* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download LINEAR VARIABLE DIFFERENTIAL TRANSFORMERS

Index of electronics articles wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Josephson voltage standard wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Wien bridge oscillator wikipedia , lookup

Power MOSFET wikipedia , lookup

Transistor–transistor logic wikipedia , lookup

Phase-locked loop wikipedia , lookup

Surge protector wikipedia , lookup

Wilson current mirror wikipedia , lookup

Standing wave ratio wikipedia , lookup

Integrating ADC wikipedia , lookup

Radio transmitter design wikipedia , lookup

Operational amplifier wikipedia , lookup

Schmitt trigger wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Valve audio amplifier technical specification wikipedia , lookup

Power electronics wikipedia , lookup

Voltage regulator wikipedia , lookup

Current mirror wikipedia , lookup

Valve RF amplifier wikipedia , lookup

Switched-mode power supply wikipedia , lookup

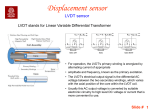

LINEAR VARIABLE DIFFERENTIAL TRANSFORMERS WHITE PAPER BY KAVLICO CORPORATION KAVLICO PROPRIETARY June 1997 Revised: May 2000 Kavlico Proprietary DESCRIPTION........................................................................................................................... 2 Excitation................................................................................................................................... 2 Output ....................................................................................................................................... 3 Resolution.................................................................................................................................. 3 Repeatability............................................................................................................................... 3 Construction ............................................................................................................................... 3 Temperature Range....................................................................................................................... 3 Mechanical Design ....................................................................................................................... 4 Length ....................................................................................................................................... 4 Typical Armature Length............................................................................................................... 4 Diameter................................................................................................................................. 4 Measurement Range ..................................................................................................................... 5 Configurations ............................................................................................................................ 5 LVDT CHARACTERISTICS ........................................................................................................ 6 FAULT DETECTION ................................................................................................................ 11 DIFFERENCE OVER SUM OUTPUT.......................................................................................... 12 NOMINAL VALUES.............................................................................................................. 13 LVDT ENVELOPE REQUIREMENTS ......................................................................................... 14 COST CONSIDERATIONS ........................................................................................................ 14 1 Kavlico Proprietary DESCRIPTION The Linear Variable Differential Transformer (LVDT) is a Displacement Transducer that produces an electrical signal proportional to the displacement of a moveable core (armature) within a cylindrical transformer. The transformer consists of a primary and two secondary windings, coaxial wound, with each secondary located on opposite ends. The nickel-iron armature is positioned within the coil assembly providing a path for magnetic flux linking the primary coil to the secondary coils. When the primary coil is energized with an alternating current, a cylindrical flux field is produced over the length of the armature. This flux field produces a voltage in each of the two secondary coils as a function of the armature position. For the longer strokes, the primary winding is designed to maintain a flux field that is a constant magnitude for any position within the linear range. A change in the position of the armature will then move the flux field into one secondary and out of the other. This results in an increase in the voltage induced in one secondary and a corresponding decrease in the other. The secondary coils are normally connected in series with opposing phase. The net output of the LVDT is the difference between the two secondary voltages. When the armature is symmetrically positioned relative to the two secondary coils the differential output is approximately zero, since the voltage in each secondary is equal but opposite in their phase relationship (see Null Voltage). There are several coil configurations that are used for LVDT’s. The very short strokes require a high sensitivity to produce a reasonable output. They are normally wound with the primary coil located between the secondary coils with the armature extending into each secondary (commonly known as three coils design). This configuration has the highest sensitivity, the lowest phase shift, and a low temperature coefficient of the sensitivity. It should be pointed out that the individual secondary voltages of this configuration contain an X2 term, where X is the displacement, and they are inherently non-linear. The differential output is very linear (the squared terms subtract out) but the sum is not linear. For three coil designs, if the stroke is larger than ±0.025 inches a difference over sum output is not recommended. The coil configuration used on older four-wire LVDT designs with strokes longer than 0.25 inches have a primary winding which is wound across the entire length with each secondary starting in the center and ramping up to the end. This produced a linear differential output but if the center tap was brought out, it was usually obvious that the sum was not linear. The computer controlled winding machines allowed ramping the secondary coils from one end to the other with a linear output that provides a constant sum. Excitation An LVDT requires an AC voltage for operation. Aircraft power or low impedance AC source specifically designed for the LVDT normally supplies this excitation. In today’s aerospace and aircraft industry, multi-channels with individual excitation sources are often used to obtain the highest possible system reliability. 2 Kavlico Proprietary Output The output voltage of an LVDT is proportional to the voltage applied to the primary. To avoid problems of excitation tolerances the output should always be stated in volts/volt. System accuracy will depend on providing a constant input voltage to the primary or compensating for variations of the input by using ratio techniques. The output can be taken as the differential voltage, or with a center tap, as two separate secondary voltages whose difference is a function of the displacement. If the Sum of the secondary voltages is designed to be a specific ratio of the difference voltage, overall accuracy can be significantly improved using the (V1-V2)/(V1+V2) ratio as the output. (See Difference Over Sum Output). Figure 1 shows the AC input; and Figure 2 the two secondary output voltage waveforms as seen on an oscilloscope. The Va secondary phase is shown referenced to the center of the coil and Vb shown referenced to the end of the two secondary coils with the phase shift of Va at 2.5o and Vb at 2.7o. Resolution Resolution of an LVDT is the smallest change in armature position that can be detected as a change in the output. Sub-micro-inch resolution is not uncommon with LVDT’s. In practice, the resolution is usually less than the noise threshold of external circuitry or resolution of the equipment used to measure the output. Repeatability Repeatability of an LVDT is defined as the ability to reproduce the same output for repeated exact positioning of the armature under the same operating conditions. The armature displacement mechanism and test equipment normally limits the ability to measure the repeatability of an LVDT. Construction Nearly all LVDT’s designed for aircraft or missile applications are wound on an insulated stainless steel spool, magnetically shielded, and enclosed in a stainless steel housing using welded construction. The armature is normally made from a 50% Nickel Iron alloy and brazed to a stainless steel extension. Secondary leads are usually shielded to minimize channel to channel crosstalk for multi channel units (See Crosstalk) and to keep RF energy from getting into the signal conditioner. An LVDT does not contain electronic components and it is unaffected by RF energy, making the LVDT nearly immune to EMI, EMP and lighting. Temperature Range The operating temperature range determines processes and materials used for construction. LVDTs have been designed for operation from cryogenic temperatures of -440°F and to operation submerged in liquefied metal (+1100°F). Construction and assembly for these extreme conditions require very special materials and processes that assure complimentary coefficients of expansion while maintaining good electrical and magnetic properties. Kavlico’s standard construction provides operational temperature ranges from -65°F to +350°F. High 3 Kavlico Proprietary temperature solder and special potting materials can extend this range from less than -80°F to over 450°F. Mechanical Design The length and diameter of an LVDT must be sufficient to mechanically allow adequate winding space to achieve the electrical performance: ¾ To meet pressure requirements ¾ To withstand the shock, vibration and static acceleration environments. Where physical size is limited, electrical performance must be flexible. Although the LVDT is basically a simple device, the operating characteristics and electrical parameters are complex and depend to a large extent on the physical limitations. Length The minimum length of a coil housing for most aerospace applications can be estimated as follows: It will require approximately 0.5 to l.5 inches for the sum of the front and rear weld washers plus possible lead connections. Small housing diameters (less than 0.5 inches), large lead wires (larger than 26 AWG) or high pressures may require the longer length for lead connection and/or support of a high pressure. Add the total electrical stroke and the length of the armature and you have the housing length. The length of the armature ranges from 0.6 inches, to up to twice the length of the electrical stroke, depending on the frequency of the excitation and the actual stroke. Table 1 gives a typical armature length for good performance at an excitation between 1800 to 3500 Hertz. Additional housing length may be needed for mounting flanges, connectors, fluid passages, cable routing or seal grooves which limit the coil length. Typical Armature Length Electrical Stroke (Inches) Armature Length (Inches) 0.10 (+0.05) 0.50 (+0.25) 1.00 (+0.50) 2.00 (+1.00) 3.00 (+1.50) 4.00 (+2.00) 5.00 (+2.50) 7.00 (+3.50) 10.00 (+5.00) 14.00 (+7.00) Table 1 Diameter 4 0.67 1.00 1.50 2.20 2.60 3.00 3.20 3.50 3.75 4.00 Kavlico Proprietary The minimum diameter of the transformer housing will depend on electrical performance criteria for the excitation frequency being used and housing wall thickness required to support a pressure requirement. Armature diameters less than 0.110 inches are easily damaged and are not recommended. The armature extension should be slightly larger than the armature in diameter to protect the armature from rubbing the bore. Ideally, the armature should have a short guide on the free end that is the same diameter as the extension. To determine the inside diameter of the spool tube, add the extension diameter and the clearance to the tube. This diametrical clearance should be 0.010 inches minimum to 0.025 inches maximum. The wall of the spool tube should be at least 0.006 inches thick but must be thick enough to contain any pressure requirement. It should be kept in mind that the tube material and wall thickness does affect the performance. The finished coil assembly diameter is determined by adding insulation to the spool tube, winding the primary coil, insulating the coil, winding the secondary coils, insulating the secondary, routing the magnet wire for lead connections, insulating the entire coil and installing the shields. Typical coil assembly diameters for operating frequencies between 1800 and 3500 Hertz are 0.420 inches. A typical assembly for 400 Hertz would be 0.625 diameter. This coil assembly must be installed in the housing that could have a wall thickness from 0.015 to 0.070 inches depending on the physical length, pressure and environment. Measurement Range The Full Scale or span is the displacement range of the LVDT’s armature for which the electrical performance is required and is referred to as the Electrical Stroke. Since an LVDT is inherently a center null device (zero output occurs at mid-stroke), the range or stroke is normally specified as a plus and minus displacement from the null position. This does not yield a 200% stroke or a 200% output. The Full Scale (100% of the stroke) being the total end to end stroke and the Full Scale Output (100% of the output) the total end to end output voltage. It is a common error to use the output at the end of the stroke as the Full Scale Output. Special winding placement of each secondary or the addition of a bias winding can reposition the null to an off-center position. A bias winding is wound to produce a constant voltage over the stroke and is added in series with the secondary coils to produce the required offset. The full scale (span) is still the end to end stroke and full scale output is still the end to end output. The null output of an LVDT has no sensitivity error and is the point in the stroke with the highest overall accuracy. Sensitivity errors due to frequency variations, load effects and temperature, have little effect on the null position. Configurations The Four Wire LVDT or Two Wire Output. A differential output only requires two secondary wires and can be used directly in AC servo systems or synchronously demodulated to a ±DC voltage. The Five Wire LVDT or Three Wire Output. More elaborate signal conditioners use a three wire secondary connection and use the two secondary voltages relative to a common 5 Kavlico Proprietary connection. This arrangement facilitates fault detection and/or a difference over sum ratio. (See Fault Detection or Difference over Sum Output) The Six Wire LVDT. Performs the same as the five-wire unit but allows a differential interface to each secondary to avoid shielding by using the common mode rejection. Multiple LVDT’s. Where system reliability requires more than one output signal for redundancy, up to four independent LVDT’s can be packaged in a single transducer assembly. Coil placement may be in series (Tandem), or grouped side by side as a (Parallel) cluster, see Figure 4. Multiple LVDT’s in one housing require less space, weight, and installation time and are lower cost than purchasing quantities of single LVDT’s. Multiple channels do present several new problems that must be considered. (See Tracking, Null Difference and Crosstalk) LVDT CHARACTERISTICS Due to the principle of operation and the application of an LVDT, the parameters can become very complex. The following requirements should be defined in a specification to permit an optimum design for coil size and housing dimensions. Electrical Stroke is the displacement range over which the specified performance and all electrical parameters will be valid. Mechanical Stroke is the guaranteed minimum physical stroke. Many LVDT’s will have physical limitations for the actual Mechanical Stroke. When the displacement exceeds the electrical stroke, the performance will be degraded. If specific output requirements for an over-stroke are needed, these requirements should be specified to insure proper design since these requirements could affect the physical length of the LVDT. Excitation Voltage is the electrical potential intended to excite the transformer. This voltage requires definition of amplitude, function, and frequency. An LVDT can be designed for operation at less than 1 volt RMS to over l00 volts RMS. Normal excitation voltages for missile or aircraft applications range from 3 to 26 volts RMS. Kavlico does not recommend mixing RMS, Peak, or Peak to Peak specification requirements. Excitation Frequency The best overall size and performance is obtained using excitation frequencies in the range of 1800 to 3500 hertz. An LVDT can be designed for operation at any frequency between 50 and l0, 000 hertz, but physical size or performance may be compromised at the extremes. The primary impedance of an LVDT is quite complex and must be designed for a specific frequency when low phase shift and high accuracy are desired. The range of frequencies over which an LVDT will operate with low phase shift and good accuracy is highly dependent on its physical size, coil geometry, displacement range and sensitivity. To achieve the best overall performance, it is recommended that the range of the excitation frequency be kept as low as possible. When multiple channels are used with different frequencies, a specific frequency with a reasonable tolerance should be assigned to each channel. Excitation Waveform It is recommended that only sine excitation is used for LVDT’s. Both triangular and square waves contain several odd harmonics of significant magnitude. 6 Kavlico Proprietary Phase shift of harmonics through an LVDT will be a similar multiple of the phase shift for the fundamental frequency. The geometry necessary for an LVDT design can produce significant primary to secondary capacitance and the high harmonics of a square wave will produce large leading and trailing spikes on the output signal. The secondary circuit of an LVDT is slightly inductive and when using square wave excitation, shunt capacitance across the secondary, both inter-winding as well as load capacitance, will lower the self resonance of the secondary circuit, which will cause severe ringing of the output signal. The primary current with square wave excitation is a triangular waveform and the IR drop across the primary resistance will cause the secondary voltage to have a dropping slope. Both triangular and square waves have been used successfully for LVDT excitation but accurate calibration is difficult and severe limitations on impedance, sensitivity and load are required for good performance. These waveforms often cause calibration correlation problems using commercial test equipment and may require using the actual circuit to determine the proper sensitivity. It is recommended that after the proper sensitivity is established, sine excitation be used for calibration using the standard commercial test equipment. Input Power describes the real power in watts, or apparent power in volt-amperes, required for the excitation of the LVDT. Since the input impedance of an LVDT is not purely resistive, input power is generally given in Volt-Amps. This limits the input current rather than actual power dissipated. It is recommended that the maximum volt-amperes be specified. Practical limits for lower frequencies (26 VRMS, 400 Hz.) could be as high as l.5 VA down to 0.1 VA when using 7.0 VRMS at 3500 Hz. Power Factor describes the ratio of the real power in watts, to the apparent power in volt amps. This ratio is normally computed from the complex impedance. The Rs/Z (See Input Impedance) will yield the power factor. Typical power factors for an LVDT are in the range of 0.4 to 0.9. Input Impedance will define the load the primary coil of the LVDT will present to the excitation source. The input impedance of an LVDT is complex and is best described with both the resistive and reactive components (Rs +jXL). It should be noted that the Rs term is not just the DC resistance but includes the equivalent series real part of a complex impedance. Eddy current losses and shunt capacitance across the inductance will add an AC resistance to the DC resistance to produce the Rs term of the complex impedance. The vector sum of Rs and XL, (impedance Z), is normally specified as a minimum value for design purposes. The maximum volt-amperes will limit the minimum input impedance - both requirements need not be specified. Quality assurance requirements normally require a specific value with a tolerance for the impedance. It is recommended that if the specific impedance value is required, it should be taken from the actual measurement when the design is completed. A +20% tolerance is practical for primary impedance. Output Impedance describes the maximum source impedance of the secondary voltage. The source impedance of the LVDT secondary will depend on input power limitations, sensitivity requirements and the constraints on the wire size due to physical space available. 7 Kavlico Proprietary It is extremely difficult to predict the actual output impedance of an LVDT and this value is normally taken from the actual coil design. The output impedance will form a voltage divider with the load (see Load). The open circuit voltage of the secondary will be reduced by the ratio of the load impedance divided by the load impedance plus the output impedance of the LVDT. Errors due to loading are minimized by calibrating with the equivalent of the actual interface load. A tolerance of +15% is practical for secondary impedance. Load. The load is the impedance of the circuit that the secondary of the LVDT is connected to. The equivalent of the actual in-service load should be specified for proper calibration. If long cable connections or RF filters are used, the shunt capacitance should be included with the description of the load. When a center tap secondary is used, the load across each coil and any additional differential load should be specified. The load on the output of an LVDT will affect the sensitivity, phase shift and temperature error. If the correct load is used for calibration, all performance requirements will be met with the service load. To minimize load errors, tolerances should be kept as small as possible and the load impedance should not be less than l0, 000 ohms. Shunt capacitance of the load circuit should be kept under 7500 pF when using excitation frequencies over 1000 hertz. Sensitivity, gain and scale factor are the same requirement. They are the slope of the output voltage Vs displacement. Kavlico prefers to define sensitivity as the slope of a best-fit straight line drawn through the output data. An LVDT is a ratiometric device and the sensitivity should be expressed as the ratio of the volts out, per volt in, per Inch of displacement (V/V/Inch). A practical upper limit for the sensitivity of short stroke units (less than 0.065 inches) that operate at frequencies less than 500 hertz would be in the range of 3.0 V/V/Inch. Up to 6.5 V/V/Inch can be achieved for short stroke units that operate at frequencies around 3500 hertz. This limit will decrease with longer strokes and should not exceed 0.5 Volts/Volt at the end of stroke for the lower frequencies or 0.85 Volts/Volt at the higher frequencies. Synchronous type demodulators will only produce a DC output for the in-phase component of it’s input signal. A simplified way of looking at a phase shifted signal is that it contains the sum of two sine waves, one that is in-phase with the reference and one that is at 90° (quadrature). When a synchronous type demodulator is used, phase shift errors are eliminated if the LVDT output is measured using an analyzing (phase sensitive) voltmeter that can measure the component of the output that is inphase (0 or 180 degrees) with the excitation. Looking at the waveforms of this type of demodulator it is not obvious but it does rectify the in-phase component. Non-synchronous (rectifier) type demodulators are used on some five or six wire LVDTs and the LVDT output is measured using the total voltage ratio (without regard to phase). A requirement for Sensitivity should include a statement for the ratio of the in-phase component or the total voltage. Temperature Coefficient Temperature error for the sensitivity is normally specified as a coefficient of the sensitivity. The temperature coefficient of the sensitivity of an LVDT is not linear over wide temperature ranges. It should be expressed as the maximum allowed change in sensitivity, as a percentage of the nominal sensitivity, averaged over 100° of temperature change. Typical coefficients range from +0.5% to -3.0% per 100°F. 8 Kavlico Proprietary Accuracy is a term that has no specific definition and requires the user to provide one. This term is often incorrectly used as being synonymous with linearity. Accuracy should be used when a group of independent errors, such as linearity, sensitivity and temperature effects, are combined. For many applications only the total error is important and not the individual error sources. Once components of accuracy are defined, it becomes useful to state the minimum and maximum deviations allowed from a specified reference (usually the nominal output) as a percent of Full Scale output. These bounds are called Accuracy or the Error Band and are the bounds of uncertainty for any measurement point under defined conditions. Acceptance testing of the LVDT is conducted at room temperature and both room temperature limits and environmental limits should be stated. Room temperature accuracy is very useful for calibration, since it establishes specific limits for acceptance and the individual error sources need not be computed. Linearity describes the maximum deviation of any calibration point from a specified straight line. The error is usually expressed as a percentage of Full Scale output. Unless linearity errors are to be included in an “Accuracy” definition, the type of straight line used for the reference must be stated. The most commonly used line is the “Best Fit Straight Line” (BSFL). Null Voltage is the minimum differential output voltage of an LVDT that can be obtained with the armature position. For most LVDTs this is at a balanced center where an equal number of secondary turns are engaged for both secondary coils. The null position is normally defined as the position where the inphase components of the differential output are zero (this is 0 VDC for a synchronous demodulator). The null voltage is primarily due to slight differences in phase shift of one secondary to the other at the null position. When taking the difference of two voltages with different phase, the in-phase components being equal, the quadrature is not and this difference is the null voltage. Figure 5 shows the null quadrature that results from taking the difference in two secondary voltages with only 0.2 degrees of phase difference. It is possible to bias the null position with an additional coil that will have a constant output over the stroke. The only known purpose of a low null voltage is for rigging the stroke to a zero position (adjusting the physical position of the LVDT housing with respect to the armature extension). This is often done using the null output measured with a non-phase-sensitive voltmeter. If the null voltage is low, a more precise zero position can be achieved for the inphase component. Imperfections in the core material, high flux densities and non-uniform hardness of metal in the flux path will generate harmonic distortion, which, if not equal in the two secondary coils, could also contribute to the null voltage. Offset Null. The Null with a biased offset winding is not at a balanced position of the secondary coils and larger phase differences in the secondary voltages will produce a larger null voltage. For a biased null position, three voltages produce the in-phase zero and will never have the same phase shift. This will result in a higher than normal null voltage. Null Voltage for a biased offset could be as high as 5.0% of the maximum output. For most 9 Kavlico Proprietary applications, only the Inphase Component is used and the null voltage will have little or no significance on the accuracy. Null Shift. Kavlico defines null shift as the change in null position that cannot be attributed to material growth. Temperature error of the null position of an LVDT may result from a number of sources but for most applications is negligible. The most significant null position errors are from different linear expansions of the materials that close the loop from the mounting point of the housing to the mounting point of the armature extension. When possible, linear expansions can be matched to minimize null shift. Most aircraft or aerospace LVDT are constructed from 300 series stainless steel and the change in length from the mounting point of the housing to the mounting point of the armature extension will be about 9.3 to 9.6 PPM/oF. Phasing. As noted in LVDT description, the differential output voltage will be in phase or l80o out of phase with the primary voltage as the armature is displaced through the null position. Phasing is used to determine in which direction the armature is displaced from the null position. When specifying the phase for a specific direction of core displacement, the common elements (low side of both primary and secondary) must be specified. Phasing for a three-wire secondary can be specified by indicating the desired phase of each secondary with the low side of the primary connected to the center tap and specifying which secondary voltage is to increase for a specific direction of the armature displacement. Phase Shift for an LVDT normally refers to the difference in angular degrees between the primary excitation voltage and the secondary output voltage when the output is taken differentially. For LVDTs that use three wire or split secondary, the phase shift requirement should indicate the specific output voltage for which the requirement applies (the differential voltage or each individual secondary voltage). Limiting the phase shift will limit the quadrature voltage. In some applications a limit on quadrature is necessary since it appears as quadrature on the output of an error amplifier in a servo system or as a reverse voltage across the switch of a synchronous demodulator. Phase Difference is used to describe the maximum allowed difference in the phase shift of the two secondary voltages when using a three wire or split secondary. It should be pointed out that this is NOT the differential phase shift. Both magnitude and phase shift of each secondary must be considered when computing differential phase shift. Typical phase difference for the two secondary voltages, at the end of the stroke, is 3 to 8 degrees. At the end of the LVDT stroke, one secondary will be at its highest voltage and have its lowest phase shift when the other secondary will be at its lowest voltage with its highest phase shift (See Figure 6). Tracking is used to define the uniformity of performance between channels of multiple channel LVDTs. Calibration data is taken from a single reference point (normally the first channel null position). Each channel’s output is compared and the maximum difference between any two channels is termed “tracking.” This is normally expressed as a percent of Full Scale. 10 Kavlico Proprietary Null Difference tracking at the null position is sometimes specified as a maximum “Null Difference” and may have a different requirement than at other stroke positions. The smallest practical Null Difference is 0.001 inch or 0.15% of the stroke whichever is larger. Null differences less than 0.010 inches will require trimming the extension prior to final calibration. Crosstalk is a term used for multiple channel units to describe the voltage produced in the secondary of one channel by the primary excitation of another channel. When separate drivers are used for different channels they may not be synchronous and slight differences in frequency will produce a beat frequency (difference frequency), which may produce an apparent oscillation of the system. Frequencies for different channels are sometimes separated such that the beat frequency is above the system response. Typical crosstalk for tandem construction is less than 0.0010 V/V and for parallel construction 0.0010 to 0.0025 V/V. FAULT DETECTION Many technological advances in the design, construction and use of the Linear Variable Differential Transformer (LVDT) have been made in the last 15 years. Utilizing computer aided winding machines, the state of the art in LVDT performance has made significant advances. Much of the progress that has been made is due to achieving the ability to produce an LVDT where the two secondary windings provide not only the normal differential signal, but also a constant sum. Add to this, the ability to adjust the sum for a specific differential output, and a whole new dimension for the LVDT is opened. The first benefit one can realize is the ability to fault detect the signal on a real time basis without affecting performance or placing the signals in jeopardy should the fault detection circuit fail. Using the LVDT output as two discrete signals relative to the center tap of the secondary can do this. From this point of reference, (assume the center tap is the signal ground) the two secondary voltages will both be linear with armature displacement and both will have the same phase relationship relative to the excitation. They may be either in-phase or out-of-phase (should be specified for the application) and neither will have a zero voltage output. At this point, two approaches are possible. The first approach would be to either actively rectify or synchronously demodulate each secondary voltage and then use the DC voltages to produce a difference and sum. Accurate calibration can be accomplished using a total voltage ratio for active rectification or calibrating using only the in-phase component of the output voltage (See Figure 7) when synchronous demodulation will be used. No phase shift correction is required when the proper calibration is performed. A second approach would be to use the AC signals, Va and Vb, directly to produce both a difference and a sum voltage (See Figure 8) using both a differential and summing amplifier, then demodulating these voltages. It should be pointed out that this approach, when used on the AC signals, must be used with caution. The individual secondary voltages have differences in phase (see Phase Difference) and the output of a differential amplifier will not be the exact algebraic difference of the secondary voltages. When only the inphase components are used, this phase difference is not significant. 11 Kavlico Proprietary When using the total component, the LVDT can be calibrated using the differential output that will yield the same voltage as the output from a differential amplifier. A differential amplifier can cause a not so obvious error in that it does not present a fixed load to its inverting input due to the common mode voltage generated by the non-inverting side. This will cause the Va secondary to be loaded differently than Vb. The input resistors for a differential amplifier should be 20K ohms or larger to minimize load errors. Also an open circuit fault in the LVDT on the inverting side will result in the differential amplifier producing a false signal to the summing amplifier due to the common mode signal produced on the non-inverting side. When using a differential and summing amplifier the ideal configuration would have a noninverting buffer for each secondary signal with the summing resistors on its input. This will present a fixed load to each half of the secondary of the LVDT and act as a pull down and not allow the input to float in the event of an open circuit in the secondary of the LVDT. The buffer will also isolate the common mode voltage from the differential amplifier since the sum is taken in front of the buffer (see Figure 9) When using a flight or engine control computer the best configuration would be to simply demodulate the Va and Vb to DC signals, digitize them and then let the computer do the rest. In any case, by establishing a minimum value for the sum voltage, any value below this would indicate a fault in the signal. The total loss of the sum would most likely indicate an open in the primary side if the excitation were still present. All significant fault conditions (opens or shorts), which could occur in the LVDT, would be detected. DIFFERENCE OVER SUM OUTPUT In addition to fault detection, a constant sum provides another possible advantage when using an LVDT. Nearly everything that affects the differential output voltage also affects the sum voltage. If the output of an LVDT is taken as the difference over sum ratio, nearly all excitation changes, temperature effects, frequency effects, loading and long term gain loss do not produce an error. (Va/Ex. - Vb/Ex.) / (Va/Ex. + Vb/Ex.) = (Va-Vb)/(Va+Vb) [The Excitation Voltage drops out] This five/six-wire configuration presents many possible alternatives for the signal conditioning of an LVDT, but also presents a few new specification clarifications that must be addressed. Definition of the difference over sum gain with its tolerance and the sum with its tolerance, describe the requirements for this use. The limits of the individual secondary voltages can be determined working from these requirements. A typical requirement might be as follows: 1. 2. 3. 4. Excitation: 7.07 VRMS with a +5% tolerance. Stroke: +3.000 inch. Sum: 0.6000 V/Vex. (4.242 VRMS) with a +10% tolerance. A difference over sum Gain: 0.16667 V/V/Inch (0.5000 V/V at each end of the stroke). 12 Kavlico Proprietary 5. And the total accuracy: +1.0% F.S. (+2%) of the reading at either end of the stroke. The nominal differential gain is the sum ratio multiplied by the difference over sum gain = 0.6000 V/Vex * 0.16667 V/V/Inch = 0.1000 V/Vex/Inch and this times 3.000 inches = 0.3000 V/Vex NOMINAL VALUES Stroke Position Inches Va V/Vex Vb V/Vex Va-Vb V/Vex 3.000 -0+3.000 0.1500 0.3000 0.4500 0.4500 0.3000 0.1500 -0.3000 0.0000 0.3000 Va+Vb V/Vex 0.6000 0.6000 0.6000 (Va-Vb)/(Va+Vb) V/V -0.5000 -0+0.5000 See Figure 10 The worst case for secondary values is: 1. For the sum tolerance, 0.6000 V/V +10% = 0.5400/0.6600 V/V and each secondary is 0.2700/0.3300 V/V. 2. When the sum is 0.5400 V/V the nominal differential must be 0.5400*0.5000 or 0.2700 V/V. Adding +2% tolerance to the gain and calculating the outputs at the ends of stroke yields 0.2754 V/V and for each secondary the change to the end of the stroke=0.1377 V/V; 3. When the sum is 0.6600 V/V the nominal differential must 0.6600*0.5000 or 0.3300 V/V. With the ±2% this is 0.3366 V/V and for each secondary =0.1683 V/V 13 Kavlico Proprietary A. For the minimum low voltage; 0.2700 V/V minimum at the zero position -0.1377 V/V maximum change = 0.1323 V/V and the lowest excitation = 6.7165 Volts, therefore the minimum value = 0.8886 volts. B. For the maximum high voltage; 0.3300 + 0.1683 = 0.4983 V/V and the highest excitation is 7.4235 Volts, and the maximum value = 3.6991 volts. These values do not allow for rigging errors or mechanical over stroke. Practical accuracy for a difference over sum unit is +0.5% of full scale at 75oF. This accuracy will include errors due to sensitivity, non-linearity, input voltage variations, frequency variations and load tolerances for the service life of the unit. The temperature coefficient of sensitivity is normally less than +0.25% per 100°F. For strokes over 2 inches, frequencies between 1500 and 2500 hertz will produce the highest accuracy. The classic use of an LVDT was the differential connection, using only a four-wire configuration. There is only one possible connection for the load, phase shift referred to the differential signal at the end of the stroke, there was only one possible output impedance to contend with and normally a null voltage occurred at mid-stroke. For nearly all applications, only the in-phase component was used for calibration. For the five and six wire configurations it gets more complicated. The load for each secondary and any additional differential loading must be specified. Phase shift for the Va or Vb outputs will change over the entire stroke with the highest phase shift at the low voltage end. The highest quadrature will occur at the high voltage end of the stroke and the phase shift for Va or Vb should be measured at that end of the stroke. The output impedance of the Va or Vb coils changes over the stroke. The output impedance is normally measured for quality purposes at the high voltage end for each secondary. When the secondary center tap is to be the signal reference, the Null Position (Zero Position) is normally defined as the place in the displacement where Va is equal to Vb (there is no “Null” voltage). A Null voltage is only obtained from an LVDT when connected such that the differential output is obtained. (see Null Voltage). Calibration of the output can be done using the in-phase or total component. Using the secondary sum for the switching circuit of a demodulator, phase shifting networks or scaling sensitivity to correct for phase shift is not recommended. LVDT ENVELOPE REQUIREMENTS Once the electrical, mechanical and performance parameters have been determined, several factors must be considered in packaging. Kavlico’s design team can provide the length and diameter necessary to meet both the environmental and electrical performance. COST CONSIDERATIONS Boilerplate and over specifying performance attributes becomes costly in production. Design options and cost savings are available when specific requirements and system performance are analyzed and practical limits placed on all requirements. 14 Kavlico Proprietary 15 Kavlico Proprietary 16 Kavlico Proprietary 17 Kavlico Proprietary 18 Kavlico Proprietary 19 Kavlico Proprietary 20 Kavlico Proprietary 21