* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download speed control of dc motor using combined armature and field control

History of electric power transmission wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electrification wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Distributed control system wikipedia , lookup

Opto-isolator wikipedia , lookup

Current source wikipedia , lookup

Resilient control systems wikipedia , lookup

Control theory wikipedia , lookup

Buck converter wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Power electronics wikipedia , lookup

Control system wikipedia , lookup

Rectiverter wikipedia , lookup

Stray voltage wikipedia , lookup

Mains electricity wikipedia , lookup

Voltage optimisation wikipedia , lookup

Alternating current wikipedia , lookup

Electric motor wikipedia , lookup

Commutator (electric) wikipedia , lookup

Induction motor wikipedia , lookup

Electric machine wikipedia , lookup

Stepper motor wikipedia , lookup

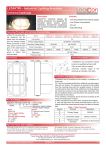

SPEED CONTROL OF DC MOTOR USING COMBINED ARMATURE AND FIELD CONTROL Mustafa Aboelhassan Doctoral Degree Programme (2), FEEC BUT E-mail: [email protected] Supervised by: Jiří Skalický E-mail: [email protected] ABSTRACT The aim of this investigation is to describe the principle of DC motor speed control using nonlinear combined control (armature voltage and field current). For the armature control mode, the field current is held constant and an adjustable voltage is applied to the armature. In the field control mode, the armature voltage is held constant and an adjustable voltage is applied to the field. The mathematical model of a separately excited DC motor (SEDM) with independent armature/filed control can be obtained by considering the electrical system, electromagnetic interaction and mechanical system. Simulation models of DC motor speed control methods and feedback control system for DC motor drives have been developed using MATLAB/Simulink. 1. INTRODUCTION DC motors consist of rotor-mounted windings (armature) and stationary windings (field poles). In all DC motors, except permanent magnet brushless motors, current must be conducted to the armature windings by passing current through carbon brushes that slide over a set of copper surfaces called a commutator, which is mounted on the rotor. The commutator bars are soldered to armature coils. The brush/commutator combination makes a sliding switch that energizes particular portions of the armature, based on the position of the rotor. This process creates north and south magnetic poles on the rotor that are attracted to or repelled by north and south poles on the stator, which are formed by passing direct current through the field windings. It's this magnetic attraction and repulsion that causes the rotor to rotate. The greatest advantage of DC motors may be speed control. Since speed is directly proportional to armature voltage and inversely proportional to the magnetic flux produced by the poles, adjusting the armature voltage and/or the field current will change the rotor speed. Today, adjustable frequency drives can provide precise speed control for AC motors, but they do so at the expense of power quality, as the solid-state switching devices in the drives produce a rich harmonic spectrum. The DC motor has no adverse effects on power quality. The dynamic behavior of the DC machine is mainly determined by the type of the connection between the excitation winding and the armature winding including the commutation and compensation winding: Separately excited DC machine: excitation and armature winding supplied at separate voltages. Shunt DC machine: excitation and armature winding are connected in parallel (i.e. fed by the same source). Series-wound machine: the excitation and the armature winding connected in series; if the stator is laminated, series-wound machines can operate at AC current. Compound machine: This is a combination of shunt DC machine and series-wound machine (both shunt and series winding are available). In special cases shunt-, series-, and separate excitation can be combined There are three methods of controlling the speed of the shunt and separately excited dc motor, armature voltage speed control, field flux speed control and armature resistance speed conrol (speed may be controlled by changing Ra). 2. VOLTAGE SPEED CONTROL OF A SEPARATELY EXCITED DC MOTOR The field current, if, is constant (and hence the flux density B is constant), and the armature voltage is varied. A constant field current is obtained by separately exciting the field from a fixed dc source. The flux is produced by the field current, therefore, essentials constant. Thus the torque is proportional only to the armature current. 3. FIELD SPEED CONTROL OF A SEPARATELY EXCITED DC MOTOR We can also control the dc motor, that is vary its speed by varying the field flux. The method of control is generally used when the motor has to run above its rated speed. To understand the operation of field control suppose that the dc motor running at a constant speed. If the field current is reduced by reducing the voltage across the field coil, the flux density will be reduced. This will reduce the back emf instantaneously and will cause armature current to increase resulting in the motor speed increasing. Consequently the back emf will increase and a new equilibrium will be established at a higher speed. With field control one can achieve as high a speed as five time the rated speed. The armature current, ia, is kept constant and the flux density B is varied by varying if. 4. COMBINED ARMATURE AND FIELD CONTROL OF SEDM The speed of a separately excited dc motor could be varied from zero to rated speed mainly by varying armature voltage in the constant torque region. Whereas in the constant power region, field flux should be reduced to achieve speed above the rated speed. Torque and limitations in combined armature voltage and field control can be shown in figure 1. Torque Pm Torque Pm Armature Voltage Control m Field Control rated Speed Fig. 1: Combined armature voltage and field current control 5. MODELING AND CONTROL OF SEDM USING MATLAB/SIMULINK scope Ia Scope ome Armature Current Step 0.04s+1 0.06s+1 40 0.02s 0.266s 0.00167s+1 PI - Controller (ome) PI - Controller (ia) Out1 Step TL In1 Armature Current Limiter Out1 Armature Converter In1 In1 In2 Out1 Angular Velocity Out2 Out3 Bach EMF Voltage Out4 DC motor Field Current Limiter all 370 Constant 1 0.001s+1 0.01s+1 0.4s PI - Controller (E) Out1 0.3s+1 0.003s PI - Controller (ib) 18 Scope E 0.005s+1 Exciter Converter Scope Ib In1 Field Current Limiter Fig. 2: Block diagram of combined armature voltage and field current control Armature Current ia [A] Field Current if [A] 100 4.5 4 50 3.5 3 0 2.5 2 -50 1.5 1 -100 0.5 -150 0 100 200 300 400 500 600 Time (Seconds) 700 800 900 1000 0 0 200 400 600 Time (Seconds) a) 800 1000 1200 b) Fig. 3: a) Step response of armature current b) Step response of field current Back EMF voltage [V] Angular Velocity ome[rad/sec] 500 250 400 200 300 150 200 100 100 50 0 0 -50 -100 0 200 400 600 Time (Seconds) a) 800 1000 1200 -200 0 200 400 600 Time (seconds) 800 b) Fig. 4: a) Angular velocity step response b) Back EMF voltage Step response 1000 1200 6. CONCLUSION Non-linearity of the combined field and armature control system has been studied and carried out using Matlab/Simulink. A DC motor drive for the armature and associated field winding of the motor includes an armature feedback loop responsive to the current flow in the armature, an input command signal such as a speed control signal, and the actual speed of the armature for providing a control of the current supplied by a DC source means to the armature to thereby provide speed control of the motor. A field feedback loop control is also provided and includes means responsive to the voltage across the armature and to the line voltage supplied to the armature for providing a control of the field intensity to assure that the back EMF of the armature is always less than the available DC voltage supplied to the armature. This dual feedback control provides for a faster response time of the armature throughout its total speed range together with the feature of a constant torque for different speeds. REFERENCES [1] Isaac, A., Victor, S.: Mathematical Modeling and Computer Simulation of a Separately Excited dc Motor with Independent Armature/field control. In proc. IEEE. Ind. Electron., vol. 37. [2] IEM RWTH, Institut Fur Elektrische Machinen, Lab electrical Power Engineering 1. Operating behaviour of the DC machine. [3] John, J., Constantine, H., Stuart, N.: Linear Control System Analysis and Design with MATLAB, CRC Press, 2003. [4] Michael A., Mohammad, H.: PID Control, New Identification and Design Methods 2006. [5] Mongkol, K.: Electric motor drive, lecure 4, KMUTT [6] Muhamad, Z.: Electrical machina, DC Motor-2 [7] http://ecmweb.com/ops/electric_direct_current_motor/ [8] Zuo L., Fang L., Muhammad H.: Speed Nonlinear Control of DC Motor Drive With Field Weakening. IEEE. Ind. Applications., vol. 39. no 2, March/April 2003.