* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download generator (alternator) overhaul

Electronic paper wikipedia , lookup

Power engineering wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Electronic music wikipedia , lookup

Electrician wikipedia , lookup

Electronic musical instrument wikipedia , lookup

Electric machine wikipedia , lookup

History of electric power transmission wikipedia , lookup

Fault tolerance wikipedia , lookup

Voltage optimisation wikipedia , lookup

Rectiverter wikipedia , lookup

Portable appliance testing wikipedia , lookup

Surge protector wikipedia , lookup

Automatic test equipment wikipedia , lookup

Opto-isolator wikipedia , lookup

Stray voltage wikipedia , lookup

Electrical engineering wikipedia , lookup

Alternating current wikipedia , lookup

Electronic engineering wikipedia , lookup

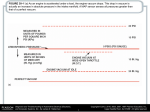

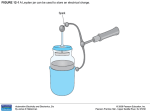

OBJECTIVES After studying Chapter 21, the reader should be able to: 1. Prepare for ASE Electrical/Electronic Systems (A6) certification test content area “D” (Charging System Diagnosis and Repair). 2. Discuss the various generator test procedures. 3. Explain how to disassemble a generator and test its component parts. 4. Discuss how to check the wiring from the generator to the battery. 5. Describe how to test the operation of a computer-controlled charging system. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE • The charging system can be tested as part of a routine vehicle inspection or to determine the reason for a no-charge or reduced-charging circuit performance. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Charging Voltage Test Step 1 Select DC volts. Step 2 Connect the red meter lead to the positive (+) terminal of the battery and the black meter lead to the negative (-) terminal of the battery. Step 3 Start the engine and increase the engine speed to about 2000 RPM (fast idle) and record the charging voltage. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Charging Voltage Test FIGURE 21-1 The digital multimeter should be set to read DC volts, with the red lead connected to the positive (+) battery terminal and the black meter lead connected to the negative (-) battery terminal. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman FIGURE 21-2 A scan tool such as this Chrysler DRB III can be used to check the generator output voltage. © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Magnetized Rear Bearing Test • With the engine running, use a screwdriver or other metallic object to test for magnetism at the rear bearing of the generator. FIGURE 21-3 If the rear bearing is magnetized, the voltage regulator, generator brushes, and rotor are functioning. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Magnetized Rear Bearing Test • If the rear bearing is magnetized, then the following facts are known. 1. The voltage regulator is working. 2. The generator brushes are working. 3. The rotor in the generator is producing a magnetic field. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Magnetized Rear Bearing Test • If the rear bearing is not magnetized, then one or more of the following problems exist. 1. The voltage regulator is not working. 2. The generator brushes are worn or stuck, and they are not making good electrical contact with the rotor slip rings. 3. The generator rotor could be defective. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Full-Fielding Test • If the rear bearing is not magnetized, then a procedure for bypassing the voltage regulator should be used to determine if the generator is capable of producing its designed output. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Full-Fielding Test FIGURE 21-4 A GM generator with an internal voltage regulator can be identified by the horizontal plug-in connector. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman FIGURE 21-5 Connections required to fullfield a GM generator with an external voltage regulator. © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Full-Fielding Test FIGURE 21-6 Connections required to full-field a Ford generator with an external voltage regulator. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman FIGURE 21-7 Jumper wire connections required to full-field a Ford (or Leece-Neville) generator with an internal electronic voltage regulator. © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Full-Fielding Test FIGURE 21-8 Wiring diagram of a Ford integral generator or regulator (IAR) assembly. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM TESTING AND SERVICE Full-Fielding Test FIGURE 21-9 Connections required to fullfield a Chrysler generator with a mechanical voltage regulator. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman FIGURE 21-10 Connections required to full-field a Chrysler generator with an electronic voltage regulator. © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 THE LIGHTER PLUG TRICK • Simply construct a test tool using a lighter plug at one end of a length of twoconductor wire and the other end connected to a double banana plug. FIGURE 21-11 Charging system voltage can be easily checked at the lighter plug by connecting a lighter plug to the voltmeter through a double banana plug. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 USE A TEST LIGHT TO CHECK FOR A DEFECTIVE FUSIBLE LINK • A quick and easy test to check if the fusible link is okay is to touch a test light to the output terminal. • This test confirms that the circuit between the AC generator and the battery has continuity. FIGURE 21-12 Before replacing a generator (alternator), the wise technician checks that battery voltage is present at the output and battery voltage sense terminals. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 ACCESSORY DRIVE BELT INSPECTION • When a belt that turns the water pump breaks, the engine could rapidly overheat, causing serious engine damage, and if one belt breaks, it often causes the other belts to become tangled, causing them to break. FIGURE 21-13 This accessory drive belt should be replaced because it has many cracks. The usual specification for when a serpentine belt requires replacement is when there are three or more cracks in any one rib in any 3 in. length. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 ACCESSORY DRIVE BELT INSPECTION Tension Measurement • There are four ways that vehicle manufacturers specify that the belt tension is within factory specifications. 1. Belt tension gauge 2. Marks on a tensioner 3. Torque wrench reading 4. Deflection Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 AC VOLTAGE CHECK • The procedure to check for AC voltage, called ripple voltage, includes the following steps. Step 1 Set the digital meter to read AC volts. Step 2 Start the engine and operate it at 2000 RPM (fast idle). Step 3 Connect the voltmeter leads to the positive and negative battery terminals. Step 4 Turn on the headlights to provide an electrical load on the generator. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 AC VOLTAGE CHECK • A higher, more accurate reading can be obtained by touching the meter lead to the output terminal of the generator. FIGURE 21-14 AC ripple at the output terminal of the generator is more accurate than testing at the battery due to the resistance of the wiring between the generator and the battery. The reading shown on the meter is only 78 mV (0.078V),far below what the reading would be if a diode were defective. (Courtesy of Fluke Corporation) Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 THE MINI CLAMP ON DMM TEST • The generator output can be easily measured using a mini clamp-on-type digital multimeter. • A reading of greater than 10 amperes AC indicates defective generator diodes. FIGURE 21-15 A mini clamp-on digital multimeter can be used to measure generator output. This meter was set on the 200-A DC scale. With the engine running and all lights and accessories on, the generator was able to produce almost exactly its specified rating of 105 A. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 AC CURRENT RIPPLE CHECK • To measure the AC ripple current to the battery, perform the following steps. Step 1 Start the engine and turn on the lights to create an electrical load on the generator. Step 2 Using a clamp-on meter, place the clamp around either all of the positive (+) battery cables or all of the negative (-) battery cables. Step 3 Read the meter display and determine the needed service. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM VOLTAGE DROP TESTING • When there is a suspected charging system problem (with or without a charge indicator light on), simply follow these steps to measure the voltage drop of the insulated (powerside) charging circuit. Step 1 Start the engine and run it at a fast idle (about 2000 engine RPM). Step 2 Turn on the headlights to ensure an electrical load on the charging system. Step 3 Using any voltmeter, connect the positive test lead (usually red) to the output terminal of the generator. Attach the negative test lead (usually black) to the positive post of the battery. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM VOLTAGE DROP TESTING • The results should be interpreted as follows: 1. If there is less than a 0.4 volt reading, then all wiring and connections are satisfactory. 2. If the voltmeter reads higher than 0.4 volt, there is excessive resistance (voltage drop) between the generator output terminal and the positive terminal of the battery. 3. If the voltmeter reads battery voltage (or close to battery voltage), there is an open circuit between the battery and the generator output terminal. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHARGING SYSTEM VOLTAGE DROP TESTING • If the reading is over 0.2 volt, connect one end of an auxiliary ground wire to the case of the generator and the other end to a good engine ground. FIGURE 21-16 Voltmeter hookup to test the voltage drop of the charging circuit. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERAL MOTORS SI TEST LIGHT TEST • All General Motors System Integration (SI) (internal voltage regulator) series Delcotron generators (alternators) can be easily tested using a standard 6 to 12 volt test light. FIGURE 21-17 Typical GM SI generator. Note the location and wire color used for terminals 1 and 2. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERAL MOTORS SI TEST LIGHT TEST Normal Operation • The following steps outline the procedure for testing an SI series generator for normal operation. Step 1 With the ignition on (engine off), a test light should be bright if touched to the “BAT” terminal and terminal 2. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERAL MOTORS SI TEST LIGHT TEST Normal Operation Step 2 With the engine running, touching any of the three terminals should produce a bright test light. The BAT terminal and terminal 2 should both cause a bright light because both are battery voltage sources. Terminal 1 should also light the test light brightly because when the generator is producing a current, the internal voltage rises and applies an opposing voltage on the dash light bulb, which causes current to stop flowing through the bulb and the charge light to go out. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERAL MOTORS SI TEST LIGHT TEST Problems and Possible Causes • If the test light is not on at all on terminal 1 (brown or tan wire), the problem is an open circuit in the wiring between the dash and the generator. • If the test light does not light on either the BAT terminal or terminal 2, an open circuit exists between the positive post of the battery and the generator. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERAL MOTORS CS SERIES AC GENERATORS • The CS series generators are designed to operate as stand-alone generators or be controlled by a vehicle computer system. FIGURE 21-18 Typical GM CS generator wiring plug identification. Note that terminal F is sometimes terminal I on some generators. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 DIAGNOSING PROBLEMS WITH THE GENERAL MOTORS CS SERIES • If the charge indicator light is on in the dash, unplug the connector (which can have up to four wires connected). • Check all fuses, all fusible links, and the charge light indicator bulb. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR OUTPUT TEST • A generator (alternator) output test measures the current (amperes) of the alternator. FIGURE 21-19 Typical hookup of a starting and charging tester. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR OUTPUT TEST • The testing procedure for generator output is as follows: Step 1 Connect the starting and charging test leads according to the manufacturer’s instructions. Step 2 Turn the ignition switch on (engine off) and observe the ammeter. This is the ignition circuit current, and it should be about 2 to 8 amperes. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR OUTPUT TEST Step 3 Start the engine and operate it at 2000 RPM (fast idle). Turn the load increase control slowly to obtain the highest reading on the ammeter scale. Note the ampere reading. Step 4 Total the amperes from steps 2 and 3. Results should be within 10% (or 15 amperes) of the rated output. Rated output may be stamped on the generator. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR OUTPUT TEST FIGURE 21-20 The output rating on the General Motors generator (alternator) is stamped into the case. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman FIGURE 21-21 The output on this generator is printed on a label. © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 HOW TO DETERMINE MINIMUM REQUIRED GENERATOR OUTPUT • After connecting an ammeter correctly in the battery circuit, continue as follows: 1. Start the engine and operate to about 2000 RPM (fast idle). 2. Turn the heat selector to air conditioning (if the vehicle is so equipped). 3. Turn the blower motor to high speed. 4. Turn the headlights on bright. 5. Turn on the radio. 6. Turn on the windshield wipers. 7. Turn on any other accessories that may be used continuously (do not operate the horn, power door locks, or other units that are not used for more than a few seconds). Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 HOW TO DETERMINE MINIMUM REQUIRED GENERATOR OUTPUT • If using an inductive-pickup ammeter, be certain that the pickup is over all the wires leaving the battery terminal. FIGURE 21-22 When connecting an inductive ammeter probe, be certain that the pickup is over all wires. The probe will work equally well over either all positive or all negative cables because all current leaving a battery must return. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 HOW TO DETERMINE MINIMUM REQUIRED GENERATOR OUTPUT FIGURE 21-23 A diagram showing the location of the charging system wiring of a typical vehicle. The best location to use to check for the generator alternator) output is at the output wire from the B+ (BAT) terminal. Notice that the generator supplies all electrical needs of the vehicle first, then charges the battery if needed. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 HOW TO DETERMINE MINIMUM REQUIRED GENERATOR OUTPUT • Most vehicles that use a computer-controlled charging system can be diagnosed with a scan tool. • Not only can the charging voltage be monitored, but in many vehicles, the field circuit can be controlled and the output voltage monitored to check that the system is operating correctly. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) REMOVAL • A typical removal procedure includes the following steps. Step 1 Before disconnecting the negative battery cable, use a test light or a voltmeter and check for battery voltage at the output terminal of the generator. A complete circuit must exist between the generator and the battery. If there is no voltage at the generator output terminal, check for a blown fusible link or other electrical circuit fault. Step 2 Disconnect the negative (0) terminal from the battery. Step 3 Remove the accessory drive belt that drives the generator. Step 4 Remove the fasteners and brackets, as necessary, and remove the generator from the vehicle. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR DISASSEMBLY • If testing has confirmed that there are generator problems, remove the generator from the vehicle after disconnecting the negative battery cable. • Mark the case with a scratch or with chalk to ensure proper reassembly of the generator case. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman FIGURE 21-24 Always mark the case of the generator before disassembly to be assured of correct reassembly. © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 WHAT IS A “CLOCK POSITION”? • Most generators of a particular manufacturer can be used on a variety of vehicles, which may require wiring connections placed in various locations. • The four through bolts that hold the two halves together are equally spaced; therefore, the rear generator housing can be installed in any one of four positions to match the wiring needs of various models. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 WHAT IS A “CLOCK POSITION”? FIGURE 21-25 Explanation of clock positions. Because the four through bolts are equally spaced, it is possible for a generator to be installed in one of four different clock positions. The connector position is determined by viewing the generator from the diode end with the threaded adjusting lug in the up or 12 o’clock position. Select the 3 o’clock, 6 o’clock, 9 o’clock, or 12 o’clock position to match the unit being replaced. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 TESTING THE ROTOR • Typical resistance values include the following: – GM: 2.4 to 3.5 ohms – Ford: 3.0 to 5.5 ohms – Chrysler: 3.0 to 6.0 ohms • Ohmmeters can also vary in accuracy. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 TESTING THE ROTOR FIGURE 21-26 Testing a generator rotor using an ohmmeter. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 TESTING THE STATOR • There should not be continuity (in other words, there should be infinity ohms, or the test light should not light) when the stator is tested between any stator lead and the metal stator core. FIGURE 21-27 If the ohmmeter reads infinity between any two of the three stator windings, the stator is open and, therefore, defective. The ohmmeter should read infinity between any stator lead and the steel laminations. If the reading is less than infinity, the stator is grounded. Stator windings can be tested if shorted because the normal resistance is very low. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 TESTING THE STATOR • An ohmmeter cannot detect an open stator if the stator is delta wound. • The ohmmeter will still indicate low resistance because all three windings are electrically connected. FIGURE 21-28 An open in a deltawound stator cannot be detected using an ohmmeter. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 TESTING THE DIODE TRIO • Many generators are equipped with a diode trio. • Because trio means “three,” a diode trio is three diodes connected together. FIGURE 21-29 Typical diode trio. If one leg of a diode trio is open, the generator may produce close to normal output, but the charge indicator light on the dash will be on dimly. The plus signs indicate the anodes, and the minus sign indicates the cathode terminal of the diodes. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 TESTING THE RECTIFIER BRIDGE (DIODES) • To test many generator diodes, it may be necessary to unsolder the stator connections. FIGURE 21-30 A GM rectifier bridge that has been disassembled to show the individual diodes. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 TESTING THE RECTIFIER BRIDGE (DIODES) • General Motors generators use a replaceable rectifier bridge containing all six diodes in one unit combined with a finned heat sink. • Some Ford and other generators also use six diodes in a single replaceable bridge. FIGURE 21-31 Diodes being soldered to the stator on a Ford generator. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 TESTING THE GM INTERNAL VOLTAGE REGULATOR • Even though the voltage regulator can be tested on the vehicle with the engine running, the internal voltage regulator can also be tested using a special tester. FIGURE 21-32 Testing a GM SI internal voltage regulator using a voltage regulator tester. This tester can be used to test most internal and external electronic voltage regulators by using the appropriate adapter harness and test leads. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 BRUSH HOLDER REPLACEMENT • After the brushes are installed (usually retained by two or three screws) and the rotor is installed in the generator housing, a brush retainer pin can be pulled out through an access hole in the rear of the generator, allowing the brushes to be pressed against the slip rings by the brush springs. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman FIGURE 21-33 A brush holder assembly shown assembled in the generator. The brush retainer is actually a straightenedout paper clip. © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 BEARING SERVICE AND REPLACEMENT • The bearing of a generator must be able to support the rotor and reduce friction. • Many generator front bearings must be removed from the rotor using a special puller. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR ASSEMBLY • After testing or servicing, the generator rectifier(s), regulator, stator, and brush holder must be reassembled. • The battery terminal should be covered with a plastic or rubber protective cap to help prevent accidental shorting to ground, which could seriously damage the generator. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 REMANUFACTURED GENERATORS • Remanufactured or rebuilt generators are totally disassembled and rebuilt. • Every generator is then assembled and tested for proper output, boxed, and shipped to a warehouse. FIGURE 21-34 (a) A generator for a GEO Prism looks like a typical General Motors CS-130 except for this adapter that converted the Toyota wiring harness to the GM generator. (b) After removing the adapter, the original generator connection is visible. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) INSTALLATION • A typical installation procedure includes the following steps. Step 1 Verify that the replacement generator is the correct unit for the vehicle. Step 2 Install the generator wiring on the generator and install the generator. Step 3 Check the condition of the drive belt and replace, if necessary. Install the drive belt over the drive pulley. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) INSTALLATION Step 4 Properly tension the drive belt. Step 5 Tighten all fasteners to factory specifications. Step 6 Double-check that all fasteners are correctly tightened and remove all tools from the engine compartment area. Step 7 Start the engine and verify proper charging circuit operation. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 GENERATOR (ALTERNATOR) OVERHAUL Step-by-Step Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman cont © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 SUMMARY 1. 2. Charging system testing requires that the battery be at least 75% charged to be assured of accurate test results. The charge indicator light should be on with the ignition switch on, but should go out when the engine is running. Normal charging voltage (at 2000 engine RPM) is 13.5 to 15.0 volts. If the charging system is not charging properly, the rear bearing of the generator should be checked for magnetism. If the rear bearing is magnetized, the voltage regulator, brushes, and generator rotor are functioning correctly. If the rear bearing is not magnetized, the voltage regulator, generator brushes, or rotor is not functioning. Bypass the voltage regulator by supplying battery voltage to the field. If the rear bearing is now magnetized and the charging system output is normal, the voltage regulator is at fault. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 SUMMARY 3. To check for excessive resistance in the wiring between the generator and the battery, a voltage drop test should be performed. 4. Generators do not produce their maximum-rated output unless required by circuit demands. Therefore, to test for maximum generator output, the battery must be loaded to force the generator to produce its maximum output. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 SUMMARY 5. Each generator should be marked across its case before disassembly to ensure proper clock position during reassembly. After disassembly, all generator internal components should be tested using a continuity light or an ohmmeter. The following components should be tested: a. Stator b. Rotor c. Diodes d. Diode trio (if the generator is so equipped) e. Bearings f. Brushes (should be more than 1/2 in. long) 6. Electronic voltage regulators can be tested either off the vehicle using a special tester or on the vehicle using the full-field bypass procedure. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 REVIEW QUESTIONS 1. 2. 3. Describe how to test the voltage drop of the charging circuit. Discuss how to measure the amperage output of a generator. Explain what tests can be performed to determine whether a diode or stator is defective before removing the generator from the vehicle. Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 1. To check the charging voltage, connect a digital multimeter (DMM) to the positive (+) and the negative (-) terminals of the battery and select _____. a) b) c) d) DC volts AC volts DC amps AC amps Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 1. To check the charging voltage, connect a digital multimeter (DMM) to the positive (+) and the negative (-) terminals of the battery and select _____. a) b) c) d) DC volts AC volts DC amps AC amps Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 2. To check for ripple voltage from the generator, select _____. a) b) c) d) DC volts AC volts DC amps AC amps Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 2. To check for ripple voltage from the generator, select _____. a) b) c) d) DC volts AC volts DC amps AC amps Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 3. The maximum allowable AC current in amperes that is being sent to the battery from the generator is _____. a) b) c) d) 0.4 A 1 to 3 A 3 to 4 A 10% of the rated output of the generator Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 3. The maximum allowable AC current in amperes that is being sent to the battery from the generator is _____. a) b) c) d) 0.4 A 1 to 3 A 3 to 4 A 10% of the rated output of the generator Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 4. Why should the lights be turned on when checking for ripple voltage or AC current from the generator? a) b) c) d) To warm the battery To check that the battery is fully charged To create an electrical load for the generator To test the battery before conducting other tests Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 4. Why should the lights be turned on when checking for ripple voltage or AC current from the generator? a) b) c) d) To warm the battery To check that the battery is fully charged To create an electrical load for the generator To test the battery before conducting other tests Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 5. An acceptable charging circuit voltage on a 13 volt system is _____. a) b) c) d) 13.5 to 15.0 volts 12.6 to 15.6 volts 12 to 14 volts 14.9 to 16.1 volts Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 5. An acceptable charging circuit voltage on a 13 volt system is _____. a) b) c) d) 13.5 to 15.0 volts 12.6 to 15.6 volts 12 to 14 volts 14.9 to 16.1 volts Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 6. Technician A says that by full-fielding the generator, you are bypassing the voltage regulator. Technician B says that voltage regulators control the generator output by controlling the field current through the rotor. Which technician is correct? a) b) c) d) Technician A only Technician B only Both Technicians A and B Neither Technician A nor B Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 6. Technician A says that by full-fielding the generator, you are bypassing the voltage regulator. Technician B says that voltage regulators control the generator output by controlling the field current through the rotor. Which technician is correct? a) b) c) d) Technician A only Technician B only Both Technicians A and B Neither Technician A nor B Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 7. Technician A says that a voltage drop test of the charging circuit should only be performed when current is flowing through the circuit. Technician B says to connect the leads of a voltmeter to the positive and negative terminals of the battery to measure the voltage drop of the charging system. Which technician is correct? a) b) c) d) Technician A only Technician B only Both Technicians A and B Neither Technician A nor B Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 7. Technician A says that a voltage drop test of the charging circuit should only be performed when current is flowing through the circuit. Technician B says to connect the leads of a voltmeter to the positive and negative terminals of the battery to measure the voltage drop of the charging system. Which technician is correct? a) b) c) d) Technician A only Technician B only Both Technicians A and B Neither Technician A nor B Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 8. When testing a generator rotor, if an ohmmeter shows zero ohms with one meter lead attached to the slip rings and the other meter lead touching the rotor shaft, the rotor is _____. a) b) c) d) Okay (normal) Defective (shorted-to-grounded) Defective (shorted-to-voltage) Okay (rotor windings are open) Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 8. When testing a generator rotor, if an ohmmeter shows zero ohms with one meter lead attached to the slip rings and the other meter lead touching the rotor shaft, the rotor is _____. a) b) c) d) Okay (normal) Defective (shorted-to-grounded) Defective (shorted-to-voltage) Okay (rotor windings are open) Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 9. A generator diode is being tested using a digital multimeter set to the diode check position. A good diode will read _____ if the leads are connected one way across the diode and _____ if the leads are reversed. a) b) c) d) 300/300 0.475/0.475 OL/OL 0.551/OL Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 9. A generator diode is being tested using a digital multimeter set to the diode check position. A good diode will read _____ if the leads are connected one way across the diode and _____ if the leads are reversed. a) b) c) d) 300/300 0.475/0.475 OL/OL 0.551/OL Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 10. A generator (alternator) could test as producing lower-than normal output, yet be okay, if _____. a) b) c) d) The battery is weak or defective The engine speed is not high enough during testing The drive belt is loose or slipping All of the above occur Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 CHAPTER QUIZ 10. A generator (alternator) could test as producing lower-than normal output, yet be okay, if _____. a) b) c) d) The battery is weak or defective The engine speed is not high enough during testing The drive belt is loose or slipping All of the above occur Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458 END Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Fifth Edition By James D. Halderman © 2010 Pearson Higher Education, Inc. Pearson Prentice Hall - Upper Saddle River, NJ 07458