* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Solutions for Today`s Low-Power LED Lighting Trends

Variable-frequency drive wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power engineering wikipedia , lookup

Mains electricity wikipedia , lookup

Power electronics wikipedia , lookup

Distributed generation wikipedia , lookup

Electrification wikipedia , lookup

Electrical ballast wikipedia , lookup

History of electric power transmission wikipedia , lookup

Voltage optimisation wikipedia , lookup

Alternating current wikipedia , lookup

Transmission line loudspeaker wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

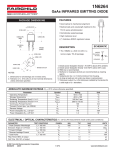

www.fairchildsemi.com Solutions for Today’s Low-Power LED Lighting Trends Brian Johnson, James Lee Abstract: Why all the interest in LED lighting? The answers are as individual as the LED lighting application. LED lighting is discussed everywhere; at times, to the depth of the physics that generates the photons or the science of creating an atmosphere receptive for the users and the environment. LED lighting presents an array of lighting choices through color, brightness, and ability to mount in any shape or location. LED lighting pushes the bounds of creativity by using lighting as the paint brush for expressing ideas. LED lighting offers directional, controllable, changeable, and architectural enhancement to the viewers’ quality of experience. However, just as important as the quality of the experience; LED lighting can save energy. The U.S. Department of Energy (DOE) Solid-State Lighting (SSL) program leverages industry partners to “spur SSL research, development, and communication. Solid-state lighting (SSL) technology has the potential to cut U.S. lighting energy usage by one-quarter and contribute significantly to our nation's climate change solutions. The U.S. Department of Energy acts as a catalyst to drive R&D breakthroughs in efficiency and performance, and to equip buyers to successfully apply SSL lighting.”[1] LED Lighting can create light comparable to incandescent bulbs using up to 85% less energy and lasting up to 50 times longer.[2] Other added benefits from LED Lighting include longer useful lifetimes, lower maintenance, no UV or IR radiation, and no mercury content. SSL can potentially save 190 terawatt-hours of energy usage by 2030.[3] This whitepaper examines LED lighting trends and Fairchild solutions. LED lighting applications fall into three basic input power levels: low-power is less than or up to 20 Watts; mid-power is between 20 Watts and 50 Watts; and high-power is above 50 watts (see Fig. 1). In the real-world, applications do not always fit nicely in these three buckets, but these power levels align when considering LED driver solutions. LED applications are focused on high-brightness LED designs. This white paper explores low-power ≤20W applications, especially bulb-type lamp replacements or retrofits, replacement of existing lamps and fixtures, and new construction fixtures. LOW-POWER LED LIGHTING TRENDS The global sales of high-brightness LEDs was estimated at $890 million in 2010 with a forecast calculated annual growth rate of 39 % from 2010 to 2015.[4] The market potential is large and growing, but challenges for the LED driver include efficacy improvements (efficacy is the ratio of lumens per watt), lowering the cost, and increasing operating lifetime. The DOE SSL program predicts the potential of high-brightness LEDs to exceed the conventional technologies of today and the past. Fig. 2 and Fig. 3 show the trends of improving efficacy. Efficacy has input power in the denominator of the metric, the input power and the efficiency of delivering energy to the LED string is related to the LED driver solution. One single driver topology is not optimal across the full range of LED power load possibilities, but there is a minimal set of topology choices to consider that meet the entire spectrum of LED driver development needs. High Power (>50W) Outdoor Lighting, Street light Applications HID Floodlight Replacement HID Street Lighting Replacement Middle Power (20 - 100W) Indoor/Outdoor Lighting Down Light, L-Light, Flat Light, PAR Replacement, CFL Replacement, LFL Replacement Low Power (1 - 20W) Ornament/Interior Lighting Light Strip, R-Lamp Incandescent Replacement Replacement of CFL Blub, MR Lamp and PAR 1 20 50 100 1000 (W) Power Range Fig. 1. Three Basic Input Power Levels © 2011 Fairchild Semiconductor 1 Solutions for Today’s Low-Power LED Lighting Trends Total cost of the lamp impacts what the end user sees and becomes a frequent impediment to the adoption of the LED light solutions, regardless of performance improvements. A presentation at the DOE 2011 Solid-State Lighting Market Introduction Workshop suggested the need for cost targets as shown in Fig. 5, almost a 50 % reduction in cost every four years.[8] The selection of the LED driver topology is important in the end overall best cost solution. Fig. 2. Efficacy and Projections of Different Light Sources [5] Fig. 3. Recent LED Efficacy Performances [6] Selecting the topology can be aided by selecting the most efficient semiconductors, but the other common design constraint is the cost of the driver. The DOE SSL program approximates today’s costs as shown in Fig. 4; the driver is 10% to 20% of the total manufacturing cost. Fig. 4. Fig. 5. Cost Reduction Targets[8] Operating life is related to the reliability of the power supply. Reliability is affected by component count, types of components used, and temperature or power dissipated in the LED driver design. Reliability can be calculated using a part-count method with the goal to reduce the number of components used in the LED driver selection. Reliability is also affected by operating temperature; so, while thermal design is important, it is equally important to reduce the power losses associated with LED driver components and topology control method. The trend is to eliminate components like electrolytic capacitors and opto-isolators and integrate these features into the control silicon. Approximate Cost Proportions[7] © 2011 Fairchild Semiconductor 2 Solutions for Today’s Low-Power LED Lighting Trends I. STANDARDS & AGENCY REQUIREMENTS There are many standards or agency programs for regulation of LED drivers, including both voluntary and mandatory programs. Table 1 is a sample of a few agency programs for lighting. TABLE 1. SAMPLE OF WORLDWIDE AGENCY PROGRAMS Agency Location Voluntary vs. Mandatory Energy Star - US United States Voluntary California Energy Commission United States California Mandatory European Commission ErP Ecodesign Directive Europe Mandatory The list should include FCC requirement 47 CFR part 15, Class A and Class B, Harmonic Emission limits ANSI C82.77-2002 or IEC 61000-3-2, safety standards UL 8750 or IEC 60650 Part 1, Line Transient protection IEEE C62.41.1991, Class A. or Class A audible noise. LM-80: specifies procedures for determining lumen maintenance of the LEDs and LED modules, not the luminaries. LM79 specifies procedures for measuring luminous efficacy. TM-21 specifies the method to determine expected operating life. Last, but not least, NEMA SSL 1 Electronic Drivers for LED Devices Arrays or Systems. While there is a lengthy list of applicable standards, examining the Energy Star program requirements highlights many of the LED driver design requirements and is shown in Table 2. The items listed are focused on the LED driver, not necessarily the lamp or fixture. TABLE 2. LED DRIVER SPECIFIC STANDARD AND AGENCY REQUIREMENTS Item Power Factor (PF) Total Harmonic Distortion (THD) Dimming Operating Voltage Reference Energy Star Program Requirements for Solid-State Lighting Luminaires Version 1.1 (Effective date: Feb 1, 2009) ≥ 0.7 (Residential) ≥ 0.9 (Commercial) Energy Star Program Requirements Product Specifications for Luminaires (Light Fixtures) Version 1.0, (Effective date: Oct 1, 2011) Residential ≥ 0.7 for >5W Commercial ≥ 0.9 for >5W EN(IEC)61000-3-2 Class C (Lighting) Class C (>25W) ≤ 30%THD (3rd Harmonic) Class D (≤25W) KS C7651/2/3 (IEC61000-3-2) Class C (>25W) Class D (≤25W) Energy Star Program Requirements Product Specifications for Luminaires (Light Fixtures) Version 1.0, (Effective date: Oct 1, 2011) Continuous dimming from 35% to 100% of total light output NEMA SSL 1-2010 120, 127, 208, 220, 230, 240, 277, 347, 480 VAC at 50 or 60 Hz, 12 or 24VAC or VDC Energy Star Program Requirements for Solid-State Lighting Luminaires Version 1.1 (Effective date: Feb 1, 2009) Off-state Power Zero Exceptions for “Controlled/Intelligent” Luminaires <0.5W Energy Star Program Requirements Product Specifications for Luminaires (Light Fixtures) Version 1.0, (Effective date: Oct 1, 2011) Off-State Power Zero Exceptions for “Controlled/Intelligent” Luminaires <1.0W Energy Star Program Requirements Product Specifications for Luminaires (Light Fixtures) Version 1.0, (Effective date: Oct 1, 2011) Within 1 second Standby Power Start Time Criteria © 2011 Fairchild Semiconductor 3 Solutions for Today’s Low-Power LED Lighting Trends Item Reference Standard Lamp MR16, PAR16/20/30S/30L/38 dimension Form Operation Frequency Transient Protection Noise Efficacy ANSI C78.21-2003 Energy Star Program Requirements for Solid-State Lighting Luminaires, Version 1.1, (Effective date: Feb 1, 2009) ≥ 120Hz Energy Star Program Requirements Product Specifications for Luminaires (Light Fixtures) Version 1.0, (Effective date: Oct 1, 2011) ≥ 120Hz (Dimming at All Light Outputs) Energy Star Program Requirements for Solid-State Lighting Luminaires, Version 1.1 (Effective date: Feb 1, 2009) IEEE C.62.41-1991 Class A Electromagnetic Energy Star Program Requirements for Solid-State Lighting Luminaires, and Radio Version 1.1 (Effective date: Feb 1, 2009), LED Luminaries: Energy Star Frequency (Effective date: 01. Sep. 2011) Interference Operating Min. Temperature Criteria FCC 47 CFR part 15 similar with CISPR15 Energy Star Program Requirements for Solid-State Lighting Luminaires, Version 1.1 (Effective date: Feb 1, 2009) Minimum of -20℃ NEMA SSL 1-2010 -40 to 60℃ Energy Star Program Requirements for Solid-State Lighting Luminaires, Version 1.1 (Effective date: Feb 1, 2009) Class A Sound Rating Energy Star Program Requirements for Solid-State Lighting Luminaires, Version 1.1 (Effective date: Feb 1, 2009) From 24 to 45 lm/W Category B: ≥70 lm/W Effective Sep. 30, 2011 Energy Star Program Requirements Product Specifications for Luminaires (Light Fixtures), Version 1.0 (Effective date: Oct 1, 2011) ≥65* lm/W Effective Sep. 1, 2013 Life Time Residential Indoor: 25K Energy Star Program Requirements for Solid-State Lighting Luminaires, Hours Version 1.1 (Effective date: Feb 1, 2009) & Energy Star Program Residential Outdoor: 35K Requirements Product Specifications for Luminaires (Light Fixtures) Version Hours 1.0 (Effective date: Oct 1, 2011) All Commercial: 35K hours Warranty Energy Star Program Requirements Product Specifications for Luminaires (Light Fixtures), Version 1.0 (Effective date: Oct 1, 2011) Safety UL 8750, UL1598, UL153, UL1012 (Other than class2), UL1310 (class 2), UL1574, UL2108, UL60950-1 © 2011 Fairchild Semiconductor Non-Replaceable Drivers: 5 Years Replaceable Drivers: 3 Years 4 Solutions for Today’s Low-Power LED Lighting Trends II. LOW-POWER LED DRIVER DESIGN CHALLENGES Today’s LED driver designs face the following challenges and these become the design constraints to be balanced and prioritized: Development cycle-time Cost Design complexity Finding a power topology that meets the input and output voltage-current parameters, thermal design, safety regulations, and protection needs Efficiency and efficacy Meeting global regulations, i.e. reducing power losses, power factor correction and low THD in the LED driver Reliability and lifetime of the driver Constant current output tolerance Dimming and dimming range (phase cut dimmer requirement, dimming ratio, inrush current limit, damping circuit, bleeder, etc.) No flicker Limited printed circuit board (PCB) space or volume (height) constraints Protections – OVP, OCP, OTP, short-circuit LED, open-circuit LED Operating temperature Vendor selection and consolidation MR11/16 Lamp LED System Configuration The typical design of existing halogen designs is shown in Figure 6. Fig. 6. Existed Conventional Halogen Infra structure The input voltage can be DC 12V or 24V or plugged directly into a 120V or 230V AC mains supply. The 12V or 24V can also be derived from a simple transformer that takes the mains AC voltage and outputs a 12 V / 24V AC input to the light socket. The LED replacement needs to be controlled as a constant-current source. A 4 W LED MR lamp is the equivalent to a 20W halogen lamp design. Diming is a feature found on some models, with the trend toward dimming increasing in availability. MR11/16 Lamp LED Driver Design Challenges The top challenges for the MR11/16 design are the lack of standards on the lamp fixture and the bulb shape, the power factor, total harmonic distortion requirement (Energy Star for LED luminaries ≥0.9, integral lamp ≥0.7 for >5W), and low system power efficiency. The small space for the LED driver can be appreciated by considering the Fig. 7 lamp dimensions, which must include the driver. III. LOW-POWER LED APPLICATION ANALYSIS The following reviews low-power LED lighting; its construction, function, design challenges, and trends by application. MR11/16 LED Lamp The MR11/16 lamp is typically a halogen lamp and common types are 20W, 35W, and 50W ratings. © 2011 Fairchild Semiconductor Fig. 7. MR Lamp Dimensions There are two types of printed circuit board form factors. One shape, shown in Fig. 8, is round to adapt with the LED module back side. The round diameter should be smaller than 30 mm with taller components located within 5 mm from the center connector. 5 Solutions for Today’s Low-Power LED Lighting Trends Fig. 8. MR Lamp Round Type PCB Design The other, shown in Fig. 9, is vertical; it needs to be smaller than 30 x 20 mm. Fig. 9. MR Lamp Vertical Type PCB Deign MR11/16 Lamp Fairchild Solutions If the input voltage is 12V or 24V DC, the LED driver DC-DC topology choice is either a boost or buck topology. If the LED total string forward voltage is higher than the rectified input voltage, use a boost topology; otherwise, use the buck topology. The DC-DC power stage efficiency is high; it can generally reach up to 90%. However, the ballast transformer efficiency is poor. The ballast transformer is not a switched-mode power supply (SMPS), just a transformer converting 110V/220VAC to 12V/24VAC. Although the DC-DC power stage efficiency is high, the total system efficiency for the AC-DC transformer + DC-DC topology is low. The poor system efficiency and PFC and THD requirement need to be solved for the MR LED lamp driver to fit within a limited small PCB space. The current solution using an AC-DC transformer plus © 2011 Fairchild Semiconductor DC-DC topology is the current installed infrastructure: a Halogen socket and ballast transformer. It results in saving on installation investment cost, but electrical efficiency is sacrificed. This infrastructure trend is to be replaced by a more efficient configuration. Manufacturers are starting to release an AC-DC MR lamp into the market place. The AC-DC MR lamp integrates the LED driver into the lamp case without the need for the ballast transformer. It is possible to achieve over 80% total power efficiency in this configuration. In general, it is not easy to build an AC-DC LED driver board into the small bulb case while also meeting PF and THD requirements in the application. It is also preferred not to use an electrolytic capacitor whose life time is less than the other semiconductor components or passive electric components like the resistors, ceramic capacitors, and inductors. The AC-DC MR-type LED lamp design is a new design challenge. Fairchild suggests a new LED driver device to solve the AC-DC issues; the FL7701, shown in Fig. 10. It is a “smart” non-isolated PFC buck LED driver solution. With direct AC line input voltages, it is possible to achieve a small PCB outline adaptable to the MR lamp case. This LED driver device eliminates the need for all electrolytic capacitors typically used for the input, output, and IC VCC voltages. Eliminating the electrolytic capacitors lengthens the product life and reduces the PCB space, while resulting in a low BOM cost. Using only a few external components, it meets PF and THD requirements, while achieving efficiency over 80%. The buck topology also has the advantage of constant output current (reduced ripple current) versus a boost design, since the inductor is placed in series with the output, i.e. the buck topology looks like a constant current source to the LED load. The boost topology has discontinuous output current unless an output capacitor is used to filter the ripple current. A waveform comparison is shown in Fig. 11. 6 Solutions for Today’s Low-Power LED Lighting Trends Vsup D1 + VLED - ILINE LED Load L IL FL7701 VCC C VSUP_SEN DSG ZCD_OUT HV HV Device DSG: Digital Sine-Wave Generator HV Device : High-Voltage Device DAC_OUT Driver S Reference OUT Isw Q R CS GND Fig. 10. Smart Non-Isolated PFC Buck LED Driver Solution Fig. 11. Figure 11 Buck versus Boost Topology Comparison IV. A19, E14/17, E26/27 BULB LAMP Some bulb types are known as “Edison socket” and “candle lights.” The majority are incandescent light bulbs with CFL or LED replacements gaining the majority of the application requirements. A19, E14/17, E26/27 Socket Bulb Configuration When input voltage is direct from the AC mains line, the socket types are: E14/17 (candle), A19/E26/27 (screw type) with the power rating of 1~5W for candle lights and 4~17W for the incandescent replacement. The form factor is shown in Fig. 12 and Fig. 13. Fig. 13. Example of Socket Bulb Type (L: 105mm, D55mm, B26mm) A19, E14/17, E26/27 Socket Bulb LED Driver Design Challenges The LED driver design challenges for the candle light is the small PCB space. It is smaller than the MR lamp space and operates from AC input voltage lines. The incandescent lamp replacement targeted for a LED driver design has a larger PCB space than the candle lamp or MR type lamp, but the power rating is larger, so the LED driver is larger. The net effect is the PCB space is limited, similar to the candle lamp. PF and Fig. 12. Example of Candle Type (L: 99mm, D: 26mm, E: 17mm) © 2011 Fairchild Semiconductor 7 Solutions for Today’s Low-Power LED Lighting Trends THD are almost mandatory for the socket bulb designs and there is the extra burden of dimmer operation. The PCB form factor for the E26/27 bulb with socket-side parabolic shape is socket side: 20 mm, LED module side: 35 mm, width: 70mm (see Fig. 14). A19, E14/17, E26/27 Socket Bulb Fairchild Solutions Isolation-type driver choices are preferred for safety. In this power range, the preferred LED driver solution is the flyback topology. With PF and THD becoming mandatory for candle lights, although it is a low-power application; many designers are using the single-stage flyback solution. The single-stage PFC flyback topology reduces PCB size because it can eliminate the input electrolytic bulk capacitor. A further reduction in component count is realized by using a single-stage Primary-Side Regulation (PSR) flyback solution. With its low BOM cost, isolated characteristic, PFC, and wide input voltage range; the PFC PSR flyback is poised to become the preferred LED driver topology. TABLE 3. FAIRCHILD PSR CONTROLLERS Solutions Product Number Fig. 14. Example E26/E27 PCB Form Factor Efficiency needs to be over 75%. Dimmer design requirements include being compatible with various holding currents, operating linearly over a wide range of light amplitude, and preventing flicker. PSR and PSR PFC Flyback Controller IC FL103 (SOIC-8) FL7730 (SOIC-8) FL7732 (SOIC-8) Controller IC with integrated MOSFET FSEZ1317NY (DIP-7) FSEZ1317MY (SOIC-7) In the PSR topology, no secondary-side feedback is required; which eliminates the opto-isolator, the error amplifier (such as TL431), and the compensating and bias resistors and capacitors. Fig. 15 illustrates a simplified PSR schematic. Passive Filter VS BD FL103 FSEZ1317 Fig. 15. Primary Side Regulator Schematic © 2011 Fairchild Semiconductor 8 Solutions for Today’s Low-Power LED Lighting Trends The advantages of PSR flyback topology include: The single-stage solution limits the number of components and ultimately fits into a smaller design space. The FL103 50kHz operating switching frequency helps the flyback magnetic transformer fit within volume constraints. The integrated MOSFET option with the FSEZ1317 reduces the component count, saving additional PCB space. The reduction in components from a PSR topology helps meet cost reduction pressure. No secondary-feedback circuits are needed, which creates an immediate reduction in components and an improvement in reliability (without counting the opto-isolator or TL431). Fairchild’s PSR topology includes TRUECURRENT™ technology, the industry leading-edge constant-current performance of <±3 %, which provides consistent high-quality light radiation. The solution is isolated. The single-stage flyback topology can meet PF and THD requirements. The PSR flyback operates in two modes, Constant Voltage (CV) and Constant Current (CC). LED drivers should operate in the CC Mode to better control the light output from the LED string. Fig. 16 shows the I-V characteristics of the PSR regulated flyback. Fig. 16. I-V Output Characteristics of a PSR Flyback LED Driver Discontinuous Conduction Mode (DCM) is preferred for PSR because it allows for better output regulation. Typical waveforms are shown in Fig. 17. © 2011 Fairchild Semiconductor Fig. 17. Waveforms of DCM Flyback Converter When operating in Constant Voltage regulation mode, during the inductor current discharge time tDIS, the sum of the output voltage and diode forward-voltage drop is reflected to the auxiliary winding side. Since the diode forward-voltage drop decreases as current decreases, the auxiliary winding voltage reflects the output voltage at the end of diode conduction time tDIS. By sampling the auxiliary winding voltage at the end of the diode conduction time, the output voltage information is obtained. When operating in Constant Current regulation mode, the output current can be estimated using the peak drain current IPEAK and the inductor current discharge time tDIS because the output current is the same as the average of the diode current in steady state. With Fairchild’s TRUECURRENT™ technology, constant current output can be precisely controlled. For more LED driver design information using primary-side regulated controllers, reference Fairchild application notes AN-9735 — Design Guideline for LED Lamp Control Using Primary-Side Regulated Flyback Converter, FAN103 & FSEZ1317 and AN-9741 — Design Guideline for LED Lamp Control Using Primary-Side Regulated Flyback Converter, FL103M. These are on the Fairchild website under LED Lighting Low Power at the following address: http://www.fairchildsemi.com/applications/diagrams/l ighting_low_power.html 9 Solutions for Today’s Low-Power LED Lighting Trends V. PAR16,20,30,38 LAMP PAR16,20,30,38 Lamp System Configuration These lamp types are AC voltage input, power rating between 4W~20W, socket is screw type E26/27 or 2 pin type GU10, as shown in Fig. 18. good solution is the single-stage flyback control PWM IC with CRM PFC, space permitting. The advantage is less design complexity with good efficiency. Compared with a complex two-stage approach, it provides high PF and low THD and does not require an input electrolytic bulk capacitor. Fig. 20 shows a basic single-stage PFC schematic. No Input Bulk Capacitor Passive Filter ZCD Fig. 18. Example PAR Lamp Dimensions (L: 95mm, D: 92mm, B: BD 26mm) With the larger lamp size, there is more space to contain the LED driver solution and PF and low THD are mandatory. PAR16,20,30,38 Lamp LED Driver Challenges The higher wattage values of these LED lamps can create a higher Vds,peak across the MOSFET, resulting in the need for a higher BVDss-rated MOSFET. The BVDss rating must derate for the high-voltage spike due to a higher input current. Fig. 19 shows the voltage spike as the sum of Vds,peak = VIN+nVO+VOS where nVO is the reflected output voltage, also known as VRO. CRM PFC PWM IC PFC FL6961 OR FL7930B/C CC&CV isolated feedback Fig. 20. Representative Single-Stage PFC Schematic Fairchild solutions are shown in Table 4 with a comparison of single-stage flyback versus a two-stage approach compared in Table 5. TABLE 4. FAIRCHILD SINGLE-STAGE PFC FLYBACK SOLUTIONS Single Stage PFC Flyback Solutions Product Number FL6961 (SOIC-8) Controller IC FL7930B/FL7930C (SOIC-8) TABLE 5. SINGLE-STAGE VS. TWO-STAGE LED DRIVER Single Stage Two Stage VIN Universal Universal Configuration Flyback Boost + Flyback Switch ~800V MOSFET~200V Rectifier ~500V MOSFET X 2ea ~ 100V Rectifier Control IC 1ea PWM IC 2ea PWM IC (or Combination Controller) Electrolytic Capacitor Output (~100V) DC Link (450V) Output (~100V) Efficiency Higher Lower Output Ripple Current Higher Lower BOM Lower Higher Fig. 19. Vds,peak vs. MOSFET Derating A snubber is used to limit the VOS peak voltage spike, but the snubber dissipates energy, which decreases the LED driver efficiency: (1) PAR16,20,30,38 Lamp Fairchild Solutions The LED driver designer can chose among the PSR PFC Flyback, a single-stage PFC flyback, or consider a two-stage approach. The PSR PFC solution described in the previous section is a good choice for this LED driver topology. In certain designs, however, another © 2011 Fairchild Semiconductor 10 Solutions for Today’s Low-Power LED Lighting Trends In addition to the previously mentioned PSR LED design driver application notes, reference AN-9737 — Design Guideline for Single-Stage Flyback AC-DC Converter Using FL6961 found on the Fairchild website under LED Lighting Low Power at: http://www.fairchildsemi.com/applications/diagrams/l ighting_low_power.html VI. CONCLUSION Low-power LED driver applications were reviewed, presenting trends and challenges. Although there are differences in the various types of LED lamps, there are only a few different requirements for the LED driver by lamp type. In general, the basic requirements are similar: a low BOM count and cost, small outline for the PCB, high efficiency, high PF, and low THD. Fairchild solutions include the AC-DC non-isolated PFC buck topology or single-stage PFC primary-side regulation offline topology, reducing the need for multiple suppliers and technology inputs. Visit Fairchild’s low-power LED website for information on LED driver controllers, discrete semiconductors, reference designs, and application notes: http://www.fairchildsemi.com/applications/diagrams/l ighting_low_power.html In addition, Fairchild’s Global Power ResourceSM Center is the industry standard for customer design support. The site offers online tools, FAE contacts, and information about regional centers staffed by power engineers. Fairchild Semiconductor: Solutions for Your Success™. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] U.S. Department of Energy: Solid State Lighting website, http://www1.eere.energy.gov/buildings/ssl/index.html Cree’s Lighting the LED Revolution, LED 101, http://www.creeledrevolution.com/learn U.S. Department of Energy , Solid-State Lighting: Brilliant Solutions for America's Energy Future, http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/ssl_broc hure_june2011.pdf Business Wire , 2010 Worldwide High-Brightness LED Market Grew 93 Percent According to Strategies Unlimited, http://www.businesswire.com/news/home/20110223005343/en/2010Worldwide-High-Brightness-LED-Market-Grew-93 U.S. Department of Energy, SSL Research and Development Multi-Year Program Plan Mar 2011 (Updated May 2011), http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/ssl_myp p2011_web.pdf U.S. Department of Energy: Solid State Lighting website, http://www1.eere.energy.gov/buildings/ssl/sslbasics_whyssl.html U.S. Department of Energy, SSL Research and Development Manufacturing Roadmap July 2011, http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/ssl_man uf-roadmap_july2011.pdf Fred Welsh, Cost Trends for Solid State Lighting, DOE 2011 Solid-State Lighting Market Introduction Workshop, http://apps1.eere.energy.gov/buildings/publications/pdfs/ssl/welsh_c ost_sslmiw2011.pdf Brian Johnson is the Lighting Specialist for Fairchild’s LED lighting products segment in Americas and Europe. He joined Fairchild after 20+ years of rotating in Development and Marketing positions in the power electronics industry. He graduated from Purdue University with a B.S.E.E. and M.S.E.E. James Lee is the Marketing Specialist for VII. CONTACT INFORMATION To contact Fairchild Semiconductor, please go to: http://www.fairchildsemi.com/cf/sales_contacts/. For information on other products, design tools, and sales contacts, visit: http://www.fairchildsemi.com © 2011 Fairchild Semiconductor Fairchild’s lighting products segment. He has worked for over eight years as a power solution semiconductor development marketer at Fairchild. He graduated from Ajou University with a B.S.E.E. and L.L.B Laws. 11