* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Laboratory Exercise 4 The Solenoid (two weeks – 200 pts)

Voltage optimisation wikipedia , lookup

History of electric power transmission wikipedia , lookup

Stray voltage wikipedia , lookup

History of electromagnetic theory wikipedia , lookup

Loading coil wikipedia , lookup

Spark-gap transmitter wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Induction motor wikipedia , lookup

Stepper motor wikipedia , lookup

Power engineering wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Mains electricity wikipedia , lookup

Wireless power transfer wikipedia , lookup

Capacitor discharge ignition wikipedia , lookup

Rectiverter wikipedia , lookup

Alternating current wikipedia , lookup

Electric machine wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Buck converter wikipedia , lookup

Magnetic core wikipedia , lookup

Ignition system wikipedia , lookup

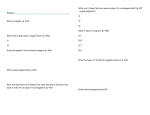

Laboratory Exercise 4 The Solenoid (two weeks – 200 pts) Procedure – Week 1 Objective: The objective of this lab is to plot force-strokes and force-amp-turn graphs in order to determine the capability of given solenoids to pull or push weights far out of its position. These graphs shows that how much force we can expect from the solenoid. The knowledge of these plots facilitate the customers to decide best suitable solenoid for their purpose. Solenoids A solenoid typically converts electrical power into linear mechanical power. One can think of solenoid as a motor but the difference is that a motor converts electrical power into a rotational mechanical power. Two solenoids, SMO-0837L (turn ratio = 2000) and SMO-0420L (turns ration = 2190) are used in this lab. Both are open frame and pull type (although one was labeled push type in one literature cut: Fig.1 Screenshot describing an open Frame Solenoid. Although they are supplied from Tai Shing Electronics Components Corp, they were purchased from Jameco for this class. In the Jameco catalog, one was described as a push and one as a pull type solenoid. When bought, both turned out to be pull-type. 1 Caution: Do not pull on the hot-glue gun glue dabbed on the end of the shaft! Fig. 2 Tai Shing Electronics Components Corp Solenoids Used The two solenoids have stroke vs force curves and ampere-turn vs force curves for various percent on of the solenoid. We are assuming 100% for both solenoids since the solenoids are to be turned on 100% for this test. Devise a test to substantiate these curves for various values of length of stroke. Use the weights in the lab and remember that 1 gram = 0.035274 oz. Procedure Use the circuits given in Fig. 3 to test the two solenoids and collect data for the curves + solenoid Plunger: attached to fixed weights on string 12 VDC - Fig. 3 Circuit diagram For the force, use hexagon nuts and tie them with plunger of the solenoid with the help of thread. Before connecting the nuts, weight (in gm) the nuts the help of digital weigh scale. Fig. 4 is showing images of experimental set-up. A linear scale (or ruler) would be used to measure the distance (stroke) in mm. Tape the scale with solenoid and a pencil as seen in figure 4. The number of turns of the smaller solenoid (SMO-0420L-12AA) is 2190. Resistance = 120 Ω. The number of turns of the larger solenoid (SMO-0837L-12AA) is 2000. Resistance = 36 Ω. 2 Solenoid Scale Threads Weights Fig. 4 Set-up of the experiment Use the following tables to record your values of force vs stroke and force vs ampere-turns for the two solenoids. Use the following table to record your values. Force(gf) Stroke (mm) Ampere-Turns Force (gf) 3 Figures as shown below are showing typical Stroke Vs Force and Ampere-Turns Vs Force characteristics of the solenoid. Fig. 5 Typical plots of Force Vs Strokes and Force Vs Ampere-turns Conclusion Once you get all the data filled in above tables, plot the graphs as shown in Fig. 5. Also measure and record the solenoid resistance. Comment on the value compared to the published data. 4 Procedure – Week 2 Devise a circuit to demonstrate the duty cycle approach to turning on a solenoid. Why is a diode used in these circuits? Describe the circuit and success with turning on the solenoid. Describe the circuit and record your results. Verify your results with the original solenoid graphs. See the circuit at the bottom of page 17 for a suggested circuit. To verify your design, show your results to the instructor and get initials: __________________ 5 Supplement to Lab 4 - Introduction to Solenoids / Basics of a Solenoid Two basic laws govern solenoids: Faraday's Law Ampere's Law Faraday's Law The voltage induced in a coil is proportional to the number of turns and rate of change of flux. The induced current flows in the direction that opposes the changing flux. Flux has no source or sink (What goes in comes out) Ampere's Law The magneto-motive force (mmf) around a closed loop is equal to net current enclosed by the loop. The objective of solenoid design is to transfer the maximum amount of NI (energy) from the coil to the working air gap. Types of Solenoids There are two main categories of solenoids: Rotary Linear Linear solenoids have applications in appliances, vending machines, door locks, coin changers, circuit breakers, pumps, medical apparatus, automotive transmissions and postal machines to name just a few. Rotary solenoids have applications in machine tools, lasers, photo processing, media storage, medical apparatus, sorters, fire door closures, and postal machines, also just to name a few. Solenoids are used in almost every conceivable industry in the world and are well known as an efficient, affordable and reliable actuation alternative. Eight Essential Application Considerations when designing a solenoid into your assembly Stroke Force or Torque Voltage Current / Power Duty Cycle Temperature Operating Time / Speed Environmental AC / DC Life 6 Stroke – when applying solenoids, keep the stroke as short as possible to keep the size, weight and power consumption to a minimum. Force – applies to linear products. Starting force is typically more important than ending force. A safety factor of 1.5 is suggested. For example, an application requiring 3 pounds of force should employ a solenoid that provides at least 4.5 pounds of force. Force is inversely proportional to the square of the air gap with flat face plunger designs. The air gap is the space in the magnetic circuit allowing the armature to move without interference, and the magnetic flux to circulate with minimum resistance (reluctance). To determine your requirements for force or torque, you need to consider the following: The actual load you are moving Return spring force or torque Frictional loads Temperature rise Duty cycle Orientation of the solenoid vs. gravity (the weight of the plunger is added or subtracted depending on how the solenoid is mounted. In linear solenoids, force can be modified by the shape of the plunger used. A conical face plunger is used for medium to long stroke applications. The effective air gap changes to become a fraction of actual stroke. Flat face plungers are used for short stroke applications. Stepped conical face plungers can provide various stroke (medium to long) dependent on the angle of the step. These are advantageous for high holding force requirements. Torque – applies to rotary products. Starting torque is typically more important than ending torque. A safety factor of 1.5 is suggested. For example, an application requiring 3 pound of torque should employ a solenoid that provides at least 4.5 pounds of torque. Torque produced by Ledex™ Rotary Solenoids is inversely proportional to the total length of the stroke. The longer the stroke, the lower the torque output. The shorter the stroke, the higher the torque output. Voltage – the voltage source determines the coil winding to be used in the appropriate solenoid. Common DC power supply ratings are 6,12,24,36, and 48 VDC. AC vs. DC solenoids – AC solenoids are most commonly used in household appliances. Generally AC solenoids have been specified when there was a high cost to rectify to DC. AC solenoids typically require twice the in rush power of an equivalent DC solenoid. As a result, many more DC solenoids are chosen for today's applications. Current / Power – Force produced by a DC solenoid is proportional to the square of the number of turns (N) in the coil winding and current flow (I). This determines the ampere turns or NI. Solenoid coil requirements must match the power source. Duty Cycle – The duty cycle of your application is the ratio of the "on-time" divided by the total time for one complete cycle (on + off). Duty cycle is usually expressed as a percentage or a fraction (50%, 100%). A more simplistic representation of duty cycle is to call < 100% duty solenoids "Intermittent" and 100% duty cycle solenoids "Continuous". All intermittent duty 7 solenoids (< 100% duty cycle) also must have a maximum "on-time" allowed to avoid overheating that can eventually lead to a burned out coil. The "on-time" must not exceed the power dissipation limits of the coil. Proper heat sinking and/or additional cooling improves heat dissipation which allows a broader duty cycle range. Very close attention must be paid to the maximum "on-time" data provided in conjunction with the duty cycle calculation to avoid damaging your solenoids. For example, although an application with a one hour cycle time and a 3 hour off-time might calculate to a 25% duty cycle, this is not realistic in practice. A more realistic solenoid application might be an on-time of one second and an off-time of 3 seconds for the same 25% duty cycle. Temperature – Both the ambient temperature of the solenoid environment and the self -heating of the solenoid at work must be considered. The resistance of the coil varies with temperature which affects force output. The self-heating temperature is dictated by the duty cycle. Each 1 increase above 20º C equates to an increase of 0.39% of rated resistance; thereby reducing force or torque output. There are various ways to compensate for temperature restrictions: Specify a Class C Coil Specify an over-molded coil Use a E Model Rotary solenoid vs. the S Model Actuate at one power level and cut back to a reduced power level for holding (pick and hold) Use a latching solenoid Use a multiple winding solenoid Operate intermittently, not at continuous duty Use a larger solenoid Use a heat sink Add a cooling fan The limiting factor of operating temperature of a solenoid is the insulation material of the magnet wire used. Insulation classes: Class B- 130º C Class F- 155º C Class H- 180º C Class C- 220º C A typical solenoid requires 10% of the normal current to remain energized. To accomplish this, you may choose to use one of the following: Mechanical hold in resistor Capacitor discharge and hold in resistor Transistorized hold in circuit Pulse-width modulation Pick and Hold Dual voltage Multiple coils 8 Operating Time / Speed – Factors affecting time and speed include the mass of the load, available power / watts and stroke. De-energizing also plays an important role and is affected by the air gap, coil suppression, the plunger or armature return mechanism, and residual magnetism. The air gap is the space in the magnetic circuit allowing the armature to move without interference, and the magnetic flux to flow with minimum resistance (reluctance). The smaller the air gap, the longer it takes for the magnetic field resulting from the excited coil to diminish. This causes a longer de-energizing time. The application of electronic protection devices to reduce spikes caused by interrupting the current in the coil is necessary to ensure protection of your switching device. Coil suppression tends to increase the de-energizing time of the solenoid. Since solenoids have force in one direction only, there must be some restoring force (such as gravity or a spring) to take the solenoid back to the starting or de-energized position. This positions the solenoid for the next operation. Air gap surfaces of a solenoid become the north pole and south pole of a magnet when energized. When the solenoid is off, a small but measurable magnetic attraction between the poles still exists called residual magnetism. Residual magnetism can be reduced by hyper-annealing the solenoid parts of by increasing the size of the air gap. Environmental – Many environmental factors must be noted when choosing a solenoid. These include temperature, sand/ dust, humidity, shock, vibration, altitude, vacuum, chemicals and paper dust. Solenoid Life – Life is determined by / optimized by the: Bearing system and shaft surface finish Side loading and load alignment Preventing the pole pieces from slamming together Reducing impact shock upon energizing Solenoid life expectations range from 50 thousand cycles to over 100 million cycles. Custom Solenoids - 80% of solenoids used are custom designs. Typical modifications include termination, lead wires, plunger configurations, shaft extensions, mounting changes and linkages. 9 Application Hints To achieve extended life, try the following options: o Drive the load from the armature end of a rotary solenoid rather than the base end o Use vespel or oilite bearings in a low profile solenoid design o Use dual ring bearings or a groove in the shaft to act as a lube reservoir o Use glass-filled or carbon-filled nylon couplings To achieve increased holding torque / force performance try the following options: o Use indented ball races in a rotary solenoid o Use flat pole pieces o Use latching solenoids To determine the temperature at which a coil has stabilized follow this sequence of steps: o Measure the coil resistance at room temperature o Measure the current at the stabilized temperature and determine the coil resistance using Ohm's Law o Divide this resistance by the resistance at room temperature to obtain the resistance factor o Using the resistance factor chart, read the temperature at which the solenoid coil has stabilized. To compensate for temperature rise: o Mount the solenoid on a metal surface (heat sink) o Use a cooling fan o Use a larger solenoid o Operate at < 100% duty cycle o Consider a higher insulation class o Use a solenoid with multiple windings o Use a pick and hold circuit such as PWM The Linear Solenoid Another type of electromagnetic actuator that converts an electrical signal into a magnetic field is called a Solenoid. The linear solenoid works on the same basic principal as the electromechanical relay (EMR) seen in the previous tutorial and like relays, they can also be controlled by transistors or MOSFET. A Linear Solenoid is an electromagnetic device that converts electrical energy into a mechanical pushing or pulling force or motion. Linear Solenoid 10 Solenoids basically consist of an electrical coil wound around a cylindrical tube with a ferromagnetic actuator or "plunger" that is free to move or slide "IN" and "OUT" of the coils body. Solenoids are available in a variety of formats with the more common types being the linear solenoid also known as the linear electromechanical actuator (LEMA) and the rotary solenoid. Both types, linear and rotational are available as either a holding (continuously energized) or as a latching type (ON-OFF pulse) with the latching types being used in either energized or power-off applications. Linear solenoids can also be designed for proportional motion control were the plunger position is proportional to the power input. When electrical current flows through a conductor it generates a magnetic field, and the direction of this magnetic field with regards to its North and South Poles is determined by the direction of the current flow within the wire. This coil of wire becomes an "Electromagnet" with its own north and south poles exactly the same as that for a permanent type magnet. The strength of this magnetic field can be increased or decreased by either controlling the amount of current flowing through the coil or by changing the number of turns or loops that the coil has. An example of an "Electromagnet" is given below. Magnetic Field produced by a Coil When an electrical current is passed through the coils windings, it behaves like an electromagnet and the plunger, which is located inside the coil, is attracted towards the center of the coil by the magnetic flux setup within the coils body, which in turn compresses a small spring attached to one end of the plunger. The force and speed of the plungers movement is determined by the strength of the magnetic flux generated within the coil. When the supply current is turned "OFF" (de-energized) the electromagnetic field generated previously by the coil collapses and the energy stored in the compressed spring forces the plunger back out to its original rest position. This back and forth movement of the plunger is known as the solenoids "Stroke", in other words the maximum distance the plunger can travel in either an "IN" or an "OUT" direction, for example, 0 - 30mm. 11 Linear Solenoids This type of solenoid is generally called a Linear Solenoid due to the linear directional movement of the plunger. Linear solenoids are available in two basic configurations called a "Pull-type" as it pulls the connected load towards itself when energized, and the "Push-type" that act in the opposite direction pushing it away from itself when energized. Both push and pull types are generally constructed the same with the difference being in the location of the return spring and design of the plunger. Pull-type Linear Solenoid Construction Linear solenoids are useful in many applications that require an open or closed (in or out) type motion such as electronically activated door locks, pneumatic or hydraulic control valves, robotics, automotive engine management, irrigation valves to water the garden and even the "Ding-Dong" door bell has one. They are available as open frame, closed frame or sealed tubular types. Rotary Solenoids Most electromagnetic solenoids are linear devices producing a linear back and forth force or motion. However, rotational solenoids are also available which produce an angular or rotary motion from a neutral position in either clockwise, anti-clockwise or in both directions (bidirectional). 12 Rotary solenoids can be used to replace small DC motors or stepper motors were the angular movement is very small with the angle of rotation being the angle moved from the start to the end position. Commonly available rotary solenoids have movements of 25, 35, 45, 60 and 90o as well as multiple movements to and from a certain angle such as a 2-position self-restoring or return to zero rotation, for example 0-to-90-to-0o, 3-position self-restoring, for example 0o to +45o or 0o to -45o as well as 2-position latching. Rotary solenoids produce a rotational movement when either energized, de-energized, or a change in the polarity of an electromagnetic field alters the position of a permanent magnet rotor. Their construction consists of an electrical coil wound around a steel frame with a magnetic disk connected to an output shaft positioned above the coil. When the coil is energized the electromagnetic field generates multiple north and south poles which repel the adjacent permanent magnetic poles of the disk causing it to rotate at an angle determined by the mechanical construction of the rotary solenoid. Rotary solenoids are used in vending or gaming machines, valve control, camera shutter with special high speed, low power or variable positioning solenoids with high force or torque are available such as those used in dot matrix printers, typewriters, automatic machines or automotive applications etc. Solenoid Switching Generally solenoids either linear or rotary operate with the application of a DC voltage, but they can also be used with AC sinusoidal voltages by using full wave bridge rectifiers to rectify the supply which then can be used to switch the DC solenoid. Small DC type solenoids can be easily controlled using transistor or MOSFET switches and are ideal for use in robotic applications, but again as we saw with relays, solenoids are "inductive" devices so some form of electrical protection is required across the solenoid coil to prevent high back emf voltages from damaging the semiconductor switching device. In this case the standard "Flywheel Diode" is used. 13 Switching Solenoids using a Transistor Reducing Energy Consumption One of the main disadvantages of solenoids and especially the linear solenoid is that they are "inductive devices" which convert some of the electrical current into "HEAT", in other words they get hot!, and the longer the time that the power is applied to a solenoid coil, the hotter the coil will become. Also as the coil heats up, its electrical resistance also changes allowing more current to flow. With a continuous voltage input applied to the coil, the solenoids coil does not have the opportunity to cool down because the input power is always on. In order to reduce this selfgenerated heating effect it is necessary to reduce either the amount of time the coil is energized or reduce the amount of current flowing through it. One method of consuming less current is to apply a suitable high enough voltage to the solenoid coil so as to provide the necessary electromagnetic field to operate and seat the plunger but then once activated to reduce the coils supply voltage to a level sufficient to maintain the plunger in its seated or latched position. One way of achieving this is to connect a suitable "holding" resistor in series with the solenoids coil, for example: 14 Reducing Solenoid Energy Consumption Here, the switch contacts are closed shorting out the resistance and passing the full supply current directly to the solenoid coils windings. Once energized the contacts which can be mechanically connected to the solenoids plunger action open connecting the holding resistor, RH in series with the solenoids coil. This effectively connects the resistor in series with the coil. By using this method, the solenoid can be connected to its voltage supply indefinitely (continuous duty cycle) as the power consumed by the coil and the heat generated is greatly reduced, which can be up to 85 to 90% using a suitable power resistor. However, the power consumed by the resistor will also generate a certain amount of heat, I2R (Ohm's Law) and this also needs to be taken into account. 15 Duty Cycle Another more practical way of reducing the heat generated by the solenoids coil is to use an "intermittent duty cycle". An intermittent duty cycle means that the coil is repeatedly switched "ON" and "OFF" at a suitable frequency so as to activate the plunger mechanism but not allow it to de-energize during the OFF period of the waveform. Intermittent duty cycle switching is a very effective way to reduce the total power consumed by the coil. The Duty Cycle (%ED) of a solenoid is the portion of the "ON" time that a solenoid is energized and is the ratio of the "ON" time to the total "ON" and "OFF" time for one complete cycle of operation. In other words, the cycle time equals the switched-ON time plus the switched-OFF time. Duty cycle is expressed as a percentage, for example: Then if a solenoid is switched "ON" or energized for 30 seconds and then switched "OFF" for 90 seconds before being re-energized again, one complete cycle, the total "ON/OFF" cycle time would be 120 seconds, (30+90) so the solenoids duty cycle would be calculated as 30/120 secs or 25%. This means that you can determine the solenoids maximum switch-ON time if you know the values of duty cycle and switch-OFF time. For example, the switch-OFF time equals 15 secs, duty cycle equals 40%, therefore switch-ON time equals 10 secs. A solenoid with a rated Duty Cycle of 100% means that it has a continuous voltage rating and can therefore be left "ON" or continuously energized without overheating or damage. The TIP 115 Darlington and 1N4001 diode are shown connected to a power supply and a frequency generator to demonstrate the duty cycle circuits above. Demonstrate it with a solenoid and turn the duty cycle down until the solenoid’s magnetic force weakens sufficiently to allow the solenoid to be pulled apart easily. Demonstrate this to your instructor. 16 17 18 solenoid 1N4001 12 V DC Oscilloscope -.5 - 4.5V from Source 19