* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Becoming familiar with QPS systems in the LHC

Survey

Document related concepts

Transcript

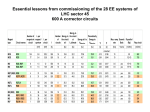

Becoming familiar with QPS systems in the LHC (incl. EE) Presentation 02 Sept. 2008 PART 1 of 3. Part 1: General layouts and principles Presentation of equipment Knud Part 2: Presentation of typical QPS signals and their interpretation. Bob Part 3: Operational aspects Possible events and first diagnostics / treatment by 1st-line team -incl. summary of failures experienced during Hardware Commissioning. Support by QPS specialists Reiner / Knud Challenge 1: Adiabatic Temperature Rise At 13 KA it takes only 200 mS to destroy a dipole magnet. 31 Miits (for TeV 7 Miits) • 970 Km/Hr • 11 GJ Challenge 2: Stored Energy 10.6 GJ •84,000 Tons •60 Km/Hr •11 GJ Protection features in the LHC • Four basic protection principles: – – – – Detection of resistive build-up Spread of the quenching area by firing of heaters By-passing the quenching magnet by cold diode Extraction of the stored energy Not all circuits require all four protection measures. LHC What to power? • The beams are controlled by: -1232 SC main dipoles -392 SC main quadrupoles -124 SC quads/ dipole insertion magnets -6340 SC corrector magnets -112 warm magnets Total current in the 8000 magnets: 1.72 MA (1718 distinct circuits) Comparison of the stored energy (10.6 GJ) with Hera: 0.5 GJ Tevatron: 0.3 GJ RHIC: 0.2 GJ Reference for viewing circuit topologies and parameters: http://at-mel-pm.web.cern.ch/at-mel-pm/ Also available in CCC in paper form (the QPS Reference File) Main elements of QPS and EE • 16’000 quench heaters • More than 2’000 specially doped diodes for 13 kA commutation at 1.9 K • 40’000 instrumentation wires • 6’200 quench heater power supplies (DQHDS) • 3’400 multi-channel detectors • 2’650 data acquisition and monitoring controllers (AMC, AMS, AMG, (AMR in future)) • 32 energy extraction facilities for 13 kA, comprising - 256, 4.5 kA electro-mechanical switches - 64 breaker control modules (DJPC) - 32 current-equalizing busways - 48 / 16 dipole- / quadrupole extraction resistors • 202 energy extraction systems for 600 A. Quench Detection in the LHC • Type of detectors: -DQQDL ‘local’ quench detector, one per arc dipole and quadrupole (in total 1232 + 392 (51 x 4 + 47 x 4) = 1624 racks). Dipoles: Aperture to aperture comparison Quadrupoles: Half-coil to half-coil comparison in the same aperture (F or D) Mainly analogue electronics (because of location in the tunnel). Balanced Wheatstone bridges used for comparison. Two channels per card and two redundant cards. Operating principle: Double 1 oo 2 (one out of two) Featuring: Missed-quench probability is negligible (for asymmetric quenches!) Less than 10 false quench detections per year in worst modeled scenario. Possibility to detect broken voltage tap wires Controller: AMC Quench Detection in the LHC • Type of detectors: -DQQGPU: Digital quench detectors: Installed outside radiation areas exclusively TYPE A: For global protection of corrector circuits. As no voltage taps were provided (an unforgivable mistake !) the detection principle is based on compensation for inductive voltage, using pre-loaded inductance tables, which have been fine-tuned during the Hardware Commissioning. TYPE B: ADC-based digital comparators – on Individually Powered Dipoles and Quadrupoles (voltage taps available). Controller: AMG Quench Detection in the LHC • Type of detectors: -Main Busbar Quench Detector: A ‘local’ detection for the main magnets implies to have a ‘global’ detection for the associated busbars The instrumentation wires on the busbars have been minimized The topology of the detector requires two reference magnets and measurements of the circuit voltage at the current leads (for the dipole circuit in either end of the sector). The resistive voltage is calculated as the sum of the two measured voltages minus the average of the measured reference magnet voltages multiplied by the number of magnets in the circuit. The ‘global’ detector also protect the associated current leads with combined feature of HTS quenching and resistive heating Quench Detection in the LHC • The Quench Loop: – Role: Passing remotely the information about quench detection to other systems such as the energy extraction facilities and the Power Interlock Controller. – Solution: Two hard-wired current loops (50 mA) across each sector, one for the main dipole circuit and one for the QF/QD circuits combined (with simultaneous activation in both circuits). – Every quench detector can open the current loop, the energy extraction facilities can open the loop (in case of internal faults) as well as react on a rupture of the loop by opening the extraction switches. – Information about the rupture of the quench loop will be transmitted to the PIC for further action (shutting down of power converter, ejection of the beams). – NOTE: The fire-preselected-heaters loop has been deactivated. Compression Rings Heat Sinks 13 KA Diodes Why Energy Extraction in the LHC ? • • For the LHC 13 kA circuits of the arc dipole and main quadrupole chains the EE system is activated in the following cases: – In case of a quench in a magnet coil: A rapid current decay is required after transfer of the current to the cold diode of the quenching magnet in order to preserve the by-pass diode and its associated busbars. – In case of a quench in a superconducting busbar or in a current lead or in case of risk of overheating of a component of the warm part of the power circuit (water-cooled cables or crowbar): A rapid current decay is needed to remain within the thermal limits of the component, which has a problem – In case of a failure in the energy extraction switches: A rapid transfer of the current to the dump resistors is required to avoid damage of the breaker system In each of the above cases, the rapid current decay is obtained by switching external resistance into the circuit. Almost the complete stored energy is absorbed by the external dump resistors (99.5 % in the dipole chains and 92 % in the quadrupoles). Why Energy Extraction in the LHC (contd.)? • For the LHC 600 A corrector magnet circuits: – No quench heaters nor by-pass diodes are provided in the corrector magnet chains – Apart from the presence of parallel resistors across certain corrector magnets, protection relies entirely on the operation of an energy extraction system • Particularly important: Short reaction time and small time constant for the current decay is required due to reduced thermal margins for the superconducting busbars (typically 60 ms reaction time is required). – Two different energy extraction systems are foreseen: • Medium-voltage, separate extraction facilities • Low-voltage, converter-integrated systems Current-equalizing Busways for distribution of currents into the four branches of breakers. The Dump Resistors for the LHC 13 kA Circuits • In spite of the large energy difference (664 MJ per diode system and 22/24 MJ per quadrupole circuit) the two extraction resistor types have much in common. The basic design criteria for both types are: – In order to maintain the peak voltage across the resistor at its lowest possible level, as defined by the resistance at room temperature, a ‘zero’ inductance concept are applied and an absorber material with low temperature coefficient have been selected. – The resistor bodies are dimensioned for high temperature operation, but within safe margins for long term reliability of its materials and components. Typically, the operating temperature at the end of the energy deposit attain 200-280 oC. – The design assures a high short- and long term reliability. – The resistor units are available for energy extraction without need of any infrastructure, such as mains power and cooling water, during the extraction period. – The heat dissipation to the surrounding air is close to zero, due to underground installation. Connection to LHC de-mineralized cooling water circuit is therefore needed for evacuation of the heat. – A design, in which the resistor body is not immersed in water, has been favored. Direct cooling by forced air is a good choice, but requires an air-to-water heat exchange. Such a device is incorporated in the resistor assembly. – The units have their own water reservoir with sufficient capacity to assure worst-case no-boiling conditions. – The maximum cooling period shall be maximum 2 hours Energy Extraction Updated on 16-Jul-06 Version 1 600A EE CERN - AT / MEL 1 600 A Extraction Constructional Details • • • • • • • • Separate facilities, located back-to-back or next to the associated power converter. Two systems share one standard rack. The chosen topology is a Series-inserted system with two main breakers (A & B) operated simultaneously, with a third breaker (Z) as back-up. The extraction switch is based on 3-pole electro-mechanical AC breakers (RU military standard), retro-fitted with DC Arc Shutes and Capacitive Snubber Circuits for arc suppression. The capacitor bank, bridging the switches, will strongly reduce the contact erosion (no arcing contacts), it will reduce the noise and it will shorten the arcing time. The 600 A is shared by the three poles in parallel. Also these AC switches have two independent modes of release, herewith providing a four-fold redundancy. The system controls are based on the controller AMS. The Power Abort Link is common with the associated power converter. All cards are made as SMD and burnt-in. The control electronics is commonly designed by CERN and BINP. Other Basic Parameters • Typical total opening time with pulsed release: 11 - 17 ms • Typical total opening time with under-voltage release: less than 20 ms • Total opening time with motor drive / electromagnetic driver: 65 ms! • Maximum DC voltage across one breaker during opening: 420 V • Required Snubber Capacitance: 320 F. • Extraction Resistor: 0.7 . Stainless steel. • Equalizing resistors are required for current balance through the multi-pole breakers. • All elements are natural-air cooled (low losses). • Cooling time of Rdump after complete discharge with max. energy (160 kJ): Typically 10 min. • Local controls and the supervision electronics mounted in a single 3U Euro-chassis. 600 A Energy Extraction Facility 600 A warm cables 400mm2 Switch A Fuse 32 A Switch B Snubber Capacitor 0.8 mF Switch Z Equalizing Resistors each 600 A warm cables 400mm2 Block Diagram Extraction Resistance Voltage Measurement Extraction Resistance Temperature A Interlock Switch Status S3A S3-B Switch Control B S3-Z Z Switch Control Z Mains Control 230V UPS Mains Interface 0 WorldFip B Snubber C Extraction Resistance Switch Control A AMS Interface 1 FPA OPEN - CLOSE Fast Power Abord Power Interlock Controller Final Remarks • All components were designed, manufactured and tested in close collaboration with CERN • The 234 Energy Extraction Systems represent 296 Tons of Components • 89 % is procured through contributions from Non-Member States (11 % from European Industry) • The total cost of the systems is 18 MCHF (European Reference Price).