* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download machines unit 1

Survey

Document related concepts

Transcript

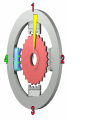

SPECIAL MECHANIES Motor Basics What is a motor Converts electrical energy into kinetic energy Where did it come from Identification of rotating magnetic field principle by Nicola Tesla in 1882 Introduction of Electric Motor by Nicola Tesla in December 1889 (U.S. Patent 0416194) How It Works • When electric current passes through a coil in a magnetic field, the magnetic force produces a torque which turns the motor. • Force in Motor: F=ILB F = Force B = Magnetic Field L = Length of Conductor I = Current in Conductor • Torque in Motor: T = IBA sin θ A = LW L = Length of Winding W = Width of Winding Ac series motor Ac series motor Application to mixer Repulsion motor A repulsion motor is a type of electric motor for use on alternating current (AC). It was formerly used as a traction motor for electric trains but has been superseded by other types of motors and is now only of historical interest. Repulsion motors are classified under single phase motors. In repulsion motors the stator windings are connected directly to the AC power supply and the rotor is connected to a commutator and brush assembly, similar to that of a direct current (DC) motor.[ Construction The motor has a stator and a rotor but there is no electrical connection between the two and the rotor current is generated by induction. The rotor winding is connected to a commutator which is in contact with a pair of short-circuited brushes which can be moved to change their angular position relative to an imaginary line drawn through the axis of the stator. The motor can be started, stopped and reversed, and the speed can be varied, simply by changing the angular position of the brushes. Stop positions Idle Run positions Position for clockwise operation Run positions Position for counterclockwise operation RELUCTANCE MOTOR CROSS SECDTIONAL VIEW OF RELUCTANCE MOTOR Cross-section of reluctance machine with 6 stator and 4 rotor poles. Notice the concentrated windings on the stator poles. • A reluctance motor is a type of electric motor that induces non-permanent magnetic poles on the ferromagnetic rotor. Torque is generated through the phenomenon of magnetic reluctance. There are various types of reluctance motor: •Synchronous reluctance motor •Variable reluctance motor •Switched reluctance motor •Variable reluctance stepping motor Hysteresis Motors • Stator – same as for induction motor • Rotor Smooth cylinder Principle of Operation Stator Flux establishes these magnetic poles Rotor poles “induced” by Stator Flux Spin the stator poles with the rotor blocked Stator poles moving CCW Rotor poles follow the rotating flux, but lag behind by angle δh Spin the stator poles with the rotor blocked If the rotor is released, it will accelerate to synchronous speed Mechanical Power developed 1 s Pmech Ph s n Ph kh f Bmax Th nr n 1 s kh f Bmax 5252 s nr ns (1 s ) f r sf s Mechanical Power developed 1 s Pmech Ph s n Ph kh f Bmax Th nr n 1 s kh f Bmax 5252 s nr ns (1 s ) f r sf s Mechanical Power Developed (cont) n 5252kh f s Bmax Th ns 120 f s ns P n 5252kh Bmax Independent of frequency and Th speed! 120 P Hysteresis Motor at Synchronous Speed No load and negligible rotational losses Induced rotor magnets remain locked with the rotating poles produced by the stator Hysteresis Motor at Synchronous Speed Apply a step increase in shaft load. The rotor slows down and the induced rotor magnets lag the rotating poles of the stator by an angle δmag . The rotor returns to synchronous speed at the new torque angle. Hysteresis Motor at Synchronous Speed Tmag sin( mag ) Tmagmax occurs @ mag 90 If shaft load causes δmag>90°, the rotor pulls out if synchronism, the magnet torque drops to zero, and the machine develops hysteresis torque. This torque is not sufficient to carry the load. Torque-Speed Characteristic Constant Hysteresis Torque allows the motor to synchronize any load it can accelerate “Normal” Operating Range STEPPER MOTOR J. Belwin Edward Assistant Professor Senior School of Electrical Engineering VIT University Vellore Stepper motor characteristics •Stepper motors are constant power devices. •As motor speed increases, torque decreases. Most motors exhibit maximum torque when stationary, however the torque of a motor when stationary (holding torque) defines the ability of the motor to maintain a desired position while under external load. The torque curve may be extended by using current limiting drivers and increasing the driving voltage (sometimes referred to as a 'chopper' circuit; there are several off the shelf driver chips capable of doing this in a simple manner). •Steppers exhibit more vibration than other motor types, as the discrete step tends to snap the rotor from one position to another (called a detent). The vibration makes stepper motors noisier than DC motors. This vibration can become very bad at some speeds and can cause the motor to lose torque or lose direction. This is because the rotor is being held in a magnetic field which behaves like a spring. On each step the rotor overshoots and bounces back and forth, "ringing" at its resonant frequency. If the stepping frequency matches the resonant frequency then the ringing increases and the motor loses synchronism, resulting in positional error or a change in direction. At worst there is a total loss of control and holding torque so the motor is easily overcome by the load and spins almost freely. The effect can be mitigated by accelerating quickly through the problem speeds range, physically damping (frictional damping) the system, or using a micro-stepping driver. Motors with a greater number of phases also exhibit smoother operation than those with fewer phases (this can also be achieved through the use of a micro-stepping driver). Stepper motors with higher inductance coils provide greater torque at low speeds and lower torque at high speeds compared to stepper motors with lower inductance coils. Switched reluctance motor Stepper motor Stepper motor Applications Computer peripherals Textile industries IC fabrications Robotics Applications requiring incremental motion Typewriters Line printers Tape drives Floppy disk drives Numerically-controlled machine tools Process control systems X-Y plotters Applications contd…. •Commercial, military and medical applications •Mixing, cutting, striking, metering, blending •Application in manufacture of packed food stuffs •Application in manufacturing of commercial end products •Production of science fiction movies. Step Angle - β • As small as 0.78o to 90o • Most commonly used – 1.8o, 2.5o, 7.5o, 15o β = (Ns-Nr) x 360o = 360o Ns.Nr mNr Ns – No. of Stator poles (teeth) Nr – No. of Rotor poles (teeth) m - No. of stator phases Types • Variable Reluctance - VR • Permanent Magnet - PM • Hybrid VR, PM and Hybrid types Variable Reluctance ( VR) stepper motor • Wound Stator poles – Single Stack – Multiple Stack – smaller step angle • Rotor poles – ferromagnetic material • Direction – stator current polarity • Reluctance of the magnetic circuit formed by rotor and stator teeth varies with angular position of the rotor Variable Reluctance stepper motor Single Stack VR – Multi stack VR-Operation Modes of operation –VR type • 1-phase ON – full step operation • 2-phase ON • Half-step – alternate 1-phase & 2-phase mode • Micro stepping Permanent Magnet (PM) Stepper Motor Permanent Magnet stepper motor • Wound Stator poles – Single Stack – Multiple Stack – smaller step angle • Rotor poles – permanent magnet • Rotor Shape - Cylindrical • Direction – stator current polarity PM - operation PM - operation Modes of Operation – PM type • 1-phase ON mode • 2-phase ON mode • Half step mode Modes of Operation – PM type Hybrid Stepper Motor Hybrid stepper motor • Combination of VR and PM • Wound Stator poles – (similar to VR) – Single Stack – Multiple Stack – smaller step angle • Rotor poles – permanent magnet • Rotor shape – not Cylindrical • Direction – stator current polarity Stepper motor applications Automated Test Equipment Surveillance Systems Avionics Defense Contracting Labeling Machinery Medical Equipment Packaging Semiconductor Manufacturing Metering and Dispensing Engraving Machine Automatic Feeding Machine 3D Image Acquisition System Label and Die Feeder Wave Length Meter Bar Code Printing Antenna Fiber optics Switch Laser Measurement Press Printing Color/ Photo Imaging