* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Output comparison: 50 mm LED, quartz halogen

Survey

Document related concepts

Transcript

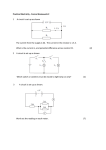

LIGHTING DESIGN & APPLICATION South African middle and high income homes use 50 mm diameter reflector lamps for general lighting, but these weren't designed for this purpose. Output comparison: 50 mm LED, quartz halogen reflector In bedrooms, these lights are typically placed one in each corner with a fifth light sometimes added in the centre, totalling between four and five lights and light points. The rest of the house would have four lights in the study; four to eight in bathrooms and kitchens; six to twelve in dining rooms, television rooms and lounges; one light per metre in passages, and between four and six lights in the entrance hall. Hotel rooms commonly feature up to 15 light points. The standard power of these lamps is 50 W for both the 12 and 230 V versions. The lighting power density in these homes should be below 5 W/m 2 but 50 lamps with a total load of 2500 W in a 200 m2 house would have a light power density of 12,5 W/m2, which is not compliant with SANS 204. A 15 m2 bedroom with four 50 W lamps would have a power density of 13 W/m2. We cannot afford this energy waste in South Africa. by André Blignaut and Robert Henderson, Eskom Fig. 1: Goniometer type (a) and type (b). The authors conducted comparative light output testing of 50 mm LED and quartz halogen using intensity distribution measurements, the zonal flux method, the integrating sphere and electrical measurements. Testing methods for light output Intensity distribution measurements Light intensity distribution curves provide designers with information on how light is distributed from all angular positions. A goniometer measures the light intensity from all the angles and a Fig. 2: Goniometer with moving mirror. September 2013 - Vector - Page 25 curve is plotted. For symmetrical lamps and luminaires, the number of points measured can be decreased by means of symmetry. The total light flux can then be calculated by means of the zonal flux method. The goniometer usually keeps the luminaire or lamp in a fixed position to avoid changes in lamp temperature, as shown in Fig. 1 (a). Alternative goniometers which rotate the lamp or luminaire, shown in Fig. 1 (b), can be used and the results corrected for the change in lamp temperature. The zonal flux method The zonal flux method uses the measured light intensity at a point in the imaginary sphere and then assumes that its value is the same around the sphere within a preselected band. The product of the intensity and the area of the band will give the light flux within that band. This is repeated for each band and typical zonal factors for 1, 2, 5 and 10° can be found in Table 1. Zonal factors for 2°, 5° and 10° zones 2° zones 5° zone 10° zone Zone limits (degrees) Zonal factors Zone limits (degrees) Zone limits (degrees) Zonal factors Zone limits (degrees) Zone limits (degrees) Zonal factors 0–2 0,0038 0–5 175 – 180 0,0239 0 – 10 170 – 180 0,095 2–4 0,0115 5 – 10 170 – 175 0,0715 10 – 20 160 – 170 0,283 4–6 0,0191 10 – 15 165 – 170 0,1186 20 – 30 150 – 160 0,463 6–8 0,0267 15 – 20 160 – 165 0,1649 30 – 40 140 – 150 0,628 8 – 10 0,0343 20 – 25 155 – 160 0,2097 40 – 50 130 – 140 0,774 10 – 12 0,0418 25 – 30 150 – 155 0,2531 50 – 60 120 – 130 0,897 12 – 14 0,0493 30 – 35 145 – 150 0,2946 60 – 70 110 – 120 0,993 14 – 16 0,0568 35-40 140 – 145 0,3337 70 – 80 100 – 110 1,058 16 – 18 0,0641 40 – 45 135 – 140 0,3703 80 – 90 90 – 100 1,091 18 – 20 0,0714 45 – 50 130 – 135 0,4041 50 – 55 125 – 130 0,4349 55 – 60 120 – 125 0,4623 60 – 65 115 – 120 0,4862 65 – 70 110 – 115 0,5064 70 – 75 105 – 110 0,5228 75 – 80 100 – 105 0,5351 80 – 85 99 – 100 0,5434 85 – 90 90 – 95 0,5476 Table 1: Zonal factors. The authors used 2,5° intervals for testing the downlighters. The lamp flux is the product's light intensity and the sum of the solid angles (see Fig. 2) given in the formula in Fig. 3. This method required that the lamps be rotated by hand and the intensity recorded manually at each point. This is time consuming and the new automated system will yield results faster. The integrating sphere The integrating sphere is a comparative method to determine the light flux of a lamp or luminaire (see Fig. 7) The system uses a reference lamp of known light output to be placed in the integrating sphere. A reading is taken and the reference lamp replaced by the test lamp. A second reading is then taken. Fig. 3: Zonal factor angles and factors formula. Two correction factors must be taken into account: the effect of the physical interference of the reference lamp and the test lamp. When testing these small downlighter lamps, the interference was not measureable and considered to be unity. The position of the baffle screen and the direction of the lamps were kept constant for all tests. The total light output was initially measured, but was revised to Fig. 4: Light distribution of a halogen downlighter. September 2013 - Vector - Page 26 measure only the downward light for the lamps used in the residential sector. The main reason for this was that the upward light was not used in the general lighting applications when the lamps are installed in the ceiling. The results of measuring the downward light only are lower than the published information from the suppliers. In some instances, the difference was large and this will be reflected in the results. The revised system is the 2π system and not the normal 4π system associated with the integrating sphere (see Fig. 6). Fig. 5: Light into the ceiling space from a quartz halogen and a LED (lamp). Electrical measurements The lamps were connected to a controlled voltage supply of 230 and 12 V respectively, as required by the lamps. The power, apparent power and power factor were measured using a Fluke 43B power analyser and referenced to a Yokogawa power analyser (see Fig. 8). Results and discussion Using the 2π system, a sample of quartz halogen lamps and LEDs was tested (see Table 2). Fig. 9 shows the light distribution from the 230 and 12 V downlighters. The quartz halogen lamps have lower light flux and efficacies than expected at 230 V, while the 12 V quartz halogen lamps have higher efficacies because transformer losses are not included. The LED lamps operating at 230 and 12 V have lower light output compared to the quartz halogen lamps. The lamps were selected for similar beam angles, however the LED lamps have a faster drop-off after 50% of the peak. The quartz halogen lamps have a higher upward light component than the LED lamps, as was expected (see Figs. 4 and 5). Conclusion and remarks The LEDs can replace the quartz halogen lamps. However, the LEDs’ power must be selected to provide the same light output. This depends on the supplier and the model used. End-users must be informed what the terms “lumens” and “beam angle” mean so that they can purchase the correct lamp for their application. This will achieve greater acceptance of LED by the middle and high-income sectors, and the reduction in energy use the Fig. 6: The 2π proposed system. Lamp Lamp description Voltage Efficacy lm/W Light lm Power Watts Power factor VA Var Quarts halogen lamps RQ7 50 W Gu10 quartz halogen 230 6,58 324 49,2 1,00 49,70 3,00 RQ9 50 W Gu10 quartz halogen 230 7,26 333 45,8 1,00 45,90 3,40 RQ10 50 W Gu10 quartz halogen 230 8,07 381 47,2 1,00 47,30 3,60 RQ14 50 W Gu5,3 quartz halogen 12 18,50 838 45,3 1,00 45,30 1,20 RQ17 50 W Gu5,3 quartz halogen 12 17,43 800 45,9 1,00 45,90 1,00 RQ20 50 W Gu5,3 quartz halogen 12 15,35 698 45,5 1,00 45,60 1,20 LED sample lamps P10 6 W LED GU10 230 49,97 310 6,2 0,65 9,6 7,3 V44 6,5 W PAR16 LED GU10 230 44,13 269 6,1 0,89 6,8 3,1 R55 6,5 W LED GU10 230 51,77 337 6,5 0,43 15 13,6 R70 6,5 W LED GU5,3 12 52,16 339 6,5 0,61 10,6 8,4 P20 6,5 W LED GU5,3 12 62,10 397 6,4 0,97 6,6 1,7 V49 6,5 W MR16 LED GU5,3 12 46,70 290 6,2 0,63 9,7 7,5 Table 2: Electrical and illumination results. September 2013 - Vector - Page 28 Fig. 7: The modified comparative integrating system. Fig. 8: Circuit for testing 230 V lamps. colour rendering index (CRI) etc. to help them make a more informed selection. Light output is most important to users when switching to LED or CFL: they require from these lamps the same light levels and colours which they are accustomed to. Light output is linked to colour appearance and colour rendering. Incandescent lamps, including quartz halogen lamps, provide a "warm" appearance and a continuous spectrum, so their colour rendering is 100. CFLs and LEDs are made with different CRIs, ranging from 60 to 90 and colour temperatures from 2700°K to 6500°K. Acknowledgment This article is based on a paper presented at the ninth IESSA Conference in 2013 and is published here with permission. References [1] J Pan, F Minand Y Li, Everfine Photo-e-info, Hangzhou, China, and F Qian, Hangzhou Institute of Calibration and Technical Supervision, Hangzhou, China,“Total luminous flux and chromacity measurement for led luminaires using the absolute interating sphere method”, CIE 2011. [2] B Rowell, Lighting design and application, a practical guide for lighting practionioners. Fig. 9: Light distributions from 230 and 12 V downlighters. offer will help lower the nation evening peak load. Most buyers in the domestic market use electrical power as the deciding factor when selecting lamps while others consider price and brand. Users need more technical information on light flux, lumen output, colour temperature, September 2013 - Vector - Page 30 [3] AR Bean and R H Simons,Lighting Fitting Performance and Design. [4] R H Simons and A R Bean, “Lighting engineering applied calculations”. Contact André Blignaut, Eskom, Tel 011 629-5111, [email protected]