* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download BF/400 VAC RACK

Immunity-aware programming wikipedia , lookup

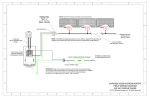

Opto-isolator wikipedia , lookup

Radio transmitter design wikipedia , lookup

Index of electronics articles wikipedia , lookup

Power electronics wikipedia , lookup

Gender of connectors and fasteners wikipedia , lookup

Electrical connector wikipedia , lookup

Valve audio amplifier technical specification wikipedia , lookup

Audio power wikipedia , lookup

Valve RF amplifier wikipedia , lookup

BF/400 VAC RACK gb BF RACK / 400 VAC 1 BF RACK / 400 VAC This is a general manual describing a series of racks receiving servo amplifiers having output capability for driving AC brushless servo motors. This manual may be used in conjunction with appropriate and referenced drawings pertaining to the various specific models. Maintenance procedures should be attempted only by highly skilled technicians (EN 60 204.1 standard) using proper test equipment. The conformity with the standards and the "CE" approval are only valid if the items are installed according to the recommendations of the racks and amplifiers manuals. The user will be responsible for any non following of connection recommendations and drawings. Any contact with electrical parts, even after power down, may involve physical damage. Wait for 3 minutes after power down before handling the rack or the amplifiers (residual voltage). INFRANOR does not assume any responsibility for any physical or material damage due to improper handling or wrong descriptions of the ordered items. INFRANOR reserves the right to change any information contained in this manual without notice. Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty. This manual is a translation of the original document and does not commit INFRANOR's responsibility. The french manual is the only reference document. © INFRANOR, July 2003. All rights reserved Issue: 2.2 2 BF RACK / 400 VAC BF RACK / 400 VAC Contents CONTENTS............................................................................................................................................. 3 CHAPTER 1 – GENERAL....................................................................................................................... 5 1 - CONFORMITY WITH THE EUROPEAN STANDARDS: "CE" APPROVAL ................................... 5 1.1 - General description ................................................................................................................ 5 1.2 - Reference to the standards .................................................................................................... 6 1.3 - "CE" mark ............................................................................................................................... 6 2 - ORDERING CODE OF THE "BF/400" RACK ................................................................................. 7 3 - ORDERING CODE OF THE MAINS FILTER ................................................................................. 7 CHAPTER 2 - SPECIFICATIONS........................................................................................................... 8 1 - MAIN TECHNICAL DATA............................................................................................................... 8 2 - DIMENSIONS OF A 3 AXES BF RACK, 24 TE............................................................................... 9 3 - MAINS FILTER DIMENSIONS ..................................................................................................... 10 4 - DIMENSIONS OF THE EXTERNAL RESISTOR WITH PROTECTION HOUSING (DP, E).......... 10 CHAPTER 3 – CONNECTIONS ........................................................................................................... 12 1 - RACK BACKPANEL CONNECTION............................................................................................ 12 1.1 - Connection diagram ............................................................................................................. 12 1.2 - Configuration table ............................................................................................................... 12 2 - SETTING-UP DIAGRAMS OF THE BACK PANEL (X5 SWITCH, JUMPERS) ............................ 13 3 - SETTING-UP OF THE CONNECTION CONNECTORS .............................................................. 14 4 - XA1 AND XA2 SUPPLY CONNECTORS ..................................................................................... 14 5 - X MOT MOTOR CONNECTOR .................................................................................................... 15 6 - 400VAC THREE-PHASE MAINS OPERATION .......................................................................... 15 7 - MAINS FILTER OPTION .............................................................................................................. 18 8 - SPECIAL CONNECTION REQUIREMENTS ............................................................................... 20 APPENDIX ............................................................................................................................................ 21 Contents 3 BF RACK / 400 VAC ------------------------------------------------------- BLANK PAGE -------------------------------------------------------------- ------------------------------------------------------- BLANK PAGE -------------------------------------------------------------- 4 BF RACK / 400 VAC BF RACK / 400 VAC Chapter 1 – General 1 – CONFORMITY WITH THE EUROPEAN STANDARDS: "CE" APPROVAL 1.1 – General description The 400 V rack type of the "B" series is "BF/400". The "F" means "floating" power bus voltage, because it is not referenced to the chassis. This range is ALWAYS equipped for rear mounting. The motor outputs and the supply inputs are ALWAYS on a terminal bar. The logic inputs - outputs of the X5 rear connector allow the serial connection of the protection signals AMP. READY and POWER READY. All connections are ALWAYS made on the top of the rack (power supply, motors, logics). The "BF/400" rack is to be directly connected to the 400 VAC mains. A progressive loading system is integrated in order to limit the inrush current at power up. A current smoothing reactance coil can be used for improving the current harmonics. But this rack can, of course, also work with an insulation transformer. The whole SMT-BD1-400/15, 30, 45, 60 range is particularly well suited for the "BF/400" rack. The SMT-BD1/400/I amplifiers width is 24 TE. The power supply unit ALWAYS includes the auxiliary supply, the power supply and the braking system. It is mounted on a chassis fixed on the left rack flange. Its width is 12 TE. The braking system is equipped with a safety function indicating its correct operation. This function is called "D/R OK" (braking system OK): it controlls a relay that can be serially used with the "Σ POWER READY" signal of the X5 connector (pins 3 and 4) in order to interrupt the power contactor in case of incorrect operation. The power supply can be equipped with a 70 A or 90 A rectifier bridge. The braking system includes all options D2, Dp and E. Resistor Continuous resistance Peak power OPTION D2 33 Ω on rack flange 280 W 27 KW OPTION dp 33 Ω external 280 W 27 KW OPTION E 2 x 33 Ω = Req = 16,5 Ω 560 W 55 KW The "D2" option is factory mounted and wired on the left rack flange whereas the options "Dp" and "E" require external mounting and wiring. The braking resistor is under high voltage (800 V) and may become very hot. It is mandatory to mount it at a correctly cooled place or outside the cabinet. But, in any case, the resistor housing of D2, Dp and E must be mounted at least 30 cm away from any part that could burst into flame because of the heat radiated by the braking resistor. The "BF/400" rack answers the requirements of the EN 55011 standard regarding the electromagnetic compatibility, with optional input filter for the mains rejection. The common mode filter of the motor output as well as the mains filter of the auxiliary supply are integrated in the rack, as standard. The fan must always be mounted on the top of the rack. Chapter 1 – General description 5 BF RACK / 400 VAC 1.2 – Reference to the standards The SMT-BD1/400/I amplifiers mounted into the BF rack in 400 VAC, which is equipped with the mains filter F-400-70, have been approved for their conformity with the EMC standards: • • EN 55011, Group 1, Class A, regarding radioelectric disturbances CEI 801 - 2 - 3 - 4, regarding the immunity. The tests have been performed by the external laboratory of the SCHAFFNER company, which is approved for its competence regarding EMC. The results of the tests made according to the Low Voltage directive are referenced in the LCIE report n° 413777. Standard for the electrical equipments of industrial machines: EN 60204.1. 1.3 – "CE" mark The racks have been "CE" marked since 1995. 6 Chapter 1 – General description BF RACK / 400 VAC 2 – ORDERING CODE OF THE "BF/400" RACK BF-400 / - A x i s A x i s A x i s 1 2 3 - V 1 axis rack = V01 2 axes rack = V02 3 axes rack = V12 Axis 2 Axis 3 Power supply AXES LOCATION 2 2 spaces (24 TE) NOTE : Decreasing current ratings from left to right. The power supply requires 1 space (12 TE) Axis 1 BRAKING RESISTOR D2 33 Ω/280 W resistor mounted on the rack flange dp 33 Ω/280 W external resistor E 16,5 Ω/560 W external resistor 3 axes of 24 TE each A B 6 84 TE 462,80 481,80 4 60 TE 340,88 359,88 2 218,96 237,96 36 TE A 30 B Dimensions of the D2 braking resistor 45 90 45 ADC on the power bus 90 ADC on the power bus 3 – ORDERING CODE OF THE MAINS FILTER F-400 FILTER SIZING 70 Chapter 1 – General description 7 BF RACK / 400 VAC Chapter 2 – Specifications 1 – MAIN TECHNICAL DATA Rated AC input voltage 400 Vac three-phase +/- 15 % Maximum AC input voltage 480 Vac three-phase(including all tolerances) Minimum AC input voltage 340 Vac three-phase Rated auxiliary supply voltage 230 Vac single-phase +/- 10 % Minimum auxiliary supply voltage 100 Vac single-phase Maximum auxiliary supply voltage 260 Vac single-phase (including all tolerances) Maximum section of the supply connector 6 mm Maximum section of the motor connector 4 mm2 Rated output current on the DC bus 45 A for version 45 A 90 A for version 90 A Ouput current of the auxiliary supply 1A Triggering threshold of the braking system 785 Vdc +/- 10 V Minimum braking resistance (option E) 2 x 33 Ω separately controlled, that is Req = 16,5 Ω Possible rated braking power (option E) 560 W Peak braking power (max. 0,5 s) – option E 55 kW Maximum section of the braking resistor cables 2,5 mm2 Conformity with the standards - CE approval EMC standards: - immunity: CEI 801-2-3-4, - Conducted and radiated disturbances: EN 55011, group 1, class A Electrical standards for industrial machines: - EN 60204-1: Insulator 2500 Vdc - Leakage current > 3 mA (EMI filter) 2 The conformity with the standards and the "CE" approval are only valid if the items are installed according to the recommendations of the racks and amplifiers manuals. 8 Chapter 2 - Specifications BF RACK / 400 VAC 2 – DIMENSIONS OF A 3 AXES BF RACK, 24 TE 513mm (option D2) 483mm 266mm 80mm D2 90mm 190,5mm 355mm 462,8mm 36,7mm Ø 7 x 12 286mm NOTE: The heatsink does not modify the dimensions. Example 3 axes rack: Axes 1 to 3 = 24 TE. NOTE For other dimensions than 3 axes, see table of Chapter 1, part 2: "Ordering code of the BF/400 rack". Chapter 2 - Specifications 9 BF RACK / 400 VAC 3 – MAINS FILTER DIMENSIONS 60 229 1,5 36 73 84 95 LINE L1 L2 L3 40 7 88 218 5 L1 L2 L3 LOAD 4 – DIMENSIONS OF THE EXTERNAL RESISTOR WITH PROTECTION HOUSING (dp, E) A D BRAKING RESISTOR dp E 10 C 40 7 7 B POWER A B C D 280 W 560 W 290 290 278 278 83 145 57 52 Chapter 2 - Specifications BF RACK / 400 VAC DIMENSIONS OF THE REACTANCE CHOKES This table is mentioned for information. INFRANOR does not supply, as standard, theses reactances. REF. L400/25 L400/35 L400/80 I rated (A) 25 35 80 A (mm) 183 183 274 B (mm) 142 145 211 C (mm) 86 97 142 D (mm) 60 66 88 E (mm) 76 76 92 Mass (kg) 6,8 7,3 23 80 A and less SPECIFICATIONS - Min. Inductance: 0,4 mH - Non saturable for 3 I rated. Chapter 2 - Specifications 11 BF RACK / 400 VAC Chapter 3 – Connections 1 – RACK BACKPANEL CONNECTION 1.1 – Connection diagram The AMP. READY, POWER READY and Idyn signals can be serially or individually wired for all axes according to the configuration below. The ENABLE signal can also be wired individually or as a common signal to all axes on the front panel connector X4. GND +24V Switch on backpanel Log > 0 Log < 0 ENABLE +24V 0V 2 ∑ ENABLE 1 29 7 30 ∑ Idyn GND Axis 1 X5 Idyn 8 R1 +24V GND +24V GND N 1 O 2 P 3 E 4 F 5 G 6 H 7 Idyn N Bridge 4 ∑ POWER READY Last wired axis D 3 6 R2 ∑ AMP. READY 5 31 POWER READY B 32 AMP. READY A R3 B POWER READY AMP. READY A 8 The jumpers A, B, N are located on the backpanel - see section 2 -. symbolizes the closed contact of the BD1 amplifier relays. The POWER READY signal is only available on the rack backpanel connector X5. If the POWER READY signal is not used, make jumper JK on the amplifier in order to get the AMP. READY signal taking into account the power status. The POWER READY signal includes both power supply status and braking system operation (DR OK). 1.2 – Configuration table JUMPER/SWITCH A closed on last wired axis Switches G and H "ON" A closed on each axis Switches G and H "OFF" B closed on last wired axis Switches E and F "ON" B closed on each axis Switches E and F "OFF" N closed on last wired axis Switches O and P "ON" N closed on each axis Switches O and P "OFF" Switch D "ON" Switch D "OFF" ENABLE AMP. READY Idyn POWER READY and DR OK serial Independent serial Independent serial Independent Common to all axes Independent with X4 on each axis As standard, all these signals are serially wired: jumpers A, N and B are closed on the last wired axis and switches D, E, F, G, H, O and P are all ON. 12 Chapter 3 - Connections BF RACK / 400 VAC DEFINITION OF THE BACKPANEL X5 CONNECTOR PIN 1 2 3 and 4 5 and 6 7 and 8 FUNCTION ENABLE signal of all axes 0 Volt POWER READY signal of all axes AMP. READY signal of all axes Idyn signal of all axes REMARK Common ENABLE signal to all axes POWER READY relay of all serially connected axes AMP. READY relay of all serially connected axes OPTION (Idyn of all serially connected axes) The X5 connector allows to have: - the logic ENABLE signal common to all axes, - the POWER READY relay serially wired on all axes, - the AMP. READY relay serially wired on all axes, - the Idyn relay serially wired on all axes. SPECIFICATIONS : Umax : 50 V Imax = 100 mA Pnom = 5 W IMPORTANT On some INFRANOR amplifier types, the Idyn relay may have another function, particularly the control of the motor brake relay on the ranges BD1/m, BD1/h, BD1/p and BD1/s. In this case, the Idyn relay must be independent on the rack backpanel (switches O and P = OFF). 2 – SETTING-UP DIAGRAMS OF THE BACK PANEL (X5 SWITCH, JUMPERS) Rack front view 24 TE BACKPANEL 8 1 2 3 4 5 6 7 8 1 X5 D O P E F G H View from components side a b B A N 01644 Chapter 3 – Connections 13 BF RACK / 400 VAC 3 – SETTING-UP OF THE CONNECTION CONNECTORS XA1 XA2 X MOT X MOT 1 X5 Switch Power supply Axis 1 Axis 2 FRONT VIEW 4 – XA1 AND XA2 SUPPLY CONNECTORS The power supply connector includes the power supply inputs (XA1), the auxiliary supply and the connections for the braking resistor(s), according to the selected option (XA2). 400 VAC three-phase: 3 x 400 VAC three-phase supply max. section: 6 mm2 max. continuous current: 82 A XA1 1 2 3 L1 L2 L3 Earth: Ø5 screw XA2 1 2 3 4 5 Braking resistor option E 230 VAC auxiliary supply Braking resistor options dp and E NOTES Power cables must not run in the proximity of low potential cables. Option D2: the braking resistor is mounted and wired on the left rack flange, pins 3 and 4 of XA2 are free but unusable. Options dp and E: the braking resistor is mounted and wired outside the rack. 14 Chapter 3 - Connections BF RACK / 400 VAC 5 – X MOT MOTOR CONNECTOR The motor connection connector is particularly well suited for the electromagnetic compatibility and the motor cables shield connection over 360° to the chassis is easy to make by means of a clamping collar. The ground connection is made by a fastening lug according to the safety standards regarding the grounding. Motor cable Motor cable shield 360° shield connection collar Earth Ø 5 screw Motor screw connector U V W Support module having the chassis as mechanical reference potential 2 Maximum section: 4 mm . Maximum continuous current: 44 Arms. NOTE The conformity with the EMC standards requires the mandatory shielding of the motor cables, with a 360° connection at both ends. The motor cables must not run in the proximity of input command and resolver cables. 6 – 400VAC THREE-PHASE MAINS OPERATION To improve the current harmonics on 400 VAC mains operated items, a reactance sized to match the rack or amplifier current rating can be used. This choke is connected in series with the rack input.. Reactance choke ref.: L-400/25/35/80. The direct mains operation without reactance choke requires an appropriate supply cable section with a factor of 1,5 with regard to the rack rating. The power supply must ALWAYS be three-phase connected via a differential three-phase circuit breaker. EXAMPLE: Type Réfex XC40 + Unit Vigi 300 mA, ref. 20340 (by Merlin Gérin). The circuit breaker sizing is depending on the application or on the rack or amplifier ratings: 10 A = ref. 18134 ; 15 A = ref. 18135 ; 20 A = ref. 18136 ; 25 A = ref. 18137 ; 32 A = ref. 18138 ; 38 A = ref. 18139 (by Merlin Gérin). NOTE Fuses cannot be used on the line input because the blowing of one of the three fuses would reduce the lifetime of the whole equipment. A magnetothermal circuit breaker must be used instead of fuses if not using the recommended differential circuit breaker. The auxiliary supply must ALWAYS be connected to the 230 VAC single-phase mains. The connection to the 230 VAC single-phase mains must made via a phase + neutral circuit breaker: EXAMPLE: Type DPN, curve C, ref. 20743 or DPN N, curve D, ref. 19233 by Merlin Gérin. Chapter 3 – Connections 15 BF RACK / 400 VAC NOTES On the three-phase connection, for the power supply, or the single-phase connection, for the auxiliary supply, all supply must ABSOLUTELY be cut-off to ALL POLES The direct mains connection is more cost effective but it is still possible to use a 400 VAC / 400 VAC insulation transformer (connection similar to the connection diagram with a grounded screen transformer). EMC The motor output is equipped with a common mode choke and the auxiliary supply is also equipped with a mains filter. In order to conform with the EN 55011 standard, group 1, class A, the mains filter for the power is optional and must be mounted before the 400 VAC three-phase rack input and as close as possible to the rack in order to ensure equipotentiality. The BF/400 rack chassis MUST be GROUNDED in order to ensure the user's physical protection in case of mains isolation failure. INFRANOR will withdraw its warranty on any item that does not meet these requirements. 16 Chapter 3 - Connections BF RACK / 400 VAC CONNECTION DIAGRAM K K.1 L1 L2 L3 GND N 400 VAC 1 3 5 N . 1 Aux. relay N 24 V K1 (#) ( ) Power Aux. relay ON 2 Power ON Enable Amp. ready Disable 2 4 Aux. OFF 6 OPTION Reactance choke L400/25/35/80 Power relay +24V 2 Aux. relay Aux.relay Power relay Braking resistor Aux 3 XA2 1 2 3 4 Power relay Enable relay 0V L1 L2 L3 1 (*)POWER READY Aux. relay FILTER F400-70 XA1 Power OFF (*) POWER READY only available on the backpanel X5 connector. If the POWER READY is unused, make jumper JK on the amplifier in order to have the AMP.READY signal taking into account the power status. GND Log>0 Log<0 X5 X4 1 20 5 6 18 19 ! ENABLE GND U V W ! Rack chassis grounding MOTOR 4 cables + shield AMP. READY AMPLIFIER 3 4 POWER READY X1 RES 6 pair shielded cables (+thermal probe) (#) 3 A phase-neutral circuit breaker, curve C. . ( ) Mandatory differential circuit breaker. Chapter 3 – Connections 17 BF RACK / 400 VAC 7 – MAINS FILTER OPTION The mains filter is MANDATORY for the compliance with the CE approval. The curves below show the recordings of the conducted and radiated disturbances according to the EN 55011 standard, group 1, class A, with mains filter BF-400/I. - Mains rejection: curves 8 and 9. - Radiated electrical field: curve 10. MAINS FILTER CONNECTION The mains filter must be connected as close to the BF-400 rack as possible (max. 30 cm). A metallic braiding must connect the filter ground terminal to a fastening screw of the BF-400 rack in order to get the equipotentiality. It is recommended to use the cabinet housing for ensuring the equipotentiality. The current rating must correspond to the rack current rating, that is: - F-400/35 for 35 A - F-400/70 for 70 A. CURVE NR. 8 18 Chapter 3 - Connections BF RACK / 400 VAC CURVE NR. 9 CURVE NR. 10 Chapter 3 – Connections 19 BF RACK / 400 VAC 8 – SPECIAL CONNECTION REQUIREMENTS Wiring and ground connections must be very carefully made. CAUTION Low potential cables MUST NEVER run in the proximity of high potential cables. NC, amplifier, motor and machine housing must be grounded via connections as short as possible. Use the cabinet housing for ensuring the equipotentiality. Use rather braidings than wires, even thick ones. Keep the equipotentiality between NC/amplifier, machine housing and motor. The connectors must be metallic or metallized (according to the CEI 801 standard) and must allow "360°" shield connections. The reference potential is the earth (ground). The input command and the command cables MUST be shielded. The motor cable MUST be shielded and connected at both ends over 360°. Connect the shield to the motor or machine housing, as close to the motor as possible, by means of a metal flange after having removed the paint if the connector is not metallic. The sensor cable must be shielded. The correct sensor wiring is an absolutely necessary condition for the correct operation of the amplifier. If these recommendations are not answered, the described specifications will not be obtained. Further, the wiring will not comply with the EMC requirements and will commit the user's responsibility. The shield connections must be made as follows: The connector housing is metallic or plated and allows an "360" shield connection, according to the CEM - CEI 801 - 2 - 3 - 4 - 5 recommendations. DRAWING SHOWING THE CONNECTION BETWEEN METALLIZED HOUSING AND SHIELD U 20 V W Chapter 3 - Connections BF RACK / 400 VAC Appendix SHIELDING RECOMMENDATIONS RULE The shield must never be interrupted or corrupted over the whole cable length. Self-sticking copper ribbon if necessary, for increasing the shield diameter in order to get it correctly tightened under the clamp W V U Ground L1 L2 U V W N Motor connector for resolver and motor ; BF RACK The cable can be soldered on the shield because the connector box is metallic. This solution does not exactly meet the EMC requirements but it is acceptable. Motor connector box Metallic or metal plated plastic SUB-D pin package 360° shield ensured by the tightening clamp As short as possible Ground U V W X SMT.AS / M.AS X U VW The fastening screws must be tightened in order to ensure the shield continuity on the amplifier housing INFRANOR amplifier Earth BM 20 A SUB-D connectors NOTE When the 360° shield is made by means of a clamp, it is not necessary to additionally connect a cable on the appropriate connection pin of the SUB-D connector. Appendix 21