* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Digital Trip Coil Supervision Relay

Spark-gap transmitter wikipedia , lookup

Ground (electricity) wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Power inverter wikipedia , lookup

Fault tolerance wikipedia , lookup

Electrical ballast wikipedia , lookup

History of electric power transmission wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Loading coil wikipedia , lookup

Current source wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power electronics wikipedia , lookup

Electrical substation wikipedia , lookup

Schmitt trigger wikipedia , lookup

Earthing system wikipedia , lookup

Capacitor discharge ignition wikipedia , lookup

Power MOSFET wikipedia , lookup

Surge protector wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Stray voltage wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

Voltage regulator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Voltage optimisation wikipedia , lookup

Galvanometer wikipedia , lookup

Mains electricity wikipedia , lookup

Opto-isolator wikipedia , lookup

Ignition system wikipedia , lookup

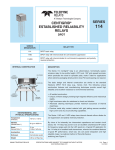

g GE Consumer & Industrial Multilin DBT Digital Trip Coil Supervision Relay Instruction Manual GEK-105597C Copyright © 2004 GE Multilin GE Multilin 215 Anderson Avenue L6E 1B3 Markham, ON -CANADA Tel: (905) 294 6222 Fax: (905) 294 8512 GE Multilin Avda. Pinoa, 10 48170 Zamudio SPAIN Tel: +34 94 485 88 00 Fax: +34 94 485 88 45 E-mail: [email protected] E-mail: [email protected] Internet: www.gemultilin.com TABLE OF CONTENTS TABLE OF CONTENTS 1. DESCRIPTION 3 2. APPLICATION 5 2.1 2.2 2.3 2.4 5 5 5 6 DIRECT CONNECTION TO COIL USE AS A DC UNDERVOLTAGE RELAY DIFFERENT CONNECTIONS FOR INDEPENDENT BATTERIES RECOMMENDED SETTINGS 3. MODEL LIST 7 4. OPERATING PRINCIPLES 9 5. TECHNICAL CHARACTERISTICS 11 5.1 TECHNICAL CHARACTERISTICS 5.3 TYPE TESTS 11 12 6. RELAY SETTINGS 15 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 15 16 16 16 17 17 17 18 ‘READY’ LED ‘ENABLE’ SWITCH ‘RESET TARGET’ SWITCH LED INDICATORS COIL RESISTANCE SETTING VOLTAGE SETTING TIME DELAY SETTING ADJUSTMENT SUMMARY TABLE OF SETTINGS 7. RECEPTION TESTS 19 7.1 7.2 7.3 7.4 7.5 7.6 19 19 20 21 22 22 VISUAL INSPECTION INSULATION TRIP LEVEL TEST TIME DELAY TEST RESISTANCE MEASUREMENT TEST ENABLE TEST GEK-105597C DBT Digital Trip Coil Supervision Relay 1 TABLE OF CONTENTS LIST OF FIGURES Figure 1 Nameplate (226B1298H3) Figure 2 External connections - one coil model (226B6291H5) Figure 3 External connections - three coils model(226B6291H4) Figure 4 External connections – model DBT3000A*0H02 (226B6291H6) Figure 5 Mechanical dimensions and cut-out (226B6086H11) Figure 6 Rear terminal plate (226B6292H1) Figure 7 Block diagram (226B2209H1) 2 DBT Digital Trip Coil Supervision Relay GEK-105597C DESCRIPTION 1. DESCRIPTION The DBT is a digital trip coil supervision relay. This supervision includes: • • • Integrity of coils (monitoring continuously their resistance). In case coils are in a good condition, the output COIL OK will be activated. Control voltage (supervision of low voltage). If voltage is correct, the output BREAKER VOLTAGE OK will be activated. Checks the breaker control circuit. If both control voltage AND coils integrity are correct, then the output BREAKER CIRCUIT OK will be activated. Note: The activation of a NO (Normally Open) output means contacts will be closed, whereas the activation of a NC (Normally Closed) output means contacts will be opened. In its single-coil version, the DBT monitors coil continuity whether the breaker is open or closed. It also has a timing device to avoid indicating failure signals during opening to closing transitions. The three-coils version of the DBT can monitor three coils at a time, regardless of the position of the breaker, and with timer delay for transitions. In addition to coil monitoring, both versions (single- and three-coil) have a continuous DC undervoltage function to monitor the battery’s power supply. The supervised coils can be either the tripping or the closing ones, futhermore, in the three-phase version coils can be coming from different breakers. Instead of measuring the continuity of the circuit (like other relays), the DBT measures real resistance. It injects a current of 5 mA, limited to a maximum of 24 V. By measuring the voltage drop in the coil the DBT calculates the resistance. Figure 3 shows a typical three-coil DBT connection to a coil. In this way the relay can measure the coil resistance at any time (in reality, the association of the breaker coil with any other auxiliary coils), either by the 52/a type contact, if the breaker is closed, or the 52/b type if it is open. The relay also measures the breaker power supply at terminals B1 and B2. The advantage of measuring real resistance is in selectivity, as failures in trip circuits can be detected apart, even in cases where auxiliary circuit coils are connected in parallel. In these situations a break or interruption of the breaker coil would not be detected by a continuity measurement because the auxiliary coils would create an alternative path to the current flow. On the other hand, a resistance measurement like that made by the DBT is a valid procedure because the resistance will rise when the breaker coil fails. An extra advantage of the DBT is in its limitation of current sources to a maximum of 24 V, which avoids the DBT operating other high impedance auxiliary circuits. This kind of circuits run the risk of being enabled by the low level of milliamperes injected by conventional monitoring relays. When maintenance work is carried out on the breaker, a disable switch available on the front of the relay should be operated in order to deactivate all the outputs. The effect produced is similar to a lack of continuous auxiliary voltage as shown in figures 2 and 3. This inhibition can also be done by energizing a digital input. The three-coil model has four inputs and the single-coil model just one. GEK-105597C DBT Digital Trip Coil Supervision Relay 3 DESCRIPTION 4 DBT Digital Trip Coil Supervision Relay GEK-105597C APPLICATION 2. APPLICATION The DBT has been designed to monitor the biggest possible number of elements in the tripping and closing circuits of the breaker. The relay checks voltages, coil resistance and the integrity of the auxiliary contacts 52/a and 52/b, since they are also part of the trip and close circuits of the breaker. For safety reasons, in order to avoid signalling BREAKER CIRCUIT OK when auxiliary voltage is low, it is strongly recommended using a NO output. When using a NO output the DBT protection will energize that relay and will CLOSE that output contacts if both voltage and coil are correct. When auxiliary voltage is low (or null) or there is a failure in the breaker coil circuit, that output will be OPENED, indicating breaker circuit failure. 2.1 DIRECT CONNECTION TO COIL Although there are two connections for each coil (one through 52/a and the other through 52/b) these cannot be used for two different coils because the relay compares the resistance measured by each contact. A three-phase relay is designed to monitor up to 3 coils and a single-phase relay just one. If, for whatever reason, there is a need to make a direct connection to the coils without going through contacts 52/a and 52/b (in this case monitoring of these would be lost), it can be done. The connection of the coil at the input of 52/a has to be wired and leave input 52/b unconnected. 2.2 USE AS A DC UNDERVOLTAGE RELAY If you only want to use the undervoltage unit this can be done by simply disabling the coil monitoring units. This inhibition is done by connecting inputs 52/a (terminals B3, B5 and B7 on the three-phase model, terminal B3 on the single-phase) to the negative of the breaker power supply (terminal B2), leaving inputs 52/b unconnected (terminals B4, B6 and B8 of the three-phase, B4 of the single-phase). Once the resistance monitoring is disabled, when undervoltage condition occurs the BREAKER VOLTAGE OK and the BREAKER CIRCUIT OK contacts will become deactivated. 2.3 DIFFERENT CONNECTIONS FOR INDEPENDENT BATTERIES Although the installation has just one battery, voltage can be distributed through different circuits (each one protected by a MCB). If you connect the auxiliary voltage (terminals B9-B10) to a different circuit from the breaker power supply circuit (terminals B1-B2), in the event of an incident in the breaker power supply (where the MCB trips) the DBT continues working and is fully operative. This gives us the necessary information regarding BREAKER VOLTAGE OK and BREAKER CIRCUIT OK. When the auxiliary voltage fails the DBT gives a warning through the ALARM contact. GEK-105597C DBT Digital Trip Coil Supervision Relay 5 APPLICATION 2.4 RECOMMENDED SETTINGS This section is only included for customer information, given the importance of the right choice of settings to ensure good protection and a range of possible applications. Resistance Because the coil is made of copper its resistance varies considerably with temperature. The temperature coefficient of copper is approximately 0.43%/ºC (see UNE 20-003 “Annealed and industrial copper for electrical applications”). This means that, at an ambient temperature of 0ºC, resistance is 8.6% lower than that measured at an ambient temperature of 20ºC. Furthermore, the resistance of cables connected to resistance measurement inputs of the relay can vary the resistance measured by the DBT (as a result of common mode impedance effect). It is also sometimes difficult to measure the resistance of a coil, or perhaps this information does not appear in the technical data on the coil. A practical way of adjusting the DBT is to vary the resistance setting, starting from the minimum value (50 Ω) until the relay disables its resistance monitoring output. It is advisable to increase this setting to approximately 20% to reduce the impact of temperature and ground impedance. If the setting cannot be made in this manner, apply the maximum setting (200 Ω) to avoid unwanted operation. Voltage The recommended setting is al 10% less than the lowest expected voltage from the battery. Time The recommended time varies depending on the application. In any case, the time set must be greater than the maximum time during which both auxiliary breaker contacts (52a and 52b) are open simultaneously. The reason for this requirement is that during that time, the resistance measured by the DBT protection is infinite for both inputs (52a and 52b) indicating a fault. This fault could produce a COIL alarm if this situation is maintained over the time set in the relay. If other auxiliary contacts are connected in series with 52a or 52b contacts (i.e. springs, etc.) their response time should be included in the calculation of the total time of coincidence of 52a and 52b open. 6 DBT Digital Trip Coil Supervision Relay GEK-105597C MODEL LIST 3. MODEL LIST The data required to fully define a model are those shown in the chart below. The possible models are: DBT * 0 0 * A 0 * 0 H 0 * DESCRIPTION Number of coils 1 1 coil (single-phase) 3 3 coils (three-phase) Coil resistance 0 75-300 Ohm 1 150-600 Ohm Breaker Voltage 1 110/125 V DC 2 220/250 V DC Output relays option for DBT1 models 0 See Figure 2 at the end of the manual Output relays option for DBT3 models GEK-105597C 0 See Figure 3 at the end of the manual 1 See Figure 3 at the end of the manual 2 See Figure 4 at the end of the manual DBT Digital Trip Coil Supervision Relay 7 MODEL LIST 8 DBT Digital Trip Coil Supervision Relay GEK-105597C OPERATING PRINCIPLES 4. OPERATING PRINCIPLES Figure 7 (Block diagram) shows the basic operation of the DBT (the most common case of a 3-phase version). Seven units of measurement can be seen: 1. Voltage measurement for undervoltage function of breaker power supply. 2. Resistance measurement of coil 1 through contact 52/b. 3. Same through contact 52/a. 4. Resistance measurement of coil 2 through contact 52/b. 5. Same through contact 52/a. 6. Resistance measurement of coil 3 through contact 52/b. 7. Same through contact 52/a. The first measurement unit serves an undervoltage comparator which will give a signal if the voltage is lower than the setting, activating an adjustable timer between 0.2 and 20 seconds. If the undervoltage continues for at least the set time, the timer output will activate the signal breaker voltage failure and also the signal general failure. The activation of failure signals deactivate the corresponding output relays. Note: ‘deactivation of a relay’ is understood to mean that it changes to its standby position as shown in the external connections diagram, i.e. a NO closes and a NC opens. The timer has a preset voltage drop time of 100 ms, thereby ensuring a minimum time in which the output contacts are maintained for at least 100 ms. Two resistance measurement devices are located after the undervoltage unit, both monitoring the first coil. The resistance measurement is calculated through the voltage drop produced by the current injected by the current sources. Supposing that the breaker is closed, auxiliary contact 52/a would also be closed, whereas 52/b would be open. The measuring unit connected to 52/b would show a higher voltage than that of the resistance setting, i.e. the DBT will measure a higher resistance than the setting. On the other hand, the unit connected to 52/a will give a lower resistance reading than the setting, taking into account that the coil circuit is correct. Both resistance measuring unit outputs are the inputs of an equality comparator (this is a comparator that produces output when both inputs are high or low, i.e. equal). In the example mentioned, one measuring unit gives a HIGHER resistance than the setting whereas the other gives a LOWER resistance. Therefore, the comparator detects inputs are not equal and does not produce an output signal, which means coil circuit is in a good condition. In case the coil is broken, resistance measured by both units is infinite (i.e. equal) and the equality comparator produces a failure signal. That signal is feed into a timer. After the set time elapses with a failure signal, two signals are generated, coil failure and general failure. As described for coil 1, the 3-phase DBT has circuits for a second and third coils. In the case of a single-phase DBT, there are only resistance measuring unit for coil 1 (in addition to the undervoltage unit). GEK-105597C DBT Digital Trip Coil Supervision Relay 9 OPERATING PRINCIPLES Internal setting In the 3 coils DBT model, there is an internal setting which can be made by moving a jumper in the printed circuit, that allows to configure all the outputs as general ones (BREAKER CIRCUIT OK). Any failure (undervoltage or resistance) will mean that all outputs will be deactivated. In addition to the outputs mentioned, and as described in detail in Figures 2 & 3: External Connections, the DBT has a SYSTEM READY output relay. This closes the contact in case the relay is not available due to one of the following causes: • An internal fault. • An auxiliary voltage drop of the supply. • The relay has been disabled. The DBT can be disabled either externally by enabling one or several of any of the 4 digital inputs for inhibition (in the case of the 3-phase) or by the single input for the single-phase, or locally by the switch labelled ENABLE. A disabled DBT will continue to measure and give information through the LEDs but all its relays will be inoperative except the SYSTEM READY relay, which will close its contact. 10 DBT Digital Trip Coil Supervision Relay GEK-105597C TECHNICAL CHARACTERISTICS 5. TECHNICAL CHARACTERISTICS 5.1 TECHNICAL CHARACTERISTICS • AUXILIARY SUPPLY A ripple factor is allowed provided that the instantaneous voltage does not exceed the indicated upper and lower limits. For example, on the 110-125 V model the voltage at any given time should never drop below 88 V nor go above 150 V. • 110-125 V DC ± 20% • 220-250 V DC ± 20% • TEMPERATURE RANGES Operational range: -25ºC to + 55ºC Storage range: -40ºC to + 70ºC Complies with IEC 255-6 and ANSI C37.90 Standards. • HUMIDITY Up to 95% without condensation. • OUTPUT CONTACTS Breaking capacity: 4000 VA Maximum DC voltage: 300 V DC Maximum AC voltage: 440 V AC Continuously: 16 A Making capacity: 30 A • ACCURACY Voltage: Resistance: Time: ± 5% ± 10% 20 ms • VOLTAGE CIRCUIT BURDEN 110-125 V DC model: 48 kΩ 220-250 V DC model: 96 kΩ DIGITAL INPUT BURDEN 110-125 V DC model: 66 kΩ 220-250 V DC model: 132 kΩ • AUXILIARY POWER CONSUMPTION Standby: Operated: GEK-105597C 3 W (only NC alarm relay activated) 7.5 W (all relays activated) DBT Digital Trip Coil Supervision Relay 11 TECHNICAL CHARACTERISTICS • WEIGHTS Net: Packed: 3 kg 4 kg • WATERTIGHTNESS Index: IP51 • DIMENSIONS Width: 483 mm (19” rack) Depth: 200 mm Height: 45 mm (1 height unit) • INSULATION As per IEC 255-5. Between terminal and case: 2000 V AC for 1 minute at industrial frequency. Between independent circuits: 2000 V AC for 1 minute at industrial frequency. 5.3 TYPE TESTS 1 MHz interference test 2.5 kV common mode, 1 kV differential, class III as per IEC 255-4. Impulse test 5 kV peak 1.2/50 µs, 0.5 J as per IEC 255-4. Radiointerference As per IEC 1000-1-2. IEC 255-22-2 class IV. Electrostatic discharge As per IEC 1000-1-3. IEC 255-22-3 class III. Fast transient As per IEC 1000-1-4. IEC 255-22-4 class IV. Emissivity As per EN 55022, class B. Magnetic fields As per IEC 100-4-8, class V Vibration 12 DBT Digital Trip Coil Supervision Relay GEK-105597C TECHNICAL CHARACTERISTICS As per IEC 255-21-1, class II. Shock test As per IEC 255-21-2, class II. The DBT relay complies with these Standards, which includes the GE Standard on the level of insulation and electromagnetic compatibility required by CE Directive 89/336 for CE marking, according to standardised European regulations. It also complies with the European Low Voltage Directive and the environmental and operational requirements laid down in Standards ANSI C37-90, IEC 255-5, IEC 255-6 and IEC 68. GEK-105597C DBT Digital Trip Coil Supervision Relay 13 TECHNICAL CHARACTERISTICS 14 DBT Digital Trip Coil Supervision Relay GEK-105597C RELAY SETTINGS 6. RELAY SETTINGS The settings are located on the relay’s nameplate in the form of dip switches. Their meanings are printed, indicating ranges in addition to the functions. In the DBT3000 there is an internal setting. This setting enables individual or general selection of the output relays. If General mode is chosen (position G), any fault (in the coil or the control voltage) will trigger all the relays. If the jumper is put in the Independent mode (position I) each relay will operate only on its own function when the corresponding fault occurs. LEDs are also located on the relay and serve as indicators to give information on the relay and the circuits being monitored. The next section describes the LEDs and their settings, seen from left to right. If a relay is not available, use Figure 1: Characteristics nameplate for reference. 6.1 ‘READY’ LED A two-colour LED which can be in any one of the following three situations: - Off: indicates absence of auxiliary supply voltage. - Green: the relay is fully operational. - Red: The relay is disabled, either because one of the disabling inputs has been enabled or because it has been disabled with the ENABLE switch. When the DBT is disabled all its outputs are disabled and the SYSTEM READY relay is closed. However, all the measuring, decision and timer units stay operational, as do the LED indicators. GEK-105597C DBT Digital Trip Coil Supervision Relay 15 RELAY SETTINGS 6.2 ‘ENABLE’ SWITCH This switch has two positions: - Left: relay disabled, READY LED will go red. - Right: enabled relay, the READY LED goes green, provided none of the external disabling inputs are active. At the back of the relay there are digital disabling inputs on terminals C1-D1, C2-D2, C3-D3 and C4-D4 (3phase model) and C1-D1 for the single-phase model (see Figure 6: Rear terminal plate). The enabling of any of these inputs has the same effect as the ENABLE switch in the left position. The enabling of the inputs is DC operated (same margin as supply voltage). As there is galvanic insulation between them they can be enabled by voltage from different batteries or can be grouped in a single one. These inputs are polarised, the positive on the C terminals and the negative on the D terminals. An inversion of polarity has no negative effects on the relay, although the input would not be enabled. 6.3 ‘RESET TARGET’ SWITCH This switch has two uses: - Acknowledgement of indicators. A fault is recorded by an LED with memory. This is erased by pressing and releasing the RESET button. If the auxiliary voltage drops the registered LED operation will be erased too. - Checking indicators: This feautre is used to ensure indicators are working properly. When the RESET button is pressed all the indicators which are out will lit up. 6.4 LED INDICATORS There are four LEDs, the first indicates a breaker power supply fault and the others coil faults. They are red LEDs, and can be in one of the three following states: - Off. This means there is no fault. In the case of the breaker power supply it would be above the preset voltage. For coils, that their resistances are not above the preset value. - Flashing red: fault situation. If this situation continues for the preset time period, the output relay will be enabled and the LED will continue to flash. - Red: a fault has occurred but disappeared, although not yet acknowledged by the user. This acknowledgement is done by pressing RESET. If a red light is present and another fault occurs the LED does not flash, but when RESET is pressed the LED starts to flash. 16 DBT Digital Trip Coil Supervision Relay GEK-105597C RELAY SETTINGS 6.5 COIL RESISTANCE SETTING This is the coil failure circuit threshold. It is a block of 4 dip switches. The minimum value is 75 Ω, the maximum 300 Ω and the step 15 Ω. For example, if a setting of 150 Ω is required, put dip switches 1 and 3 in the UP position. You then have: 75 + 15 + 60 = 150. The DBT will consider that there is a fault condition if BOTH resistances measured in 52a and 52b inputs are OVER the setting. It also will consider a fault when both resistances are BELOW the setting, because this is not a normal condition. The fault has to be maintained during the set time to allow the output relay operate. This time prevents misoperation during breaker status transition. 6.6 VOLTAGE SETTING This is the threshold for the breaker power supply failure unit. As in the case of the resistance setting, it is a block of 4 dip switches. For the 110/125 V DC model the minimum value is 50 V, the maximum 125 V and the step 5 V. For the 220/250 V DC model the values are double the above, so the minimum is 100 V, the maximum 250 V and the step 10 V. If a setting of 115 V is required (110/125 model), raise dip switches 1, 3 and 4, making a total of: 50 + 5 + 20 + 40 = 115. This is equivalent to 230 V on the 220/250 V model. 6.7 TIME DELAY SETTING ADJUSTMENT This is the timer adjustment, made through a block of 3 dip switches. The minimum value is 0.2 seconds, the maximum 20 and the step 0.1. Note: although it is theoretically possible to select a time which is higher than the maximum (for example, if all the dip switches are put in the UP position you apparently have a setting of 27.5 seconds, the maximum), in reality, if all the dip switches are in the UP position the setting is 20 seconds. Therefore, any adjustment above 20 seconds will be considered as if it were 20 seconds. This has been done because there is no point in having a higher setting. GEK-105597C DBT Digital Trip Coil Supervision Relay 17 RELAY SETTINGS 6.8 SUMMARY TABLE OF SETTINGS 18 Name of setting Enable Max. Enabled Min. Disabled Step ____ ____ Set to Enabled Disabled Resistance Voltage 110/250 model 220/250 model 300 Ω 75 Ω 15 Ω _____ Ω 125 V 250 V 50 V 100V 5V 10 V _______ V _______ V Time delay 20 s 0.2 s 0.1 s _______ s DBT Digital Trip Coil Supervision Relay GEK-105597C RECEPTION TESTS 7. RECEPTION TESTS 7.1 VISUAL INSPECTION Check that the information on the nameplate coincides with the details of the order. A check should also be made to ensure that the relay is not scratched or has received impacts, and that there are no loose parts as a result of bad handling in transit. 7.2 INSULATION As a result of the presence of filter capacitors (used to protect the relay from external interference) a reading of approximately 3 mA (at 2000 V AC/50Hz) will be had on each capacitor. This may create problems for the insulation test equipment if it is unable to supply all the current. To avoid this problem, remove the connection from terminal B11 to B 12, thus separating the capacitor ground circuit (B 11) from the relay housing (B 12). Important: for safety reasons, the relay housing should always be earthed by an earthing cable connected to terminal B 12. Do not forget to make the shortest possible connection to terminals B 11 and B12, so that the capacitors can perform their filtering operation correctly. Important: to avoid serious damage to the relay, make sure that all the terminals from the same group are connected to each other while test voltage is being applied to that group. The groups are as follows: Breaker circuits: G1: G1: B1, 2, 3, 4, 5, 6, 7 & 8 B1, 2, 3, & 4 3-phase model single-phase model Auxiliary supply: G2: B9, B10 Digital inputs: G3: G3: C1, D1, C2, D2, C3, D3, C4, D4 3-phase model C1, D1 single-phase model Relay contacts: G4: G4: C6, D6, C7, D7, C8, D8, C9, D9 3-phase model C10, D10, C11, D11, C12, D12 C9, D9, C10, D10, C11, D11 single-phase model C12, D12 These tests will only be done on new relays. A ‘new relay’ is defined to be one which has not entered in service, has been delivered in the previous year and has been suitably stored to avoid deterioration. Note: apply the insulation voltage (2000 V AC) gradually, and reduce it gradually to zero to avoid stored charges. GEK-105597C DBT Digital Trip Coil Supervision Relay 19 RECEPTION TESTS 7.3 TRIP LEVEL TEST Connect the relay as indicated in the external connections diagram (Figs. 2 & 3), using a DC power supply (110/125 or 220/250 V) for the auxiliary voltage (terminals B9-B10), according to the model. Variations of ±20% are admitted (20% of the minimum and +20% of the maximum). For breaker power supply (terminals B1-B2) a second variable DC power supply is needed. Apply different voltages and check that the undervoltage LED flashes (pick-up) with the pick-up voltage (see table below). The LED remains flashing, until the undervoltage condition disappears (drop-out voltage). When the drop-out voltage is reached, and the set time ellapses, the LED stop flashing and is lit permanently (fault memory function). It is recommended to set the time to the minimum in order to ease the test. 110/125 model VOLTAGE setting (V) 50 55 60 70 90 125 20 Pick-up voltage (V) (voltage failure) 45 50 55 65 85 118 220/250 model Drop-out voltage (V) (voltage ok) VOLTAGE setting (V) 55 60 65 75 95 133 100 110 120 140 180 250 DBT Digital Trip Coil Supervision Relay Pick-up voltage (V) (voltage failure) 90 100 110 130 170 236 Drop-out voltage (V) (voltage ok) 110 120 130 150 190 264 GEK-105597C RECEPTION TESTS 7.4 TIME DELAY TEST The check the tripping time the loss of continuity of the coil connected to terminals B2 and B3 will be simulated. CLOCK start stop DBT P U S H B U T T O N C11 D11 Breaker circuit failure Insert a dual-circuit switch. One of the circuits which is normally closed will short-circuit terminals B2 and B3, simulating that the coil is correct. The other contact (normally opened) will be connected to the start-up of a timer. The timer stop will be connected to one of the breaker circuit failure relays. When the pushbutton is pressed the B2-B3 will be opened, leading to a start of failure. Create a fault as described (above) and check that the results in the table are complied with. B3 B2 TIMER DELAY setting 200 ms 300 ms 400 ms 600 ms 1s 1.8 s 3.4 s 6.6 s 13 s Maximum * Minimum time Maximum time 200 ms 300 ms 400 ms 600 ms 1s 1.8 s 3.4 s 6.6 s 13 s 19.9 s 240 ms 340 ms 440 ms 640 ms 1.04 s 1.84 s 3.44 s 6.64 s 13.04 s 20.1 s * The maximum setting will be made by placing all the dip switches in the UP position The setting is limited to 20 s (as explained previously). Measure the drop-out time of the output relay. This time will be between 100 and 150 ms (nominal value 125 ms). During this test it can be seen that the measured times may vary slightly owing to the response time of the measuring units and the output relays. GEK-105597C DBT Digital Trip Coil Supervision Relay 21 RECEPTION TESTS 7.5 RESISTANCE MEASUREMENT TEST To carry out this test, which is done on the measuring unit of coil 1, disconnect terminal B4 and leave it unconnected (simulating an open circuit). Place a resistor (simulating the breaker coil) between terminals B2 and B3. This resistance should give the readings indicated in the table below. Resistance setting (Ω) 75 90 105 135 195 300 Minimum R (Ω) 67 82 95 122 175 270 Maximum R (Ω) 82 99 115 149 215 330 Check that the relays do not trigger at the minimum values and that they do at maximum values. The test is done in the sequence described for each of the settings indicated Repeat this test for the units Corresponding to coils 2 and 3. 7.6 ENABLE TEST Disable the relay by putting the ENABLE switch in the left-hand position. Check that there is no disabling through the digital inputs (disconnect or deenergize these inputs). The alarm contact will close and the enabled relays will drop-out. The ‘READY’ LED will go from green to red. Enable the relay by putting the ENABLE switch in the right-hand position. Repeat this test by applying nominal voltage to each of the 4 digital inputs (3-phase model) and the single input for the single-phase model. The same will happen as in disabling by the ENABLE switch. 22 DBT Digital Trip Coil Supervision Relay GEK-105597C FIGURES FIGURE 1: NAMEPLATE (226B1298H3) GEK-105597C DBT Digital Trip Coil Supervision Relay 23 FIGURES (PUEDEN SER POSITIVOS SEPARADOS) CAN BE CONNECTED TO ISOLATED CIRCUITS (+) B9 TENSION MANDO BREAKER VOLTAGE TRIP C1 B1 O C O C C O O= OPEN / ABIERTO C= CLOSED / CERRADO C12 B4 52b a SIN Vaux NO Vaux Vaux y Fallo Vaux & Fail Vaux y NO Fallo Vaux & No Fail B3 52a 52 LOGICA CONTACTOS: CONTACT LOGIC ALARMA EQUIPO D12 SYSTEM READY FUENTE DE ALIMENTACION POWER SUPPLY 52 b C11 INHIBICION INHIBITION CIRCUITO INTERRUPTOR CORRECTO D11 BREAKER CIRCUIT O.K. C10 CIRCUITO INTERRUPTOR CORRECTO D10 BREAKER CIRCUIT O.K. 52 TC C9 D9 CIRCUITO INTERRUPTOR CORRECTO TENSION MANDO BREAKER VOLTAGE ANTIPARASITOS / SURGE CHASIS / CASE BREAKER CIRCUIT OK B2 B11 (*) B12 B10 (-) (*) Desconectar solo en prueba de aislamiento D1 TIERRA DE PROTECCION PROTECTIVE EARTH (PUEDEN SER NEGATIVOS SEPARADOS) CAN BE CONNECTED TO ISOLATED CIRCUITS Only disconnect in Hipot testing FIGURE 2. EXTERNAL CONNECTIONS – ONE COIL (226B6291H5) 24 DBT Digital Trip Coil Supervision Relay GEK-105597C FIGURES FIGURE 3: EXTERNAL CONNECTIONS – THREE COILS (226B6291H4) GEK-105597C DBT Digital Trip Coil Supervision Relay 25 FIGURES FIGURE 4: EXTERNAL CONNECTIONS – MODEL DBT3000A*0H02 (226B6291H6) 26 DBT Digital Trip Coil Supervision Relay GEK-105597C FIGURES FIGURE 5: MECHANICAL DIMENSIONS AND CUT-OUT (226B6086H11) GEK-105597C DBT Digital Trip Coil Supervision Relay 27 FIGURES FIGURE 6. REAR TERMINAL PLATE (226B6292H1) 28 DBT Digital Trip Coil Supervision Relay GEK-105597C FIGURES FIGURE 7: BLOCK DIAGRAM GEK-105597C DBT Digital Trip Coil Supervision Relay 29