* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download MCW101C, E Time Proportional Level Controller

Mercury-arc valve wikipedia , lookup

Fault tolerance wikipedia , lookup

Current source wikipedia , lookup

Negative feedback wikipedia , lookup

Ground loop (electricity) wikipedia , lookup

Power engineering wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Induction motor wikipedia , lookup

Power inverter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Public address system wikipedia , lookup

Stepper motor wikipedia , lookup

Ground (electricity) wikipedia , lookup

Electric machine wikipedia , lookup

Schmitt trigger wikipedia , lookup

Audio power wikipedia , lookup

Electrical substation wikipedia , lookup

Pulse-width modulation wikipedia , lookup

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

Integrating ADC wikipedia , lookup

Voltage regulator wikipedia , lookup

Control theory wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Voltage optimisation wikipedia , lookup

Distribution management system wikipedia , lookup

Alternating current wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

PID controller wikipedia , lookup

Power electronics wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Mains electricity wikipedia , lookup

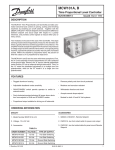

MCW101C, E Time Proportional Level Controller Technical Information 4 6 2 8 SENSITIVITY ON L STANDBY R SLOPE MCW101C, E Time Proportional Level Controller Technical Information Overview DESCRIPTION The MCW101 Time Proportional Level Controller provides automatic transverse-axis control on paving, curbing and trenching machines. Together with the Q625A or MCQ101 Remote Setpoint Unit it senses the difference between setpoint and actual slope with respect to a gravity reference. Two modules are housed in the case of the Controller. The slope sensing module electromagnetically measures the deviation between a gravity reference and the equipment it is mounted on. The amplifier module accepts the signal from the sensor and produces a voltage output to drive solenoid valves which, on a typical paving machine, operate lift cylinders to position the tow point of a floated screed. Within the amplifier’s proportional band, the percent of time the output is on is proportional to slope error. The MCW101 may be used together with the MCW100 Time Proportional Rotary Position Controller to control both parameters simultaneously. FEATURES • Proportional output suitable for driving on-off solenoids. • Accepts remote slope setpoint. • Dual clockwise/counterclockwise tilt lamps show deviation from setpoint in RUN and STANDBY modes. • Adjustable deadband varies sensitivity. • RUN/STANDBY switch permits operator to switch to manual control. • Rugged aluminum housing. • 12 VDC or 24 VDC supply voltage. • Reverse polarity and short circuit protected. • Moisture and corrosion resistant. • Withstands vibration and shock. ORDERING INFORMATION Controller Supply voltage Type of output Id. No. MCW101C1005 12 VDC Ground side switching 679852 MCW101C1013 24 VDC Ground side switching 679860 MCW101E1003E 12 VDC High side switching 730994 MCW101E1011E 24 VDC High side switching 725374 © 2001, Sauer-Danfoss Sauer-Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Sauer -Danfoss reserves the right to alter its products without prior notice. This also applies to products already ordered provided that such alterations can be made without subsequent changes being necessary in specifications already agreed. All trademarks in this material are properties of the respective companies. Sauer-Danfoss and the Sauer-Danfoss logotype are trademarks of the Sauer-Danfoss Group. All rights reserved. 2 BLN-96-9214-E • Rev. C • 08/2001 MCW101C, E Time Proportional Level Controller Technical Information Technical Data and Block Diagram TECHNICAL DATA Operating voltage 12 VDC: 11 VDC to 15 VDC Operating voltage 24 VDC: 22 VDC to 30 VDC Maximum supply current: 0,6 A (not including output current to the valve) Maximum voltage droop: 3,5 V (3 A load current) Maximum current output: 3A Time proportional output: f = 3 Hz ± 1 Hz Minimum pulse width: t = 37 ms ± 12 ms Reverse polarity protection: 200 VDC, maximum Full, with 0,5 Ω maximum resistance Short circuit protection: BLOCK DIAGRAM MCW101C - Ground side switching V 3Hz t + - V + + t Microsyn Sensitivity potentiometer V f 440Hz V t Voltage regulator F V U + - t t Battery S01800 BLN-96-9214-E • Rev. C • 08/2001 3 MCW101C, E Time Proportional Level Controller Technical Information Block Diagram and Dimensions BLOCK DIAGRAM MCW101E - High side switching V 3Hz t + - V + + t Microsyn Sensitivity potentiometer V f 440Hz V t Voltage regulator F V U + t - t Battery S00418 17 97 DIMENSIONS 12,7 237,3 4 6 2 117,3 8 SENSITIVITY ON L STANDBY R SLOPE 250 114 136,7 254 4 BLN-96-9214-E • Rev. C • 08/2001 S00280 MCW101C, E Time Proportional Level Controller Technical Information Theory of Operation THEORY OF OPERATION The MCW101 Time Proportional Slope Controller consists of a slope-sensing transducer and an amplifier. The sensor and amplifier are housed in a single aluminum channel and can be removed easily for repair or replacement. They are connected with a MS-connector. Figure 1 is a representation of the internal construction of the sensor showing the rotor/ stator relationships at null and in tipped position. A 440 Hz square wave oscillation from the amplifier is applied to the primary of each of the four coils. The stator position with respect to the rotor (therefore gravity) determines the voltages from the coil secondaries. Opposing coils are wired in series. The two voltages are demodulated in the amplifier to power a bridge network. A 3 Hz triangular wave is summed with the error signal, defined by the difference between the voltages, to effect the time proportioning. See Figure 2. The sum is compared to a reference voltage by two Schmitt triggers, which drive the solenoids. When a Remote Setpoint is used, the difference between the voltages is kept proportional to the commanded slope. The separation between the reference voltages (the deadband) is adjustable through a trim potentiometer in the front panel. At minimum sensitivity (wide deadband) a 0,4 % slope error signal will fire the triggers. At maximum sensitivity (narrow deadband), both triggers will fire alternately at the peaks of the triangular waves, even when the system is level. Figure 1: Rotor-stator relationship Figure 2: Deadband min. sensitivity Rotor Rotor max. sensitivity ON OFF max. deadband 0 Stator ON OFF t OFF ON output signal to the solenoid valve Slope sensor at null Slope sensor 10 degrees from null 0 t S00456 ON OFF 0 t error 1 error 2 OFF ON output signal to the solenoid valve 0 t S01748_40e BLN-96-9214-E • Rev. C • 08/2001 5 MCW101C, E Time Proportional Level Controller Technical Information Connection Diagrams CONNECTION DIAGRAM MCW101C - Ground side swiching A B F C 5A - + D Battery E UP DOWN F G H I J MS-connector, 10-pin S00371 CONNECTION DIAGRAM MCW101E - High side swiching A B F C 5A - + D Battery E DOWN F UP G H I J MS-connector, 10-pin S00372a 6 BLN-96-9214-E • Rev. C • 08/2001 MCW101C, E Time Proportional Level Controller Technical Information Notes BLN-96-9214-E • Rev. C • 08/2001 7 Our Products Open circuit axial piston pumps Gear pumps and motors Fan drive systems Closed circuit axial piston pumps and motors Bent axis motors Hydrostatic transmissions Transit mixer drives Hydrostatic transaxles Electrohydraulics Sauer-Danfoss Mobile Power and Control Systems – Market Leaders Worldwide Sauer-Danfoss is a comprehensive supplier providing complete systems to the global mobile market. Sauer-Danfoss serves markets such as agriculture, construction, road building, material handling, municipal, forestry, turf care, and many others. We offer our customers optimum solutions for their needs and develop new products and systems in close cooperation and partnership with them. Sauer-Danfoss specializes in integrating a full range of system components to provide vehicle designers with the most advanced total system design. Integrated systems Microcontrollers and software PLUS+1™ GUIDE Sauer-Danfoss provides comprehensive worldwide service for its products through an extensive network of Global Service Partners strategically located in all parts of the world. Displays Joysticks and control handles Local address: Sensors Orbital motors Inverters Electrohydraulic power steering Hydraulic power steering Hydraulic integrated circuits (HIC) Cartridge valves Directional spool valves Proportional valves Sauer-Danfoss (US) Company 2800 East 13th Street Ames, IA 50010, USA Phone: +1 515 239-6000 Fax: +1 515 239 6618 Sauer-Danfoss GmbH & Co. OHG Postfach 2460, D-24531 Neumünster Krokamp 35, D-24539 Neumünster, Germany Phone: +49 4321 871-0 Fax: +49 4321 871 122 BLN-96-9214-E • Rev C • Aug 2001 www.sauer-danfoss.com Sauer-Danfoss ApS DK-6430 Nordborg, Denmark Phone: +45 7488 4444 Fax: +45 7488 4400 Sauer-Danfoss-Daikin LTD. Shin-Osaka TERASAKI 3rd Bldg. 6F 1-5-28 Nishimiyahara, Yodogawa-ku Osaka 532-0004, Japan Phone: +81 6 6395 6066 Fax: +81 6 6395 8585