* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download IGT Secure Count Optics and Controller Board for Randy

Distributed control system wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Control theory wikipedia , lookup

Printed circuit board wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Buck converter wikipedia , lookup

Stepper motor wikipedia , lookup

Fault tolerance wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Control system wikipedia , lookup

Variable-frequency drive wikipedia , lookup

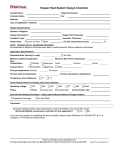

IGT Secure Count Optics and Controller Board We all know what it is. What we want to do is bench test the sucker without having a complete machine on our workbench just to run the hopper. We can build a test fixture for an assembly like this a lot easier than you think. At present my “Test Fixture” is nothing more than a wired connector that plugs into the hopper and a Lab Grade (Adjustable Voltage, Adjustable Current Limiting) power supply, and two resistors. You can build a nicer looking box and use switches for inputs instead of jumping wires, but I was in a hurry to get this one operational. I went “Cheap and Easy”. Worth discussing are the Coin-Out optics assembly and the Hopper Control Board, itself. We will cover how these work first, then go into specifics on the test fixture. The Secure Count Coin Out Optics Assembly (IGT p/n 76922504) This assembly differs from the Non-Secure optics in that the secure type has 6 leads. There are two sets of optics inside the assembly. Inside the assembly we find the expected two towers. The most interesting feature physically is that each tower has both an Infrared LED and a Phototransistor. When assembled the LED on the “Near Side” (nearest the connector side of the board) shines on the phototransistor on the “Far Side” of the board (farthest away from the connector side of the board), and vice-versa. (Reference, picture of Phototransistor) The phototransistor is a three-terminal type. One side is ground, the opposite side goes to +5 V, and the center terminal is the output. When the light from the LED shines on the phototransistor, the output goes low. Just for a note: I could not determine if the phototransistor assembly was just a resistor pull-up design or actually the output of a logic circuit. I attempted to disassemble the phototransistor to no result. Not finding anything big enough to be a logic chip, I assumed it was a resistor. An ohmmeter measures about 1,800,000 Ohms from output to the +5V side. That seems rather large for a pull-up resistor. There is a 10K pull-up resistor on the Hopper Control board, so whatever is between the Collector and the +5V side is mute. (Reference, picture of the IR LED) The LED is a common Infrared Led from all I could tell. Both are rectangular box shape as can be seem in the figures included. A bubble-lens is on each assembly. There is a 24 Ohms current limiting resistor on the Hopper Control board that is in series with the this LED. Both towers solder to a small board. There are no other components in the assembly other than what is inside the towers. The pictures below show the tower with the components, without the components from the front and from the bottom. (Reference, three pictures of the Towers) (Reference, schematic of the Optics assembly) The schematic of the assembly would look something like that shown below. The Anode of the LEDs and the top of the pull-up resistors are connected to +5 Volts. The Emitters of the phototransistors are connected to ground. The Cathodes of the LEDs and the Collectors of the phototransistors are individually connected to the other four pins. The towers are pulsed. About every 160 microseconds each LED is pulsed for about 30 microseconds, with an alternating space between them of about 25 or 75 microseconds. See the timing diagram below. (Reference, timing diagram) This signal is found coming off of both phototransistors. It is very likely the two are staggered in timing. I didn’t think to check it at the time I was looking at them. The Hopper Control Board (IGT p/n 76922504) (Reference, PDF file of the control board) At the heart of the Hopper Control Board is our old friend a PIC16. Specifically a PIC16C54. This is a fairly simple microcontroller, as microcontrollers go. A 10 MHz ceramic resonator drives the clock for the PIC16. R2, CR1, and C1 provide a “Power-up Reset” to the PIC16 on power up. The Status LED is a direct drive off of the PIC16. No other circuitry than a current limiting resistor (R1) is required for this circuit. On more familiar designs the Hopper Probe makes a contact, through the coins, to the probe itself. In this design, another probe supplies the ground, and can be pulsed low (through Q5 to sense the hopper level through feedback from one of the probes. We have two sensing probes, but only one feeds back to the PIC16. Both probes feed out to the game. Our Coin-Out Pulse comes from one of the PIC16 outputs, through Q6. When a coin is sensed leaving the hopper, and no errors were encountered, this Coin-Out line is pulsed low. A jumper on the board (J3) is used to indicate when the hopper is used in a “Side Exit” style game, as opposed to an escalator type. This allows the game to confirm that the hopper is set up for the proper style. This jumper also feeds back to the game. We have three inputs to the Hopper Control Board (from the game). One is Active Low (Hopper Brake, through U2 and Q4), and the other two require a current limited Active High input (Hopper Direction, through U4; and Hopper Safety, through U7). The Brake may be activated from the game interface or by the PIC16, through Q7. A Switching Regulator Power Supply (U6, L7, CR2, and C14) is on the Hopper Control Board to convert the +25V to +5V to drive the logic circuits. Hopper motor control is accomplished by a Bridge Motor Driver (U3) that controls motor direction. Power to the Bridge Motor Driver goes through Q1 and Q2 to allow the PIC 16 to interrupt power to the motor driver if a runaway is detected. Current through the motor is sensed by a voltage drop across R36. U5 senses two levels of motor current, “Motor On” and “Overcurrent”. Building a test fixture for the Secure Count Hopper The interface required to manipulate the Hopper is a simple design. Power required is +25 Volts (at about 1 Amp, maximum during Motor Stall condition) and +13V (at 13 mA to drive the LED side of U2). Inputs may all be open collector drivers or even simple switches. The Brake input needs no pull-up resistor, but Hopper Direction and Hopper Safety do require a pull-up resistor of 1K ohms to +13V. To move the hopper forward Safety needs to be high (switch off), and Brake and Direction need to be low (switch to ground). To move the hopper reverse Safety needs to be high (switch off), and Brake needs to be low and Direction need to be high (switch off). Hopper off is accomplished by bringing Safety Low, or Brake high. Signals coming from the hopper assembly to the control board are: “Hopper Full Probe” (from the top probe on the bowl, orange/green wire); “Hopper 2/3 level” (from the middle probe, orange/blue wire); and “Hopper 1/3 level” (the bottom probe, orange / violet wire). Signals leaving the Hopper Control Board going to the game are: (“Hopper Probe Output”; “Coin Out”; and “Coin Tolerance” (the position of the jumper J3 talked about earlier). All of these may feed TTL level signals. The Hopper Probe output may come from either of two places, depending on the position of jumper J2. With Jumper J2 across pins 1 and 2 the “Hopper Probe Output” comes from Q5. This is the normal position for using the “1/3”, or “2/3” probes on the hopper. In this position the PIC16 controls the “Hopper Full” function. With J2 between pins 2 and 3 the top probe “Hopper Full” actually feeds the “Hopper Probe Output” and the PIC16 is not involved with the Hopper Full function. With all that in mind our test fixture needs to emulate three signals that would be coming from the game: “Hopper Brake”, “Hopper Direction”, and “Hopper Safety”. All these may be simple switch inputs. Clean (debounced) signals would do no harm. The test fixture also has to handle three outputs from the Control Board: “Hopper Probe Output”, “Hopper Motion”, and “Brake”. All are open collector type outputs. Our basic switch input may be as shown in the Basic Input drawing. (Reference, Basic Input) Our basic LED drive to sense the board or hopper outputs may be as simple as shown in the Basic Output drawing. (Reference, Basic Output) If we create this test fixture as four basic inputs and four basic outputs in a general purpose box, we will find that this test fixture will be usable for many other boards and assemblies. Shown as is it is dedicated to IGT Hopper testing and will work for Secure or regular hoppers. (Reference, Hopper Test Fixture)