* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download 2.7 helpful bacteria

Traveler's diarrhea wikipedia , lookup

Quorum sensing wikipedia , lookup

Microorganism wikipedia , lookup

Phospholipid-derived fatty acids wikipedia , lookup

Hospital-acquired infection wikipedia , lookup

Human microbiota wikipedia , lookup

Triclocarban wikipedia , lookup

Disinfectant wikipedia , lookup

Marine microorganism wikipedia , lookup

Bacterial cell structure wikipedia , lookup

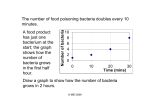

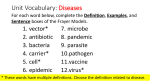

Unit 02 - Student book 9/25/03 12:59 PM Page 48 TECH CONNECT 2.6 QUESTIONS (Page 115) Understanding Concepts 1. UHT milk can be transported and stored without refrigeration. Bacteria have been destroyed in processing, and the unopened container has a shelf life of 9–12 months. No additives or preservatives have been added, and the nutritional value is identical to fresh milk. 2. pasteurization: the process of heating milk to a specific temperature for a specific period of time in order to kill microorganisms that could cause disease, spoilage, or undesired fermentation homogenization: the process of making homogeneous or uniform in consistency; with milk, the emulsification of its fat content sterilization: the process of making milk free from live bacteria or other microorganisms standardization: the process of comparing with a standard; an acknowledged measure of comparison for quantitative or qualitative value 3. Aseptic packaging is free of pathogenic organisms. The contents will remain this way until the packaging is opened. Aseptic packaging is a safe way of transporting and storing a perishable product. Making Connections 4. Evaluation of UHT technology: Advantages of UHT Technology Disadvantage of UHT Technology – provides a safe source of protein in tropical areas where refrigeration is not available – allows the consumption of milk in wilderness situations where packing fresh milk is not feasible – can be used in emergency or survival kits or shelters – packaging is compact and easy to transport and store – requires expensive equipment, skilled workers, and expertise in production techniques – product is more expensive than fresh milk – packaging may not be biodegradable – some problems with flavour have contributed to slow consumer acceptance – can result in the loss of vitamins and amino acids 5. Any group that wants to consume milk over a period of time without access to refrigeration would benefit from UHT processing: Guide and Scout camps; wilderness tour groups; boaters and campers. Packets of UHT milk are useful in emergency ration kits. The Canadian and American armies use this product. 6. One in four Canadian workers is employed, either directly or indirectly, in agriculture and food production. Careers in the dairy area may involve processing and manufacturing, packaging and handling, distribution and retailing, market research, product development, food quality management, or dairy farm management. Several colleges and universities in Canada have co-op programs, internships, and work placements to provide hands-on experience in agriculture and food science. Extensive information is available on an agriscience link from the Nelson Science Web site. More than 25 specific careers in the diary industry are listed, along with their National Occupation Classification (NOC) Codes. The Human Resources Development Canada Web site at http://jobfeatures.ca/noc/browse-occupations-noc.shtml provides details of each coded career. 2.7 HELPFUL BACTERIA SECTION 2.7 QUESTIONS (Page 117) Understanding Concepts 1. E. coli bacteria act as recyclers in the human intestine, releasing digestive enzymes and breaking down organic matter. E. coli may also be involved in probiotics. E. coli is a normal resident of the large intestine in healthy people. It is a type of probiotic organism because it crowds out disease-causing bacteria. E. coli also makes vitamin K, which humans need to be healthy. 48 Unit 2 Student Book Solutions NEL Unit 02 - Student book 9/25/03 12:59 PM Page 49 2. Key information in this section: Pollution control bioremediation uses bacteria to consume toxins in the environment Recyclers saprophytes release digestive enzymes to decompose organic matter HELPFUL BACTERIA Probiotics some bacteria help maintain health and may prevent disease Industry bacteria make enzymes which are used to produce consumer products Applying Inquiry Skills 3. As organisms metabolize, heat is released. If the temperature of compost relates directly to bacterial activity, the bacteria were most active on Day 3. Making Connections 4. When bacteria metabolize, enzymes are released. In nature, these enzymes promote decay of organic matter. In industry, these enzymes are harvested to produce consumer products. Bacterial enzymes are essential in each situation. 5. Microorganisms have been used for centuries to produce food and wine. The many exotic cheeses we enjoy today would not be available without controlled use of bacteria. The key word here is “control.” A live organism may be unpredictable when even small changes are made during processing. Good safety and quality control procedures must be in place in all industrial procedures. Exploring 6. Industry uses bacteria to make many consumer products. Some examples additional to those listed in Table 1 (p. 117 of the Student Text) are: Aspergillus niger (production of citric acid, which is used in soft drinks, candies, inks, engraving materials, and a variety of pharmaceuticals such as anticoagulants and effervescent tablets like Alka-Seltzer); Lactobacillus bulgaricus (makes lactic acid, which is used to preserve foods, finish fabrics, prepare hides for leather, dissolve lacquers, and ferment a variety of foods); E. coli and Enterobacter aerogenes (produce lysine, used in production of breads, breakfast cereals, and other foods); Bacillus subtilis and Aspergillus oryzae (produce the enzyme protease, used in liquid glues, laundry presoaks, meat tenderizers, drain openers, and spot removers); Ashbya gossypii, Pseudomonas, Propionibacterium, and Streptomyces (used to produce vitamins B2 and B12). A sample report on the commercial production of yogurt: (a) Consumer product (photo of yogurt should be included here): Yogurt is a dairy product produced by the controlled fermentation of milk. Two species of bacteria ferment the sugar in milk (lactose) to acid (lactic acid). Production of acid causes the formation of the characteristic curd in yogurt. Acid also restricts growth of bacteria that cause spoilage and food poisoning. For this reason, the storage capacity of yogurt is about 10 days under refrigeration, compared to only a few days for fresh milk. (b) Bacteria involved (diagrams of shapes should be given): Streptococcus thermophilus and Lactobacillus lactis subspecies cremoris are the two types of bacteria used in yogurt production. S. thermophilus is a Gram-positive, nonmotile, nonsporulating coccus (0.2 2.5 µm) found in chains. It is a microaerophilic, aerobic organotroph. L. lactis is a Gram-positive, usually nonmotile, nonsporulating bacillus (0.8 2 µm) found singly or in variable-sized clusters. It is an anaerobic organotroph that must obtain energy exclusively by substrate-level phosphorylation. Both bacteria are homofermentative—they produce lactic acid as the sole product of fermentative metabolism. Yogurt quality is determined by the correct balance of the two bacteria. A master culture is formed by growing a dried culture on pasteurized milk. Refrigerated portions can be used to inoculate the milk, and the last portion can be re-inoculated into milk to form a new master culture. With good hygiene practices, the process can continue for weeks; eventually undesirable bacteria will contaminate the culture and it must be replaced. Spoilage by bacteria or moulds and maintenance of correct incubation temperature are two potential problems in making yogurt. NEL Section 2.7 49 Unit 02 - Student book 9/25/03 12:59 PM Page 50 (c) Steps for the commercial production of stirred yogurt: 1. Heat milk to 85–95°C for 15–30 min. 2. Homogenize milk. 3. Cool milk to incubation temperature. 4. Add bacterial starter. 5. Incubate mixture at 40–46°C for 4–5 h (until the pH has fallen to around 4.3). 6. Stir thickened yogurt and cool to 5°C. 7. Add fruit, flavourings, colourants (if required). 8. Pack and transport yogurt, keeping it refrigerated. (d) Variations: Yogurt can be either set or stirred. Stirred yogurt is fermented in bulk, stirred, then dispensed into pots. For set yogurt, inoculated milk is poured into pots and fermented in place. Thoroughly cleaned fruit and blanched nuts may be added as flavouring. In some countries, a layer of fruit syrup is placed on top of set yogurt. In other areas, a thicker stirred yogurt is popular. This is made by adding dried skimmed milk to the original milk before pasteurizing. Sometimes, other thickeners (starch or pectin) are used. 2.8 CASE STUDY: HARMFUL BACTERIA CASE STUDY 2.8 QUESTIONS (Page 119) Understanding Concepts 1. Symptoms of E. coli O157:H7 poisoning include vomiting, cramps, bloody diarrhea, fever, and death in some cases. 2. Sources of E. coli O157:H7 contamination include ground beef, processed meats, sprouts, leafy green produce, unpasteurized milk and juice, and contact with cattle. Drinking inadequately chlorinated water or swimming in contaminated lakes or pools is a potential source of exposure. The organism is easily transmitted from person to person. 3. Graphic organizer for Table 1 on page 119 of the Student Text: Lactobacillus souring of milk Streptococcus strep throat, scarlet fever, pneumonia, food spoilage, blood infections, eye infections Staphylococcus boils, food poisoning, skin infections, pneumonia Clostridium botulism, tetanus, gangrene Pseudomonas food spoilage, gasoline spoilage, blood infections, eye infections Bacillus destruction of silkworms, tuberculosis, anthrax Spirillum syphilis coliform bacteria pollution of water sources, soft rot in plants, gastroenteritis, dysentery Applying Inquiry Skills 4. The graph shows that E. coli cases in Canada rose exponentially from 400 cases in 1985 to 2400 in 1989, fell to 1600 during 1990, rose to 1800 in 1991, dropped to 1000 in 1994, and rose to 1300 by the end of the test period. Awareness of the problem likely led to better tracking and recording practices, early recognition of symptoms, and prompt medical attention. Government legislation and practices involving water testing and treatment may have taken effect since 1989. Weather may play a role, considering that bacteria multiply at optimum temperatures. Because the disease is readily transferable, one case quickly turns into others, so it is unlikely that a flat line will appear on the tracking graph, despite best attempts to eradicate this infection. Making Connections 5. Government legislation on testing and treatment of municipal drinking water, proper chlorination of water, and maintenance of heath standards in public pools can prevent E. coli contamination. People must be vigilant: cook hamburger 50 Unit 2 Student Book Solutions NEL