* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download The behaviour of full-scale steel-framed buildings subjected to

Survey

Document related concepts

Transcript

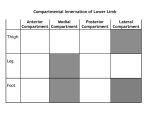

Paper: Bailey et a1 Paper The behaviour of full-scale steel-framed buildings subjected to compartment fires C. G . Bailey, BEng, PhD Building Research Establishment T. Lennon, BEng Building Research Establishment D. B. Moore, BTech, PhD, CEng, MIStructE Building Research Establishment Synopsis During 1995 and 1996, a major fire test programme was conducted on a full-scaleeight-storey steel-jiramedbuilding. The principle aim of these tests was to investigate the actual behaviour of a steel-jiramed buildingsubjected to aseries of compartment (1ocalised)fires. This paper presents the results from two of these tests, which were conducted by the Building Research Establishment. The results from the tests showed that existingfire Codes are not addressing the correct building behaviour during afire and, as a consequence, are extremely conservative. In addition, the fire tests on the full-scale frame showed that the actual global and local structural behaviour of buildings is different,and typically far better; than that shownin standard small-scale fire tests. The paper discusses in detail the behaviour of the building observed during thefire tests,and preliminary conclusions are presented. Introduction When heated, steel will lose both strength and stiffness. For life safety and property protection, the use of steel within buildings will obviously need to be designed to withstand the effects of a fire. This design must ensure no additional threat, caused by possible collapse of the steel structure, to either escaping occupants or fire fighters. In addition, no disproportionate damage should occur to the building during a fire. The level of fire resistance that a structure requires is specified in terms of time inthe Building Regulations'. It isdependent on the function and height of the building and, in some cases, whether sprinklers are used. In addition, maximum fire compartment sizes are specified, where thecompartment boundaries are designed to contain the fire. In multistorey buildingsthis will typicallycreate an areaof structure that is being heated by the fire, withthe structure surrounding this area remaining much cooler and thus retaining its strength and stiffness. The most common and traditional design method of ensuring strength and stability to steel-framed buildings during a fireis to cover all exposed steel areas with a protective material. Typical types of protection material consist of boards, sprays, and intumescent paints, with the choice of material depending on cost, appearance, and durability. Specification of material thickness for a known fire resistance, time and steel section size can be obtained from individual manufacturers or from (what is commonlytermed) the 'Yellow Book''. The required thickness is based on the principle of ensuring that the steel remains below 550°C for thespecified fire resistance period. This assumes that steel members fully stressed in accordance with BS 44933 or BS 5950 Part 1' will lose their design safety margin when they reach a temperature of approximately 550°C. Although, the philosophy of specifying protection thickness is adequate, it is extremely conservative. This is result a of the assumption that the member is uniformly heated, together with a disregard for both actual applied load levels during the fire and true material behaviour at elevated temperatures. To address this issue, research was conducted into the actual behaviour of isolated bare steel beams and columns, resulting in the first ever fire design Code, BS 5950: Part S".This treats the occurrence of fire asan accidental limit state, with its own associated load and material partial safety factors. Similar principles were adopted in the development of EC3: Part 1.26 (which covers steel structures)and E C 4 Part 1.2' (which covers composite structures).Although similar, the Eurocodes are more comprehensiveand cover a much wider range of structural configurations. The Structural Engineer Volume 77/NO 8 20 April 1999 The development of the design Codes provides a more solid scientific foundation for the provision of fire resistance to steel-framed structures. However, the design Codes were mainly developed from standard fire tests on isolated columns and beams. In these tests, columns are 3.0m high and beams are 4.5m long, and the failure criteria are governed largelyby the size of the furnace. There is general agreementasthat standard tests ignore significant structural behaviour by disregarding the interaction between members. This was shown in 1990 when a fire developed in a partly completed 14-storey office block on the Broadgate development in London'". secLarge tions of the steel frame were totally exposed at the time of the fire. Investigation following the fire allowed a back-analysis of the structure to BS 5950: Part 8. This highlighted that the Codes, although conservative, were not addressing the true behaviour, since thebuilding was notacting as a seriesof individual members. The nature of a localised fire, at Broadgate, caused a zone of heated structure to expand against the surrounding cold structure. Owing to the relative greater strength and stiffness of the surrounding cold structure, additional axial forces were induced into the heated structural zone. Considering the global structural behaviour, this caused larger displacements in the horizontal and vertical members owing tothe P6 effect. In addition, local buckling occurred in the proximity of the connections, within the fire-affected zone. However, no signs of collapse were Fig I . Eight-storey steel-jramed test building 15 Paper: Bailey et al 9 9000 9000 2 9000 2 9000 6000 @-I9000 @f. 6000 Indicatestestsconductedby I,_ BRE Indicates tests conducted byBritish Steel Fig 2. Plan showing locatiorl ofjire tests evident. This indicates that there was a redistribution of load away from the fire-affected areas, witha large inherent reserveof strength within the structure that is not considered by the present design Codes. The main conclusion from the Broadgate fire was the obvious lack of engineering knowledge about the behaviour of the whole structure when subjected to a fire. Therefore, although there is confidence that insulating exposed steel or using design Codes ;c conservative, the factor of safety is unknown. If, at present, this factor of S :‘’?ty, whenapplied to overall collapse, is unrealistically high, it may be reduced whilst maintaining adequate levels of safety. The saving in cost could then be used to install additional active fire safety measures such as sprinklers. This will result in an overall safer environment againstfire, which can be created more economically compared with using present design methods. To achieve this, we must fully understand the actual overall structural behaviour of the buildingin a fire. Realistically, this knowledge can be obtained only by conducting fire tests on a full-scale building. The construction of the eight-storey steel-framed test-building” by the Building Research Establishment (BRE) at its Cardington Laboratory provided a unique opportunity to conduct thesetests. The test building design the underlying philosophy was to obtaina structure thatused the minimum amount of material, was simple to manufacture, and at all stagesof construction and erection reflected normal building practice, rather than specialist research procedures. The imposed load was achieved using sandbags, + each weighing 1 1 kN. This resulted in an overall applied load (dead imposed) of 5.48kN/m2/floor. The fire tests A European collaborative programme of firetests was undertaken on the test structure. The programme was coordinated jointly by BRE and British & Steel Steel. Financialsupportwasprovided by theEuropeanCoal Community and the Department of the Environment, Transport & the in the programme,i.e. the Steel Regions. Other organisations were involved Construction Institute, TNO Building & Construction Research, Centre Technique Industrial de la Construction Metallique. and the University of Sheffield. In addition to the structural experimental programme, a large risk and hazard assessment study dealing with the development of the natural fire safety concept’’for steel-framed buildings is currently underway. A total of six major fire tests”, which were designed to be complementary, were conducted: fourtests by British Steel and twoby BRE. These are summarised in Table2, with the locationof the tests (on plan) shownin Fig 2. The aims of the tests were to: The steel-framed test-building was designed and constructedto resemble a typical modern city-centre eight-storey office development (Fig l). On plan, the building covers an areaof 2 1m X 45m (Fig 2), with an overall height of - observe, under test conditions, the behaviour of the complete building 33m. There are five equally spaced bays along the length of the building. when subjected to localised fires (it was important to consider localised Across the width there are three bays spaced 6m, 9m and 6m. Placed cenfires owing to the regulatory requirement of separating multistorey trally on the footprint of the building is a 9mx 2.5m lift core with two 4.5 buildings into fire compartments) x 4.5m stairwells placed at each end. The sizes of the main steel members - damage the structure in an attempt to find the limit of its inherent used in the frame are shown in Table 1. The structure was designed as a strength in a fire, which will enable the present design factor of safety braced frame with lateral restraint provided by cross-bracing around the to be quantified three vertical access shafts.The beams were designed as simply supported, acting compositely (via shear studs) with the supported floorslab. The composite floorslab was 130mm deep and consisted of a steel trapezoidal deck, TABLE 2 - Summary cfthr,fire tests with lightweight concrete and anticrack mesh. Throughout the structural Organisation Floor Location Test conducting area (tloor Description No. TABLE l -Main steel sizes used in the test frunze the test level) (m’) Location Steel section size 1 24 One level beam7British St 305 x 165 x 40 UB (Grade S275) 9.0m secondary beam 2 Slice across the building British53Steel level 4 610 x 229 x 101 UB (Grade S 2 7 3 356 x 17 l x 5 l UB (Grade S355) 3 4 9.0m perimeter beam Upper internal columns 254 356 x 17 1 x 5 1 UB (Grade S 3 5 3 S Lower internal columns 305 x 305 x 137 UC (Grade S 3 5 3 9.0m primary beam 6.0m primary beam 16 x 254 x 89 UC (Grade S 3 5 3 6 I 1 I BRE BritishSteel I ~ 76 Corner compartment British Steel level 2 Corner compartment BRE S4 level 3 Large compartment Large compartment with office furniture The Structural Engineer I 1 340 136 Volume 77/No 8 I 1 level 3 level 2 20 April 1999 Paper: Bailey et a1 - obtain quality test data to validate,or develop further, computer models which will allow different structural andfire scenarios to be investigated, together with different sizeof fire compartment - develop design guidance based on actual structural behaviour 1200 , 1 Removal of : : first plane 4, i Presented in this paper is adescription of the two compartmenttests carried out by BRE, with preliminary conclusions. -Maximum BRE test 1 (corner compartment) A 9.0m x 6.0m compartment was constructedin the corner of the building (Fig 3), between the second and third floors. The internal compartment walls were constructed using steel stud partitions with fire-resistant board and a deflection allowance of 1Smm. These were placed centrally on gridline E and slightly offset from gridline 3 (Fig 3). A full-height blockwork wall on gridline F and a 1 .Om-high dado wall and double glazing on gridline 4 completed the compartment. Allsteel beams and beam-to-beam connectionswere left exposed,togetherwiththeundersideofthesteel 0 20 40 60 80 100 120 160140 trapezoidal deck. All columns were fire protected up to the undersideof the Time (mins) floorslab. This was required to ensure that the compartment fire caused only localised damage, which will allow the rest of the building to be used Fig 4. Maximum and uveruge utmosphere temperutures in corner after the fire. This is an extremely important factor from the insurer's point compartment fire test of view. A previous test" conducted by British Steel, where parts of the columns were unprotected, caused disproportionate damage to the structure, by the columns reducing in lengthby 200mm. The compartment was totally enclosed, with all windows and doors artito closed. No additional ventilation was provided and no attempt made ficially seal the compartment. In addition to investigating the exposed steel frame and composite floor, the behaviour of the glazing system on the development of the fire was also of interest. The glazing comprised a 9mwide x 3m-high, 12-pane aluminium grid. Each pane consisted of 6: 12:6 double-glazed sealed units 1.5m X 1.5m. To achieve the temperatures required to test the structure, the fire was designed on the basis of the glass cracking in the early stages of fire development and thus providing the maximum ventilation possible. The behaviour of the test showed that this assumption was incorrect, orat best an over-simplification. A total of 12 timber cribs were used to give a fire load of 40kg/m2. This represents the 90% fractile value for amodern office buiIdingl4. This means that 90% of all the office buildings surveyed had a fire load (total combustible material) less than 40kg/m2.The compartment area, together with 0 20 40 60 80 100 120 140 1 160 Time (mins) One metre high dado wall -and glazing to underside of floor above Q Fig 5. Muximum vertical displucement in corner compartmentfire test 9000 0 rl 5mm deflection allowance 5mm deflection allowance Section A - A Section B - B Fig 3. Fire compartment layout of BRE corner test The Structural Engineer Volume 77INo 8 20 April 1999 the surrounding structure in the proximityof the compartment, was extensively instrumented. This included thermocouples, displacement transducers, clinometers, and strain gauges, together with a laser system to measure thermal curvature of the full-height blockwork wall on gridlineF. After ignition the developmentof the fire was influenced by the lack of oxygen within the compartment, owing to the glazing remaining intact. Fig 4 shows the maximum and average recorded atmosphere temperature within the compartment. It can be seen that, after an initial temperature rise, the fire died down and continued to smoulder. This continued until the fire brigade intervened to vent the compartment by removal of a single paneof glazing, at 56 min into thetest. This resulted ina small increase in temperature, followed by a decrease. Flashover did not occur until a second pane, at a lower level, was removed(at 66 min). This initiateda sharp rise in temperature that continued as the fire spread throughout the compartment (Fig 4). The maximum recorded atmosphere temperature in the centre of the compartment was 105 1°C after 102 min. The maximum steel temperature of 903°C was recorded after1 14 min.To put this temperature into context, the presentfire design Codes suggest that the beam will 'fail' at 680°C. The displacement at the centre of the compartment reached a maximum of 269mm (Fig 5). Measurements taken the day after thetest showed that the slab had recovered toa residual displacement of I60mm. The unprotected edge beam (gridline4)was observed during thetest to be completely engulfed infire (Fig 6). However, the beam reached a maximum temperature of only 680"C, with a corresponding maximum displacement of 52mm. This displacement was very small and attributed to the windposts above thefire compartment that were included in thetest building. These windposts, although not incorporated directly into the design of the frame, acted in tension, providing considerable support to the weakening edge beam. The unprotected steel beams above the compartment walls on gridlines 17 Paper: Bailey et a1 Fig 6. Developingjre in corner compartment test Fig 8. Distortionally buckled beam (compartment has been removed) 9000 Double glazing (middle 113 left open) $ 1 Fig 7. Stud partition compartment wall following thejre E and 3 had nominal vertical displacement, resulting in the stud partition walls retaining their integrity during the fire. Fig 7 shows the stud partition intact following the fire. The beam ongridline 3 buckled distortionally during the test (Fig 8). This was attributed to thebeam being heated on one side, together with restraint preventing thermal expansion, provided by the surrounding structure (including the stair wellkorearea). Although the beam on gridline E was also heated from one side only, it had nominal restraint to thermal expansion and therefore did not buckle. Overall, the damage to the structure was extremely localised, which will allow remedial works to be carried out quickly and with little disruption to the rest of the building. Allconnections remained intact during both the heating and cooling phases of the fire. Although the columns within the compartment were protected, strain gauges indicated that additional moments were induced into the columns. The values of these moments were in the range of 20-30% of the ultimate moment capacity of the columns. The structural behaviour involved in developing this increase in moment is not yetfully understood. One possible explanation is that the columns, owing to their location, had a thermal 18 9000 0 * W I 15mm deflection allowance I1 Section A -A Fig 9. Fire compartment layout ofBRE large compartment fire test gradient through their cross-section. Restraint to this thermal gradient from the continuation of the column aboveand below the fire compartment could, in part, account for these induced moments. Additionally, the thermal expansion of the adjacent heated beams could have laterally displaced the columns, thus inducing restraining moments. This lateral movement would have also increased the column moment due to the P-6 effect. This presents some feasible explanations of the possible structural behaviour that may have resulted inthe high induced column moments measured during the test. Further work, involving computer simulations, is under way to try to identify the predominant cause of these additional column moments. The Structural Engineer Volume 77/NO 8 20 April 1999 Paper: Bailey et al BRE test 2 (large compartment test) A compartment was constructed between the second and third floors, extending over the full width of the building, between gridline A and 0.5m from gridline C (Fig 9). The total floor area of the compartment was 340m2. The same fire load as the previous test (40kg/m2) was placed in the compartment in the form of 42 wooden cribs. The compartment was formed by constructing a fire-resistant stud partition wall across the width of the building, and also around the vertical access shafts. Double glazing was installed on two sides of the building on gridlines 1 and 4. Unlike the previous test, it was decided to leave the middle third of the glazing open on both sides of the building. This was to allowsufficient ventilation for the fire to develOP. All steel beams, including edge beams, were left unprotected. Beam-tobeam connections were also exposed, together with the underside of thesteel trapezoidal deck of the composite floor. The columns were once again protected up to the underside of the floor, to limit the structural damage to the compartment area. In a manner similar to the previous test the ventilation conditions governed the development and severity of the fire. Rapidignition resulted in the windows breakingduring the early part ofthe test. This resulted in a fire scenario where the maximum temperature reached wasfairly low, butthe duration at which the maximum temperature occurred was much longer (Fig 10). This is fairly a severe scenario forthe behaviour of the composite floor, due to the heat transfer through the concrete to the mesh reinforcement.This will reduce the strength of the reinforcement, which is the main component of resistance in these types of floor. Obviously, a fire with higher temperatures which remains constant for a long duration will be even more severe. The 800. fire produced a maximum atmosphere temperature of 763°C and a maximum steel temperature of 691 This "C.resulted in a maximum displacement of 557mm, which was measured halfway between gridlines 2 to 3 and B to C. This recovered to a residual displacement of 48 1mm, once the structure had cooled. Fig 1 1 shows the deformed structure in the latter stages of the fire. No signs of possible collapse are evident,and overall the structure performed very well. However, there was some interesting localised behaviour that merits further discussion. Most internal beams showed signs of local buckling in the lower flange, and part of the web, in the proximity of the connections (Fig 12). It wasfelt that this was caused by the restraint to thermal Fig 12. Typical localbuckling of beams in the proximity ojthe connections 700 a 600 Y F /-. 500 Shear capacity of connection maintained by unfractured side of plate a, 400 L 2 g 300 U) z 200 Tensile force induced during cooling 100 0 -0 20 40 60 80 l00 Time (mins) l20 140 1fio \ Typical fraiure in end-plate occuring during cooling Fig IO. Maximum and average atmosphere temperaturesin large comart mentjre test Fig 13. Typical fractureof endplate during cooling Fig 11. Large compartment test withdevelopedjre Fig 14. Damage to stud partition compartment wall following thejire TheStructural Engineer Volume 77/No 8 20 April 1999 19 Paper: Bailey et a1 f -F 1- Tension zone A Fig 15. Possible structuralmechanism in the composite floor (tensile membrane action) we reached the limit of the inherent strength of the frame, which was one of the major aims. Is it possible that the temperatures could have reached higher values?This is a question that needs to be answered by possible computer modelling.. Undoubtedly, the major contribution to the survival ofthe frame was the composite floor. This performed extremely well during all the tests, reinforcing the results from previous small-scale tests, which have shown that this type of floor has a good inherent fire resistance. During each test, as the beams increased in temperature and lost a large proportion of their loadcarrying capacity, the composite slab supported the applied load over the fire compartment area. In the first instance this was achieved by utilising the slab’s full moment capacity, as the supporting steel beams lost their strength. As the temperatures continued to rise and the supporting beams had nominal strength, the slab utilised its tensile membrane action through its mesh reinforcement. In the case where there is no horizontal restraint (i.e.slab at an edge of a building), a compressive membrane ring will form around the area of slab which is in tensile membrane action, as shown in Fig 15. Research work has begun to look at the contribution of tensile membrane action of the slabl6. It is hoped that this work will allow a fuller understanding of the mechanism and define the span (orsize of fire compartment) limits. In addition to investigating tensile membrane action, detailed computer models are being developedlvalidated. Fig 16 shows the prediction of the BRE corner compartment fire test, using a finiteelement computer model. Full comparisons between the model and test results have been presented in detail elsewhere”.Once the models have beenfully developed, different fire and structural scenarios can be investigated, which will enable design guides to be produced. Conclusions 0 Fig 16. Computer simulation(at maximum temperature) of the cornerfire test expansion and the negativemoment caused by the rotational restraint from the surthe connection. The restraint to thermal expansion was provided by rounding cold structure, together with differential heating through the compartment. The connections also showed signs of being subjected to high tensile forces. In the partial depth endplates the plate had fractured down one side (Fig 13) and, in one instance, the web had fractured. In the finplates (beam-to-beam connections) the bolts had sheared.The high tensile forces were induced during the cooling phase of the fire.This was caused by the steel beam, which has restraint against thermal expansion, cooling down from a plastic state. This behaviour has also been shown analytically and presented in detail elsewhere”. The stud partition wall parallel to gridline C had 15mm deflection allowance. The deflection ofthe slab was greater thanthis value and caused integrity failure of the compartment wall (Fig 14). In a fire failure of the compartment walls must be avoided and therefore the wall must be designed to accommodate the deflection ofthe structure or placed on gridlines (under beam positions) wherethe deflection will be less, as shown from the previous test. Similar to the previous test, the strain gauges on the protected columns indicated high induced moments during the test. As explained previously, the exact structural behaviour thatcauses these column moments is not yet fully understood. Further work is currently being conductedto investigate the behaviour of the tested protected columns. From the observations of the two tests presented in this paper, the following conclusions are drawn. ( I ) No collapse was evident, even though the unprotected beams reached temperatures over 900°C (temperatures over 1100°C were reached in the British Steel tests). (2) Existing fire design Codes are too conservative, predicting structural collapse at 680°C. (3) Only localised damage occurred, provided thatcolumns were protected over their full length. (4) Non-loadbearing compartment walls placed on the gridlines (i.e. under steel beams) performed well. ( 5 ) Non-loadbearing walls placed off the gridlines showed signs of integrity failure owingto the deflection of the structure. Walls will have to be spec ified with an adequate deflection allowanceor placed on gridlines. (6) The behaviour of the structure was differentand better than that shown in standard fire tests. (7) Local buckling typically occurred in the heated steel beams in the proximity of the connections. Therefore, conservatively, the connections should be assumed to be pinned in afire design. (8) The behaviour of theconnections during cooling needs to be addressed. This may result in the need to specify more ductile connections to ensure shear capacity following a fire. (9) Thecomposite slab was extremely beneficial to the survivalof the frame. It was felt that this was due to the tensile membrane capacity of the slab, which requires further investigation. It must be emphasised that the above conclusions apply only to buildings of the same form as the test building.Computer models are being developed to investigate different structural layouts, member sizes, compartment sizes, etc., together with different fire scenarios. Once this investigation is complete, comprehensive design guidancecan be produced. It is envisaged that most, if not all,steel beams could be left unprotected. The saving from not using passive fire resistance in terms of material c and time required to fidapply the protection could be used to provide active fire measures (such as sprinklers). This will inevitably create overall safer buildings. Acknowledgements Discussion and utilisation of the test results These two tests, together withthe four British Steel tests, have shown comprehensively thatthe existing design Codes are conservativeby calculating structural collapse when the beam steel temperature reaches 680°C. The maximum steel temperature in the BRE tests was 903”C, and in the British Steel tests” the maximum steel temperature was above 1100°C. There was no sign of collapse in any ofthe tests. This raises the question of whether 20 Financial support for the work presented in this paper was provided by the Department ofthe Environment, Transport& the Regions. This is gratefully acknowledged. References 1. TheBuildingRegulations (a) Approved Document B, Fire Safety, Department of the Environment and the Welsh Office, HMSO, 1991; The Structural EngineerVolume 77/No 8 20 April 1999 Paper: Bailey et al 2. 3. 4. 5. 6. 7. 8. 9. IO. 11. 12. 13. 14. 15. 16. 17. (b) The Building Standards (Scotland) Regulations, Scottish Office, HMSO, 1990; (c) TheBuildingRegulations(NorthernIreland), Department of the Environment, HMSO, I990 Fire protection for structural steel in buildings (2nd ed., revised), Association of Specialist Fire Protection, Ascot, Steel Construction Institute, 1992 London,British BS 449 Theuse of structuralsteelinbuilding, Standards Institution, 1969 1: Code ofprucBS 5950 Structural use of steelwork in building: Part rice f o r design in simple and continuous construction: rolled hot sections, London, British Standards Institution, 1990 BS 5950Structural use ofsteelworkin building: Part8: Code ofpracrice for fire resistant design, London, British Standards Institution, I990 Eurocode 3 Design uf steelstructures:Part1.2:Generalrules, ENV1993-1 -2, European Committee for Structuralfiredesign, Standardisation, 1995 Eurocode 4 Design of composite steel and concrete srructures: Part 1.2: General rules, Structural fire design, ENV 1994- 1-2, European Committee for Standardisation, 1994 Kirby, B. R.: ‘Recent developments and applications in structuralfire engineering design - a review’, Fire Safety Journul,11, 1986 pp 141179 Purkiss, J. A.: ‘Developments in the fire safety design of structural steelwork, Journal ufConstructiona1 Steel Research,11, 1986, pp149173 ‘Structural fire engineering: investigation of Broadgate phase 8 fire’, Ascot, Steel Construction Institute, 1991 Armer, G. S. T., Moore, D. B.: ‘Full-scale testing on complete multistorey structures’,The Structural Engineer,72, No.2,18 January 1994, pp30-3 1 Schleich, J. B.: ‘A natural fire safety concept for buildings’, 2nd Cardington Con., March 1996 Martin, D. M., Moore, D. B.: ‘Introduction and background to the research programme and major fire tests at BRE Cardington’,National Steel Construction Conf:,May 1997 Natural Fire Safety Concept: CEC Agreements 7210-SA/ 125, 126, 213,214, 323,423, 522,623, 839,937, Technical Report No. 6, period from l January 1997 to 30 June I997 Bailey, C. G., Burgess, I. W., and Plank, R.J.: ‘Analyses of the effects Fire Safety of cooling and fire spread on steel-framed buildings’, Juurnal, 26, 1996, pp273-293 its application to the Wang, Y.: ‘Tensile membrane action in slabs and Cardington fire tests’, 2nd BRE Cardington Con$, March 1996 test Bailey, C. G.: ‘Computer modellingof the comer compartment fire on the large-scale Cardington test frame’, Journal of Constructional Steel Research (to be published) REPORT The Institution of Structural Engineers Temporary demountable structures (Second edition) Updated guidance on the use of these structures aimed at event organisers, venue owners, regulatory authorities, contractors and suppliers. ------------------------------------------------, Order Form The Institution of Structural Engineers VAT No 497 6944 68 Temporary demountable structures (2nd ed.) Please supply copy(ies) of the Temporary demountable structures (2nd ed.)report at €35 each. Total remittance enclosed € Name Initials Organisation Title Address Membership no. (if applicable) Remittances should be made payable to ‘SETO’,and forof StructuralEngineers, warded to theInstitution 11 Upper Belgrave Street, London SWlX 8BH. GUIDE The Institution of Structural Engineers Guide to The structural useof adhesives A guidefor Engineers with little or no knowledgeof adhesives to be aware of the applications and carry out, where appropriate, preliminary designs and to prepare outline specifications. Manufacturers, suppliers and contractors may also find the Guide to be of use. The Guide is not intended as a text book and extensive references to other sources of information are included. Copies will not be sent out until the end of January 1999. VAT no. 497 6944 68 The Institution of Structural Engineers The structural use of adhesives Please send copy(ies) ofGuide. the I enclose a remittanceof € (€21 per copy members; €35 per copy non-members). Surname Title/qualification Address IStructE membership no. Remittance should be made payable to ‘SETO’ and forwarded to the Institution of Structural Engineers, 11 Upper Belgrave Street, London SWlX 8BH. The Structural Engineer Volume 77/No 8 20 April 1999 21