* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Option B

History of electric power transmission wikipedia , lookup

Current source wikipedia , lookup

Opto-isolator wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage optimisation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Induction motor wikipedia , lookup

Buck converter wikipedia , lookup

Mains electricity wikipedia , lookup

Alternating current wikipedia , lookup

Three-phase electric power wikipedia , lookup

Automation bias wikipedia , lookup

Rectiverter wikipedia , lookup

Distribution management system wikipedia , lookup

Transformer wikipedia , lookup

Transformer types wikipedia , lookup

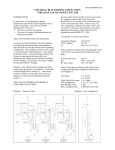

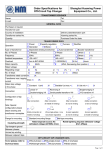

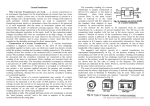

Doc # 1ZUA003101-AAA BIAS WINDING APPLICATION FOR LOAD TAP CHANGER TYPE-USB INTRODUCTION: APPLICATION: The number of transformer tap connections can be reduced by incorporating an additional isolated tap section. This isolated tap section, better known as the bias or tickler winding, adds to, or subtracts from, the effective turns of the regulating winding. The TypeUSB load tap changer has been designed to take advantage of this arrangement and requires only nine tap sections for 33 positions. Additionally, this aids the manufacturing process as fewer transformer leads have to be handled for the high current capability of the Type-USB load tap changer (1,800 amps). The most convenient application of the bias winding is when the tap sections of the RV winding are approximately equal with more than one turn per section. The ideal application is when all RV tap sections are exactly equal (i.e. same number of turns) with an even number of turns. This condition would result in ideal 5/8% steps. With proper design consideration, a non-ideal division can be used if 0.5% deviations (IEEE C57.12.00) from the desired values can be maintained. For non-ideal case, refer to document 1ZUA003101-AAB. THEORY OF OPERATION: For an example of an ideal OLTC application: One can see from Diagram 1, that the bias winding is an isolated tap section having one half the number of turns and volts as in the tap section of the regulating winding (RV). As the tap changer operates, the diverter is connected to the same tap for two operations, one with the bias winding, and one without the bias winding. This produces two output voltages for each tap of the RV winding. Trxfmr Rating: OLTC Applied: V2: Step Voltage: RV: Diagram 1 shows that the bias winding is not in the circuit when the diverter is on position “v” with load current through selector contact “b” . Bias insertion would occur when the diverter moves to position “x” and current being drawn through contact “a”. Diagram 1: Sequence Chart 115/13.8kV 13.8 kV (V2 x 3) 8 kV = 13.8/3 50 v = V2 x 5/8% 800 v = 50 v/step x 16 step For the ideal conditions, eight effective sections (nine actual) having two turns each would be used for the regulating winding plus a one turn bias winding. Since the 800v RV winding is divided into 8 two turn tap sections, the volts/turn will be 50V/t. Therefore: N2: 160 turns = 8 kV / 50 volts/turns LOCATION: There are various locations for insertion of the bias winding. Diagram 2 shows two convenient arrangements which have been successfully used by transformer manufactures for many years. Option A shows a single bias turn wound adjacent to turns of the regulating winding such that only the bias winding ends after one turn and the rest of the winding continues for a second turn. This can only easily be used when two turn tap sections are applied. Keep in mind, the bias winding must be fully insulated from the tap sections. Option B applies an equal number of bias turns at the top and bottom of the tap section winding which are loaded in parallel to attain balanced short circuit forces. This arrangement can be used for designs of more than two turns per tap section. GLOSSARY: LTC - Load Tap Changer Tap - A connection to a sectionalized winding Tap Section – A group of one or more turns between taps. Option A Diagram 2 – Possible locations of bias winding Tap Voltage – Volts per turn times turns per tap section. Step Voltage – The change in the output voltage with each LTC operation. Bias Winding – An isolated tap section used to produce ½ size steps in voltage. Regulating winding (RV) – The total collection of all tap sections. Effective Turns – Vector sum of turns carrying load current at a given moment. Effective Sections – Max. number of tap sections that could be loaded at one time. V2 – Line to ground voltage of transformer secondary. Option B Diagram 3 – Single Phase Diagram Notes: