solar wall

•

Temperature test:

We used the same system to test the temperature. In the following graphic we

can see temperature (ºC) and relay voltage (V).

Here also we can see the hysteresis zone and the thermal inertia that the

temperature takes when the shutter goes down.

V relay

Temperature

Fig 34: Temperature test

37

Implementation of an automatic

protection for a solar wall

IV.7 Execution of source boxes

One of the objectives of the project is to install the control system in some

houses. To do the installation in a house, in comparative of the laboratory, we need a

isolated box, which has to resist the hard conditions of working outside the work-room.

We have utilised one plastic box from the factory MERLYN GERIN. The

material that we have chosen is plastic. The industrial junction boxes in ABS have a

waterproof resistance and they are designed to protect electronics cards, which are

placed in a environments where there're risks of dusk and/or liquid entry.

To put our ensemble of electronic-card, converter-card and the guide for the

protections, we utilise the same support utilised in the experimental version. The

support is fixed in the box by four screws. The difference in that case, is that we have

rounded the corners because the box corners are not perfects squares. To solve that

problem we have rounded the corners with the help of a power-drill and a crown

On the following photos, we can see the ensemble of the box and the cards that

we have built:

Fig 35: Source box

Fig 36: Source box

To have an isolated box, also we have to protect the hold that we have done to pass all the

source and sensor cables. We have utilised a pass-cable to protect the box from liquid projections.

38

Implementation of an automatic

protection for a solar wall

V. Areas of improvement

After our study, there are some areas of improvement for our project. Now we

will see some of these areas that will be for our successors.

Our study is limited because only it considers the heater working in a vertical

position. Would be so interesting, for a following project, to automatise the movement

of the heating. That means that while the blind is in open position, we can incline the

heater. When we should close the blind the heater will go to the vertical position. Use

the command PWM would be possible doing this.

When we where studding during the year all the possible options, we have

thought to put an hour module. That gadget is an element isolated that we can program

in function of the solar hour. It has to give us the complementary information of sensors

(day, night, summer, winter). With this module we give extra information to the

program, so we can make it more efficient.

39

Implementation of an automatic

protection for a solar wall

VI. Conclusion

Personally, I have learnt a lot about different methods of working. After the

realization of this project, my knowledge of manual work, mechanisation of pieces and

programming with C. Always it's good to work in a project of renewals energies, this is

the future.

40