* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Heat Resistance, Water Resistance and Bin Storage Stability in

Survey

Document related concepts

Transcript

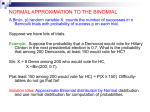

ELASTOMERE UND KUNSTSTOFFE ELASTOMERS AND PLASTICS Chlorosulfonated polyethylene Heat resistance Water resistance Bin stability Achieving optimum heat and water resistance in chlorosulfonated polyethylene (CSM) based compounds has usually required the use of lead containing materials as acid acceptors. Bin storage stability, or specifically poor or marginal bin stability, can be an issue with some CSM formulations under hot, humid storage conditions. This paper discusses results showing hydrotalcite is a suitable replacement for lead in heat and water-resistant CSM formulations. It also discusses ways to compound CSM for improved bin stability and the use of maleated polybutadiene resins as mill release agents having minimal impact on bin stability. Hitze-, WasserbestaÈndigkeit und LagerstabilitaÈt bei CSM-Compounds Chlorsulfoniertes Polyethylen HitzebestaÈndigkeit WasserbestaÈndigkeit LagerstabilitaÈt Um eine optimale Hitze- und WasserbestaÈndigkeit bei auf chlorsulfoniertem Polyethylen (CSM) basierenden Elastomermischungen zu erreichen, wurden uÈblicherweise bleihaltige Verbindungen eingesetzt, um entstehende SaÈure zu binden. Unzureichende oder kritische LagerstabilitaÈt der Fertigmischung kann fuÈr einige CSM-Mischungen bei warmen, feuchten Lagerbedingungen zu Problemen fuÈhren. Die vorliegende Arbeit beschreibt den Einsatz von Hydrotalcit als eine geeignete Alternative fuÈr bleihaltige Verbindungen in waÈrme- und wasserbestaÈndigen CSM-Mischungen. Es werden ebenfalls MoÈglichkeiten beschrieben, CSM fuÈr verbesserte LagerbestaÈndigkeit anzumischen, und in wieweit maleinsaÈuremodifizierte Polybutadienharze als Trennmittel auf dem Walzwerk eingesetzt werden koÈnnen, ohne die LagerstabilitaÈt der Fertigmischung nennenswert zu beeintraÈchtigen. 506 Heat Resistance, Water Resistance and Bin Storage Stability in CSM Hose Compounds R. E. Fuller and K. S. Macturk , Stow, OH USA Chlorosulfonated Polyethylene (CSM), available from DuPont Dow Elastomers L.L.C. under the trade name Hypalonâ, has been used in hose applications for 50 years because of its balance of properties including good resistance to heat, oils and chemicals, ozone and weather. Chlorosulfonated Polyethylene also possesses good mechanical toughness, color stability and a degree of inherent flame resistance. In addition, it adheres well to metal and fabric reinforcement. This unique balance of properties makes CSM an ideal choice for many hose tube and cover applications. Properly compounded, CSM can be used in hot environments up to 140 8C or 150 8C. Achieving optimum heat and water resistance, however, has usually required the use of lead compounds as the acid acceptor. Lead improves heat aging of CSM compounds by reacting with, and thus trapping, chloride ions released as hydrogen chloride (HCl) during curing and subsequent exposure to heat. The resulting lead chloride (PbCl2 ) is very heat stable with low solubility in water. In cases where the elimination of lead is deemed advantageous due to environmental or health issues, there remains a strong desire to eliminate lead wherever possible from rubber formulations. Several grades of hydrotalcite were evaluated as alternatives to lead in heat and waterresistant CSM formulations designed for use in the hose industry. Hydrotalcite (magnesium aluminum hydroxy carbonate) has a crystalline structure of magnesium, aluminum, hydroxyl and carbonate ions. Hydrotalcite occurs naturally as a mineral and is also produced synthetically. The chemi- cal formula for naturally occurring hydrotalcite is Mg6 Al2 OH16 CO3 4 H2 O. When hydrotalcite reacts with hydrogen chloride upon exposure to heat, the chloride ion is incorporated into the crystal structure rendering the resulting crystal structure heat stable with low solubility in both water and oil. A bin stable rubber compound is one that will process, cure and yield consistent physical properties independent of the time between when it is mixed and when it is processed. A bin stable compound should also show no changes in viscosity or scorch behavior when stored after mixing and prior to use. Bin stability issues with CSM stocks are manifested by an increase in stock viscosity over time. Scorch times, i. e. time to a 5 or 10 point rise during a Mooney Scorch test, are not a reliable measure of, or control tool for, bin stability in CSM. Increases in the Mooney Scorch (MS @ 121 8C) initial and minimum viscosities are a much more reliable predictor of processing problems resulting from bin aging. It is postulated that water accelerates crosslinking by hydrolyzing the sulfonyl chloride groups making them reactive with metal oxides and curing agents. Water may also play a part in forming reversible ionomeric bonds between the sulfonyl chloride groups and the metal oxides. In any event, storage of CSM stocks under warm, moist conditions can lead to significant increases in stock viscosity and subsequent processing difficulties. The best strategy for minimizing bin stability issues with CSM stocks is to practice good stock control and management. Stocks should be used within a KGK Kautschuk Gummi Kunststoffe 53. Jahrgang, Nr. 9/2000 Heat Resistance . . . Table 1. Synthetic Hydrotalcite Grades Used in This Study Table 2. Formulation for Hydrotalcite Study Tradename Chemical Formula Particle Size (lm) Heat Treatment DHT-4A DHT-4A2 DHT-4C KW2200 KW2100 Mg4:5 Al2 OH13 CO3 3:5 H2 O Mg4:5 Al2 OH13 CO3 Mg4 Al2 OH12 O0:2 CO3 0:8 4:5 MgO Al2 O3 4:5 MgO Al2 O3 0.5 0.5 0.5 0.5 6±7 No Yes Partially Calcined Fully Calcined Fully Calcined week or two after being mixed and exposure to hot humid conditions should be minimized. Since this may not always be possible or practical, it is also important to formulate the compound to achieve the best balance of bin stability, processing and desired cured properties. There are certain materials that should be avoided or eliminated from CSM stocks when formulating for the best bin stability. Acidic materials can contribute to ionomeric bond formation which causes a viscosity increase. Hygroscopic materials can increase the water absorption of the stock. Neither of these types of materials should be used where bin stability is likely to be an issue. The effect of several compounding ingredients on bin stability is discussed in the results and discussion section of this paper. The impact of hydrotalcite and other compounding ingredients on CSM bin storage stability is also discussed. Experimental Several grades of synthetic hydrotalcite, differing primarily in particle size and heat history during production, were used in this study. DHT-4A is a standard grade that has a small particle size, ap- phr proximately 0.5 lm average, and has not been heat-treated. DHT-4A2 has been heat-treated to remove the water of hydration. DHT-4C has been further heat-treated, in fact partially calcined, to remove not only the water of hydration but also about 20 % of the carbonate. KW2200 has been fully calcined to remove all of the water and carbonate. KW2100 is also fully calcined but with a much larger particle size, on the order of 6 to 7 lm. A summary of the hydrotalcites used in this study is provided in Table 1. In this study, all of the above grades of hydrotalcite were evaluated in a high quality, black CSM hose formulation. This allows for separation of the effects of heat treatment and particle size on the performance of the hydrotalcite. Huber's Hysafe 510 synthetic hydrotalcite was included for comparison. Magnesium oxide, litharge (lead oxide, PbO) and a litharge-magnesium oxide compound were included as controls. Twenty parts of the acid acceptor was used in all formulations with the exception of the magnesium oxide control, where only 10 parts of magnesium oxide was used. The formulations are shown in Table 2. Compounds used in the bin stability HYPALON 4085 HYPALON HPG-6525 ST2320 CARBON BLACK DOS TOTM CARBOWAX 3350 PE 617A HVA 2 MBTS NBC TETRONE A PE 200 ACID ACCEPTOR HYDROTALCITE or 90% LITHARGE (PbO) in PIB or MAGNESIUM OXIDE or 90% LITHARGE (PbO) in PIB MAGNESIUM OXIDE 75 25 70 5 25 3 3 1.25 1 2 1 3 20 25 10 12 8 and maleated polybutadiene studies are shown in Tables 3, 4 and 5. The compounds were mixed in a OOC laboratory Banbury mixer in a single pass, up-side-down mix with the accelerators and curatives added at the sweep. The compounds were dumped at an indicated temperature of 190 8C. The dump temperature of the stocks as measured with a pyrometer ranged from 220 8C to 255 8C. The stocks were cooled on a sheet off mill. Test slabs were compression molded and cured for 30 minutes at 162 8C. Compression set pellets were cured for 35 minutes at 162 8C. Testing was performed according to the applicable ASTM test procedure. Table 3. Formulation for Non±Black Bin Stability Study Description Carbo wax PE 3MA20 5MA20 3MA8 5MA8 HYPALON HPG±6525 TACKTENE 1203 ATOMITE SUPREX CLAY TIPURE R960 CALSOL 8240 BLUE ULTRAMARINE TMTD MAGLITE D PE 200 SULFUR CARBOWAX 3350 PE 1702 PE 617A RICON 131 MA20 RICON 130 MA 8 100 3 150 50 20 40 0.25 2 5 3 1 3 ± 3 ± ± 100 3 150 50 20 40 0.25 2 5 3 1 ± 3 3 ± ± 100 3 150 50 20 40 0.25 2 5 3 1 ± ± 2 3 ± 100 3 150 50 20 40 0.25 2 5 3 1 ± ± 2 5 ± 100 3 150 50 20 40 0.25 2 5 3 1 ± ± 2 ± 3 100 3 150 50 20 40 0.25 2 5 3 1 ± ± 2 ± 5 TOTAL 380.25 380.25 379.25 381.25 379.25 381.25 KGK Kautschuk Gummi Kunststoffe 53. Jahrgang, Nr. 9/2000 507 Heat Resistance . . . Table 4. Formulation for Black Bin Stability Study Description Carbowax PE None 3MA20 5MA20 3MA8 5MA8 HYPALON 4085 N762 ATOMITE DOS KENFLEX A1 TOTM HVA 2 MBTS NBC TETRONE A MAGLITE D PE 200 CARBOWAX 3350 PE 1702 PE 617A RICON 131 MA20 RICON 130 MA 8 100 75 100 15 5 20 1 1 0.5 1 5 5 3 ± 3 ± ± 100 75 100 15 5 20 1 1 0.5 1 5 5 ± 2 2 ± ± 100 75 100 15 5 20 1 1 0.5 1 5 5 ± ± ± ± ± 100 75 100 15 5 20 1 1 0.5 1 5 5 ± ± ± 3 ± 100 75 100 15 5 20 1 1 0.5 1 5 5 ± ± ± 5 ± 100 75 100 15 5 20 1 1 0.5 1 5 5 ± ± ± ± 3 100 75 100 15 5 20 1 1 0.5 1 5 5 ± ± ± ± 5 TOTAL 334.5 332.5 328.5 331.5 333.5 331.5 333.5 Table 5. Formulation for Plasticizer Bin Stability Study Description DOS/ Sundex TOTM Drapex/TOTM Hypalon 4085 N762 N990 Atomite DOS Drapex 409 Kenflex A1 SUNDEX 790 TOTM CARBOWAX 3350 PE 617A HVA 2 MBTS NBC Tetrone A Maglite D PE 200 100 60 ± 90 7.5 ± 5 22.5 ± 3 3 1 1 2 1 5 3 100 60 ± 90 ± ± 5 ± 30 3 3 1 1 2 1 5 3 100 60 ± 90 ± 15 5 ± 20 3 3 1 1 2 1 5 3 Total phr lab 304 304 309 Results and discussion The effect of hydrotalcite heat history and particle size on several key properties will now be discussed. Unless otherwise stated the results are given in Table 6. The compound viscosity (ML(1 4) @ 100 8C) of the hydrotalcite formulations is comparable to that of the lead-magnesium oxide and magnesium oxide controls and somewhat higher than that of the lead oxide formulation. The heat history of the hydrotalcite does not appear to affect viscosity but hydrotalcite particle size has a large effect. The larger particle size KW2100 gives a significant increase in compound viscosity compared Table 6. Variations in Properties with Acid Acceptor Type Hysafe DHT-4A DHT-4A2 Mooney Viscosity, ML @ 100 8C ML(1+4) [MU] 57.9 62.1 59.0 Mooney Scorch, MS @ 121 8C T5 [min] 15.0 11.4 17.0 Mooney Scorch, MS @ 121 8C, Aged 14 days 95 % RH/40 8C Change ML [MU] 5.4 6.3 4.8 MDR2000 30 min @ 162 8C t95 [min] 10.3 7.2 10.6 Original Physical properties Cure 30 min @ 162 8C M100 [MPa] 4.1 4.8 5.3 Average Change After Heat Aging Change M50 [%] 179 172 110 Change Eb [%] 51 50 46 Oil Aging, IRM 903 Oil Aged 70 hr @ 150 8C Volume Change [%] 57 47 46 Compression Set Pellet (B) CS 70 hr @ 125 8C [%] 60 52 50 Water Aging Aged 70 hr @ 100 8C Volume Change [%] 21 17 19 508 DHT-4C KW2100 KW2200 Pb Mag Pb-Mag 59.4 83.3 61.5 52.9 59.9 61.5 19.8 13.2 20.9 13.1 16.0 10.5 3.1 3.5 3.2 19.6 15.2 17.8 11.1 11.2 14.0 14.5 14.3 13.6 5.9 5.0 4.9 5.7 3.9 5.4 113 46 222 53 110 40 175 60 157 54 126 45 46 73 54 45 62 47 52 67 60 39 63 47 17 10 8 2 50 20 KGK Kautschuk Gummi Kunststoffe 53. Jahrgang, Nr. 9/2000 Heat Resistance . . . to KW2200 and the other hydrotalcite grades. Processing safety can be measured by time to a five-point rise of Mooney Scorch at 121 8C (T5). The processing safety of the hydrotalcite stocks is comparable to, or better than, that of the controls. In this case, there is a significant effect of the heat history of the hydrotalcite. Scorch safety increases as the amount of heat treatment increases as evidenced by the larger T5 times. The T5 for the fully calcined KW2200 is nearly twice that of the untreated DHT-4A (21 min. v. 11.5 min.). The poorer scorch safety of the stock with the larger particle size hydrotalcite (KW2100) has at least two possible explanations. The first is increased chemical reactivity. The second is an increased tendency to build heat due to the higher compound viscosity. In any event, the scorch safety of the KW2100 stock is equivalent to that of the litharge control. The effect on cure rate parallels that of Mooney Scorch. The T95 times measured by an MDR2000 at 162 8C increase with increasing hydrotalcite heat history and decrease somewhat as the particle size increases from KW2200 to KW2100. Note that the cure times of the hydrotalcite stocks, except for the KW2200 sample, are all shorter than the controls. In some cases these shorter cure times may translate into an economic advantage in the factory if the curing cycle is a limiting factor in production. The use of hydrotalcite results in compounds with cured physical properties comparable to those obtained with other acid acceptor systems. There does not appear to be a significant impact of hydrotalcite heat history or particle size on the original physical properties. One possible exception is that room temperature modulus may be increasing as the hydrotalcite heat history increases, at least up to the partially calcined DHT-4C grade. Any effect is probably due to ionomeric interactions influenced by surface area effects. This hypothesis is supported by the fact this effect is not seen in the 100 8C properties where the ionomeric interactions are destroyed by the higher temperatures. The heat aging performance of the hydrotalcite stocks compared favorably with the lead-magnesium oxide control. Traditionally, the lead-magnesium oxide acid acceptor system has given the best heat aging performance in CSM stocks. Here we have presented the average modulus change over four aging periods (3 and 7 days at 150 8C and 7 and 14 days at 135 8C) and the average elongation change over the same periods. This averaging method was chosen in order not to give undue weight to any one set of conditions. The conclusion that heat-treated hydrotalcites, with the exception of the small particle size, fully calcined version (KW2200), give heat aging performance as good as or better than lead-magnesium oxide system is consistent for all of the aging periods. The poorer performance of the small particle size, fully calcined grade of hydrotalcite appears to be real since this effect was seen for different aging periods and for multiple batches of this hose compound. However, this poorer relative performance was not seen in another formulation tested. In that case, both calcined versions were equivalent. Further work is needed to verify that the effect is compound dependent. Compression set (Method B) of the hydrotalcite compounds, measured after conditioning for 70 hours at 125 8C, is not quite as low as the lead oxide system. The standard hydrotalcite grades give set values approximately equal to those of the lead-magnesium oxide system and somewhat better than those of magnesium oxide control. There is an effect of hydrotalcite heat history on compression set as is evidenced by the differences between the compression set values for the calcined versus the non-calcined grades. The fully calcined hydrotalcites yield com- pounds with higher compression set. Increasing the hydrotalcite particle size appears to be deleterious to set. Use of hydrotalcite, especially the fully calcined versions, yields water swells (70 hr and 100 8C) approaching those of the lead oxide system. While the use of hydrotalcite does not yield the extremely low water swells of a straight lead oxide system, it offers significant improvement over the standard magnesium oxide system and does so without the health and environmental issues associated with lead. Standard hydrotalcite grades give water swells similar to those achieved in a lead-magnesium oxide system. The fully calcined hydrotalcites reduce water swell by an additional factor of two and yield swells approaching those of a lead oxide system. There appears to be little or no effect of hydrotalcite particle size on water swell. Oil swell in IRM903 oil (70 hr and 150 8C) with the non-calcined hydrotalcites is approximately equal to that of the lead and lead-magnesium oxide compounds and significantly better than that of the magnesium oxide system. Stocks made with the calcined hydrotalcites are poorer in oil swell than those made with the non-calcined grades. The larger particle size gives stocks that have significantly worse oil swell. Before addressing the impact of hydrotalcite on CSM bin stability, the influence of several types of compounding ingredients on bin stability will be discussed. Bin stability can be influenced by the plasticizer choice. Fig. 1 shows the change in Mooney Scorch minimum viscosity after Fig. 1. Effect of Plasticizer Type on CSM Bin Stability KGK Kautschuk Gummi Kunststoffe 53. Jahrgang, Nr. 9/2000 509 Heat Resistance . . . humid aging (14 days at 40 8C and 95 % relative humidity) for a typical CSM hose compound containing 60 parts carbon black, 90 parts whiting and 30 parts of plasticizer. The compound with trioctyl trimellitate (TOTM) shows less viscosity increase than one with a blend of aromatic oil (Sundex 790) and dioctyl sebacate (DOS). However, both show smaller viscosity increases than the compound with a blend of TOTM and an adipic acid polyester plasticizer (Drapex 409). Polyethylene glycol based plasticizers such as polyethylene glycol 400-di-2-ethylhexoate (TegMeR 809) are particularly poor for bin stability. One stock tested with this plasticizer had experienced such a large viscosity increase during bin storage that it was not possible to measure the Mooney Scorch viscosity after 14 days aging at 40 8C and 95 % relative humidity. While no data exists for other plasticizers with polyether backbones, these also may lead to poor bin stability and should be evaluated prior to use. The choice of cure system components can also affect bin stability. TMTD, for example, can yield stocks that are more prone to bin stability problems. MBTS, in contrast, usually produces stocks that show good bin stability. Nickel dithiocarbamate (NBC) is used in CSM to give the optimum in heat resistance. NBC can contribute not only to short original scorch times but also to poor bin stability. It should be used at the minimum level necessary to impart the degree of heat stabilization required for the particular application. Bin stability is also influenced by process aids. Stearic acid, while very effective as a process aid in CSM, should be not be used if bin stability is an issue. CSM stocks with as little as 0.5 or 1 phr of stearic acid can become unprocessable in a relatively short time when stored in hot, humid environments. Polyethylene glycol process aids, such as Carbowax, also are very effective in CSM and are often used to impart good mill and Banbury release. However, these contribute to poor bin stability and should be avoided where bin stability is likely to be an issue. Process aids that have minimal effect on bin stability are combinations of low molecular weight polyethylenes (e. g. a blend of PE617A and PE1702), high cis content polybutadiene, and maleated polybutadiene resins. Maleated polybutadiene resins are particularly effective release aids in CSM stocks. Our lab evaluations and limited factory experience show that maleated polybutadienes are at least as effective, and in some cases more effective, than polyethylene glycol for imparting good mill and mixer release to CSM. Two versions of maleated polybutadiene from Ricon Resins were evaluated at the 3 and 5 part level in both a black and a non-black hose compound. The grades differed primarily in their anhydride content with one containing 20 % anhydride (Ricon 131MA20) and one containing 8 % anhydride (Ricon 130MA8). In general, we found that higher levels of these resins produced better Fig. 2. Release Aid Bin Stability in a Carbon Black Filled CSM Stock 510 release properties. In addition, higher anhydride contents also gave better release properties. These materials tend to increase the compound modulus and thus the formulation chemist needs to evaluate the impact on physical properties prior to selecting the grade and level. The effect of these resins on bin stability is shown in Fig. 2 and 3. The effect of hydrotalcite on bin stability (14 days @ 40 8C and 95 % relative humidity) can be seen in Table 6. Note that these stocks contain both NBC and Carbowax and haven't otherwise been optimized for bin stability. The viscosity increases with hydrotalcite are significantly less than for the other acid acceptor systems. The heat-treated hydrotalcites are somewhat more bin stable than the standard grades. In this case, there is no effect of hydrotalcite particle size. Summary Chlorosulfonated Polyethylene (CSM) is widely used in hose applications due to good heat, oil, chemical, ozone and weather resistance, good physical properties and ease of processing. This paper shows that hydrotalcite is a viable alternative to lead and lead-magnesium oxide acid acceptor systems in CSM compounds where excellent heat and/or water resistance is required. These results are noteworthy since hydrotalcite offers a good balance of properties without the health and environmental issues associated with lead containing stocks. Fig. 3. Release Aid Bin Stability in a Mineral Filled CSM Stock KGK Kautschuk Gummi Kunststoffe 53. Jahrgang, Nr. 9/2000 Heat Resistance . . . Hydrotalcite also offers improvements in bin stability, scorch safety and cure rate while giving heat aging performance that is as good as or better than that of a lead-magnesium oxide system. Water swells, while not as low as for a lead oxide system, are very good, especially with the calcined hydrotalcite grades. Several grades of hydrotalcite are available and performance is dependent on the degree of heat treatment of the hydrotalcite and its particle size. For example, the best water resistance is achieved by using a fully calcined grade of hydrotalcite while the best heat resistance is achieved by using a grade that has been heat-treated to a lesser extent. Since there are likely to be cost differences among the grades, the formulation chemist needs to evaluate the available grades and strike a balance between cost and desired performance. Finally, several mechanisms responsible for poor bin stability were discussed. Bin stability can be improved by the proper choice of compounding ingredients KGK Kautschuk Gummi Kunststoffe 53. Jahrgang, Nr. 9/2000 such as plasticizers, cure system components and process aids. Acidic and hydrophilic materials should be avoided in order to produce acceptable bin stability. Results were presented which show the beneficial aspects of the use of maleated polybutadiene as a process aid that gives good mill release and bin stability. Corresponding author Kenneth S. Macturk Du Pont Dow Elastomers 4330 Allen Road Stow, OH USA 44224 511