* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download SOCOM ANVIS Helmet Mount - Wilcox-Res

Survey

Document related concepts

Transcript

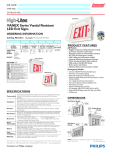

SOCOM ANVIS Helmet Mount Patent Pending For Official Use Only Details: The SOCOM is an extremely rugged ANVIS helmet mount constructed from solid blocks of Aluminum and tough self-lubricating Delrin. What makes this mount so much tougher than any other is the use of Aluminum instead of Ultem plastic. The main Frame of the SOCOM is CNC Machined from a single block of Aluminum as pictured here, which gives it superior strength. Other Key parts are also made from Aluminum such as the locking bar shown below and the base plate (not shown) used to mount the SOCOM to the Helmet's Front Bracket. The other Frame member, shown in the two pictures below, is CNC Machine from a single block of super tough self-lubricating Delrin. Because of its strength and self-lubricating properties, Delrin is also used for other parts such as the ANVIS PAS Knuckle Guides shown above. The SOCOM uses the standard Norotos type helmet mount locking plate and can be used on the ACH front bracket and the Ops Core FAST helmets. It uses the standard LEMO connector used on all other ANVIS Flight and Ground helmets, but includes the black bend relief to reinforce the cable entering the LEMO connector. The SOCOM’s cable assembly is approximately 11 ¼ inches long from mount to end of LEMO connector. This cable assembly uses the four wire braided shielding AlphaWire 1122 wire that is used on Flight helmets, but instead of the braided shielding section terminating at the junction where the power and low voltage warning signal wires split off and go into the mount… …the braided shielding continues into the SOCOM mount and is routed thru a channel along with the feeder cables inside of the SOCOM as shown below: Once the wires and braided shielding are routed into the mount, they are anchored using a crimp and glued into place as shown here: The wires feeding power to the contact pins and into the ANVIS PAS to the NVGs are a braided shielding AlphaWire 1120 two conductor wire. This cable has the shielding unbraided then twisted into a wire that is anchored on both end as seen in this example: As depicted below; when this cable (2) is run to the contact pins, it is anchored (3) just before the wire (1) going to the contact pins thru a hole (4) in the Aluminum body. This anchoring transfers any tensile loads to the shielding instead of the thin wires carrying the battery voltage. S.M.A.R.T: The SOCOM uses a Self-Monitoring, Analysis and Reporting Technology (SMART) which is done by the onboard ruggedized tiny microcontroller (computer) that sends a signal to the SOCOM’s Red LED to blink when the battery voltage feeding the ANVIS drops to 2.4 volts. At 1.6 volts the LED stops blinking which tells the ANVIS Operator that the NVGs will stop working very soon. NOTE 1: The ANVIS stops working at 1.5 volts as tested with MX-10160A OMNI V tubes. NOTE 2: When first powered, the SOCOM’s LED illuminates for two seconds as part of its Power On Self Test (POST) function. Backward Compatible: The SOCOM works with all of the standard OEM battery packs that have been used for as long as the ANVIS has been in use. It should be noted that if the circuitry, in the standard issue battery pack, that performs the low battery warning functions fails or the green or white wire in the cable gets cut, any other type of ANVIS helmet mount will not have the ability to warn the Operator that the battery is low. In this situation ONLY the SOCOM can continue to perform the needed functions it was designed for. The SOCOM can work with other non-standard ANVIS battery packs such as my Simple Battery Pack - Accessory Rail Connector aka SBP-ARC. Optical Stealth: Other version of ANVIS helmet mounts produce a blinking red light that can be seen for a distance with the naked eye at night and at greater distances when view with night vision equipment. The SOCOM’s low battery warning light was been designed to diffuse and direct the Red LED’s light so that only the ANVIS Operator can see it, thus not giving away the Operator’s position when his batteries are getting low. Radio Frequency Protection: The SOCOM uses an RF shunt across its internal battery bus that protects the ANVIS’s electronics as well as the SOCOM’s electronics from stray voltages that can be picked up by the SOCOM’s cables acting as antennae which can pick up RF signals in high electromagnetic fields existing in systems tested in accordance with MILSTD 461 and 462 which comprise the 14KHz to 40 GHz Bands of the electromagnetic spectrum. Such fields are produced in High Powered Aircraft and Vehicle Communications Radios and RADAR. Wilcox Engineering & Research THE Vanguard of Electro-Optic innovation and Advanced Products for Military and Law Enforcement Advanced Applications with over 45 years of Manufacturing Experience.