* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Manipulation of powder characteristics by interactions at the solid

Ultrahydrophobicity wikipedia , lookup

Sessile drop technique wikipedia , lookup

Pseudo Jahn–Teller effect wikipedia , lookup

Low-energy electron diffraction wikipedia , lookup

History of metamaterials wikipedia , lookup

Condensed matter physics wikipedia , lookup

Semiconductor wikipedia , lookup

Crystal structure wikipedia , lookup

X-ray crystallography wikipedia , lookup

Self-assembled monolayer wikipedia , lookup

Colloidal crystal wikipedia , lookup

Nanochemistry wikipedia , lookup

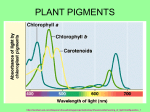

European Journal of Pharmaceutical Sciences 8 (1999) 283–290 Manipulation of powder characteristics by interactions at the solid–liquid interface: 1-sulphadiazine Y.E. Hammouda*, L.K. El-Khordagui, I.A. Darwish, A.H. El-Kamel Department of Pharmaceutics, University of Alexandria, Alexandria, Egypt Received 8 July 1998; received in revised form 23 January 1999; accepted 23 February 1999 Abstract A solvent-treatment technique aiming at manipulating the properties of powdered materials is reported. Potentials of the technique were assessed using sulphadiazine (SD). A suspension of the drug in a preselected solvent (5% aqueous ammonia solution) was stirred under controlled conditions. The solvent was subsequently removed and the material dried. The effect of experimental variables such as stirring speed and time, powder / solvent ratio and inclusion of additives (Tween 80, sodium chloride and PVP) on the properties of solvent treated SD was assessed. Data obtained were compared with those for SD recrystallized under identical conditions. Solvent treatment of SD in the absence of additives resulted in a limited change in crystal morphology as indicated by SEM. This was associated with improved flowability and a limited reduction in dissolution rate relative to untreated SD. On the other hand, recrystallized SD exhibited superior flowability but a considerably low dissolution rate. Solvent treatment of SD in the presence of 2% PVP produced a microgranular directly compressible material. 1999 Elsevier Science B.V. All rights reserved. Keywords: Solvent treatment technique; Sulphadiazine; Additives; Flow properties; Dissolution rate; Direct compression 1. Introduction Modification of the characteristics of pharmaceutical solids to solve formulation and processing problems related to inadequate physico-technical properties is receiv¨ ing considerable interest (Hutenrauch, 1983; York, 1992). Building the desired properties into the pure powdered solid provides a great potential for reducing the number of formulation components and processing operations to a tolerable minimum, thus rendering production simpler and more economic. Crystallization techniques are the most widely used solvent-based, pretreatment methods for the production of pure chemicals with altered solid state properties. Crystals with engineered properties (crystal habit, form, density, order / disorder state, wettability, etc.) can be obtained by changing the crystallization solvent (Gorden and Amin, 1984; Marshall and York, 1991) and conditions (Fachaux et al., 1995), or by using alternative crystallization techniques. These include solvent change crystallization (Nath and Khalil, 1984, Khan and Jiabi, 1998), spherical crystallization (Gat et al., 1997), solvation / desolvation (Fachaux et al., 1993), etc. Further, the presence of small *Corresponding author. Fax: 120-3-483-3273. amounts of additives and impurities in the crystallization solvent may produce crystal lattice imperfections or crystal habit changes, resulting in major effects on the physicochemical properties of powders, such as the dissolution rate (Chow and Hsia, 1991; Femi-Oyewo and Spring, 1994). Usually, solvent-induced changes in the solid state properties of recrystallized materials are associated with modifications of their physico-technical properties, such as packing, flowability and compaction, (York, 1983, 1992; Marshall and York, 1991). These changes involve interactions between solute and solvent molecules at the various crystal / solutions interfaces (Bourne and Davey, 1976a,b; Davey et al., 1982). By virtue of such interactions, the surface characteristics may be altered, producing a change in the growth kinetics of the crystals (Davey et al., 1982; Berkovitch-Yellin, 1985; Marshall and York, 1989). In the present study, a solvent treatment approach aiming at modifying the solid state and probably the physico-technical properties of powdered materials is investigated. The method is based on possible solute / solvent interaction at the solid / liquid interface. It involves treatment of the powdered material with a limited amount of a preselected solvent under controlled conditions and subsequent removal of the solvent. 0928-0987 / 99 / $ – see front matter 1999 Elsevier Science B.V. All rights reserved. PII: S0928-0987( 99 )00026-3 284 Y.E. Hammouda et al. / European Journal of Pharmaceutical Sciences 8 (1999) 283 – 290 The potentials of this solvent treatment approach were investigated using sulphadiazine (SD), a large dose drug with poor flowability and compressibility (Sakr et al., 1978) and 5% ammonia solution as the treatment solvent. This solvent system has been reported earlier (Hammouda et al., 1984; El-Massik, 1987) to produce prismatic, flowable and directly compressible SD crystals. The formation of SD prisms was assumed to be due to the interaction of SD and ammonia solution, allowing the ordered arrangement of SD molecules. Selection of the system sulphadiazine / 5% ammonia solution in the present study, would allow a direct comparison of the outcome of the solvent treatment approach with that of crystallization. 2.3. Scanning electron microscopy ( SEM) 2. Experimental procedures 2.5. Flow properties of solvent-treated and recrystallized sulphadiazine Samples of SD powder, recrystallized SD and solventtreated SD in the absence or presence of 2% PVP were examined using scanning electron microscope (Jeol, SEM model JSM-25 SII, Tokyo, Japan). 2.4. X-ray diffractometry X-ray diffraction pattern analysis of SD powder, solvent-treated SD and recrystallized SD was carried out using Siemens D-500 Diffractometer with Co-Rad radia˚ voltage 35 kV, current 20 mA at a tion ( l51.784 A), scanning rate of 28 / min and chart speed 1cm / min. 2.1. Materials Sulphadiazine crystalline powder (SD) (ACF Chemiefarma, Holland), polysorbate 80 and sodium chloride (BDH Chemicals Ltd, U.K.), ammonia solution ˆ (Rhone-Poulenc, France), methylene blue, polyvinylpyrrolidone and hydrochloric acid (Sigma Chemical Corporation, U.K.), maize starch (B.P.) and croscarmellose sodium (a gift from EL-Amyria Company, Egypt) were used in the study. 2.2. Preparation of solvent-treated and recrystallized sulphadiazine ( SD) 2.2.1. Solvent-treated sulphadiazine Sulphadiazine powder was added to 5% aqueous ammonia solution as the treatment solvent in the required ratio w / v (1:1.5 and 1:3). The slurry was stirred mechanically (at 100, 200 and 300 rpm) at room temperature for the specified time (1 and 4 h). The ammonia-treated undissolved powder was separated using a sintered glass funnel, and left to dry at room temperature away from light. 2.2.2. Recrystallized sulphadiazine The dissolved SD in the filtrate was left to crystallize out in a shallow crystallizer at room temperature away from light. The crystals were then collected by filtration and left to dry at ambient temperature. Further, solvent-treated and recrystallized SD fractions were obtained from 5% ammonia solution containing Tween 80 (0.2% w / v), sodium chloride (0.5% w / v) and PVP (0.1, 0.5 and 2.0 w / v%). Sulphadiazine powder and both solvent-treated and recrystallized SD fractions obtained under different experimental conditions were sieved and the particle size range 250–400 mm collected. 2.5.1. The angle of repose The angle of repose of all solvent-treated or recrystallized SD samples (250– 400 mm), was determined using the method described by Train (1958). 2.5.2. Bulk density The bulk density of solvent-treated or recrystallized SD samples (250–400 mm) was determined using the method described by Parrott (1970). 2.6. Measurement of the wetability of solvent-treated SD The wetability of ammonia-treated SD in the absence and presence of additives (0.2% w / v Tween, 0.5% w / v sodium chloride and 2% w / v PVP) was measured accord` ing to the method reported by Lefebvre et al. (1988). Three grams of solvent-treated SD powder were introduced into a specially designed sintered glass tube, the bottom of which was immersed in a saturated solution of SD at 1 mm above the sintered glass. The solution was allowed to rise through the SD powder bed. Wetting of the powder bed surface was made evident with crystals of methylene blue placed on top of the bed. The time necessary for the capillary rise of the saturated SD solution through the SD powder bed under standardized conditions (tw) was used as a parameter for comparison. The same procedure was also used to determine the wetability of untreated SD powder (the starting material). The results presented are the mean of three measurements. 2.7. Preparation of SD tablets by direct compression Attempts were made to directly compress solvent-treated and SD crops (particle size 250–400 mm) into tablets after mixing with 5% maize starch or croscarmellose sodium as disintegrant using Erweka single punch tablet machine. Y.E. Hammouda et al. / European Journal of Pharmaceutical Sciences 8 (1999) 283 – 290 Tablets (500 mg each) obtained from compressible SD samples were subjected to dissolution rate testing, as outlined under dissolution rate study. 2.8. Dissolution rate study The dissolution rates of SD powder, solvent-treated and recrystallized SD samples obtained under different experimental conditions were determined using the USP dissolution apparatus (Type II). The dissolution medium was 900 ml of 0.1 M hydrochloric acid stirred at 100 rpm. At specified time intervals, up to 90 min, 5 ml samples were withdrawn and analyzed spectrophotometrically at lmax 244 nm after suitable dilution with 0.1M hydrochloric acid. Experiments were run in triplicate. 3. Results and discussion Recrystallization of SD microcrystalline powder from 5% ammonia solution was reported earlier (Hammouda et al., 1984) to result in a change of the crystal habit. Prismatic crystals with better flowability and compressibility were obtained. Polymorphism and possible formation of a detectable ammonium salt of SD were ruled out. Interaction of SD with ammonia in solution was assumed to have resulted in an ordered arrangement of SD molecules and formation of crystals with different solid state properties. The effect of solvent treatment on the properties of powdered SD is the subject of the present study. Solvent treated and recrystallized sulphadiazine samples (250–400 mm) were obtained using 5% ammonia solution as a treatment or recrystallization solvent respectively. 285 sharp and major peak in the starting material and recrystallized form. On the other hand, appearance of new peaks in the X-ray diffraction pattern at 2u 5308 to 328 and 498 of recrystallized SD indicates increased crystallinity. Minor changes in the X-ray diffraction pattern of solvent treated SD may be due to the unsuitability of X-ray powder diffractometry to identify changes that take place only at the particle surface for a small distance into the crystal (York, 1983). 3.2. Effect on flow properties The effect of treatment conditions on the values of the angle of repose and bulk density of solvent treated compared to recrystallized SD samples is shown in Table 1. SD powder exhibits poor flow properties (angle of repose574.6 and bulk density 0.31). Solvent treatment resulted in a limited improvement of SD flowability as indicated by the decrease in the angle of repose and the slight increase in bulk density. On the other hand, recrystallization resulted in a marked improvement of SD flowability. Changes in the flow properties of both solvent treated and recrystallized SD were only slightly affected by the change in the drug:solvent ratio, stirring rate and stirring time (Table 1). Bulk density and angle of repose are functions of particle shape and surface smoothness (Carstensen et al. 1993). As solvent treatment did not affect the crystal shape of SD (Fig. 1), improved flowability can be attributed to the reduction in surface roughness and edge sharpness leading to reduction in inter-particle friction. 3.3. Effect on dissolution rate 3.1. Effect on solid state properties Fig. 1 shows the scanning electron micrographs of SD (control), solvent treated and recrystallized SD samples. Control SD crystals are tabular with rough edges and surface irregularities. Treating SD with 5% ammonia solution did not appreciably affect the crystal shape. A slight decrease in surface roughness and edge sharpness can be observed. This may be attributed to the deposition of SD from the treatment solvent onto the surface of the original SD particles. Recrystallization expectedly produced well formed, longer prismatic crystals with smoother surfaces and more rounded edges. X-ray diffractograms of these samples are shown in Fig. 2. Minor changes could be observed in the X-ray diffraction pattern of solvent treated SD with respect to that of control SD crystalline powder. A small peak at 2u 158 instead of a sharp clear peak in the original powders and recrystallized SD coupled with the disappearance of the peak at 2u 178. Also there is a peak splitting into two peaks in the region of 2u 5248 to 268 instead of one single The dissolution profiles of SD (control), solvent treated SD and recrystallized SD in 0.1 M HCl are shown in Fig. 3. Results show fast dissolution of SD (control), 100% dissolution was attained in 10 min. Treatment of SD with 5% ammonia solution reduced the initial dissolution rate, while recrystallization from the same solvent expectedly suppressed the dissolution process (50% dissolution in 90 min). The reduction in initial dissolution rate of solventtreated SD points to a greater dissolution resistance of the surface layers of SD particles. This might imply a higher degree of crystallinity and / or a lower degree of wetting or surface hydrophilicity of these layers. Wetability measurements of SD (control) and solvent treated samples using a liquid penetration technique ` (Lefebvre et al., 1988), indicated a marked decrease in wetability of the treated samples (Table 2). The time required for complete wetting (T w ) of a sample bed was 15 min and 40 min for SD (control) and solvent treated SD respectively. Wetability of powdered materials is a function of their chemical and crystal structures (Lerk et al., 1977), 286 Y.E. Hammouda et al. / European Journal of Pharmaceutical Sciences 8 (1999) 283 – 290 Fig. 1. Scanning electron micrographs of (a) untreated SD, (b) solvent-treated SD, (c) recrystallized SD using 5% ammonia and (Magnification power 700), (d) solvent-treated SD using 5% ammonia–2% PVP (Magnification power 300). and their pretreatment history (Hansford et al., 1980; Chow et al., 1995). As molecules contain regions which are hydrophobic and regions which are hydrophilic, the outer face of a crystal will be influenced by the liquid from which it was crystallized, with possible internalization of the functional groups which are less attracted to the liquid Y.E. Hammouda et al. / European Journal of Pharmaceutical Sciences 8 (1999) 283 – 290 287 Fig. 2. X-ray diffraction pattern. (Buckton, 1995). Wetability and dissolution rate data of solvent treated SD tend to indicate that the orientation of SD molecules in the ammonia solution during treatment, resulted in the deposition of a less hydrophilic and less wetable surface layer. The relatively slow dissolution of this surface layer appears to be followed by rapid dissolution of the layers underneath. 3.4. Effect of additives Additives or impurities even in trace amounts can exert major effects on the physicochemical and solid state properties of solids (York, 1983). In the present study, the effect of inclusion of Tween 80 (0.2% w / v), NaCl (0.5% w / v) and PVP (0.1, 0.5 and 2% w / v) in the treatment Table 1 Effect of treatment conditions on the angle of repose and bulk density of solvent treated and recrystallized SD Treatment condition SD: 100 SD: 100 100 200 200 300 5% Ammonia 1:1.5 rpm, 1 h 5% Ammonia 1:3 rpm, 1 h rpm, 4 h rpm, 1 h rpm, 4 h rpm, 1 h Bulk density (g / cm 3 )6SD Angle of repose (8)6SD Solvent treated Recrystallized Solvent treated Recrystallized 51.660.6 – 0.3860.005 – 53.160.4 52.660.5 52.660.8 53.760.6 52.860.5 37.660.3 35.760.4 36.860.4 37.260.4 36.960.3 0.3860.004 0.3860.004 0.3660.003 0.3560.002 0.3760.003 0.6160.01 0.6160.01 0.6260.01 0.5560.01 0.5960.01 288 Y.E. Hammouda et al. / European Journal of Pharmaceutical Sciences 8 (1999) 283 – 290 Fig. 3. Percent dissolution of untreated, solvent-treated and recrystallized SD using 5% ammonia. Table 2 Time for complete wetting (T w ) of solvent treated sulphadiazine in absence and presence of additives. Treatment T w (min)6SD SD: 5% Ammonia 1:3 SD: 5% Ammonia 1:3 0.2% w / v Tween 80 0.5% w / v NaCl 2.0% w / v PVP Untreated 40.062.0 0.5 60.0 30.061.0 5.0 60.5 15.061.0 solvent, on the properties of SD was assessed. It is worth noting that only trace amounts of the additive would remain in the treated powder after separation of the solvent. Tween 80 slightly improved the flow properties of solvent treated sulphadiazine (Table 3) and enhanced dissolution (Fig. 4). About 94% dissolution was attained in 10 min. Dissolution enhancement can be associated with the marked increase in wetability (Table 2). The time required for complete wetting decreased from 40 min. to 0.5 min. in the presence of Tween 80. Faster dissolution of Fig. 4. Effect of additives on the percent dissolution of solvent-treated SD using 5% ammonia. crystals treated with trace amounts of surfactants has been attributed to increased wetability and or crystal structure defects caused by the uptake of the surfactant onto the crystal (Chiou et al., 1976). The presence of Tween 80 did not appreciably affect the flow properties (Table 3) or the dissolution rate (Fig. 5) of recrystallized SD. It can be speculated that Tween 80, being nonionic, failed to disturb the arrangement of SD molecules in ammonia solution. This arrangement appears to involve the ammonia / SD dipole structure, resulting in dissolution retardation. Sodium chloride (0.5% w / v) slightly influenced the flow properties of solvent treated SD (Table 3) but increased its dissolution rate (Fig. 4). Dissolution enhancement was not associated with a corresponding increase in wetability (Table 2). The time for complete wetting of a sample bed decreased from 40 min for solvent treated SD to 30 min for NaCl-solvent treated SD. An increase in the dissolution rate of recrystallized SD was also observed (Fig. 5). Sodium chloride probably reduced the interaction of ammonia with SD through ion-dipole interaction, thus opposing the effect of ammonia on the orientation of SD Table 3 Effect of additives on the angle of repose and bulk density of solvent treated and recrystallized SD using 5% ammonia solution as solvent Additive No additive 0.2% w / v Tween 80 0.5% w / v NaCl 0.1% w / v PVP 0.5% w / v PVP 2.0% w / v PVP Bulk density (g / cm 3 ) 6SD Repose angle (8)6SD Solvent treated Recrystallized Solvent treated Recrystallized 53.160.4 52.860.7 52.161.1 48.661.0 49.261.2 39.360.7 37.660.3 37.160.3 38.760.6 37.660.7 37.561.0 35.760.5 0.3860.004 0.4260.003 0.3960.004 0.4060.004 0.3760.003 0.5060.005 0.6160.01 0.6660.01 0.6760.02 0.5660.01 0.6560.02 0.7760.02 Y.E. Hammouda et al. / European Journal of Pharmaceutical Sciences 8 (1999) 283 – 290 Fig. 5. Effect of additives on the percent dissolution of recrystallized SD using 5% ammonia. molecules during solvent treatment or recrystallization and its dissolution-suppressing effect. This could explain the dissolution enhancement observed in Figs. 4 and 5. Retardation of SD dissolution by ammonia has been reported earlier for recrystallized SD (El-Massik, 1987) and observed in this study for both solvent treated and recrystallized SD (Figs. 4 and 5). PVP effectively decreased the angle of repose and increased the bulk density of solvent-treated SD, the largest changes being obtained with 2% PVP (Table 3). Scanning electron micrographs (Fig. 1,d) indicated the formation of SD microgranules with round edges, which may account for the marked increase in flowability. The small amount of polymer interacting at the surface layers of solvent-treated SD did produce a free flowing microgranular material. However, inclusion of 2% PVP in the ammonia solution resulted in a limited decrease on dissolution rates of both solvent-treated and recrystallized SD (Fig. 4 and 5 repectively), probably due to the binding properties of PVP (Adeyeye and Barabas, 1993). 289 tablets exhibited good in vitro and in vivo performance. It appears that the degree of change induced by solvent treatment of powdered materials varies with the inherent physicochemical and solid state properties of the material and the type of solvent used. Additives in the treatment solvent did not improve the tableting properties of SD with the exception of 2% PVP. The microgranular material obtained with 2% PVP could be successfully compressed into tablets. The material was used to prepare 500mg tablets containing 5% starch as disintegrant by direct compression. The tablets had acceptable hardness but exhibited poor disintegration and dissolution (Fig. 6). The use of croscarmellose (5%) in place of starch resulted in tablets with a high dissolution rate, 100% dissolution in 20 minutes (Fig. 6) and good overall in vitro performance (hardness was 5 kg, disintegration time, 1 min.). These tablets obviously met the USP dissolution limit for SD tablets (70% dissolution at 1h) and the rate of drug release was comparable to the best sulphadiazine release obtained from tablets prepared by fluidized bed granulation (Erni and Ritschel, 1977). In conclusion, the solvent-treatment technique proposed in the present work offers promises as a simple, rapid and economic technique for the improvement of tableting properties of powders. It can be applied to manipulate the surface crystal morphology of powders having poor physico-technical properties with a limited effect on dissolution. Improvement of the desired properties can be further increased by using additives during solvent-treatment and / or a limited number of formulation excipients during processing. This may have important practical implications for the engineering of tablet excipients and large dose drug substances for direct compression. 3.5. Preparation of SD tablets by direct compression Although treatment of SD with 5% ammonia improved its flow properties, attempts to compress the solvent treated material using a single punch tablet machine failed to produce tablets with acceptable properties. In another study (Molokhia et al., 1997), however, application of the solvent-treatment technique improved the flow properties and compressibility of paracetamol, allowing its direct compression into tablets after mixing with 15%w / w Avicel and 5%w / w starch. The formulated paracetamol Fig. 6. Dissolution profiles of SD tablets prepared by direct compression and containing maize starch or croscarmellose as disintegrant. 290 Y.E. Hammouda et al. / European Journal of Pharmaceutical Sciences 8 (1999) 283 – 290 Acknowledgements This paper has been presented at the AAPS Annual Meeting and Exposition, October, 1996, Seatle,USA. References Adeyeye, C.M., Barabas, E., 1993. Povidone. In: Brittain, H.G. (Ed.), Analytical Profiles of Drug Substances, Vol. 22, Academic Press, California, USA, pp. 575–576. Berkovitch-Yellin, Z., 1985. Toward an in vitro derivation of crystal morphology. J. Am. Chem. Soc. 107, 8239–8253. Bourne, J.R., Davey, R.J., 1976a. The role of solvent–solute interactions in determining crystal growth mechanisms from solution. I. The surface entropy factor. J. Cryst. Growth 36, 278–286. Bourne, J.R., Davey, R.J., 1976b. The role of solvent–solute interactions in determining crystal growth mechanisms from solution. II. The growth kinetics of hexamethylene tetramine. J. Cryst. Growth 36, 287–296. Buckton, G., 1995. Surface characterization: Understanding sources of variability in the production and use of pharmaceuticals. J. Pharm. Pharmacol. 47, 265–275. Carstensen, J.T., Ertell, C., Geoffroy, J.M., 1993. Physico-chemical properties of particulate matter. Drug Dev. Ind. Pharm. 19, 195–219. Chiou, W.L., Chen, S.J., Athanikar, N., 1976. Enhancement of dissolution rates of poorly soluble drugs by crystallization in aqueous surfactant solution: sulphathiazole, prednisone and chloramphenicol. J. Pharm. Sci. 65, 1702–1705. Chow, A.H.L., Hsia, C.K., 1991. Modification of phenytoin crystals: influence of 3-acetoxymethyl-5,5-dimethylhydantoin on solution-phase crystallization and related properties. Int. J. Pharm. 75, 210–230. Chow, A.H.L., Hsia, C.K., Gordon, J.D., Young, J.W.M., Vargha-Butler, E.I., 1995. Assessment of wetability and its relationship to the intrinsic dissolution rate of developed phenytoin crystals. Int. J. Pharm. 126, 21–28. Davey, R.J., Mullin, J.W., Whiting, M.J.L., 1982. Habit modification of succinic acid crystals grown from different solvents. J. Cryst. Growth 58, 304–312. El-Massik, M.A., 1987. Optimization of certain drug delivery systems. Ph.D. Thesis, University of Alexandria, Egypt. Erni, W., Ritschel, W.A., 1977. Effect of granulation method on dissolution of sulfadiazine experimental tablets. Pharm. Ind. 39, 284–290. Fachaux, J.M., Guyot-Hermann, A.M., Guyot, J.C., Conflant, P., Drache, M., Huvenne, J.P., Bouche, R., 1993. Compression ability improvement by solvation / desolvation process: application to paracetamol for direct compression. Int. J. Pharm. 99, 99–107. Fachaux, J.M., Guyot-Hermann, A.M., Guyot, J.C., Conflant, P., Drache, M., Veesler, S., Biostelle, R., 1995. Pure paracetamol for direct compression. Part 1. Development of sustained-like crystals of paracetamol. Powder Technology 82, 123–128. Femi-Oyewo, M.N., Spring, M.S., 1994. Studies on paracetamol crystals produced by growth in aqueous solutions. Int. J. Pharm. 112, 17–28. Gat, G.V., Dixit, R., Pawar, A.P., Mahadik, K.R., Paradkar, A.R., 1997. Spherical crystallization of sulphamethoxazole pretreatment in tableting. In: FIP’s abstracts, SCI- 023, August, Vancouver, Canada. Gorden, R.E., Amin, S.I., 1984. European patent, no. 0120587. Hammouda, Y.E., El-Massik, M.A., El-Fattah, S.M., 1984. Optimization of sulfadiazine tablets. In: 37th National Meeting of APhA Academy of Pharmaceutical Sciences, October, Philadelphia, PA. Hansford, D.T., Grant, D.J.W., Newton, J.M., 1980. The influence of processing variables on the wetting properties of a hydrophobic powder. Powder Technology 26, 119–126. ¨ Hutenrauch, R., 1983. Modification of starting materials to improve tabletting properties. Pharm. Ind. 45, 435–440. Khan, G.M., Jiabi, Z., 1998. Preparation, characterization, and evaluation of physicochemical properties of different crystalline forms of ibuprofen. Drug Dev. Ind. Pharm. 24, 463–471. Lefebvre, C., Barthelemy, C., Guyot-Hermann, A.M., Guyot, J.C., 1988. An attempt at bringing to light a ’phase inversion’ in a binary mixture of two dimensional rounded particles. Drug Dev. Ind. Pharm. 14, 2443–2465. Lerk, C.F., Lagas, M., Boelstra, J.P., Broersma, P., 1977. Contact angles of pharmaceutical powders. J. Pharm. Sci. 66, 1480–1481. Marshall, P.V., York, P., 1989. Crystallization solvent induced solid-state and particulate modifications of nitofurantoin. Int. J. Pharm. 55, 257–263. Marshall, P.V., York, P., 1991. Compaction properties of nitrofurantoin samples crystallized from different solvents. Int. J. Pharm. 67, 59–65. Molokhia, A.M., Nada, A.H., El-Khordagui, L.K., Hammouda, Y.E., 1997. In vitro and in vivo evaluation of tablets of a directly compressible form of paracetamol. In: The British Pharmaceutical Conference, September, Scarborough, UK. Nath, B.S., Khalil, S.S., 1984. Studies on paracetamol crystals produced by solvent change method of crystallization. Indian J. Pharm. Sci. 46, 106–110. Parrott, E.L., 1970. Pharmaceutical Technology Fundamental Pharmaceutics. In: Burgess Publishing Company, US, pp. 17–18. Sakr, A.M., El-Sabbagh, H.M., Aboutaleb, A.E., Ali, A.M., 1978. A technological study on the direct compression of sulphonamide tablets. Pharm. Ind. 40, 1385–1388. Train, D.J., 1958. Some aspects of the property of angle of repose of powders. Pharm. Pharmacol. 10, 127T–135T. York, P., 1983. Solid state properties of powders in the formulation and processing of solid dosage forms. Int. J. Pharm. 14, 1–28. York, P., 1992. Crystal engineering and particulate design for the powder compaction process. Drug Dev. Ind. Pharm. 18, 677–721.