* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Automotive Compilation

Control system wikipedia , lookup

Stepper motor wikipedia , lookup

Resilient control systems wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power engineering wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Buck converter wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Fault tolerance wikipedia , lookup

Voltage optimisation wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electric vehicle conversion wikipedia , lookup

Power electronics wikipedia , lookup

Mains electricity wikipedia , lookup

Resonant inductive coupling wikipedia , lookup

Rectiverter wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Distribution management system wikipedia , lookup

Alternating current wikipedia , lookup

Electromagnetic compatibility wikipedia , lookup

Counter-IED equipment wikipedia , lookup

Automotive

Compilation

Volume 7 December 2010

Contents

Table of Contents

Configurable RF Architecture Gives Engineers

Greater Design Flexibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Design and Security Considerations for Passive

Immobilizer Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Automotive LIN Bus Driving Sensor Applications . . . . . . . . 12

Designing Next Generation Key Fobs . . . . . . . . . . . . . . . . . . 15

Capacitive Proximity Detection in the Automotive

Industry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Extending the Range of E-vehicles with Li-ion

Batteries Using Active Balancing . . . . . . . . . . . . . . . . . . . . . . 24

Precision Battery Monitors for Standard Lead Acid

Batteries Ensure Engine Start-up . . . . . . . . . . . . . . . . . . . . . . 27

DC and BLDC Motor Control ICs . . . . . . . . . . . . . . . . . . . . . . . 29

EMC – Synonym for Exasperating, Magic, Confusing? . . . 36

EMC Pulse Immunity System-level Tests . . . . . . . . . . . . . . . 41

Configurable

RF Architecture Gives

Engineers Greater Design

Flexibility

Ahmad Chaudhry and Jim Goings

In the automotive environment, RFenabled sub-systems continue to

evolve and proliferate. Such systems

include Tire Pressure Monitoring

Systems (TPMS), which are mainly

unidirectional on a single RF channel at

relatively high data rates; Remote Start

(RS) systems, which are generally

bidirectional on single or multiple

RF channels at relatively low data

rates; Passive Keyless Entry (PKE)

and Remote Keyless Entry (RKE)

applications, which are unidirectional

on single or multiple RF channels at

moderate data rates. TPMS uses both

On Off Keyed (OOK) and Frequency

Shift Keyed (FSK) modulation, RS uses

OOK only, and RKE uses either OOK

or FSK. To accommodate such multiple

systems and applications, automotive

RF semiconductor devices must

possess flexible as well as configurable

architectures. The need for architectural

flexibility, combined with customer

expectations of high performance,

improved range, and reliability, is driving

the next generation of RF IC designs.

Beginning with range and reliability,

improvements here are easier to

realize when the transmit path has

programmable parameters. One can

1

usefully employ a Power Amplifier

(PA) with reserve capacity, which can

be trimmed in output power level to

provide the maximum allowable output

in accordance with local regulatory

requirements. Further benefit can be

obtained from a PA whose output

impedance can be trimmed to optimize

the antenna match. Range and

reliability gains on the receive side can

be enhanced through proper selection

of sensitivity-related parameters,

such as RF carrier frequency, subchannels, modulation, data rate, and IF

bandwidth.

and RS. The devices also support all

automotive bands: 310 to 318MHz,

418 to 477MHz, and 836 to 928MHz

and use one device and a single crystal

frequency.

These two devices are also designed

for architectural flexibility. A dualLNA architecture with two separate

input pins natively supports multiband applications using one single

IC, PCB, and bill of materials (BOM).

Additionally, dual-parallel demodulation

paths support simultaneous ASK and

FSK sensing capability. These features

Atmel Has Introduced Next-Generation Transceiver

And Receiver Devices With Configurable Options

Flexibility for the design engineer

is also gained through access to a

receiver in which these parameters are

available as a programmable option.

Atmel® has introduced next-generation

transceiver and receiver devices

with these configurable options.

For example, the Atmel ATA5830

transceiver and Atmel ATA5780

receiver can accommodate automotive

applications such as RKE, PKE, TPMS,

accommodate multiple polling schemes

including TPMS, RS and up to three

RKE channels, and can be configured

to support RF protocols across multiple

frequency bands, modulation schemes,

and data rates.

To implement the vast array of

configurable content in both Atmel®

devices, the desired configuration

settings are stored in the built-in

EEPROM and automatically applied to

© 2010 / www.atmel.com

(Optional)

(Optional)

PB3

PB4

PB5

PB6

PB7

AGND

TEST

_

102

SPDT_RX

RFIN

_HB

SPDT_ANT

SPDT_RX

PB3

PB4

PB5

PB6

PB7

PB2

23

24

22

23

DGND

PB0

21

22

DVCC

DGND

20

21

PC5

DVCC

19

20

PC4

PC5

18

19

PC3

PC4

17

18

Atmel

SPDT_TX

ANT_TUNE

RF_OUT

SPDT_TX

PC2

PC1

PC0

VS

AVCC

XTAL2

XTAL1

VS_PA

XTAL2

VS_PA

RF_OUT

PC3

PC2

PC1

PC0

VS

AVCC

TEST_

EN

10 11 12 13 14 15 16

9

24

PB1

PB2

PB0

PB1

ATA5830

Atmel

ATA5830

ANT_TUNE

SPDT_ANT

9

AGND

TEST

_

102

32 31 30 29 28 27 26 25

TEST_

EN

8

RFIN

_LB

RFIN

_HB

RFIN

_LB

XTAL1

1

1

3

1

4

3

5

4

6

5

7

6

8

7

ATEST

_

101

1

ATEST

_

101

32 31 30 29 28 27 26 25

17

10 11 12 13 14 15 16

VS = 3V

Elements

Number

Inductor

Elements

Capacitor

2Number

(3)

Matching

Comments

72(9)

3Matching

(5) for matching

(3)

43for

Blocking

7 (9)

(5)

for matching

Crystal

1

Capacitor

Inductor

Crystal

1

VS = 3V

Comments

14single

crystal for 3

for Blocking

different frequency ranges

1 single crystal for 3

different frequency ranges

Figure 1. Atmel ATA5830 Transceiver Application Circuit

SPDT_RX

RFIN

_HB

SPDT_ANT

SPDT_RX

N.C

N.C

MISO

PWPON

LED1

NSS

ATA5780

MISO

PWPON

LED1

24

SCK

MOSI

NRESET

VS

AVCC

XTAL2

NRESET

XTAL2

NPWRON3

TMDO

VS

AVCC

10 11 12 13 14 15 16NPWRON2 17

TEST_

EN

9

XTAL1

9

MOSI

23

24

CLK_OUT

SCK

22

23

DGND

CLK_OUT

21

22

DVCC

DGND

20

21

NPWRON5

DVCC

TRPB

19

20

NPWRON4

NPWRON5

TRPB 18

19

NPWRON3

TMDO

NPWRON4

NPWRON2 17

18

TRPA

NPWRON1

NPWRON1

N.C

N.C

N.C

NSS

Atmel

ATA5780

Atmel

N.C

SPDT_ANT

N.C

N.C

AGND

AGND

RX_Active

RX_Active LEDO

LEDO

NPWRONG

NPWRONG

IRQ

IRQ

TEST

_

102

TEST

_

102

32 31 30 29 28 27 26 25

TEST_

EN

8

RFIN

_LB

RFIN

_HB

RFIN

_LB

XTAL1

1

1

3

1

4

3

5

4

6

5

7

6

8

7

ATEST

_

101

1

ATEST

_

101

32 31 30 29 28 27 26 25

TRPA

10 11 12 13 14 15 16

NSS

MISO

MOSI

NSS

MOSI

VS = 4.5v to 5.5v

Microcontroller

SCK

Elements

Number

Inductor

Elements

1Number Matching

Comments

41

1Matching

for matching

Capacitor

Inductor

Capacitor

VS = 4.5v to 5.5v

Microcontroller

MISO

SCK

Crystal

Crystal

4

1

1

Comments

31for

forBlocking

matching

13single

crystal for 3

for Blocking

different frequency ranges

1 single crystal for 3

different frequency ranges

accessible firmware, making it

possible to develop an entire

application using just one single IC.

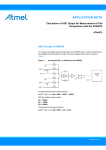

Both the ATA5830 transceiver and

the Atmel ATA5780 receiver are also

highly integrated, requiring very few

external components. The application

circuits (see Figures 1 and 2) show

a standard implementation of each

device. For a typical application, the

ATA5830 transceiver only requires 10

external elements and the ATA5780

only six external elements. Both

devices are packaged in a 5 x 5mm,

32-pin QFN package.

In conclusion, the

newest generation

of configurable Atmel

RF semiconductor

devices provides the

design flexibility needed

for rapidly evolving

automotive RF-enabled

subsystems .

Figure 2. Atmel ATA5780 Receiver Application Circuit

Atmel Devices Also Have Enhancements Which

Simplify Design and Reduce BOM Cost

the device on power-up. This enables

autonomous (stand-alone) operation

and polling for incoming signals from

multiple RF systems with differing RF

carrier frequency bands, modulation

formats, and data rates. Stand-alone

operation allows an external controller

to sleep while the device polls,

validates start of frame, and checks for

proper transmitter ID data. The device

only wakes the controller when a valid

message is detected. This is critical to

reducing Ignition Off Draw (IOD) in

Automotive Compilation Vol. 7

vehicle-mounted applications and to

extending battery life in handheld fob

applications.

Atmel devices also have some other

enhancements which simplify design

and reduce BOM cost. The Atmel

ATA5830 transceiver device, for

example, has an embedded Atmel

AVR® microcontroller on the same

silicon die. The microcontroller

includes 6kByte of Flash and a

24kByte ROM library of user-

2

Design and Security

Considerations for Passive

Immobilizer Systems

Jim Goings, Toby Prescott, Michael Hahnen, Karl Militzer

For years, consumers have come to rely on the convenience and added security that

a passive vehicle immobilizer system offers . These systems consist of a key fob, carried

by the driver, and a base station, mounted in the vehicle . They work together to

determine if the driver is authorized to start the vehicle . Of equal or greater importance

is the system’s ability to prevent unauthorized sources from using the vehicle . While

top-level functionality of a vehicle immobilizer is simple to describe, the underlying

technology enabling it is intriguing and sophisticated . This article will explore both

the hardware and software aspects of vehicle immobilizer systems as well as offer

noteworthy comments on design and security considerations .

Communication

The prevailing method of communication between key fob

and vehicle in passive vehicle immobilizer systems today

is with a modulated magnetic field. This field is created by

the vehicle’s immobilizer base station from a low frequency

alternating current, typically 125kHz. The magnetic field

serves three fundamental purposes: A) the power source for

the key fob, hence the term “passive”, B) a carrier on which

information from the base station to key fob is conveyed, e.g.

“downlink”, C) a carrier on which information from the key

fob to the base station is conveyed, e.g. “uplink”.

authentication process, which has a direct impact on response

time. The sections that follow will address these topics in

greater detail.

System Interfaces

The system architecture of a vehicle immobilizer has several

layers of abstraction, each representing different system

interfaces. Figure 1 provides a visual representation of these

layers.

Crytographic

Protocol

Characteristics of magnetic fields that are of particular appeal

for a vehicle immobilizer system pertain most to the key fob’s

need to operate completely passively, e.g. without a battery.

“Downlink” field detection and “uplink” field modulation

can both be achieved using circuitry that consumes very

little current. Furthermore, harnessing sufficient field energy

to power these circuits in the key fob electronics can be

achieved with relative ease.

During the system design phase, care must be taken to

carefully consider key performance parameters such as key

fob energy requirements, which affect

antenna coil geometries and drive levels, and the

3

Logical

Physical

Figure 1. Vehicle Immobilizer Interface Layers

The Physical Layer

A t the lowest level of a vehicle immobilizer system is the

physical layer. It consists of a vehicle-mounted antenna coil

capable of creating a magnetic field of sufficient magnitude

to enable its detection and modulation by an antenna coil

mounted in the user’s key fob.

© 2010 / www.atmel.com

Field Generation and Modulation

Vehicle immobilizer systems can be classified in one of two

different ways based on how the magnetic field is used

to support the transfer data: half duplex or full duplex. In

a half-duplex system, the vehicle-mounted antenna coil

alternates between periods of energy transfer and data

transfer. Uplink data (e.g., fob to vehicle) is modulated using

Frequency Shift Keying (FSK). A graphical representation of

this communication method is shown in Figure 2. Two points

should be intuitively obvious from viewing Figure 2. First, the

rate of data transfer suffers from a significant compromise

due to the recurring need to perform the energy transfer,

e.g., charge up the key fob. Second, the modulated signal is

very small compared to the field present during the energy

transfer period, making it more susceptible to interference

from ambient noise which results in reduced range. These

characteristics have caused the popularity of half-duplex

systems to wane.

The dominant system in use today is the full-duplex system

in which the vehicle-mounted antenna coil performs energy

transfer AND data transfer simultaneously. Uplink data is

modulated using Amplitude Shift Keying (ASK). A graphical

Magnetic Field Charges Key Fob

FSK Key Fob Return Frequency ƒ¹ (red)

Figure 2. Half-duplex Communication Using FSK

Automotive Compilation Vol. 7

FSK Key Fob Return Frequency ƒ (blue)

0

4

Magnetic Field Charges Key Fob

ASK Key Fob Return Signal - Resistively Damped ( Green )

ASK Key Fob Return Signal - Undamped ( Black )

Figure 3. Full-duplex Communication Using ASK

representation of this communication method is shown in

Figure 3. Clearly, the ability to simultaneously transfer data

while keeping the key fob energized, or charged, provides

the design engineer a significant data transfer rate advantage

over half-duplex systems. Additionally, the constant carrier

field tends to mask out interferences and enables robust

communication during the data transfer. Furthermore, this

approach can be realized using simple envelope detection

circuitry. Because of the popularity of the full-duplex vehicle

immobilizer system in the market place today, the rest of this

document will focus on this type of system.

to predetermined times; T0 for a logic “0” and T1 for a

logic “1”. The advantage to this approach is that it embeds

energy transfer from vehicle to key fob into the data

encoding and ensures the key fob will be supplied enough

energy to process the encoded data. However, a side effect

of this encoding method is that the data transfer baud rate

depends on the logical value of the data bit stream being

sent since the transmission times for each binary state are

different. See Figure 4 for a more detailed graphical depiction

of this coding method.

System Interfaces: the Logical Layer

1-bit value

The next layer above the physical layer is the logical layer.

This layer captures the characteristics and requirements for

the coding and transfer of data across the magnetic field. It

applies to the bi-directional data transfer that takes place

from vehicle to key fob, commonly referred to as “downlink”,

as well as key fob to vehicle, also known as “uplink”.

‘0’

Downlink

‘1’

Downlink information is coded using Pulse Length

Modulation; typically Binary Pulse Length Modulation

(BPLM) or Quad Pulse Length Modulation (QPLM). This

method is based on inserting a carrier field gap, Tgap, of

fixed duration and setting the gap to gap timing intervals

5

BPLM bit frame example

LF-Field

Tgap

12 x CLKFC

LF-Field

Tgap

20 x CLKFC

Figure 4. BPLM Coding Method

© 2010 / www.atmel.com

QPLM is a variation of BPLM that is sometimes used. With

this modulation, two bits are transmitted after one gap, and

therefore more power is available on the transponder side. In

addition, the average baud rate is higher compared to BPLM.

The coding method follows the same basic implementation

as BPLM, except the allowed number of states is extended

from two to four and the predetermined gap to gap timing

Clock

Data

0

0

1

1

0

1

0

0

Manchester

Bi-phase

Figure 6. Manchester and Bi-phase Coding

2-bit value

QPLM bits frame example

LF-Field

‘00’

Tgap

18 x CLKFC

‘01’

LF-Field

Tgap

Both encoding techniques enable clock extraction from

the encoded data stream. This is possible because all time

durations in the coded bit stream are quantized to one of two

values; T or 2T, where T is what is referred to as a “half bit”.

Data rate is fixed by the relationship 1/(2T). Clock extraction

merely requires the detection of the minimum time duration

element, T, and synchronizing its phase with the coded bit

stream.

28 x CLKFC

LF-Field

Tgap

‘10’

40 x CLKFC

‘11’

LF-Field

Tgap

62 x CLKFC

Figure 5. QPLM Coding Method

intervals are expanded to cover the additional states. See

Figure 5 for a visual representation of QPLM.

Uplink

Information communicated from the user fob to the vehicle

base station is typically encoded using Manchester or Biphase. These encoding methods share several characteristics

that differ from the downlink: A) the encoded bit stream

always has an average duty cycle of 50%, B) the time

to send encoded data is based solely on the baud rate.

Automotive Compilation Vol. 7

Protocol Layer

The protocol layer defines how individual data bits are

grouped to enable communication between the vehicle

base station and key fob. It defines how many bits and in

which order they are transmitted between the reader and

the transponder. As a simple analogy, this can be compared

to the rules governing the formation of sentences in using

words. The protocol layer would be like the sentence formed

from the logical layer which would be like the words. It forms

a fixed set of commands along with their allowable responses.

Authentication

Authentication is the term used to describe the process of

deciding whether the driver is authorized to start the vehicle.

The simplest form of this is called unilateral authentication.

In this case, the vehicle “tests” the key fob to determine

if it has been associated/learned to the vehicle. When an

additional step is added to this process, in which the key

attempts to “test” the vehicle to determine if it has been

associated with the key fob, it becomes bilateral or mutual

authentication. Clearly, this added step increases security

strength but comes at the expense of longer authentication

time.

6

Unilateral Authentication Protocol

Key

Read UID

Command

Car

LF-Field On

Detection Header

(optional)

Key

Memory

ID

Memory

ID

4-bit Command

+ 4-bit CRC

Key

Memory

Read UID

ID

OK?

8-bit Header

+ 32-bit ID

+ 8-bit CRC

Stop

N

Y

Random Number

Challenge

8-bit Command

+ N Challenge-bit

+ 8-bit CRC

AES-128

(enc.)

Response

Challenge

AES-128

(enc.)

8-bit Header

+ M Response-bits

+ 8-bit CRC

=

Response

N

Stop

Y

Valid

OK, it is the

right key

Start Authentication

Command

Figure 7. Unilateral Authentication

Unilateral Authentication

Key Learn: Open/ Secure

Typically, the unilateral authentication protocol is initiated by

the vehicle and consists of the following steps:

1. Vehicle reads the key fob’s unique ID (not to be

confused with the secret key)

The Key Learn Protocol is the process that is used to allow

the vehicle to establish a secret key and share it with the key

fob. Depending on the restrictions and safeguards placed on

the initiated Key Learn session by the vehicle, secret keys

can be shared openly or securely.

2. Vehicle generates a random number challenge and

sends it to the key fob

An open Key Learn process would typically consist of the

following steps, also shown in Figure 8:

3. Key fob encrypts the challenge (using the secret key)

and sends this response to the vehicle

1. Vehicle generates a secret key based on a random

number and “proposes” it to the key fob

4. Vehicle compares key fob’s response with its calculated

response (using same key and challenge)

2. Key fob “accepts” secret key, saves to memory, and

responds with an acknowledgment

Note: The vehicle must posses the key fob’s secret key to

enable the success of this transaction. The process of sharing

the secret key is called “Key Learn” and is described in the

next section.

7

3. Vehicle saves secret key to memory after successful

receipt of key fob’s acknowledgement

If the Key Learn Protocol can’t be protected from

eavesdroppers or unauthorized access to the vehicle, it may

be desirable to utilize a Secure Key Learn Process.

© 2010 / www.atmel.com

Open Key Learn 1/2

Key

Car

LF-Field On

Detection Header

(optional)

Secret Key

Random Number

8-bit Command

+ 128 bit Key

+ 8-bit CRC

Secret Key

Learn Secret

Key (1 or 2)

Cmd

Key Memory

=

Pass

N

Stop

Y

Response ( Pass/Fail )

8-bit Header

+8 bit Status

+ 8-bit CRC

Key Memory

Figure 8. Open Key Learn

Bilateral or Quasi-mutual

Authentication

A more complex form of an authentication process is the

quasi-mutual or bilateral authentication. It is not a full

mutual authentication that is implemented in the Atmel®

immobilizer system because it does not use random

generators on both sides of the system, the car and the

key. The implemented solution uses a MAC (Message

Authentication Code) to authenticate the car vis-à-vis the

key.

Again, the authentication protocol is initiated by the

vehicle and – in case of a bilateral authentication –consists

of the following steps as shown in Figure 9:

1. Vehicle reads the key fob’s unique ID

2. Vehicle generates a random number challenge and

sends it to the key fob

3. Vehicle encrypts the random number and appends it

to the challenge

Automotive Compilation Vol. 7

4. Key fob encrypts the challenge (using secret

key 1) and compares it with the received encrypted

challenge (MAC)

5. If the result matches, the key fob encrypts it (using

secret key 2) and sends this response to the vehicle

6. Vehicle compares key fob’s response with its

calculated response (using same key and challenge)

Cryptographic Layer

The cryptographic layer provides the highest level of

encryption. It contains the mathematical function that

transforms a plain text message into a secret message.

Ideally, this function should have two properties:

1. Unique: For every plain text input, there must be a

unique secret text output

2. Unpredictable: It must not be possible to predict a

plain text to secret text pair, even if a large sample

of known good plain text to secret text pairs was

available for analysis

8

Bilateral Authentication Protocol

Key

Detection Header

(optional)

ID

memory

ID

4-bit Command

+ 4-bit CRC

8-bit Header

+ 32-bit ID

+ 8-bit CRC

Random Number

128-bit

Key 1

AES -128

encryption

Stop

Ok, is it the

right

car, continue

N

=

Y

Read UID CMD

Read UID

ID

OK?

Stop

N

Y

Start Authenitcation

Command

Random Number

8-bit Command

+ N bit RandN

+ M bit (RandN)

+ 8-bit CRC

Hidden

challenge (HCH)

expanded to 128 bits

AES -128

encryption

128-bit

Key 2

Car

LF-Field On

128-bit

Key 1

Hidden

challenge (HCH)

expanded to 128 bits

AES-128

encryption

128-bit

Key 2

AES-128

encryption

8-bit Header

+ M bit {Resp}AES

+ 8-bit CRC

=

Y

N

Stop

Ok, is it the

right key,

car match

Valid

Figure 9. Bilateral Authentication Protocol

Public vs . Private

For many years, private cryptographic algorithms were

commonplace. However, private algorithms have drawbacks:

A) uncertainty of algorithm’s strength, B) lack of being

subjected to critical peer review, C) potential wide-scale

security compromise should the algorithm be leaked to the

public. In recent years, several high-profile examples can be

cited that illustrate these weaknesses. Perhaps even more

compelling is the lack of interoperability in systems that share

the same physical and logical layers. This interferes with basic

competitive market forces and in many cases drives higher

system costs.

In an effort to address these concerns, public opinion has

shifted toward the acceptance of a public domain encryption

algorithm – the Advanced Encryption Standard (or AES,

as it is more commonly referred to). Its origin comes from

the 1997 initiative at the National Institute of Standards and

Technology (NIST) to select a public-domain encryption

algorithm. Within a year, fifteen candidate algorithms

were identified and subjected to critical review by the

cryptographic research community. This analysis included an

9

assessment of security and efficiency characteristics for each

algorithm. After trimming the list of candidates from fifteen to

four, NIST subjected them to a second round of public review

before finally selecting the AES algorithm in 2000.

AES, as we know it today, is a symmetrical block cipher that

combines a 128-bit plain text input with a 128-bit secret key

to create a 128-bit encrypted output. Due to its symmetrical

characteristics, AES can also be used in reverse to combine

the encrypted output with the secret key to find and extract

the original plain text input.

System Security Considerations –

Attacks and Countermeasures

A common misconception held today is that the security of a

vehicle immobilizer system is established by the strength of

the encryption algorithm. While encryption algorithm strength

is important, it alone does not define the overall system’s

resistance to attack. Each of the interface layers in the

immobilizer system, algorithmic, protocol, logical and physical,

contributes to the system’s overall security and must be

studied and fortified against attack.

© 2010 / www.atmel.com

Algorithmic Security and

Countermeasures

Physical/Logical Security and

Countermeasures

As noted earlier, it is imperative that the encryption algorithm

possess unique and unpredictable characteristics. In the case

of AES, the details of how the algorithm operates is freely

available to the public and as a result, it has been subject

to critical review by the research community. This, by far,

is the best countermeasure available. To date, scientific

studies have confirmed the algorithm’s strength as it has

withstood the test of time (over 10 years). However, in the

case of private algorithms, scientific analysis by the research

community was not possible, leaving the strength of these

algorithms in question. In fact, many have failed to withstand

the test of time and in recent years their weaknesses have

been exposed.

In recent years, attack methods have grown more

sophisticated. “Side-channel” attacks such as Simple Power

Analysis (SPA) and Differential Power Analysis (DPA) as

well as other “invasive” attacks have been successfully

applied to extract secret keys from key fobs. These socalled side-channel attacks measure and evaluate the power

consumption of a cryptographic device and combine it with

knowledge of the plain text or cipher text in order to extract

an otherwise secret key. The theory underlying these

methods is quite sophisticated and beyond the scope of this

document. The strongest defense against the side-channel

attacks noted above are:

Protocol Security and Countermeasures

In systems using unilateral authentication, attacks on the

protocol layer are typically accomplished using “scan” or

“dictionary” methods. In a “scan” attack, the attacker

receives a challenge from the vehicle and returns random

values in response. If the protocol consisted of a 56-bit

response, then the bit security is 256 , i.e., it takes 256 trials to

get one valid challenge-response pair. To resist this type of

attack, the following measures can be considered:

• Increasing the response bit length to add complexity

• Having the vehicle embed exponentially growing timeouts between consecutive unsuccessful trials

• Having the vehicle block trials after a fixed number of

consecutive unsuccessful trials are attempted

In a “dictionary” attack, the attacker collects valid challenge

(from the attacker) response (from the key fob) pairs by

communicating directly with the transponder. These pairs are

placed in a look-up table or “dictionary” for future reference.

Equipped with this dictionary, the attacker then sequentially

triggers the vehicle for a challenge, which can be checked in

the dictionary for a valid response. If the protocol included a

100-bit response, one would need 251 trials to get one valid

challenge-response pair. The “birthday paradox” states that

after 2n/2 logged challenge-response pairs and

2n/2 trials, the probability of a valid result is 0.5. Using this,

it can be shown that the overall complexity of this attack is

2n/2+1 = 251. Countermeasures to consider in this case are:

• Increasing the challenge bit length to add complexity

• Implementing a bilateral authentication protocol

Automotive Compilation Vol. 7

• Randomization of clock frequency and operation

• Interleaving of digital control and the encryption

operation

“Invasive” attacks dwell on the physical implementation

of the encryption-related circuitry on the silicon die itself.

The best countermeasures are fairly simple to implement as

long as they are considered early in the design process. The

following are examples of steps that could be considered:

• Metal shielding of memory blocks

• Using non-standard synthesis libraries

• Scrambling the location of critical digital elements used

during encryption

• Restricting memory access and automatic chip-erase

function if attempted

System Performance Considerations

Current Consumption

System performance has different aspects. One is the power

consumption of the key fob. This parameter relates directly

to the achievable communication distance between key

fob and vehicle base station. Car manufacturers and Tier1

suppliers tend to emphasize the importance of the coupling

factor as a critical system parameter. However, it mainly

represents the relationship of the mechanical dimensions

between the key fob’s antenna and the vehicle base station’s

antenna. This parameter is only valid for a given system

configuration and depends on antenna inductance, Q-factor,

driver current, reader sensitivity, and ignition lock cylinder

material. Because of this, use of this parameter alone to

compare different systems is inadequate. Of equal if not more

importance than the coupling factor is current consumption,

especially given that the key side current consumption is a

limiting factor in a passive, batteryless environment where

10

the energy is harvested from a magnetic field and stored in

a small capacitor. By selecting system components designed

for extremely low power consumption and microcontrollers

capable of being programmed with well-balanced

software (putting the controller in sleep mode whenever

possible), the engineer is able to overcome earlier system

disadvantages requiring high coupling factors to compensate

for high current consumption in the key fob.

Authentication Response Time

Another important factor in immobilizer systems is the time

it takes from turning the key fob inserted inside the lock until

the engine starts. This time should be short enough to avoid

the driver’s perception of a delay. Depending on mechanical

and electrical system design and how quick a person can

introduce and turn the key, an overall timing budget in the

range of 300ms to 500ms is typically available. A significant

part of this budget is consumed through mechanics and

overhead in the body control module. What remains is

between 100ms and 200ms for the authentication process. A

good compromise in terms of speed and security seems to be

a bilateral authentication with a challenge length of 100 bits

and a response length of 56 bits. In most systems this results

in a response time of under 100ms.

Error Handling

In case an authentication failed for whatever reason, today’s

systems require the complete authentication cycle to restart

from the beginning and allowing a maximum of three retries

within a reasonable time. The retry strategy from Atmel®

looks a bit different and enables the system to recover from

communication errors more quickly. All commands and

optionally the data are protected by a Cyclic Redundancy

Check (CRC). Both the key fob and the base station can

make use of the CRC to detect errors and signal these

conditions to their respective communication partner. This

enables the base station to be selective about the amount

of repeated info, the last action, the last response, or the

last command. This feature enables quicker communication

recovery and more attempts at communication recovery

in the same amount of time (five-seven retries instead of

three).

11

Summary

By selecting system components that meet the security

and performance expectations of the automotive market

place, and support a highly configurable and open-source

immobilizer software stack, the task of developing a robust

vehicle immobilizer system can be greatly simplified. As a

leader in automotive vehicle access solutions, Atmel offers

such a complete system solution consisting of both hardware

and software.

Key fob designs can be realized with the Atmel ATA5580 and

the Atmel ATA5795. These devices boast an LF front end, an

AES hardware block to perform fast and efficient encryption

calculations, coupled with an Atmel AVR® microcontroller that

has been optimized for extremely low current operation.

Both include programmable flash memory that can be used to

run the Atmel open immobilizer protocol or other customerspecific software and are capable of completely passive

immobilizer operation.

A base station can be realized with the Atmel ATA5272. This

device integrates the LF base-station function with an AVR

microcontroller with 8K of programmable flash memory.

As a final complement to these devices, the open immobilizer

protocol software from Atmel is available to users at no

cost. It provides an unprecedented level of configurability

including many user selectable features enabling the dynamic

evaluation of system parametric tradeoffs and accelerates the

development and optimization process:

1. A logical layer with uplink and downlink baud rate, bit

encoding, and modulation depth

2. A protocol layer with challenge and response bit

lengths, unilateral or bilateral authentication, data field

CRC, two secret keys, secure or open Key Learn

3. A cryptographic layer with AES crypto clock speed from

125 kHz to 4 MHz “on the fly”

© 2010 / www.atmel.com

Automotive LIN

Bus Driving Sensor

Applications

Dr. Stephan Hartmann

Today’s cars contain, on average, more than 50 different

sensors to monitor various physical variables . This number is

growing, driven mainly by the proliferation of actuators, which

require sensors to deliver the relevant input values . In addition,

requirements for signal systems are now increasing, and analog

data transfer techniques are showing their limitations . The

engineer now faces the challenge of transforming the sensor

area into an efficient, high-performance digital subsystem .

LIN bus driving sensor technology enables efficient management

of digital data, combining the benefits of existing voltage

modulation and current modulation approaches . Atmel®

provides all necessary products independent of the integration

level of LIN applications .

Automotive Compilation Vol. 7

12

Sensor systems differ in many respects from other electronic

components of the car. The most important difference is

that sensors are mostly located outside the vehicle in harsh

environments where they are subject to changes in humidity,

temperature or pressure. In most cases, sensors also have

to be mounted in areas with very limited space and are

connected with a 2- or 3-wire harness.

pull-up resistor. For the connection to the sensor, a 2-wire

connection is used. Disadvantages include thermal power

dissipation in the sensor module, as well as a limited data

rate dominated by the pull-up resistor. Other current-based

transfer methods, such as Manchester-coded protocols,

require dedicated transceiver ICs, driving system costs up.

The Applications for Sensors are as Diverse

as the Application Areas Themselves:

• In the comfort area:

- Temperature sensors

- Solar altitude sensors

- Light sensors

- Humidity sensors

- Dew point sensors

• In the powertrain area:

- Position sensors

- Speed sensors

- Pressure sensors

- Knock sensors

• In the body control area:

- Pressure sensors

- Gyro sensors

A typical sensor node contains the sensing element itself, a

microcontroller for signal conditioning, and a transceiver for

signal transmission. As the length of the data line is often

more than 1m, the data transfer is dominated by analog

signal conditioning which has a portion of about 90%.

Analog signal conditioning does have some advantages.

It is compatible with previously existing mechanical or

electromechanical detection systems, and is also easy

to use and to plug in. Analog data can be provided in a

voltage range of, for example, 0 to 5V and the sensor can

then be monitored by an ADC port on a microcontroller

which converts the data into the digital domain. Generally,

however, requirements for sensor systems are increasing,

making analog signal conditioning less attractive. With ADC

resolutions up to 10 Bit, and the ability to indicate two

different types of failure modes by clamping the signal

voltage either to the lowest or to the highest voltage levels,

analog techniques have already reached the limits of their

performance and will be replaced by different types of digital

data transfer.

Digital data transfer can be managed either by voltage

modulation or current modulation. Both types have

advantages and disadvantages. Simple current modulation

allows a very cost-efficient design of the ECU as well as of

the wiring harness. Inside the ECU, the different current

levels can be transferred into voltage levels using a single

13

Figure 1. Basic Current Interface Set-up

Voltage modulation has the advantage of allowing a variety of

protocols, beginning with simple PWM and moving to more

complex versions like SENT, which have higher data rates

than current modulation. Additionally, the ECU input can be

designed as a capture compare unit on a timer basis. The

main drawback of voltage modulation is that a wiring harness

with a 3-wire connection is mandatory. Further issues may

arise at EMC testing because most PWM drivers do not

include a slope rate control. Additionally, ESD protection is

low.

Figure 2. Basic Voltage Interface Set-up

The LIN bus protocol combines all advantages described

above. As a two-wire interface, LIN helps save cost in the

wiring harness. LIN’s slew rate control in the transceiver

ICs supports excellent EMC performance, while LIN’s ESD

protection features allow robust system designs suitable for

harsh environments. Finally, the high production volumes

© 2010 / www.atmel.com

for LIN bus transceivers lead to very cost-efficient designs

compared to other protocols requiring transceiver ICs (e.g.,

current-based transfer protocols).

and a microcontroller for signal conditioning and protocol

handling. Atmel® serves all integration levels with LIN

transceivers, LIN system basis chips (SBCs), and LIN

system-in-package (SiP) devices. With SiP, the customer

benefits from the ultra low-power designs of Atmel AVR®

microcontrollers with Atmel picoPower® technology. As a

second step, the designs can be converted into single-chip,

multi-die SiP designs. This saves PCB space and allows the

engineer to include all electronics in the connector of the

sensor element. Finally, by integrating the sensor element

into the chip, and by implementing an intelligent state

machine, the engineer takes a further step toward advanced,

single-chip LIN sensor node designs.

Figure 3. LIN Interface Set-up Modified to Support the Current Supply of the LIN Sensor Slave

UC

The concept for the system design specifies a pull-up resistor

at the ECU level. This is required to control the current supply

for the LIN slave sensor through the data line. At the LIN

slave sensor, only a buffer capacitor is required. Depending

on the capacitor value, the data rate can be chosen up to 100

kbit/s. Supply voltage reduction provides an additional option

for influencing the data transmission speed. As the dominant

and recessive levels are referenced to the supply voltage,

a reduction of the supply voltage directly reduces the gap

between bus low and high level (the delta) to reach the

correspondent levels. A 2V supply voltage reduction leads to

an increase in the data transmission rate of roughly 15%.

Unfortunately, the supply voltage cannot be lowered in all

cases. The time portion of the bus-dominant level must also

be considered, as this state discharges the buffer capacity of

the LIN slave sensor

Sensor system design using LIN can be viewed as a threestep process. First approaches to a discrete slave-node

design include a sensing element, a LIN system basis chip,

Voltage

99%

98%

95%

86%

63%

t

1τ

2τ

3τ

4τ

5τ

1τ

2τ

3τ

4τ

5τ

Figure 5. Capacity Discharge Depending on the Bus-dominant State Time

In summary, LIN not only enhances the driving of cars

from the in-vehicle networking point of view, it also allows

the rumble change of the sensor area to a cost-efficient

and high-performing digital sub-system. Atmel offers all

necessary products regardless of the integration level of

LIN applications. To support low-power designs, the AVR

microcontroller with picoPower technology is key. In addition,

engineers can design the most robust and EMV-tolerant

systems with the leading-edge EMC and ESD performance of

LIN transceivers and SBCs from Atmel.

20

18

16

Special thanks to Daniel Yordanov and Keith Nicholson

for supporting me during the writing of this article.

14

12

10

8

VCC

6

LINH

4

2

LINL

0

Figure 4. Bus Level States Bus Level States Depending on the Supply Voltage

Automotive Compilation Vol. 7

14

Designing

Next-Generation

Key Fobs

Paul Lepek

Key Fobs Today

915MHz). However, for a PE system the LF downlink is

used by the key fob to compute a Received Signal Strength

Indicator (RSSI) value and thus the fob’s physical coordinates

in relation to the vehicle while the RF link is used to execute

the authentication protocol with the vehicle. RKE and PE

system fobs are designed to be powered by a small coin

battery intended to last for the life of the vehicle.

Today’s key fobs can be generally subdivided into two

different functional categories. The first includes Remote

Keyless Entry (RKE) devices which require some sort of

human intervention or a physical interface of the user to the

key fob (e.g., key push) in order for the fob to produce the

desired function effect such as unlocking a door or

opening a sunroof. The second group of devices

provides similar functionality but also features an

Atmel has Introduced Next-Generation Transceiver

added level of comfort by performing the same

and Receiver Devices with Configurable Options

function without physical intervention by the user.

Instead of the push button or touch sensor interface,

a Passive Entry (PE) identifies the user (and the

Moreover, all key fobs support engine immobilizer system

key fob) as a legitimate entity and automatically triggers

authentication. To prevent theft every automobile uses an

authentication or issues a request (e.g., passive door unlock,

immobilizer system which authenticates engine starts. In

trunk release, etc.).

this case the key fob acts as a passive authentication tag

Both systems are based on a preprogrammed key fob device

similar to the RFID tag but with a larger feature set. Most

ID and authentication protocols which include an encryption

automotive key fobs use Near Field Communication (NFC)

stage for authorizing the issue of key fob commands to the

transponders which communicate with the engine controller.

vehicle. In this way the key can be identified by the vehicle

The transponder is integrated into the key and is a passive

and vice versa before any action is executed. All RKE-based

device. It does not need a battery for operation, but instead

systems require key fobs to support RF links which fall into

uses a magnetic field generated by the LF vehicle coil. It also

Industrial, Scientific and Medical (ISM) frequency bands

transmits the device ID and executes a special immobilizer

(i.e., 0 - 135kHz, 13.56MHz, 315/433MHz, 869MHz, and

15

© 2010 / www.atmel.com

Table 1 . Key Fob Features Today

Class

Immobilizer1

Physical Interface 3

(Button, Touch, etc.)

Batttery/

Recharge2

Remote

Start

Remote Entry

Accessories

Passive

(Entry/Go)

Accessories

Personalization

Settings

Time/

Data Logging

in Fob4

x

Basic

x

-

-

-

-

-

x

RKE (std.)

x

x/

x

-

-

-

x

RKE (ext.)

x

x/x

x

-

x

-

x

PE (std.)

x

x/x

x

x

x

x/x

x

PE (ext.)

x

x/x

x

x

x

x/x

x

x

x

Immobilizer support includes secure fob and vehicle authentication via the LF field using an integrated LF transponder.

1

The fob includes a built-in battery with the option of recharging the battery via the LF field.

2

Remote Start and Remote Entry are controlled via RF uni- or bi-directional link. Control of accessories can either be done using RF or IrDA links.

3

4

Data can be logged such as time stamp data, last device ID, last vehicle service date, and much more either via LF or RF links.

protocol for its authentication but all communication takes

place via an LF field generated by the vehicle.

Expanding Fob Applications

Originally key fobs were designed for only one purpose:

to unlock the door and start the engine with the metal

key. Later, RKE devices were used to remotely (HF

field) unlock the door. The integrated contactless passive

transponder (LF field) then unlocked the steering column

and enabled the engine start.

Only more recently fobs began to penetrate convenience,

general utilities, secure communications, and secure access

ID applications (even extending to payment systems and

e-ticketing). These functions were not developed before

due to a lack of hardware and software resources, primarily

because of the fob’s physical size and power consumption.

Recently, however, it has become possible to overcome

these shortcomings by incorporating much larger user and

program memories, and the use of faster, more compact,

and ultra-low power processors without increasing the

cost of production. Additionally, the integration of flexible,

reconfigurable, and secure authentication peripherals can

be made feasible. These types of peripherals include crypto

units, secure key management features, and integration

of smart cards useful for payment, user ID, and cipherbased authentication systems. An automotive key fob can

therefore be used not only to interact with the vehicle but

Automotive Compilation Vol. 7

also to gain entry to a park garage, ski lift or to purchase

train tickets. This can deliver considerable benefits when

goods are purchased using one of the major credit card

networks. The secure user memory can also be used to

store personal and secure information as personal data ID

and provide transit information for e-ticketing.

System-in-fob Hardware Resources

• Ultra-low-power 8-bit microcontroller

• Large Flash program and EEPROM data memory

(memory segmentation with locks)

• RF communication interfaces

- Infrared (IrDA) IF

- Immobilizer IF at 125kHz

- Passive entry IF at 125kHz (RX only)

- Smart card IF at 13.5MHz

- RKE IF at 315, 413, 868, 915MHz

(frequency hopping)

• Power management (optional battery charge)

• Hardware cryptological unit (AES-128)

• Integrated proximity coupling smart card (ISO 14443)

• Cyclic Redundancy Check (CRC) block

• Serial interfaces (SPI, SSI)

• ISP/debug (dW)

• Analog comparator

• Flexible GP timers and WDT

• Oscillators: RTC, INTRC (125kHz, 4MHz)

16

The heart of a modern key is an ultra-low power

microcontroller with sufficient program and data memories.

Typical program memory can range from 8KB to 16KB

and beyond with its data memory ranging from 1KB to

2KB depending on application requirements. Because of

secure application support, the key fob’s program and data

memories must have provisions for memory segmentation

and locks in both memory blocks. For example, the

application firmware resident in program memory can be

divided into separate memory sectors (e.g., application and

immobilizer sections). Also data memory may have its own

partitioning which can allow for soft and hard memory locks

when it comes to releasing user-sensitive device-stored

data (e.g., authorization password or secure key). While

the microcontroller core executes application firmware, the

secure user and key data is stored in the on-chip nonvolatile

memories (EEPROM).

The core uses various wireless communication peripheral

interfaces to communicate with the infrared transceiver

(IrDA), the LF transponder (125kHz), the 3D LF receiver

(125kHz), the smart card (13.5MHz) and the RKE

transceiver (315, 413, 868, 915MHz). Flexible serial

interfaces can be shared such as SPI or Serial Synchronous

Interface (SSI) to enable data exchange with every

communication peripheral. A hardware data integrity check

module, based on a Cyclic Redundancy Check (CRC)

checksum algorithm, supports validation of received data.

The fob must also contain analog peripherals such as internal

oscillators where F = 125 kHz and 4 MHz to generate its

internal clock signals used for the transponder front end and

the microcontroller core, respectively, with low frequency

deviation across VDD and temperature. The supplied analog

comparator can facilitate detection of VDD drops and prevent

data corruption during nonvolatile data memory writes in

passive mode.

Power

Management

SPI

FRC -Oscillator

Contactless

Interface/

Transponder

EEPROM/

2KB

RTC

3D LF Receiver

Volt. Monitor

ECIN

Clock

Management

& Monitoring

Contactless

Interface/

SmartCard

SRC Oscillator

Smart

Card

Atmel AVR - Core

Watchdog

Timer

IR - Driver

Timer Block

Crypto Unit

PM – ROM

2kB

SRAM

512B

Data Mem.

Secure

EEPROM

.

CRC

POR / BOD &

RESET

PM - Flash

14kB

debug WIRE

RF

TX/TRX

Module

Serial IF

IO-Ports

Figure 1. Fob Floor Plan

A unique feature of the immobilizer transponder interface

is that it is closely bound to the power management unit

which is used to provide power supply voltage, VDD, while

exchanging LF data with the immobilizer in passive mode.

In this mode all other communication with the key fob is

disabled to support batteryless operation. Some key fobs may

also support the battery charge feature which is integrated

into the power management module for recharging the

battery with the engine running.

Wireless Data Communication Interfaces

An entry/immobilizer system consists of at least two

communication partners where one side is on the vehicle

and the other on the key fob. Depending on the link type,

there are several possible communication interfaces available,

including:

1. IrDA link for convenience and comfort applications

While in secure smart card mode the device can also

operate in passive mode and exchange as well as encrypt

and decrypt proprietary data using its own crypto module

with the reader at FC = 13.5MHz. It can use its own device

memory or the fob’s internal nonvolatile memory.

Integrated crypto modules can support many different cipher

algorithms—the most popular being the 256-bit block cipher

known as the Advanced Encryption Standard (AES) based

on the Rijndael algorithm which can be used with a 128-bit,

196-bit or 256-bit secret key.

17

2. PE/PEG link to enter and start engine, including LF

downlinks and UHF uplinks

3. Immobilizer link to start engine and emergency vehicle

entry, including LF down- and uplinks

4. Chip card as user ID, authorization, authentication at pay

stations, including HF down- and uplinks

5. RKE as entry authentication, including UHF down- and

uplinks

© 2010 / www.atmel.com

Table 2 . Modern Key Fob Communication Links – Overview

Application

Standard

Link Type

FC

Modulation

Anticollision

Data

Encoding

BR [Baud]

Range

Average

Current

PE/PEG

Custom

3D LF

downlink

0130kHz

ASK

x

PIE

3.9k

3 - 5m

2 - 20μA

UHF uplink

315, 433,

868,

915MHz

ASK/FSK

-

Manchester,

Biphase

Up to 80k

30 - 120m

8 - 20mA

LF downlink

0130kHz

ASK

-

PIE

3.1 -8.9k

2 - 10cm

40 - 260μA

Manchester

4.4k

PIE, Miller,

NRZ

Up to 20k

5 - 20cm

20 - 120μa

Up to 80k

30 - 120m

8 - 20mA

Immobilizer/

Emergency

Entry

ISO14223

/Custom

LF uplink

Chip Card

ISO14443

ISO15693

ISO18000

HF

downlink

ASK

13.56MHz

HF uplink

RKE

Custom

UHF

downlink

ASK/PSK

x

ASK/BPSK

315, 433,

868,

915MHz

ASK/FSK/

PSK

Manchester,

NRZ

x

Manchester,

Biphase

UHF uplink

VBAT=1 & VFLD=0

(Start-up)

The summary of the communication channels and a brief

overview is shown in table 2.

Enter RKE Mode

RKE

Secure and Reconfigurable Firmware

Application firmware which supports the complete

functionality and feature set is the fundamental building block

of the key fob. It may consist of many different modules and

must encompass all functional and likely operating scenarios,

including battery failure which comprises emergency or

passive operation mode. To improve reliability it is a common

practice to keep both application and immobilizer programs

separate and in two distinct program spaces. While the

immobilizer firmware supports distinct engine starts, the

application software controls all other fob functionalities

including RKE, convenience or user-ID applications. The

immobilizer/emergency functionality is required to take

priority over any other function, which is the equivalent of an

override which suspends any function currently in progress

when the LF field is detected at the transponder LF coil.

Figure 2 depicts a flow diagram and interaction between

application and immobilizer firmware.

Automotive Compilation Vol. 7

APPLICATION SW

MODULE

VFLD?

Yes

No

VBAT=0 & VFLD=1

(Start-up)

Enter IMMO. Mode

IMMOBILIZER

APPLICATIONSW

MODULE

VFLD?

No

Yes

Figure 2. Immobilizer and Application Firmware Interaction Flow Chart

All data communication is fully supported in the fob’s

firmware. Various communication protocols including

unilateral, bilateral for immobilizer, PE/PEG and RKE systems

can be fully configured by the application software. Based on

18

A major advantage of a next-generation key fob is its in-field

programmability, which can be very helpful in the event of a

firmware or user data upgrade or programming. The fob can

be initially configured using its dedicated general-purpose

software via the LF field while the final test is performed at

the factory. The user data can be added later by the Tier1

or OEM without modifying the original configuration. Even

while in the field the fobs can be reprogrammed with new

Coupling

Factors

for Immobilizer

SystemSystem

Coupling

Factors

for Immobilizer

9.00%

8.00%

7.00%

Coupling factor [%]

protocol topology, the application software controls dedicated

peripherals by enabling them, and reading data during RX

phases, and writing data during TX phases of the protocol as

soft triggers (e.g., immobilizer and PE applications) or hard

triggers (e.g., RKE or IrDA applications using a push button

interface).

6.00%

5.00%

4.00%

3.00%

2.00%

1.00%

0.00%

0

0.02

Distance d [m]

Abstraction Level

Software Model

Figure 4. Immobilizer Coupling

Application Layer

Protocol/Session Layer

API, Configuration

Data I/O

Transport/Link Layer

Physical Drivers

Resources

Figure 3. Software Partitioning as a Bottom-up Approach

application and user data via one of the communication

interfaces at a later date. Of course, in this case only a single

functionality can be enabled while using memory locks to

provide security. This is especially useful when used as a pay

token in e-commerce or e-ticketing environments.

0.04

0.06

0.08

Lr=Rehfeld, Lt=2.45mH

Lr=Rehfeld, Lt=5.1mH

Lr=738uH, Lt=2.45mH

Lr=738uH, Lt=5.1mH

Figure 5 shows one complete challenge-response

authentication protocol which could be used in a passive

automotive immobilizer application. The LF field voltage

(green) is enabled for 160ms. The field is damped (2.2V)

during RX state and then switched to the undamped

level (6V) during TX state. The charge storage capacitor

voltage (yellow) which provides VDD to the transponder is

immediately charged to 2.2V during the RX data stage. The

transponder encrypts (AES-128) received plain text data

(128-bit challenge) and transmits the response. In many

immobilizer systems the system authentication time is a

major concern. To minimize authentication time, the number

of bits transmitted can be reduced without compromising

system security. It is common for authentication time

TAUT < 130ms at BR = ~3.9kBaud.

Transponder LF Field Coupling

Transponder-to-base-station coupling still remains the most

challenging aspect for key fobs. The proper transponder

coupling can be achieved when sufficient energy is

transferred from the base station to the transponder for the

transponder to communicate with the base station. During

design, the L-C tank must be carefully selected for optimum

energy and communication performance. Figure 4 shows a

typical transponder coupling at 125kHz vs. operating distance

from the base station coil5.

Figure 5. Immobilizer Protocol Execution Scope Shot/Power Analysis

5

19

Assumes the fob coil is placed in the center of the base station coil where the coupling is best

© 2010 / www.atmel.com

Figure 6 shows field voltage and VCC traces as the key fob

is energized by the field and begins to receive a BPLM data

stream. Field gaps are visible which separate field ‘On’ interval

which is decoded by the fob using a dedicated hardware

peripheral. The fob’s microcontroller is in sleep mode 95% of

the time to save power consumption.

Table 3 . RF Transceiver Parameters

Sensitivity

Antenna

Gain

POUT

Average

Current

Receiver

-109dBm

-6dB

-

~6 - 8mA

Transmitter

-

-18dB

10dBm

~9 - 10mA

Table 3 shows some typical RF transceiver parameters.

A snapshot of the transmitter spectrum taken at 433MHz

during transmission of an RKE message to the vehicle is

shown in Figure 7. The transmitter carrier frequency, the

span, power output, and device setting are configured using

the serial interface by shifting configuration data (in this case

the 32-bit configuration word) into the RF transmitter via the

MCU when the user presses the open-door button.

Figure 6. Transponder at Power-up

RF Communication Links

Both RKE and PE/PEG systems utilize HF communications

links. In comparison to LF links, HF links are superior in their

operating range (up to several hundred meters) and baud

rate (up to 80kBaud can be achieved). RF transceivers

currently available on the market use N-fractional PLL

frequency tuning techniques where the carrier frequency

can be selected in firmware by the MCU. Some devices allow

large tuning frequency variations, permitting more design

flexibility. The transceiver’s operating range remains a key

performance parameter. To extend operating range, it is

common for the transmitter power to be as high as 12.5dBm

and the receiver sensitivity to be less than -100dBm.

Antenna design is also a determining factor providing

additional performance gain. Although whip antennas add

additional performance gain, small loop antennas printed on

the PCB are usually chosen for use in automotive key fobs.

Power consumption is another critical factor on the receiver

as well as on the transmitter side. Power consumption can be

reduced by selecting higher data baud rates. Choosing ASK

modulation tends to lower operating current since the power

amplifier is momentarily disabled during modulation.

Automotive Compilation Vol. 7

Figure 7. RF TX Spectrum at 433MHz

References:

1. ISO 14223 – Advanced Transponders Standard

2. ISO 10536 – Close Coupling Smart Cards Standard

3. ISO 14443 – Proximity Coupling Smart Cards Standard

4. ISO 15693 – Vicinity Coupling Smart Cards Standard

5. ISO 18000 – Item Management Standard

20

Capacitive Proximity Detection in the

Automotive Industry

Luben Hristov

There has been a steady rise in demand for proximity

detection sensors in automotive applications which reliably

detect the presence of objects near the sensor surface

without physical contact and the number of possible

proximity detection applications is countless:

• Door entry control: detecting a hand approaching the

door handle to initiate the car unlocking process

• Illuminating and waking up the touchscreen when a

hand approaches the screen surface

• Switching interior car lights on/off when the hand is

near the sensor

• Detection of simple spatial gestures to switch devices

on/off

• Sensing the presence of large objects around the car

during parking

Many different proximity detection methods exist, for

example, capacitive, infrared, ultrasonic, optical, etc. For

the 5mm to 300mm proximity detection range, capacitive

21

sensing has many advantages compared to other methods:

excellent reliability, simple mechanical design, low-power

consumption, and low cost base. This article describes

capacitive proximity detection technology from Atmel®.

Atmel is a leading touch solutions manufacturer with many

years of experience in this field. The company’s capacitive

sensors are based on charge-transfer technology—a method

pioneered by Atmel where voltage is generated on the

sampling capacitor during the repetition of a specific control

sequence applied over the I/O pins. Atmel currently holds

multiple patents in the area of charge-transfer technology

for self-capacitance sensors (Atmel QTouch®) and mutualcapacitance sensors (Atmel® QMatrix). The Atmel chargetransfer technology delivers key benefits to the user and

offers advantages compared to other capacitive measuring

methods: increased flexibility, very high sensitivity,

excellent moisture resistance, and noise immunity.

QTouch and QMatrix technologies have been implemented in

multiple touch controllers supporting touch buttons, sliders,

wheels as well as touchscreens. Proximity detection support

is also available with some of the standard products. Atmel is

now developing and manufacturing new proximity algorithms

© 2010 / www.atmel.com

conductive surface as shown in Figure 1. Please refer to

the Atmel application note about using active shields at

http://www.atmel.com/dyn/resources/prod_documents/ankd02_103-touch_secrets.pdf, page 7. A further advantage of

active shields is their neutralizing effect on water films.

• Moisture resistivity: Moisture-induced changes in the

measured signals can be more significant than changes

from approaching objects. Water film on the surface is one

of the biggest problems for capacitive solutions. Water films

are more or less conductive and create a change of the

measured signals that is similar to normal touch events.

There are mainly two ways to handle effects caused by

water films:

1. Use of active shields (described above)

Figure 1. Active Shielding of Proximity Sensor

to increase sensitivity to support finger or hand detection

ranges of up to 200mm and more. The release of standard

products and software library modules is being planned for

2011 and 2012.

Capacitive proximity sensors measure the capacitance

change between the single electrode and ground (selfcapacitance sensors) or between two electrodes (mutual

capacitance sensors) as objects approach electrodes.

While constant capacitance is between 10pF to 300pF, the

capacitance changes are typically extremely small, ranging

from a few fF to several pF. Since the electrical field lines

around the self-capacitance sensors spread far away from

the sensing electrode, self capacitance is the preferred

proximity detection method over mutual capacitance where

field lines are largely concentrated in the area between the

transmitting and receiving electrodes.

Characteristics of Capacitive Proximity

Sensors For Automotive Applications:

• High sensitivity: Detecting small changes in the

measured capacitance requires increased and stable

sensitivity. Special measures should be taken to reduce

negative effects on sensitivity caused by capacitive

loading, especially if the sensing electrode is placed on

a conductive surface (metal plane, car body, etc.). An

active shield layer is used to reduce the negative effect

of capacitive loading between the electrode and the

Automotive Compilation Vol. 7

2. Shorter charge transfer time – the water film could be

utilized as a distributed RC circuit (as shown in Figure

2). Reduced charge transfer pulses will prevent full

charging of the distributed capacitors C and hence

reduce the impact of the water films. Best results can

be obtained if the charge transfer time is in the range

of 100ns to 250ns. A proper mechanical design of the

sense area and the use of the appropriate materials

prevent the emergence of thick water films on the

sensing area.

Figure 2. A Water Film Acting as a Distributed RC Circuit

• Temperature stability: In automotive applications extreme

and rapid temperature changes may occur at any time.

Special care should be taken with regards to a stable

mechanical design – even the smallest gap changes near

the conductive surfaces may cause false detection.

• Noise immunity: Due to the high sensitivity, noise

interference could compromise normal operation of the

proximity sensor. The electrical and mechanical design of

the PCB should be carried out to avoid noise interference

caused by adjacent cables or conductive surfaces.

• Fast response time: The expected response time is

usually between 10ms and 100ms

22

The following sections provide more detailed scenarios of

automotive capacitive proximity detection.

Door Entry System

One example of capacitive proximity detection is in car

door entry systems (see Figure 3). The proximity sensor

that detects hand approaches is located within the car door

handle (1). Once object proximity has been detected, the

main unit (2) sends a wake-up signal via the LF antenna

(3) which activates the car key transmitter (4). The car

key transmitter then exchanges information with the RFID

receiver (5) and – if the code matches the main control unit

(2) – the door is unlocked. The entire process of proximity

detection and ID recognition takes a fraction of a second.

This means when the hand pulls the door handle, the door is

already unlocked.

causes the light to switch on, a wave of the hand in the

opposite direction switches it off. The system is able to

analyze the signals from the proximity sensors and to decide

whether to switch the lamp on or off.

There are many different options available for designing

sensing electrodes inside a light – from using thin copper

wires to conductive polymers that can be applied directly

over the plastic.

The advantage of using proximity detection rather than touch

detection in door entry systems is the extended time to

identify a person. As a result, the door lock state will always

be resolved before the door handle is pulled.

Figure 4. Spatial Gestures for Switching Devices On/Off Inside the Car

Conclusions

• Implementation of capacitive proximity sensors in

automotive applications paves the way to a broad range

of comfort applications

Spatial Gestures to Switch

Devices On/Off

The simultaneous use of two or more capacitive proximity

sensors enables simple spatial gestures such as hand waving

in front of the device to be detected. Figure 4 shows a simple

example of such a system to switch lights on/off inside the