* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download How to Use Capacitive Sensors to Help Solve Difficult Level

Tunable metamaterial wikipedia , lookup

Work hardening wikipedia , lookup

History of metamaterials wikipedia , lookup

Nanogenerator wikipedia , lookup

Industrial applications of nanotechnology wikipedia , lookup

Glass transition wikipedia , lookup

Hall effect wikipedia , lookup

Scanning SQUID microscope wikipedia , lookup

Nanochemistry wikipedia , lookup

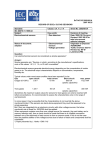

HOW TO How to Use Capacitive Sensors to Help Solve Difficult Level Applications G1032 Revised 10/21/2013 C apacitive sensors can The electrodes are placed in the feedback loop of a high sense through lower frequency oscillator. When no target is present, the sen- dielectric materials, sor’s capacitance is low and the oscillation amplitude is such as plastic or glass, to small. When a target approaches the face of the sensor it detect dielectric increases the capacitance, thereby increasing the ampli- materials, like liquids. This tude of oscillation. The amplitude of oscillation is mea- allows capacitive sensors to sured by an evaluating circuit that generates a signal to detect the level of numerous turn the output on or off. higher materials directly through Capacitance is a function of the surface area of two the wall of a plastic or glass electrodes, the distance between the electrodes, and container, or by utilizing a the dielectric constant of the material between the elec- sight glass or tank well for trodes. When a conductive target enters the sensor’s field metal containers. it forms a counter electrode to the active face of the sen- Capacitive sensors are used to detect a wide variety of sor, decreasing the distance between the electrodes and materials, including liquids of varying viscosities or solids increasing their average surface area (Figure 1). When a like powders, rocks and metals. For instance, capacitive non-conductive target enters the sensors field it acts as an sensors are often used to detect granular or powered ma- electrical insulator between the electrodes (Figure 2). terials like plastic pellets in a hopper for injection molding processes. And intrinsically safe NAMUR capacitive sensors are used in explosive areas, such as grain elevators, to detect materials ranging from rice and barley malt to corn and soybeans. A capacitive sensor’s active element is formed by two metallic electrodes positioned like an “open” capacitor. Figure 1 Figure 1 The dielectric constant of the material being sensed is a measure of its insulation properties. All liquids and solids have a greater dielectric constant than air; the ca- 2 www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 operating distance. Since capacitive sensors are used to sense liquids, any liquid touching the actual sensor will cause it to lock on. Because capacitive sensors cannot sense through metal, applications that require liquid level detection through a metal container wall require special sight glass and tank well fittings for a capacitive sensor to be effective. Generally, capacitive sensors have a wide sensitivity band that makes them capable of performing in difficult applications, like sensing very small metal parts through a tube. Capacitive sensors are also extremely versatile in pacitance of metallic and non-metallic targets is always their housing options (barrel, rectangular, probe), and are applicable in many environments and operations. This ver- greater than the capacitance of a sensor’s circuit in the ab- satility allows manufacturers to utilize capacitive sensors sence of the target. Generally, the larger the dielectric con- in numerous locations, saving expense and helping plants stant of the material, the greater the sensors achievable run more efficiently. www.turck.com • 1-800-544-7769 • Fax: (763) 553-0708 • TURCK • Minneapolis, MN 55441 3