* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download The electron accelerator of the ISOF-CNR Institute

Survey

Document related concepts

Transcript

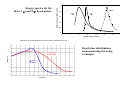

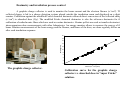

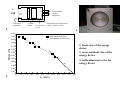

The electron accelerator of the ISOF-CNR Institute: its characteristics and use P. Fuochi, U. Corda, and M. Lavalle ISOF-CNR Institute, Via P. Gobetti 101, I-40129 Bologna, Italy LINAC Laboratory: ISOF-CNR, Via Biancafarina 2485, 40060 Fossatone di Medicina (BO) Italy The electron accelerator The Institute of Photochemistry and High Energy Radiation (now merged into the Institute for Organic Synthesis and Photoreactivity) was established in 1970 in Bologna. One of the main tasks of the Institute, which became the main reference centre for radiation chemistry in Italy, was to perform basic and applied research in the field of the effects and application of ionizing radiation. For this purpose the Institute was equipped with 60Co γ-sources and a 12 MeV linear electron accelerator. The 12 MeV linear accelerator (maximum energy with no load), built by Vickers, came into operation in 1973. It is an L-band (i.e. working at a radiofrequency of 1.3 GHz) travelling wave accelerator operating in the π/2 mode. The electron beam is pulsed and the pulse width can be varied from 10 ns to 5 µs with a repetition rate from single shot up to 1000 pps. Thus the accelerator can be used in single shot or in continuous mode and a pulse counter allows the delivery of any preset number of pulses. Pulse to pulse reproducibility is within ± 2% per day. The maximum current (peak current) obtainable is between 5 and 7 A with 10 ns pulses and 1 A for long pulses (µs). The most probable energy of the electrons is 11 MeV for pulses between 10 and 100 ns dropping to 8 MeV at 2 µs. The beam energy can be varied by changing the pulse width and/or the average beam current. The typical configuration for routine irradiation is: pulse repetition rate: 50 Hz pulse length: 2 µs electron energy: 8 MeV average beam current: 100 µA peak pulse current: 1 A Since there is no scanning system, in order to obtain good uniformity of dose distribution (≤ ± 10%) on the sample under irradiation, aluminium scatter plates are used to spread the beam for samples having dimensions ≤ 110 cm2, while for samples up to 40 x 40 cm, a computer driven x-y moving system is used to move these samples in front of the accelerator window. The 12 MeV Vickers linear accelerator. View of the accelerating waveguide. The accelerator’s and the klystron’s rooms are shielded with a copper Faraday cage to avoid electronic noise in the irradiation room. Scheme of the LINAC 1 Beam current, arbitrary unit Energy spectra for the 10 ns, 1 µs and 2 µs beam pulses. 10 ns 0.8 2 µs 1 µs 0.6 0.4 0.2 0 6 7 8 9 10 11 12 Beam energy (MeV) Depth-dose curves measured at 90 cm from the LINAC, scatterplate= 0.9 mm Al 1.6 Depth dose distributions measured using the wedge technique. 1.4 1.2 0.2 µs pulses Ep = 11.5 MeV Dose, a.u. 1 0.8 2 µs pulses Ep = 8 MeV 0.6 0.4 0.2 0 0 2 4 6 8 10 12 14 mm in Al 16 18 20 22 24 26 28 13 Dosimetry and irradiation process control A graphite charge collector is used to monitor the beam current and the electron fluence (e−/cm2). The collected charge is led to a charge detection system placed outside the irradiation room and displayed on a digital counter. Calibration against the modified Fricke chemical dosimeter allowed direct conversion of the collected charge (e−/cm2) to absorbed dose (Gy). The modified Fricke chemical dosimeter is also the reference dosimeter for the calibration of radiochromic films which are used as routine dosimeter. Alanine pellets are used as transfer dosimeter in intercomparison dose measurements with other laboratories. An energy monitor allows to measure the energy of the beam. Routine measurements of the beam energy and the fluence, and hence of the dose, are done regularly before and after each irradiation sequence. 20 18 16 Dose (Gy/pulse) 14 12 10 8 6 4 2 0 0 The graphite charge collector. 0.5 1 1.5 2 2.5 10 - 3 3.5 4 2 Fluence (10 e /cm pulse) Calibration curve for the graphite charge collector vs. absorbed dose in “super Fricke” solution. 4.5 e- To the digital current integrators 100 mm Aluminium cage dimensions: Ceramic Wall thickness: (14cm x 14cm x 10cm) pillars Connected to ground 10 mm 2. 1. 0.95 long pulses (0.5-5 µs) short pulses (0.05-0.5 µs) 0.90 0.85 0.80 1. front view of the energy device Energy ratio 0.75 0.70 2. cross-sectional view of the energy device 0.65 0.60 0.55 3. calibration curves for the energy device 0.50 0.45 0.40 0.35 3. 6.5 7.0 7.5 8.0 8.5 9.0 9.5 Ep (MeV) 10.0 10.5 11.0 11.5 12.0 Applied radiation research using the 12 MeV Linac The electron accelerator is used in a number of researches and tests connected to industrial applications which are listed below. 1. Treatment of food products and pharmaceuticals. Some studies have been conducted in this field to evaluate the effectiveness of electron irradiation in decontamination of pharmaceuticals, spices and poultry meat from pathogenic micro-organisms. 2. Curing of composites. Thick composite materials made of carbon fibres in organic matrices (epoxy resins) have been cured with high-energy electron beams. The polimerization of the methylmethacrylate in presence of rubber is under study. 3. 1. 4. 2. COMPOSITE MATERIALS. 1. and 2.: glass fibres and epoxy resins layers, aluminium honeycomb structure inside 3. and 4.: carbon fibres and epoxy resins layers, aluminium honeycomb structure inside 5. 5. epoxy resin and carbon fibres composite Applied radiation research using the 12 MeV Linac 3. Sterilization of human bone tissues for implants. Femoral heads are sterilized to be used as biocompatible material in prosthesis implants, skull fragments are sterilized before their implants in the same patient. 1. 2. HUMAN BONE STERILIZATION. 1. disposable container for surgical specimen 2. the hermetic envelope, whit the container, is in front of the LINAC window, ready for the irradiation Applied radiation research using the 12 MeV Linac 4. Modification of semiconductor devices. Starting from 1982, research in the field of electron irradiation of power semiconductor devices has been conducted at FRAE Institute (now ISOF). In collaboration with Italian power semiconductor manufacturing industries an extensive program of irradiation tests have been undertaken. Fast switching diodes and thyristors, Gate Turn Off thyristors (GTO), power MOS transistors and Insulated Gate Bipolar Transistors (IGBT) were irradiated with electron beams at different doses in order to achieve modelling of the electrical parameters and specific adjustment of carrier lifetime. The results led the above mentioned firms to introduce this technology for series production in place of the conventional high-temperature heavy metal diffusion for lifetime control. Equipment and methods for series production have been developed, tested and since 1986 put into operation MODIFICATION OF SEMICONDUCTOR DEVICES. 1. silicon wafers 2. the system for the power semiconductor irradiation 3. power semiconductor devices in the process load unit 1. 2. 3. MODIFICATION OF SEMICONDUCTOR DEVICES. 1. silicon slice for thyristor 2. finished device: thyristor 3. and 4. final device set up: 3. stud case 4. press pack case 1. 2. 3. 4. Applied radiation research using the 12 MeV Linac The linac is also used to perform irradiation tests on MOS devices with ultra-thin oxides. Present studies, conducted in collaboration with the Dept. of Physics and Dept. of Electronics and Informatics of the University of Padova, on total dose effects (devices were irradiated up to 150 Mrad) include measurements of radiation induced leakage current (RILC) and soft breakdown in gate oxides MOS capacitors. These studies have demonstrated that the RILC in these devices is due to neutral traps generated in the oxide during irradiation and that RILC conduction mechanism can be explained by a sort of electron tunnelling through gate oxide assisted by radiation induced neutral traps. These results, obtained using the linac as electron source, are similar to those obtained with γ-, x-rays and high energy ions with LET<10 MeVcm2mg-1. The use of a linac in place of gamma cells (usually used for total dose experiments) results to be more convenient because of the reduced time to reach high doses necessary to study the RILC phenomenon. X-Ray generation A water-cooled tantalum converter is used to produce X-rays. The target thickness (1.5 mm) has been selected in order to optimise the bremsstrahlung production using the 2µs pulses. 90 1 X-Ray distribution Polar distribution of the forward X-ray emission from the converter. 120 00 e- 180 210 1 240 1 270 0.9 dose, u.a. dose, a.u. 150 0.8 0.7 0.6 0.5 X-Ray penetration Depth-dose profile of the bremsstrahlung beam. 0.4 0.3 0 10 20 g/cm 2 30 LICHTENBERG TREES IN PMMA CILINDERS. The “Lichtenberg tree” effect is the electrical discharge pattern resulting from an instantaneous breakdown of an electrical field. The field results from the rest of high-speed electrons injected into the material. When the field exceed the insulating strength of the material a local discharge occurs whit consequent damage on the material itself.