* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Single Crystal Growth by AHP Method

Survey

Document related concepts

Transcript

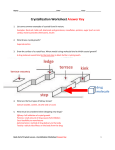

Solidification and Crystal Growth Laboratory Single Crystal Growth by AHP Method A. Dario (MSc Student), H. Ö. Sicim (MSc Student), and E. Balikci (Assist. Prof.) Department of Mechanical Engineering Introduction Single Crystal Growth Techniques Crystallization is a process in which a material in the liquid or gas phase transforms to a crystalline solid. A sample can grow as a single crystal or a polycrystal. A single crystal material has a continuous crystal lattice throughout the entire sample (Figure 1.a), whereas a polycrystal material is composed of grains having different crystal orientations separated by grain boundaries, (Figure 1.b). a) As a result of the aforementioned discussions, producing a single crystal requires a precisely controlled process. b) Figure 1. Czochralski Zone Melting Bridgman Axial Heat Processing During crystal growth an interface is formed between the solid and the second phase, liquid in melt growth. Solute redistribution, fluid flow, and heat transfer during crystal growth have a significant effect on the morphology of the solid-liquid interface. Under certain conditions a planar S/L interface may be subjected to random disturbances. If the disturbances develop into a wavy or cellular surface, the interface is unstable (Figure 2.a). If the disturbances disappear with time the interface is said to be stable (Figure 2.b). a) SCG Laboratory b) Figure 2. Instability Analysis Solid-liquid interface of a pure substance will only be unstable if the temperature gradient at the dT interface, given by G= q obeys the relationship: G<0 Currently, we are conducting a TÜBİTAK funded (1001) research project that focus on the understanding of melt growth characteristics of germanium-silicon (Ge-Si) alloy crystals, which are promising candidates in thermopower generation, photovoltaics, cell phones, handsets, GPS systems, collision warning systems, and data converters. We are using an innovative approach (Axial Heat Processing -AHP-) in this study. The AHP technique permits close control of convective effects and thermal field near the growth interface. AHP achieves these by using a heater immersed in melt near s/l interface. Power and position of the heater can be controlled as desired to promote planar interface and laminar fluid flow. Such parameters as the fluid flow, concentration fields in the melt and solid, and interface shape, position, and temperature are being assessed. All these growth parameters then will be correlated to interface instability, namely the transition from single to cellular or dendritic growth. Advantages of AHP method dz • Supplies/conducts heat axially to the s/l interface, and reduces the radial temperature gradient. Therefore reduces the radial segregation and promotes a stable and planar interface. Constitutional Undercooling: In alloys, the equilibrium solidification temperature depends on the solute composition in front of the interface. The solute piles up in front of the interface due to the smaller solubility of the solid when the distribution coefficient k is smaller than one. Figure 3. For pure diffusional mass transport mode, in the steady state situation the solute concentration decreases from C0 / k to C0 in front of the interface. This sets a temperature profile before the interface. There may be then a constitutionally undercooled region in the liquid depending on the temperature gradient at the interface imposed by an external heating system. • Minimizes buoyancy driven convection, but induces a forced flow in the melt. • Separates the melt into two region with different concentrations. How the system operates 20 Thermocouples Data acquisition system Chiller SCR, heater drivers Software Vacuum pump Motor driver Figure 5. Figure 4. Interface stability Criterion: GL Gc Output card dT GL q dz z 0 mC0 R dC dT Gc L m L DL dz z 0 dz A single crystal sample mC 0 T0 mC 0 R GL DL G L T0 R DL mC 0 k 1 T0 k GL mC0 k 1 R kDL Silicon-Germanium crystals are grown in a cylindrical shape with a height of 50mm and a diameter of 40mm. These crystals are then halved along their length and their crystal structure are analyzed using SEM, EDS, and four point probe methods. Grainy region Single crystal region Seed