* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Hearing Conservation Training Program

Survey

Document related concepts

Transcript

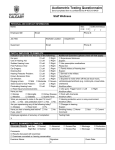

Hearing Conservation Training Program For 49 CFR Part 227 © 2009 Transportation Occupational Medicine Consultants, Inc. 1 Introduction This presentation is intended to provide you with the information and training needed to protect your hearing in the railroad working environment. It has been developed specifically for 49 CFR Part 227, ‘Occupational Noise Exposure for Railroad Operating Employees’ and the training requirements listed in section 227.119. 2 Part 1 The effects of noise on hearing 3 What is hearing? Hearing is the ability to detect sound. Sound is the result of vibrations causing waves in the air. Sound is detected by the ear. Sound waves vibrate bones and membranes in the ear and move hair cells, which creates an electrical impulse in the brain. To perceive this impulse is to hear. Noise is sound that is unpleasant, painful to hear or unwanted. 4 How is sound measured? Sound is measured in decibels. A decibel (dB) is simply a unit used to express the intensity of a sound wave. Due to how decibels are measured, every time sound increased by 5 dB, the energy of the sound doubles. So, 90 dB has twice the energy of 85 dB. 5 Common noise levels Listed below are the noise levels of some common sounds and noises: Fireworks: 160 dB Rock concert: 120 dB Power lawnmower: 90 dB Alarm clock: 70 dB Normal conversation: 60 dB Whisper: 30 dB 6 Noise can damage hearing Prolonged exposure to loud noises can damage the hair cells in your ears, which leads to noise induced hearing loss. OSHA requires that you wear hearing protection when exposed to noise equaling a time-weighted-average (TWA) of 8 hours at 90 dB or greater in the workplace. 7 Noise can damage hearing Exposure to loud noise does not end when you leave the work place. Take care to avoid excessive noise when at home, such as loud music, power tools or shooting. It’s a good idea to use hearing protection when off the job and exposed to loud noises such as those listed above. 8 Part 2 The purpose of hearing protection 9 Why use hearing protection? Hearing protection devices (HPDs) will decrease your risk of hearing loss by reducing your exposure to noise. There are two types of HPDs: Earplugs, and Earmuffs Both types generally reduce noise levels by 15-30 dB. The HPD packaging will list the noise reduction rating (NRR.) 10 Advantages & Disadvantages of HPDs Advantages: HPDs protect your hearing, preventing hearing loss and allowing you to safely and efficiently perform your job. HPDs are provided by your employer. You can use HPDs to protect yourself when off the job as well. You are not required to wear HPDs at all times; only when you are in a noisy environment. As a rule of thumb, if you cannot carry on a conversation, you’re in a high-noise environment. 11 Advantages & Disadvantages of HPDs Disadvantages: HPDs must fit properly to be effective. Dirty HPDs can cause an ear infection. Some types of HPDs may be uncomfortable to wear if not fitted or used properly. Using HPDs when not required may keep you from hearing warning alarms or important communications, which could affect your ability to safely do your job. 12 When to use HPDs As outlined in the General Code of Operating Rules (GCOR), you must where HPDs in the following situations: Hearing protection is required when working in or around the following service, repair, or mechanical areas: 1. Car and Locomotive Shop Buildings. When working in open-sided or enclosed car and locomotive shop buildings. EXCEPTION: Persons in low noise areas, identified by Safety Department, are not required to wear hearing protection. 13 When to use HPDs cont. 2. Car Repair or Service Track Buildings. When working in open-sided or enclosed areas where cars are repaired or locomotives are fueled or serviced. EXCEPTION: When in offices with doors and windows closed, these areas do not require hearing protection. 3. Load Testing, Sand Blasting, or Grit Blasting Areas. When working close to or within areas where load testing, sand blasting or grit blasting equipment is in operation. 4. Mechanical Facilities. When working in or around mechanical facilities designated by a sign or instructions. 14 When to use HPDs cont. Hearing protection is required within 150 feet of master, group, or inert retarders during humping and trimming operations. Dual hearing protection (ear plugs and muffs) is required within 10 feet of these operations. When near operating retarders: Engine windows and doors must be closed when passing through operating retarders. All occupants must be inside the locomotive cab. Do not ride a car through operating retarders. Exception: Hearing protection is not required when riding through or working around Dowty retarders, unless protection is needed for other purposes. 15 When to use HPDs cont. Employees must wear hearing protection anytime they are within a radius of 100 feet around a locomotive. However, hearing protection is not required for employees who are inside the locomotive cab with the cab doors and windows closed. Hearing protection is required within 100 feet of operating roadway or work equipment. Hearing protection is required within 150 feet of operating jet blowers or pile drivers. 16 When to use HPDs cont. Hearing protection is required when operating or within 15 feet of any of the following equipment or tools in operation: Welding or cutting equipment (oxy-fuel, gas, or electric). Abrasive wheel grinder or sander (pedestal, bench, or portable). Air lance or nozzle (for blowing compressed air). Chain saw. Nail gun (air or powder-actuated). Power saw, planer, router, or joiner. Equipment or tools powered by: Air Combustion engine Electricity Hydraulic Pneumatic Steam 17 Use and care of HPDs When using earplugs: Always read and follow all packaging instructions on fitting and care. Always inspect all plugs for dirt, wear or hardness before use. Discard the plugs if they are dirty or damaged. Do NOT use single-use plugs more than once; discard them after use. For banded and multiple-use plugs, clean with mild soap and water after each use and store in a case when not in use. FOR REMOVAL: Gently twist the earplug while slowly pulling it out of your ear. If either or both plugs do not feel like they are properly fitted, remove and reinsert the plug. 18 Use and care of HPDs Multiple-Use Plugs: 19 Use and care: multiple-use plugs 1. Reach over your head with your free hand and pull your ear up and back. 2. While holding the stem, insert the earplug so that all of the flanges are inside of your ear canal. 3. If fitted properly, the tip of the stem may be visible to someone looking at you from the front. 20 Use and care of HPDs Roll-Down Foam Plugs: 21 Use and care: roll-down foam plugs 1. 2. 3. 4. Be sure your hands and fingers are clean before touching the plugs. Roll the plug into a cylinder, as narrow as possible. Pull your ear up and back with your free hand. Insert the plug fully into your ear canal. Stop pushing when your finger touches your ear. 5. Hold the plug for 30 seconds to allow it to expand. 6. If fitted properly, the end of the plug should not be visible to someone looking at you from the front. 22 Use and care of HPDs For no-roll foam earplugs, pull your ear up and back with your free hand. Insert the plug fully into your ear canal. Stop pushing when your finger touches your ear. If inserted properly, the end of the plug will not be visible to someone looking at you from the front. Always dispose of no-roll foam earplugs and rolldown foam earplugs after use. Do not reuse. 23 Use and care of HPDs Headband Earmuffs: Before use, always examine the cups and cushions for cracks or leaks. Discard if the ear cups are damaged. 24 Use and care: headband earmuffs 1. Place the ear cups over each ear. make sure that the cups completely cover each ear. 2. Adjust the headband and cups so that the earmuffs fit comfortably and form a seal over each ear. 3. Do not allow the cups to be blocked by hair, earrings or anything else. 25 Use and care of HPDs Clean the ear cups and cushions regularly with mild soap and water. Replace the cushions every 6-8 months for normal wear, or every 3-4 months for heavy wear. The ear cups should not be crooked or tilted over your ear. They should form a seal between the cup and your head. 26 Use and care of HPDs When you are provided with your HPDs, carefully read all instructions and ask your employer or supervisor for help or instructions on properly fitting your devices. Improperly worn hearing protection devices may not fully protect your hearing. You should avoid over-use of HPDs or overprotection in locations with minimal noise. 27 Part 3 The purpose of audiometric testing 28 Audiometric testing You will be required to take an audiometric test to establish a baseline audiogram for your hearing, which will show what your initial hearing ability is. 29 Audiometric testing You will be required to take an audiometric test once every 3 years, which will be evaluated and compared to your initial baseline audiogram. This will help determine if you are experiencing noise induced hearing loss. If caught early, noise induced hearing loss may not be permanent, which is why the audiometric testing is important. These tests will be provided to you free of cost. 30 Testing procedure Prior to any audiometric test, you will be required to avoid excessive noise for 14 hours, or use hearing protection devices to lower your exposure to acceptable levels. The test will be conducted in a quiet environment. Tones will be played at various frequencies in each ear to determine what your hearing level is at that frequency. Normal hearing levels are between 0-25 dBs at each frequency, from 500 to 8,000 hertz in each ear. The results of the test will be compared back to your baseline audiogram to determine if you have experienced any change in your hearing ability. 31 Sample audiogram When you receive the results of your audiogram, they will look similar to the table below: Frequency .500K 1K 2K 3K 4K 6K 8K Left Ear 05 05 10 10 15 20 20 Right Ear 05 05 10 10 15 20 20 The following are descriptions of hearing loss levels: Normal Hearing: 0 – 25 dB Slight Loss: 25 - 40 dB Mild Loss: 40 - 55 dB Moderate Loss: 55 – 70 dB Severe Loss: 70 – 90 dB 32 Standard Threshold Shifts If your audiogram reveals a loss in hearing of 10 dB or greater in one ear when compared to your baseline audiogram, this is what is known as a standard threshold shift. If an STS has occurred, your employer may order a retesting within 90 days. Your audiogram will also be evaluated by a certified physician who will determine if further evaluation is required. Some loss of hearing occurs naturally due to age, and this will be taken into consideration when evaluating your audiogram. If an STS is confirmed, you may still be able to work, although hearing protection devices will be required. 33 Part 4 Noise at the work place 34 Noise operational controls What are noise operational controls? Noise operational controls are steps or methods used by your employer to limit your exposure to excessive noise. Noise operational controls may include, but are not limited to: Switching your work assignment to different routes, such as routes with less crossings. Placing you on a newer, quieter locomotive. Arranging your work schedule so that you are not exposed to noisy areas every day. 35 Noise monitoring Noise monitoring is the process of measuring the sound levels on the job site that employees are actually exposed to. Noise monitoring is done by using sound-level-meters (SLMs) to determine the TWA sound levels on the job. During noise monitoring, microphones may be placed on you or a co-worker to try and get an accurate idea of what sound levels you’re exposed to. Other microphones will be placed in the locomotive. If you are monitored, you will be notified of the results of noise monitoring either by your employer or by the group conducting the noise monitoring. 36 Workplace exposure There are a few common sources of noise that you can expect to be exposed to during your work. These include: Working near retarders The locomotive horn Locomotive air brakes Hump yards Switching Remember, you are required to wear hearing protectors when exposed to sound levels equal to or higher than a TWA of 90 dB. 37 Excessive noise If you notice an unusually loud or uncommon noise during your work, you may file an excessive noise report. Be sure to ask your employer for the specific details on how to file an excessive noise report for your company, and complete the TOMC excessive noise report form and return it to your supervisor. Some of the sources of an excessive noise report may be: Open windows Loose handles on doors Loose parts or equipment banging against something Do your best to determine the source of the excessive noise prior to filing your report. Your employer will be responsible for fixing any problems. 38 Part 5 Your right to access records 39 Your rights Your employer must make a copy of 49 CFR 227, the Federal Railway Regulation regarding hearing conservation, available to you. Ask your employer where you can obtain a copy at your place of work. You also have the right to request copies of your records from your employer. Your employer must allow you to inspect your records should you request it. You are responsible for complying with all rules and regulations regarding your training, audiometric testing and hearing protection. For more specific details on your responsibilities, please see the relevant sections of 49 CFR 227. 40 TOMC, Inc. This presentation was developed by Transportation Occupational Medicine Consultants, Inc. (TOMC) and is for the authorized use of its clients only. Any other use or reproduction, in part or in whole, of this program is prohibited. Questions or comments may be directed to Bill Weedmark, Operations Manager, at: [email protected] © 2007-2009 41