* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download DIP IPM Vers.3 Demo Board (1200V) Manual

Survey

Document related concepts

Electrical substation wikipedia , lookup

Electrical ballast wikipedia , lookup

Current source wikipedia , lookup

Power MOSFET wikipedia , lookup

Distribution management system wikipedia , lookup

Alternating current wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Voltage regulator wikipedia , lookup

Stray voltage wikipedia , lookup

Printed circuit board wikipedia , lookup

Surge protector wikipedia , lookup

Buck converter wikipedia , lookup

Voltage optimisation wikipedia , lookup

Rectiverter wikipedia , lookup

Surface-mount technology wikipedia , lookup

Opto-isolator wikipedia , lookup

Transcript

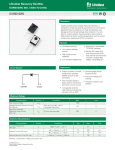

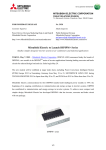

Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X 1200V DIP IPM (PS2205X) EVALUATION BOARD (EVBPS220XX) OHM Elektronik 1200V DIP IPM EVALUATION BOARD (PS2205X) The 1200V DIP IPM evaluation board is intended to functionally test the features and the performance of the Mitsubishi 1200V transfer mold DIP IPM family. This new DIP IPM family contains of 4 new products: PS22052 (5A), PS22053 (10A), PS22054 (15A) and PS22056 (25A). The control terminal pin assignment of the board is compatible with the pinning of the 600V MiniDIP IPM version 3 evaluation board although a standard 2,54mm pin-header is used instead of the JST connector as default. Such 2,54mm pin-headers are available as a world wide standard. All power terminals are accessible through FASTON 4,8mm connectors. Simply providing 15V isolated supply voltage, MCU/DSP control signals and a DC-link voltage makes the evaluation board operable. For load tests it is strongly recommended to provide a suitable cooling system in order to keep the temperature at the case reference point clearly below 100°C. Page 1 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X WARNING – read carefully ! This evaluation board is intended to be used by qualified personnel only. High voltage and the lack of a safety isolation will be dangerous during the entire operation. It is recommended to operate the evaluation board with isolated supplies exclusively. Never touch the board or any connected equipment when a voltage is applied to it. Residual voltage across the snubber capacitor may store high voltages for a very long time after the operation of the evaluation board. We recommend all the capacitors on the board to be discharged after the operation of the board to avoid damage to any connected hardware and to prevent from hazardous electrical shocks. Contents: # A. 0. 1. 2. 3. 4. 5. 6. Topic Introduction Safety advise Required external hardware for the operation of the evaluation board On the evaluation board Schematic of the evaluation board PCB layout and considerations Bill of material Disclaimer page 2 3 4 5 8 10 11 Page 2 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X 1. Required external hardware for the operation of the evaluation board: Figure 1: The 1200V DIP IPM evaluation board and its required external hardware The evaluation board (Mitsubishi order no EVBPS220XX) shown in green colour does not comprise the 1200V DIP IPM itself and its specific shunt resistors for short circuit (SC) protection. Table 1 indicates the DIP IPM range from 5A to 25A and their individual corresponding recommended shunt resistor range. The control part of the evaluation board should be supplied by a stabilized 15V DC / 100mA voltage source as shown in yellow colour. A low inductive power supply of the IGBT is established by connecting the electrolytic capacitors (DC-link capacitors) with the help of short (~8cm (~3 inch)) twisted cables to the “P” and “N” terminals of the evaluation board. The DC-link capacitors are fed by a rectifier for example through an isolated 3~ variable transformer to limit the surge current during power up. The control interface of the evaluation board is capable of operating with 5V logic signals that can be generated by microprocessors or 5V digital signal processors (DSP). The 6 control signal lines and the fault output (FO) line as well as the GND reference should be connected between the MCU/DSP board and the 1200V DIP IPM evaluation board. The fault output of the IPM is an “open drain” type that requires a pull up resistor of about 10kΩ tied to the supply voltage of the control signals. This pull up resistor is placed on the board and can be activated by connecting the “5V” terminal of the control signal pin-header to the positive supply of the MCU/DSP board. Page 3 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X 2. On the evaluation board OHM Elektronik Figure 2: The 1200V DIP IPM evaluation board and its components All necessary components for a basic operation of the 1200V DIP IPMs using the three open Emitter topology (and three shunts) for FO purposes are placed on the evaluation board. These 3 shunts are used for the SC-protection, as well. Table 1 shows the proposed values for these shunt resistor with reference to the 1200V DIP IPM rating: Module PS22052 PS22053 PS22054 PS22056 rated power of the Irms/leg (dTj=25K, Isc,tripmax [A] proposed shunt motor (approximately) Tj=125°C,15kHz) [A] (datasheet) resistor value*[Ohm] 800W 1,8 8,5 ≥0,15 1,5kW 3,4 17 ≥0,075 2,7kW 5,5 25,5 ≥0,05 4kW 9,2 42,5 ≥0,03 * assuming Vf = 0,7V (D1…D3), VSC(ref) = 0,48V (DIP IPM), ISC = (Vf + VSC(ref))/Rshunt Table 1: 1200V DIP IPM, approximate motor power rating, rms current per leg, the max SCtrip current stated in the datasheet and the suggested value for the shunt resistor. The compliance with the specified Isc,tripmax must be verified under the individual application conditions to ensure a reliable operation of the IPM during SC. Standard SMD shunt resistors up to size 2817 (manufacturer: YAGEO, Isabellenhuette…) fit into the footprint provided on the PCB. Page 4 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X OHM Elektronik Figure 3: Schematic of the DIP IPM 1200V evaluation board 3. Schematic of the evaluation board Page 5 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X The schematic shows the flexibility of the evaluation board to test components in conjunction with the DIP IPM. The board is as default populated with the standard pin-header counting 10 pins with a pitch of 2,54mm. However it is possible to place the JST connector - introduced on the recent MiniDIP IPM version 3 evaluation board. A dedicated footprint for this JST connector is provided on the EVBPS220XX to keep the compatibility with previous generation of Mitsubishi evaluation boards. The pin’s function is printed on the PCB itself for easy tracking and is redundant with the naming of the pins of the corresponding datasheet of the 1200V DIP IPM. The control signals wiring from MCU/DSP to the pin-header of the evaluation board as well as from the pin-header to the DIP-IPM terminals should be as short as possible to avoid EMI disturbances and unwanted switching of the IPM. The same precautions – tracks as short as possible - have been applied to the board design itself. The bootstrap supply area contains of an ultrafast (trr=75ns) 1200V/1A diode, a charge current limiting resistor and a pair of electrolytic and ceramic capacitor. The diodes may be housed in a surface mounted “SMB” package or in the standard wired “SOD57” or “DO-41” package. The size of the electrolytic bootstrap capacitor varies with the type of application. The electrolytic bootstrap capacitor area provides sufficient space to place SMD capacitors up to 47µF/25V to allow the IPM to be operated at very low switching frequencies or for BLDC applications or with 2-phase modulation PWM strategies operating at low output frequencies. The voltage across the bootstrap capacitors should never fall below the under voltage detection level indicated in the datasheet of the 1200V DIP IPM under normal operation. The compliance with the indicated bootstrap supply voltage can be verified easily at the pins of the IPM. The Zener diode D4 (24V/1.3W) prevents the IPM from transient over voltages of the supply voltage. It can clamp the transient over voltage efficiently to a level that does not harm the internal LVIC/HVIC of the IPM. The SC-protection circuit contains of the 3 shunt resistors R5…R7, the 3 diodes D1…D3 , R11and the low pass filter network of R9/C8 to blank the recovery peak current of the opposite freewheeling diode. The proposal for the value of the shunt resistor has been made in Table 1. The 3 diodes are operating in an “or” function. Thus, if the voltage drop of any shunt exceeds the sum of the (temperature dependent) forward voltage drop of the diode (D1 or D2 or D3) and the input threshold voltage of the SC- detecting comparator of the DIP IPM (typ. 0,48V), the SC- condition will be detected. The additional forward voltage drop of the diode (Vf) and its temperature dependency is a sensitive point when selecting the right value of the shunt for a safe SC protection over a certain temperature range. Therefore it is strongly recommended to verify the SC- detection level under real application conditions to ensure safe SC operation within the specified limits of the 1200V DIP IPM and the desired temperature operating range of the application circuit. A typical operation of the SC-detection circuit using the proposed diode OR-ing circuitry is shown in figure 4. The SC- operation has become active at 940mV across the shunt connected to NU. The detection current was Isc,detect = 940mV/ Rshunt. Page 6 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X Assuming a typical SC-detection level of 480mV (VSC(ref)) at the DIP IPMs comparator input and neglecting the influence of the R9/C8 delay, the voltage drop of the OR-ing diode must have been in the range of 460mV at this specific test. The type of diode has an influence on the performance of the SC detection and it is recommended to prefer low Vf types. Ch1: u-phase shunt voltage (1V/div), Ch2: v-phase shunt voltage (1V/div), Ch3: w-phase shunt voltage (1V/div), Ch4: Fo (5V/div) Figure 4: SC detection circuit: operation of the IPM In case that the separate current information of the three legs is not required, it is possible to connect all three open emitters together and to use just a single shunt resistor. Hence, the diodes D1…D3 and R11 have no function and could be omitted or bypassed respectively. The value of the SC- detection shunt can be calculated omitting the additional forward drop voltage of the diode. To prevent the 1200V DIP IPM from dangerous high voltage spikes, a dedicated snubber capacitor C6 (0,22µF/1250V) has been populated at the most advantageous position for highest efficiency. Thus, possible over voltage spikes generated through the stray inductance of the wiring between DC-link capacitors and the PCB are limited to a level below 1200V. Minimizing the stray inductance of this wiring by bringing the wires as close as possible together for example by twisting them will reduce the over voltage spike and ease the work of the snubber capacitor. Page 7 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X 4. PCB layout: The PCB has been made using a 1,5mm thick double sided (35µm) FR4 material OHM Elektronik Figure 4: Toplayer On the top layer all components are placed and most of the signal traces were made. Page 8 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X Figure 5: Bottomlayer OHM Elektronik The bottom layer is mainly used for supply (GND) and shielding. However the signal traces from the open Emitters are located here, too. Page 9 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X 5. Bill of material used: Part C1 C2 C3 C4 C5 C6 C7 C8 C9 C10 C13 C14 C15 C16 CON6* CON7 Value 100nF 100nF 100nF 10µF…47µF/25V 10µF…47µF/25V 0,22µF/1250V 100nF 1nF 10µF…47µF/25V 47µF/25V 22nF 100nF 100nF 100nF JST connector PINHD-1X10 Package 0805 0805 0805 SMD-C-6, SMD-C-6, C27,5B15 CAP 0805 0805 SMD-C-6, SMD-C-6, 0805 0805 0805 0805 B10P-VH JST VH 1X10 (2,54mm pitch) D1 D2 D3 D4 D5* D6* D7* D8 D9 D10 BAS21 (or equivalent) BAS21 (or equivalent) BAS21 (or equivalent) Z22...Z24/1,3W STTH112U (or equivalent**) STTH112U (or equivalent**) STTH112U (or equivalent**) SF1200 (or equivalent**) SF1200 (or equivalent**) SF1200 (or equivalent**) SOT-23 SOT-23 SOT-23 SMA SMB SMB SMB SOD57 / DO-41 manufacturer: VISHAY SOD57 / DO-41 manufacturer: VISHAY SOD57 / DO-41 manufacturer: VISHAY R1 R2 R3 R4 R5* R6* R7* R9 R11 10R 10R 10R 10k shunt (ref. table1) shunt (ref. table1 shunt (ref. table1 1,5k 220R 0805 0805 0805 0805 2817, YAGEO, Isabellenhuette (or equivalent) 2817, YAGEO, Isabellenhuette (or equivalent) 2817, YAGEO, Isabellenhuette (or equivalent) 0805 0805 U V W N P 17094A 17094A 17094A 17094A 17094A TYCO/AMP (4,8mm FASTON) (or equivalent) TYCO/AMP (4,8mm FASTON) (or equivalent) TYCO/AMP (4,8mm FASTON) (or equivalent) TYCO/AMP (4,8mm FASTON) (or equivalent) TYCO/AMP (4,8mm FASTON) (or equivalent) IPM1* PS2205x MITSUBISHI ELECTRIC * not populated ** ultrafast trr=75ns/ Vrrm =1200V Page 10 of 11 Application note AN2004-31 1200V DIP IPM evaluation board Mitsubishi PS2205X Disclaimer We (OHM Elektronik VE TIC) do not warrant that the 1200V DIP IPM evaluation board is free from claims by a third party of copyright, patent, trademark trade secret or any other intellectual property infringement. Under no circumstances are we liable for any of the following: 1. third-party claims against you for losses or damages 2. loss of, or damage to, your records or data; or 3. economic consequential damages (including lost profits or savings) or incidental damages, even if we are informed of their possibility. 4. We do not warrant uninterrupted or error free operation of the evaluation board and all related hardware. 5. We have no obligation to provide service, defect correction, or any maintenance for the 1200V DIP IPM evaluation board. 6. We have no obligation to supply any updates or enhancements to you even if such are or later become available. IF YOU USE THIS 1200V DIP IPM EVALUATION BOARD BY CONNECTING ANY WIRING TO THE PCB YOU AGREE TO THESE TERMS. THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Page 11 of 11