* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download SMART VALVE POSITIONER 4 to 20 mA

Immunity-aware programming wikipedia , lookup

Control theory wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Rotary encoder wikipedia , lookup

Signal-flow graph wikipedia , lookup

Control system wikipedia , lookup

Switched-mode power supply wikipedia , lookup

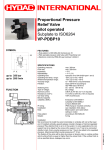

SMART VALVE POSITIONER 4 to 20 mA smar B83 DESCRIPTION The FY290 microprocessor based positioner provides fast and accurate positioning of diaphragm or cylinder actuators. The FY290 produces a pressure output as required to position a control valve according to a 4 to 20mA input signal supplied by a controller. The FY290 is compact and easy to maintain and adjust. Local calibration and parameter setting are done without external devices. Reliable and Flexible Elimination of many mechanical parts seen in other positioners has a number of advantages. Higher reliability since there are less parts that wear, safer since there are less moving parts, more accurate since there is less deadband from mechanical imprecision. Position sensing is done without any mechanical contact virtually eliminating wear and tear and subsequent degradation. FY290 directly senses longitudinal or rotary movement based on the Hall effect. Valve characteristics, action, damping, etc. are altered in software instead of changing mechanical cam and spring. Changing damping, action or characteristics between linear, equal percentage, hyperbolic (quick opening) makes the FY290 extremely flexible. ü ü ü ü ü ü ü ü smar B84 Compact and modular design. Low air Consumption. Easy installation. Direct non-contact position sensing. Operate with rotary or linear motion, single or double acting pneumatic actuators. Easy adjustment and parameter settings with local adjustment and display. Weather proof, explosion proof and intrinsically safe. Flow Characteristics change with software cams. OPERATION Output Module On-Board Parameters The main parts of the output module are the pilot, servo, Hall Effect sensor and the output control circuit. Easy local adjustment allows operator easy calibrating and parameter setting without external devices. Parameters and special functions are selected using a magnetic tool. The FY290 CPU produces an electronic setpoint signal for the control circuit. The control circuit receives an actual valve position feedback signal from a Hall Effect sensor. Calibration of the open and close position of the actuator is automatic. If another position is required the fine calibration of zero point and travel is possible using a magnetic tool. The pneumatic part is based on the well known and widely used pilot tube and spool valve technology. Gain and travel time are locally adjustable allowing the optimization of the positioner for the process conditions. A piezoelectric disk is used as flapper in the pilot stage. The flapper is deflected when a voltage is applied by the control circuit. If a change in position is demanded, the flapper deflects. A small stream of air flowing through the nozzle is changed, causing a change in pressure in the pilot chamber. This is called the pilot pressure. For a certain section used for the operation, the pilot pressure response is linear with the flapper deflection. FY290 has combined all functions in a single unit: Direct or reverse action. Single or double acting actuators. Linear and rotary motion actuators. Split range. Flow characterization: - Linear. - Equal percentage 1:50. - Hyperbolic 1:50. The pilot pressure is far too low, and has no flow capacity and must therefore be boosted. This is done in the servo section, which acts as a transducer. The servo section has one diaphragm on the pilot chamber side, and another smaller diaphragm on the spool chamber side. The pilot pressure applies a force to the pilot side diaphragm which at steady state will be equal to the force that the spool valve applies on the smaller diaphragm. The mounting set for rotary actuators complies with VDI/VDE 3845. When a change in position is demanded, pilot pressure increases or decreases as explained for the pilot stage. A change in pilot pressure forces the spool valve up or down changing the output 1 and output 2 pressures until the desired position is reached. FLOW RESTRICTION Rotary Magnet PIEZO FLAPPER The mounting set for linear actuators complies with IEC534-6 (NAMUR). NOZZLE PILOT DIAPHRAGM ø20...35 (0.79...1.38) PILOT CHAMBER 2 CLAMPS Linear Magnet 65 (2.56) SPOOL DIAPHRAGM VENT 2 OUTPUT 2 AIR SUPPLY OUTPUT 1 SPOOL VENT 1 SPRING B85 smar TECHNICAL CHARACTERISTICS Functional Specifications Performance Specifications Travel Sensitivity £ 0.1% F.S. Linear Motion: 3 - 100 mm. Rotary Motion: 30 - 120° Rotation Angle. Extended Linear Motion: 100 - 1000 mm. Repeatibility £ 0.1% F.S. Input Signal Hysteresis £ 0.1% F.S. 4-20 mA, 2-wire. Power Consumption Supplied by the 4-20 mA current. No external supply required. 0.25 Nm3/h (0.15 SCFM) at 1.4 bar (20 psi) supply. 0.70 Nm3/h (0.40 SCFM) at 5.6 bar (81 psi) supply. Voltage drop 11 Vdc max / 20 mA (equivalent to 550W). Output Capacity Minimum current 46.7 Nm3/h (28 SCFM) at 5.6 bar (80 psi) supply. 3.8 mA. Ambient Temperature Effect 0.8%/ 20 °C of span. Reverse Polarity Protection No damage occurs from reversal of normal supply current (4-20 mA) or from misapplication of up 50 mA. Supply Pressure Effect Negligible. Output Vibration Effect Output to actuator 0 100% supply air pressure. Single or double-action. ± 0.3 % /g of span during the following conditions: 5-15 Hz at 4 mm constant displacement. 15-150 Hz at 2g. 150-2.000 Hz at 1g. Reference SAMA PMC 31.1 1980, Sec. 5.3, Condition 3, Steady State. Pressure Supply 1.4 - 7 bar (20-100 psi). Free of oil, dust and water. Indication Electro-Magnet Interference Effect 4½-digit LCD indicator. Designed to comply with IEC 801 and European Standards EN50081 and EN50082. Hazardous Location Certification Explosion proof, weather proof and intrinsically safe from CEPEL, FM, CSA, NEMKO and DMT (pending). Physical Specifications Temperature Limits Operation: Storage: Display: Electrical Connection -40 to 85 °C (-40 to 185 °F). -40 to 90 °C (-40 to 194 °F). -10 to 60 °C (14 to 140 °F) operation -40 to 85 °C (-40 to 185 °F) without damage. ½ - 14 NPT, Pg 13,5 or M20 x 1,5. Pneumatic Connections Supply and output: ¼ -18 NPT. Gage: 1/ 8 - 27 NPT. Humidity Limits 0 to 100% RH. Material of Construction Flow Characterization Linear, Equal Percentage, Quick Opening. Injected low copper aluminum with polyester painting or 316 Stainless Steel housing, with Buna N O-Rings on cover (NEMA 4X, IP 67). Gain Weight Through software. Locally adjustable. Without display and mounting bracket: 2.7 kg. Add for digital display: 0.1kg. Travel Time Through software. Locally adjustable. Actual Position Sensing Magnet (Non-contact) Hall Effect smar B86 ORDERING CODE MODEL FY290 BFY SINGLE ACTING SMART VALVE POSITIONER CODE Digital Local Indicator 0 1 Without Digital Indicator With Digital Indicator CODE Without Bracket With Bracket 0 1 CODE 0 A B Type of Actuator (Not Included) Rotary-Single Action Rotary Double Action Linear Stroke Up to 15 mm - Single Action Linear Stroke Up to 15 mm - Double Action Linear Stroke Up to 50 mm - Single Action Linear Stroke Up to 50 mm - Double Action Linear Stroke Up to 100 mm - Single Action Linear Stroke Up to 100 mm - Double Action Others Specify CODE ZZ 0 1 0 Without Magnet Mounting Bracket Rotary Linear up to 15 mm Linear up to 50 mm Linear up to 100 mm Others - Specify CODE C I 7 Z Mounting Bracket Material Carbon Steel Bracket 316 SST Bracket Carbon Steel Bracket and Accessories in SST Others Specify CODE Without Gage With Gage - Input With Gage - Output 1 With 2 Gages - Input and Output 1 With 2 Gages - Output 1 and 2 With 3 Gages Others Specify 0 1 2 3 4 5 Z - Magnet Mounting Bracket Indication Gage CODE 0 Without Positioner Bracket Universal Rotary Universal Linear (Yoke and Pillar) Linear - Yoke Type Linear - Pillar Type Others - Specify 0 1 2 3 4 Z ½ - 14 NPT M20 X 1,5 Pg 13,5 DIN 1 2 3 4 5 6 7 8 Z Positioner Mounting Bracket CODE Electrical Connections CODE 1 0 1 2 3 4 Z Note: A Digital Indicator is necessary for calibration. Mounting Bracket CODE FY290 - BRACKET / * BFY - 1 2 C / Optional Items* ZZ Specify Actuador Model / Company * TYPICAL MODEL NUMBER * Leave it blank for no optional items Optional Items* Special Options - Specify TYPICAL MODEL NUMBER * Leave it blank for no optional items ** Use separete ordering code B87 smar DIMENSIONS Dimensions are mm (in) Valve Positioner SUPPLY 1/8 - 27 NPT 45 (1.77) 45 (1.77) 260 (10.24) OUTPUT 1 SUPPLY OUTPUT 2 1/4 - 18 NPT 1/4 - 18 NPT1/4 - 18 NPT 9 (0.35) 22 13 (0.87) (0.51) 39 (1.54) ø83 (3.27) 113 (4.45) 46.5 (1.83) ø69 (2.72) 55 (2.16) 39 (1.54) ø24 (0.954) ø50 (1.97) 6,5 (0.25) ø21 (0.83) OUTPUT 2 1/8 - 27 NPT MOUNTING HOLES FOR M6x1 SCREWS (2 PLACES) 83 (3.27) OUTPUT 1 1/8 - 27 NPT Rotary Magnet Linear Magnet 49.5 (1.95) 55 (2.17) HOLE 6.3 (0.25) (2 PLACES) 68 18 24 (0.94) (0.71) 24 24 (0.94) (0.94) (2.68) 53.3 (2.10) 22.5 (0.89) 33 (1.30) smar B88 15 (0.59) A TRAVEL DIMENSION A UP TO 15 mm (0.59) UP TO 50 mm (1.97) UP TO 100 mm (3.94) 44 mm (1.73) 109 mm (4.29) 185 mm (7.28)