* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download 1.2 MHz Step-up Converter for Display Bias

Immunity-aware programming wikipedia , lookup

Mercury-arc valve wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power inverter wikipedia , lookup

Three-phase electric power wikipedia , lookup

Electrical substation wikipedia , lookup

Electrical ballast wikipedia , lookup

Integrating ADC wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Two-port network wikipedia , lookup

Distribution management system wikipedia , lookup

Stray voltage wikipedia , lookup

Power MOSFET wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Current source wikipedia , lookup

Surge protector wikipedia , lookup

Schmitt trigger wikipedia , lookup

Alternating current wikipedia , lookup

Power electronics wikipedia , lookup

Voltage regulator wikipedia , lookup

Voltage optimisation wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Mains electricity wikipedia , lookup

Current mirror wikipedia , lookup

Switched-mode power supply wikipedia , lookup

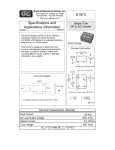

A8483 1.2 MHz Step-up Converter for Display Bias Supply This device is in production, however, it has been deemed Pre-End of Life. The product is approaching end of life. Within a minimum of 6 months, the device will enter its final, Last Time Buy, order phase. Date of status change: June 3, 2013 Recommended Substitutions: For existing customer transition, and for new customers or new applications, contact Allegro Sales. NOTE: For detailed information on purchasing options, contact your local Allegro field applications engineer or sales representative. Allegro MicroSystems, LLC reserves the right to make, from time to time, revisions to the anticipated product life cycle plan for a product to accommodate changes in production capabilities, alternative product availabilities, or market demand. The information included herein is believed to be accurate and reliable. However, Allegro MicroSystems, LLC assumes no responsibility for its use; nor for any infringements of patents or other rights of third parties which may result from its use. A8483 1.2 MHz Step-up Converter for Display Bias Supply Features and Benefits Description • Output voltage up to 35 V • 2.5 to 10 V input • 0.9 to 18 V input with separate bias supply • Delivers 15 V at 15 mA with 2.7 V input • Constant 1.2 MHz switching frequency provides low noise • 350 mA switch current limit • 1 μA shutdown current • Low-noise PWM/analog dimming The A8483 is a current mode step-up dc-to-dc converter, available in a 5-pin 3 mm × 3 mm thermally enhanced TDFN lead (Pb) free package. Smaller external components and integrated 36 V switch reduce component count and footprint for a variety of applications. Applications: • OLED bias supply / WLED backlight • Portable battery-powered equipment • Cellular phones • PDAs (Personal Digital Assistant) • Camcorders, personal stereos, MP3 players, cameras • Mobile GPS systems Package: TDFN (suffix EK) 3 × 3 mm, 0.75 mm Nominal Height Approximate Scale 1:1 VOUT 5 VIN VSUPPLY EN 4 Li-ion 2.5 V to 5.5 V GND 2 L1 10 µH 5 VIN R1 820 kΩ A8483 C1 1 µF IOUT1 + IOUT2 = 15 mA D1 1 SW FB 3 C2 1µ µF OLED L1 10 µH VSUPPLY EN 4 Li-ion 2.5 V to 5.5 V Enable R1 732 kΩ A8483 C1 1 µF GND 2 FB 3 VOUT2 VSUPPLY C1 1 µF R1 768 kΩ for VOUT = 32 V 604 kΩ for VOUT = 25 V A8483 EN 4 5V GND 2 Connect either VZ or VBIAS D1 1 SW FB 3 VSUPPLY 12 V 5 C1 1 µF Enable VIN R1 768 kΩ for VOUT = 32 V 604 kΩ for VOUT = 25 V GND 2 FB 3 R2 15 kΩ C3 0.1 µF Figure 3. LCD TV, Plasma TV Bias, FED Display, Varactor Diode Bias. Using 5 V input. Figure 4. LCD TV, Plasma TV Bias, FED Display, Varactor Diode Bias. Using 12 V input. VOUT VOUT VSUPPLY Li-ion 2.5 V to 5.5 V L1 10 µH 1 SW A8483 C1 1 µF EN 4 GND 2 R3 24 kΩ FB 3 Enable Cf 0.01 µF R2 5 kΩ L1 10 µH 5 VIN D1 C2 0.22 µF VC Analog Voltage or PWM R1 47 Ω VSUPPLY Li-ion 2.5 V to 5.5 V R1 560 kΩ A8483 C1 1 µF EN 4 GND 2 A8483-DS, Rev. 1 C2 1 µF FB 3 Enable R3 160 kΩ Analog Voltage or PWM 10 kHz Figure 5. WLED Backlighting. D1 1 SW OLED 5 VIN C2 1µ µF / 50 V Enable 5V R2 15 kΩ D1 1 SW A8483 EN 4 VBIAS 32 V, 40 mA 25 V, 80 mA VOUT L1 22 µH VZ 7.5 V C2 1µ µF / 50 V C4 0.47 µF Figure 2. Small LCD Bias Supply. Li+ battery to ±12 V. 32 V, 18 mA 25 V, 25 mA VOUT –12 V D2 R2 39 kΩ Figure 1. OLED Bias Supply. Use for cell phones, MP3 players, DSCs, and PDAs. 5 VIN C3 0.47 µF C2 0.47 µF Enable R2 39 kΩ L1 10 µH VOUT1 +12 V D1 1 SW R2 47 kΩ Cf 1 nF Cf for PWM dimming only VC Figure 6. OLED Bias Supply. Use for low-noise PWM dimming, or with analog voltage through the FB pin. 1.2 MHz Step-up Converter for Display Bias Supply A8483 Selection Guide Use the following complete part number when ordering: Part Number Packing* Description A8483EEKTR-T 7-in. reel, 1500 pieces/reel Surface Mount *Contact Allegro for additional packing options. Functional Block Diagram FB SW A1 VIN VREF 1.25 V 615 mV A2 RC R Q Driver S CC Σ Ramp Generator EN Enable 1.2 MHz Oscillator GND Device Pin-out Diagram Terminal List Table Pin Name Function 1 SW Internal power FET 2 GND Ground 3 FB Feedback input 4 EN Enable input 5 VIN Input supply SW 1 5 VIN GND 2 FB 3 4 EN Absolute Maximum Ratings Package Thermal Characteristics SW Pin ..................................................................................–0.3 to 36 V Remaining Pins .....................................................................–0.3 to 10 V Operating Ambient Temperature , TA .................................... –40°C to 85°C Junction Temperature, TJ(max)............................................................. 150°C Storage Temperature, TS .................................................. –55°C to 150°C RθJA = 50 °C/W, on a 4-layer board. Additional information is available on the Allegro Web site. Allegro MicroSystems, LLC 115 Northeast Cutoff Worcester, Massachusetts 01615-0036 U.S.A. 1.508.853.5000; www.allegromicro.com 2 1.2 MHz Step-up Converter for Display Bias Supply A8483 ELECTRICAL CHARACTERISTICS at TA = 25°C, VIN = 3 V (unless otherwise noted) Characteristics Symbol Test Conditions Min. Typ. Max. Units 2.5 – 10 V Active: IOUT = 15 mA, VOUT = 12 V – 2.5 3.5 mA Shutdown (EN = 0 V) – 0.1 1 μA 590 615 640 mV – Input Voltage Range VIN Supply Current ISUP Feedback Reference Voltage VFB – IFB VFB = 0.615 V – 50 100 nA ISWLIM – – 350 – mA FSW – 0.8 1.2 1.6 MHz D – 85 90 – % Feedback Input Current Switch Current Limit Switch Frequency Switch Maximum Duty Cycle VCE(SAT) ISW = 0.2 A – 350 – mV ISL VSW = 36 V – – 5 μA Input Threshold Low VIL – – – 0.4 V Input Threshold High VIH – 1.5 – – V Leakage IIL – – 1 μA Switch Saturation voltage Switch Leakage Current Enable Input Input Leakage Operating Characteristics (VIN = 3 V) Feedback Bias Current versus Temperature Efficiency versus Input Voltage VOUT = 15 V; Toko 1098AS-100M Inductor VFB = 0.615 V 65 90 85 62 75 IFB (nA) Efficiency (%) 80 IOUT (mA) 70 25 15 2 65 60 59 56 53 55 50 50 2 3 4 5 6 7 8 9 10 –50 0 VIN (V) 100 150 Quiescent Supply Current versus Temperature 1.25 2.6 1.20 2.5 ISUPQ (mA) FSW (MHz) Switching Frequency versus Temperature 1.15 1.10 1.05 2.4 2.3 2.2 1.00 –50 50 Temperature (°C) 2.1 0 50 Temperature (°C) 100 150 –50 0 50 100 150 Temperature (°C) Allegro MicroSystems, LLC 115 Northeast Cutoff Worcester, Massachusetts 01615-0036 U.S.A. 1.508.853.5000; www.allegromicro.com 3 1.2 MHz Step-up Converter for Display Bias Supply A8483 Functional Description Pin Functions VIN. Supply to the control circuit. A bypass capacitor, C1, must be connected from close to this pin to GND. GND. Ground reference connected directly to the ground plane. The feedback resistor should have a separate connection directly to this point. EN. Voltage lower than 0.4 V disables the A8483 and puts the control circuit into the low-power sleep mode. Voltage greater than 1.5 V fully enables the A8483. SW. Low-side switch connection between the inductor, L1, and ground. Because rapid changes of current occur at this pin, the traces on the PCB that are connected to this pin should be minimized. In addition, L1 and the diode, D1, should be connected as close to this pin as possible. FB. Feedback pin for OLED voltage control or WLED current control. The reference voltage is 615 mV. Connect the feedback resistor close to this pin to minimize noise. Device Operation The A8483 uses a 1.2 MHz constant switching frequency currentmode control scheme to regulate the output voltage or current through the load. A typical OLED bias supply is shown in figure 7. For driving OLEDs, output voltage is sensed by the FB pin through a voltage divider network. Output voltage, VOUT (V), is set according to the following equation: VOUT = R1 + R2 R2 (1) 0.615 . A typical WLED backlight supply is shown in figure 8. The load current, ILOAD, is set by the selecting the external sense resistor, R1, to produce 615 mV at the desired load, for example: Voltage sensed across the FB pin is compared with the internal 615 mV reference to produce an error signal. The switch current is sensed by the internal sense resistor and compared to the error signal for current mode PWM control. As the error signal increases, ILOAD , increases to increase either output voltage, VOUT, or current, IOUT , such that the FB pin voltage follows the internal 615 mV reference voltage. As ILOAD is reduced, the energy required in the inductor, L1, also reduces, resulting in the inductor current dropping to zero for low load current levels. This is known as Discontinuous mode operation and results in some low-frequency ripple. The average load current will, however, remain regulated down to zero. In Discontinuous mode, when ILOAD drops to zero, the voltage at the SW pin rings, due to the resonant LC circuit formed by L1 and the switch and diode D1 capacitance. This ringing is low-frequency and is not harmful. It can be damped with a resistor across the inductor but this will reduce efficiency and is not recommended. VOUT VOUT VSUPPLY Li-ion 2.5 V to 5.5 V L1 10 µH 1 SW EN 4 GND 2 5 VIN R1 820 kΩ A8483 C1 1 µF D1 FB 3 OLED 5 VIN (2) R1 = 0.615 ILOAD . C2 1µ µF Enable R2 39 kΩ Figure 7. OLED Bias Supply. Use for cell phones, MP3 players, DSCs, and PDAs. (Circuit also shown in figure 1.) VSUPPLY Li-ion 2.5 V to 5.5 V L1 10 µH 1 SW D1 A8483 C1 1 µF EN 4 GND 2 R3 24 kΩ FB 3 Enable Cf 0.01 µF R2 5 kΩ C2 0.22 µF VC Analog Voltage or PWM R1 47 Ω Figure 8. WLED Backlighting. (Circuit also shown in figure 5.) Allegro MicroSystems, LLC 115 Northeast Cutoff Worcester, Massachusetts 01615-0036 U.S.A. 1.508.853.5000; www.allegromicro.com 4 1.2 MHz Step-up Converter for Display Bias Supply A8483 Applications Information Display dimming can be achieved by controlling the output voltage, VOUT , using the FB pin. The circuitry behind the FB pin is flexible, to accommodate a variety of schemes used for dimming: • Adjust the duty cycle of the pulse train applied to the FB pin through resistor R3, as shown in figure 11. Capacitor Cf is used to generate the average voltage level. Variation of output voltage with PWM duty cycle is shown in figure 9. • Apply a constant dc voltage to the FB pin through resistor R3, as shown in figure 12. Variation of output voltage with dc voltage are shown in figure 10. • Selection of the resistor connected between the FB pin and GND, as shown in figure 12 for OLED applications, and in figure 13 for WLED applications. The voltage drop across the transistor should be negligible compared to the FB sense voltage. Soft Start Output voltage rise time at power-on can be extended by using a soft start circuit, such as the one shown in figure 14 for an OLED application, and in figure 16 for a WLED application. At poweron, the device duty cycle begins initially at a high level, drawing a large current from the input supply, VIN. The soft-start circuits shown can reduce the level of current flow by controlling the FB pin. When a signal is applied to the EN pin, capacitor C3 discharges, pulling the FB pin high, and reducing VOUT to a minimum. When the EN signal is removed, C3 recharges and as it does, the voltage drop across R3 reduces, allowing the device duty cycle to VOUT L1 10 µH 5 VIN VSUPPLY R1 560 kΩ A8483 C1 1 µF EN 4 Li-ion 2.5 V to 5.5 V D1 1 SW GND 2 C2 1 µF OLED Dimming Control FB 3 Enable R3 160 kΩ 17 R2 47 kΩ Cf 1 nF 15 Analog Voltage or PWM 10 kHz Cf for PWM dimming only VC Figure 11. OLED Bias Supply. Use for low-noise PWM dimming, or with analog voltage through the FB pin. 11 9 VOUT 7 L1 10 µH 5 VIN 5 VSUPPLY 3 10 20 30 40 50 60 70 80 90 Duty Cycle (%) D1 R1 560 kΩ A8483 C1 1 µF Li-ion 2.5 V to 5.5 V 1 SW EN 4 GND 2 C2 10 µF FB 3 Cf 1 nF Enable R3 47 kΩ Figure 9. PWM Dimming Control of Duty Cycle. Performance of 5 V input circuit shown in figure 3. OLED VOUT (V) 13 R2 47 kΩ VC Q1 20 Figure 12. OLED Dimming Control. Single-bit resolution using external transistor. 18 16 VOUT (V) 14 VOUT L1 10 µH 12 5 VIN 10 8 VSUPPLY 6 Li-ion 2.5 V to 5.5 V 4 2 1 SW D1 A8483 C1 1 µF EN 4 GND 2 FB 3 C2 0.22 µF Enable R2 80 Ω 0 0.2 0.4 0.6 VC (V) 0.8 1 Figure 10. DC Voltage Dimming Control of Duty Cycle. Performance of circuit shown in figure 11. R1 80 Ω VC Q1 Figure 13. WLED Dimming Control. Single-bit resolution using external transistor. Allegro MicroSystems, LLC 115 Northeast Cutoff Worcester, Massachusetts 01615-0036 U.S.A. 1.508.853.5000; www.allegromicro.com 5 1.2 MHz Step-up Converter for Display Bias Supply A8483 increase gradually. When the voltage drop across R3 is reduced to less than about 0.8 V, the feedback from the sense resistor, R1, takes over full control of the output voltage. The length of the soft start delay depends on the combined effect of R2, R3, R4, C3 and the amplitude of the EN signal. The delay can be adjusted by the selection of these values. VOUT VSUPPLY L1 10 µH D1 1 SW R1 820 kΩ A8483 C1 1 µF EN 4 Li-ion 2.5 V to 5.5 V GND 2 FB 3 OLED 5 VIN C2 1 µF D2 Enable R4 47 kΩ Component Selection The component values shown in figure 1 are sufficient for most applications. To reduce output ripple, the value of the output inductor, L1, may be increased, but in most cases this results in excessive board area and additional cost. Inductor Selection (L1). With an internal PWM frequency of 1.2 MHz, the optimum inductor value for most cases would be 10 μH. The inductor should have low winding resistance, typically < 1 , and the core should have low losses at 1.2 MHz. For worst-case conditions of high output voltage and current, and low input voltage, the inductor should be rated at the switch current limit of 350 mA. If high temperature operation is required, derating should be considered. In some cases where lower inductor currents are expected, the current rating can be decreased. Several inductor manufacturers, including Coilcraft, Murata, Panasonic, Sumida, Taiyo Yuden, and TDK, have and are developing suitably small-size inductors. Two recommended inductors are: • TDK: NLCV32T-100K-PF, 10 μH • Toko: 1098AS-100M, 10 μH C3 10 nF R3 24 kΩ Figure 14. OLED Soft Start Circuit EN VOUT IIN Figure 15. OLED Soft Start Circuit. Performance of circuit shown in figure 14. VOUT 5 VIN VSUPPLY Li-ion 2.5 V to 5.5 V L1 22 µH 1 SW D1 A8483 C1 1 µF EN 4 GND 2 R2 5 kΩ FB 3 age to reduce conduction losses, and a low capacitance to reduce switching losses. Schottky diodes can provide both these features if carefully selected. The forward voltage drop is a natural advantage for Schottky diodes, and it reduces as the current rating of the component increases. However, as the current rating increases, the diode capacitance also increases, so the optimum selection is usually the lowest current rating above the circuit maximum. In this application, an average current rating of 100 to 200 mA is usually sufficient. Capacitor Selection. Because the values recommended for the capacitors are low, ceramic capacitors are the best choice for this application. To reduce performance variation over temperature changes, low drift types such as X7R and X5R should be used. C2 0.22 µF D2 Enable Diode Selection (D1). The diode should have a low forward volt- R2 39 kΩ R4 47 kΩ C3 0.01 µF R3 24 kΩ R1 4.75 Ω Figure 16. WLED Soft Start Circuit C1. A 1.0 μF capacitor on the VIN pin is suitable for most applications. In cases where large inductor currents are switched, a larger capacitor may be needed. C2. The output capacitor can be as small as 0.22 μF for most applications and most VIN / VOUT combinations. Increasing this capacitor value aids in reducing ripple and increasing efficiency in low input voltage / high output voltage conditions. Suitable capacitors are available from: TDK, Taiyo Yuden, Murata, Kemet, and AVX. Allegro MicroSystems, LLC 115 Northeast Cutoff Worcester, Massachusetts 01615-0036 U.S.A. 1.508.853.5000; www.allegromicro.com 6 1.2 MHz Step-up Converter for Display Bias Supply A8483 IOUT1 + IOUT2 = 15 mA L1 10 µH 5 VIN C3 0.47 µF C2 0.47 µF 13.0 12.8 12.6 VOUT1 12.4 12.2 EN 4 Li-ion 2.5 V to 5.5 V R1 732 kΩ A8483 C1 1 µF +12 V VOUT (V) VSUPPLY Line Regulation VOUT1 D1 1 SW GND 2 FB 3 12.0 VOUT2 11.8 Enable D2 R2 39 kΩ VOUT2 11.6 –12 V 11.4 C4 0.47 µF 11.2 11.0 2.5 3.5 4.5 5.5 VIN (V) Figure 17. Line Regulation Perfomance for Small LCD Bias Supply, IOUT1 = IOUT2 = 7.5 mA (circuit also shown in figure 2) 32 V, 18 mA 25 V, 25 mA VOUT L1 10 µH VSUPPLY C1 1 µF 32 R1 768 kΩ for VOUT = 32 V 604 kΩ for VOUT = 25 V A8483 EN 4 5V GND 2 Load Regulation 34 D1 1 SW FB 3 VOUT = 32 V 30 C2 1µ µF / 50 V VOUT (V) 5 VIN 28 26 VOUT = 25 V 24 Enable 22 R2 15 kΩ 20 0 10 20 30 40 IOUT (mA) Figure 18.Load Regulation for LCD TV, Plasma TV Bias, FED Display, Varactor Diode Bias; VSUPPLY = 5 V (circuit also shown in figure 3) Connect either VZ or VBIAS 12 V 5 C1 1 µF VIN 5V 1 SW A8483 EN 4 VBIAS GND 2 FB 3 D1 32 R1 768 kΩ for VOUT = 32 V 604 kΩ for VOUT = 25 V Enable C3 0.1 µF Load Regulation 34 VOUT = 32 V 30 C2 1µ µF / 50 V VOUT (V) L1 22 µH VZ 7.5 V VSUPPLY 32 V, 40 mA 25 V, 80 mA VOUT 28 26 24 VOUT = 25 V 22 R2 15 kΩ 20 0 20 40 60 80 100 IOUT (mA) Figure 19. Load Regulation for LCD TV, Plasma TV Bias, FED Display, Varactor Diode Bias; VSUPPLY = 12 V (circuit also shown in figure 4). The A8483 can operate with a VSUPPLY from 0.9 to 18 V with a separate bias supply to operate the A8483 in the normal VIN range. The bias voltage can be supplied by an external power supply, such as 3.3 or 5 V, or by using a suitable Zener diode, VZ , for VSUPPLY > 10 V. Allegro MicroSystems, LLC 115 Northeast Cutoff Worcester, Massachusetts 01615-0036 U.S.A. 1.508.853.5000; www.allegromicro.com 7 1.2 MHz Step-up Converter for Display Bias Supply A8483 Leadframe plating 100% matte-tin. Solder pad layout compatible with SOT23-5 (SOT95P280-5). Package EK , TDFN 3.15 .124 2.85 .112 A B 5 Preliminary dimensions, for reference only (reference JEDEC MO-229 WEEA) Dimensions in millimeters U.S. Customary dimensions (in.) in brackets, for reference only Dimensions exclusive of mold flash, gate burrs, and dambar protrusions Exact case and lead configuration at supplier discretion within limits shown 3.15 .124 2.85 .112 A Terminal #1 mark area A B Exposed thermal pad (reference dimensions only, terminal #1 identifier appearance at supplier discretion) C Reference pad layout (reference IPC SON95P300X310-7WEEAN); adjust as necessary to meet application process requirements 1 2 5X D Reference pad layout with contact pads only; adjust as necessary to meet application process requirements SEATING PLANE 0.08 [.003] C 5X 0.45 .018 0.30 .012 C 0.80 .031 0.70 .028 0.10 [.004] M C A B 0.05 [.002] M C 0.95 .037 0.20 .008 REF 0.05 .002 0.00 .000 0.50 .020 0.30 .012 1 R0.20 .008 REF 2 1.00 .039 NOM B 5 2.00 .079 NOM 0.85 .033 MIN 5 0.45 .018 MIN 0.85 .033 MIN 5 2.00 .079 MAX 0.45 .018 MIN 0.45 .018 MIN 2.10 .083 MIN 3.80 .150 MAX 1 D 0.95 .037 0.50 .020 MIN 1.00 MAX .039 2.10 .083 MIN 3.80 .150 MAX 0.20 x 0.20 .008 x .008 REF 1 C 0.95 .037 0.50 .020 MIN Allegro MicroSystems, LLC 115 Northeast Cutoff Worcester, Massachusetts 01615-0036 U.S.A. 1.508.853.5000; www.allegromicro.com 8 1.2 MHz Step-up Converter for Display Bias Supply A8483 Allegro MicroSystems, LLC reserves the right to make, from time to time, such departures from the detail specifications as may be required to permit improvements in the performance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that the information being relied upon is current. Allegro products are not authorized for use as critical components in life-support devices or systems without express written approval. The information included herein is believed to be accurate and reliable. However, Allegro MicroSystems, LLC assumes no responsibility for its use; nor for any infringement of patents or other rights of third parties which may result from its use. Copyright© 2005-2013 Allegro MicroSystems, LLC For the latest version of this document, visit our website: www.allegromicro.com Allegro MicroSystems, LLC 115 Northeast Cutoff Worcester, Massachusetts 01615-0036 U.S.A. 1.508.853.5000; www.allegromicro.com 9