* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Determination of Dispersive Properties of Silicas by Inverse Gas

Multiferroics wikipedia , lookup

Auger electron spectroscopy wikipedia , lookup

Glass transition wikipedia , lookup

Surface tension wikipedia , lookup

Ultrahydrophobicity wikipedia , lookup

X-ray fluorescence wikipedia , lookup

Rutherford backscattering spectrometry wikipedia , lookup

Sessile drop technique wikipedia , lookup

Surface properties of transition metal oxides wikipedia , lookup

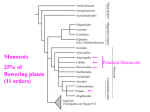

Materials Transactions, Vol. 48, No. 6 (2007) pp. 1548 to 1553 #2007 The Japan Institute of Metals EXPRESS REGULAR ARTICLE Determination of Dispersive Properties of Silicas by Inverse Gas Chromatography: Variation with Surface Treatment Young-Cheol Yang and Pyoung-Ran Yoon Department of Mineral Resources & Energy Engineering, Chonbuk National University, Jeonju 561-756, South Korea The application of inverse gas chromatography (IGC) to the examination of the surface properties of untreated crystalline and fused silica and surface-treated silicas with silane coupling agents is discussed. The carbon content of the silane coupling agents adsorbed on the surface of the silicas was determined by means of a Carbon Determinator. If the assumption is made that each silane coupling agent molecule occupies an area of 0:51 nm2 , the adsorption amounts show that multilayers are generally adsorbed onto the silica surfaces. This paper presents and discusses the dispersive properties expressed by SD , the dispersive component of the surface free energy, as determined at various temperatures. At the same temperature of IGC measurement, the values of SD determined by IGC were lower for the crystalline silica than for the fused silica. This means that crystalline silica is more stable than fused silica. The silica surface-treated with -methacryloxy propyl trimethoxy silane (MTMS) shows a relatively high SD value(42.75 mJm2 at 160 C). This means that this sample should be compatible with polyester(27 3 mJm2 at 290 C) at high temperature. The silicas that were surface-treated with -glycidoxy propyl trimethoxy silane (GMS) and -mercapto propyl trimethoxy silane (MCMS) exhibit SD values that are in close agreement with those of almost all resins(30 mJm2 at 160 C). The SD value of the silica surface-treated with -amino propyl triethoxy silane (AES) is similar to that of epoxy resin(40 mJm2 at 80 C). This means that this sample is compatible with epoxy resin at relatively low temperatures. [doi:10.2320/matertrans.MER2007046] (Received February 22, 2007; Accepted March 27, 2007; Published May 25, 2007) Keywords: inverse gas chromatography(IGC), silica, dispersive component of the surface free energy(SD ), multilayer 1. General 1.1 Introduction Silica has a broad variety of applications in industry. Silica has been treated with surface-modifying agents to obtain improved dispersibility, mechanical and electrical properties, water resistance and reinforcement in plastics systems.1) In this study, we used silane coupling agents as surfacemodifying agents for silica. The mechanical performance of a composite material strongly depends on the properties of the filler-matrix interface and, in particular, on the level of adhesion between the matrix and the reinforcing filler. The level of adhesion is determined by the surface energies of both adherents. The surface free energy, which describes the interaction potential of a given surface, has two components: the dispersive component originating from dispersive or London interactions, and the specific component due to all other types of interactions. Inverse gas chromatography (IGC) at infinite dilution conditions may be successfully applied to the determination of the surface properties of various solids.2) IGC allows the detection of the solid surface properties, using molecules of known properties, or probes, which are injected into a chromatographic column filled with the solid of interest. In this study, we chose IGC for the detection of the possible differences in the SD values of untreated crystalline and fused silica and silicas surface-treated with silane coupling agents. The IGC results are reported in this paper. 1.2 Theory of inverse gas chromatography (IGC) at infinite dilution In IGC under infinite dilution conditions, the retention volume VN is computed from the following expression (1): VN ¼ ðtR t0 ÞjDC ð1Þ where tR is the retention time of the probes, t0 the zero retention time measured with a nonadsorbing probe such as methane, j the compressibility factor depending on the pressures at the column inlet and outlet, and DC the corrected flow rate. Practically, the retention time and the retention volume VN can be determined as in a current chromatographic experiment: a larger VN will correspond to a higher affinity of the probe for the chromatographic support. In expression (1), j was calculated by the following expression (2):3) ðpi =p0 Þ2 1 j ¼ 1:5 ð2Þ ðpi =p0 Þ3 1 where pi is the inlet pressure of the carrier gas, and p0 the outlet pressure of the carrier gas which usually equals atmospheric pressure. For a test substance, the free energy of adsorption, GA , is the sum of the energies of adsorption attributable to the dispersive and specific interactions. The adsorption of nonpolar probes such as n-alkanes occurs through dispersive interactions, whereas, for polar probes, both London and acid-base interactions contribute to GA . In this study, we used the model of Donnet et al., because the injected probe is in the gas state.4) In this model, GA is given by the following expressions: SP ½GA ¼ ½GD A þ ½GA ð3Þ ¼ ½RT ln VN þ C ¼ ½K ðhS Þ þ 1=2 ½GSP A 0S ðhL Þ ð4Þ 1=2 0L ð5Þ SP where GD A and GA are the dispersive and specific components of the free energy of adsorption, respectively. The value of the constant, C, in expression (4) depends on the arbitrarily chosen reference state of the adsorbed molecule. In expression (5), K is a constant, h Plank’s constant, and 0 Determination of Dispersive Properties of Silicas by Inverse Gas Chromatography: Variation with Surface Treatment Table 1 Chemical composition (mass%) Physical properties Crystalline silica Fused silica Crystalline silica Fused silica Table 2 Expressions in this paper Chemical compositions and physical properties of samples. SiO2 Al2 O3 Fe2 O3 Na2 O 99.7 0.1561 0.0098 0.0214 SiO2 Al2 O3 Fe2 O3 Na2 O 99.89 0.0285 0.005 0.0033 Maximum diameter(mm) Mean diameter(mm) BET Surface Area(m2 /g) Average Pore Diameter(nm) 180 13.55 2.2654 4.9484 180 14.21 2.9894 7.3271 Chemical names and structures of the silane coupling agents. Chemical name Structure CH3 O MTMS γ −Methacryloxy propyl trimethoxy silane GMS γ −Glycidoxy propyl trimethoxy silane MCMS γ −Mercapto propyl trimethoxy silane HS(CH2)3Si(OCH3)3 AES γ −Amino propyl triethoxy silane NH2(CH2)3Si(OC2H5)3 the deformation polarizability of the molecules. Subscripts S and L refer to solid and liquid, respectively. In the case of nalkanes, GA is equal to the free energy of adsorption corresponding to the dispersive interactions, GD A , only, i.e., 1=2 ½GSP ¼ 0 in expression (5). The term [K ðh 0S ] SÞ A is characteristic of a given solid surface and is related to GD A . Consequently [RT ln VN þ C], between an adsorbate and an adsorbent, appears as a linear equation of the parameter [ðhL Þ1=2 0L ], and [K ðhS Þ1=2 0S ] becomes the slope of the linear equation. The above method has been used to characterize silicas, modified silicas, oxides, various minerals and solid polymers.5–11) 2. 1549 Experimental 2.1 Materials Natural crystalline and fused silica were used in this work, and the chemical compositions and physical properties of these silicas are shown in Table 1. The chemical names and structures of the silane coupling agents used in the adsorption experiment are shown in Table 2. The silane coupling agents contain three hydrolysable substituents on the right side of each silicon center(Table 2), which, in principle, would enable the formation of a chemisorbed crosslinked siloxane network by the condensation of adjacent adsorbed silantriols with each other as well as with the surface hydroxyl groups as shown in Fig. 1. The silane coupling agents also contain one or more nonhydrolyzable alkyl or aryl groups which are used to provide compatibility with organic matrices. These may also contain substituent groups that can provide reactive CH2 CH2 C CO(CH2)3Si(OCH3)3 CH2O(CH2)3Si(OCH3)3 CH O R O H O Si H O R H Si O HO H HO H O Si O R O Si OH H H O O R H H H H Silica Surface O O Si Si O H O Si Si O n O Fig. 1 Schematic diagram for the reaction of alkoxy silanes with hydroxylated silica surface. centers for graft formation between a polymeric matrix and the mineral surface. These reactive substituents can be tailored for specific applications and include vinyl, acrylate and methacrylate, chloro, amino, epoxy, and mercapto groups.12) 2.2 Adsorption experiment We used methanol and distilled water as the solvent and acetic acid as the catalyst to hydrolysis. The experiment designed to modify the crystalline and fused silica surface was performed as follows. Solvent (100 mL), silane coupling agents (0.2, 0.3, 0.4, 0.6, 0.8, 1.0 and 2.0 g) and silicas (30 g) were stirred by a magnetic bar stirrer for an hour and then separated into solid and liquid components by a centrifugal 1550 Y.-C. Yang and P.-R. Yoon Table 3 Adsorption experimental conditions. Silane coupling agent MTMS Solution Remarks 3:533:58 Acetic acid catalyzed 5:666:88 Natural 4:724:76 Acetic acid catalyzed 9:9510:66 Natural Methanol(80 v.%) Distilled water(20 v.%) GMS MCMS pH Distilled water Methanol(80 v.%) Distilled water(20 v.%) AES Distilled water Silica weight 30 g Table 4 Carbon content of four silane coupling agents adsorbed on the surface of silicas. Sample Crystalline silica Fused silica Silane coupling agent Experimental concentration C content (w/w%) The number of adsorption layers 0.0009 MTMS 1.0 g/100 mL 0.2109 3:336:67 GMS 1.0 g/100 mL 0.2005 3:77:4 MCMS 1.0 g/100 mL 0.0748 2:765:52 AES 1.0 g/100 mL 0.0905 3:346:68 0.0000 MTMS 1.0 g/100 mL 0.1364 1:633:27 GMS 1.0 g/100 mL 0.1466 2:054:1 MCMS 1.0 g/100 mL 0.1518 4:258:49 AES 1.0 g/100 mL 0.1139 3:186:37 separator. A suitable amount of acetic acid specially was added before stirring in accordance with the type of coupling agents to obtain a reasonable pH value for hydrolysis, because the pH value is the most important factor in the hydrolysis of silane coupling agents.13) The conditions used in the adsorption experiment are shown in Table 3. The separated silicas were then dried for 8 hours at 105 C. The various samples were prepared in this way for the IGC study at infinite dilution viz. the untreated crystalline and fused silica, four types of silane coupling agents-treated crystalline and fused silicas. alkanes, C5 to C10 , were used as the probe in the IGC experiment. 2.4 Analysis instruments We used a Mastersizer of Malvern Co. for the particle size analysis, an ICP-7500 of Shimadzu Co. for the chemical analysis of the samples, an ASAP 2010 of Micromeritics for the BET surface area, a WR-112 Carbon Determinator of Leco Co. for the carbon analysis and an HP 6890 Plus of Hewlett Packard Co. for the IGC experiment. 3. 2.3 IGC experiment conditions Since the particle size of the silica was too small to make chromatographic supports, silica disks were prepared by compression of the powders in an IR die under a pressure of 108 Pa. The disks were then hand-crushed and sieved to select the fraction of particles having diameters between 250 and 425 mm. Particles of the correct size were introduced into a stainless steel column, 50 cm long and 3.17 mm in diameter. Approximately 1 g of each sample was used as the filling of the chromatographic column. Each column, filled with the sample, was conditioned at 200 C for 24 hours to remove any impurities in it. The IGC measurements were performed with a Hewlett Packard 6890 GC system equipped with a highly sensitive flame ionization detector (FID). The carrier gas was nitrogen (N2 ) and the flow rate was 10 mL/min. The temperature of the IGC measurement was varied from 70 to 180 C. Very small amounts of the probes were injected using the following stratagem: 1 to 5 mL of the probe was introduced via a septum into a 1L flask, which was flushed with N2 , after which about 0.3 mL of the diluted probe was injected into the GC system. A homologous series of n- Results and Discussion 3.1 The number of adsorption layers We performed the hydrophobic experiment of all of the samples to generally examine that which concentration was achieved monolayer adsorption at. It was found that the MTMS- and MCMS-treated samples with a concentration of 0.8 g/100 mL and above completely floated on the water. However, the hydrophobic experiment of the samples surface-treated with GMS and AES was unable to be performed, because both of these samples have hydrophilic properties. Consequently, we chose the samples at a concentration of 1 g/100 mL as the standard samples for the IGC experiment, because it was considered that higher than monolayer adsorption of the silane coupling agents was achieved at this concentration. We performed the carbon analysis to calculate the number of layers adsorbed on the surface of the standard samples. The carbon analysis results of the standard samples are presented in Table 4. The molecular possession area of silane coupling agents is approximately 0.5 to 1 nm2 .14,15) If we choose the crystalline silica surface-treated with MCMS, Determination of Dispersive Properties of Silicas by Inverse Gas Chromatography: Variation with Surface Treatment That is, the mole number per 1 g of the crystalline silica surface-treated with MCMS ¼ 20:8 106 mol This can be changed to molecular numbers as follows. 20:8 106 mol 6:02 10 mol 23 ¼ 125:22 1017 125:22 10 50 10 20 4 -1 2 CH2 ∆GA 0 -2 -4 -6 4 5 6 7 8 9 10 11 Carbon number of the probe 2 Fig. 2 Determination of the GCH value. A If the molecular possession area of the silane coupling agent(0.5 to 1 nm2 ) is 0.5 nm2 , the total molecular possession area is: 17 6 RT ln VN (kJ·mol ) because its carbon content is the lowest, the number of adsorption layers can be calculated as follows. BET surface area of crystalline silica = 2.2654 m2 /g (Table 1) Mass of carbons in functional group of MCMS: C3 ¼ 36 g/mol Carbon content per 100 g of the crystalline silica surfacetreated with MCMS ¼ 7:48 102 g (Table 4) This can be changed to mole numbers as follows. mol 7:48 102 g 0:208 102 mol 36 g ¼ 20:8 104 mol 1551 2 CH2 ¼ 35:6 þ 0:058ð293 TÞ in mJm2 ð7Þ 2 m ¼ 6:261 m /g Finally, the number of adsorption layers is as follows. total molecular possession area of MCMS BET surface area of crystalline silica ¼ 6:261 m2 =g 2:2654 m2 /g 2:76 layer If the molecular possession area of the silane coupling agent is 1 nm2 , the number of adsorption layers will be twice that. The number of adsorption layers calculated using the above method is presented in Table 4. That is, the results presented in Table 4 suggest that the above monolayer adsorption of the silane coupling agents was achieved for all of the samples. A schematic diagram of the multilayer is shown in Fig. 1. The surface properties of the samples reflect the innate characteristics of the functional group of each silane coupling agent, regardless of the number of adsorption layers, because the functional groups protrude from the layer as shown in Fig. 1. 3.2 The dispersive component of the surface free energy (SD ) The dispersive component of the surface free energy, SD , is obtained by injecting a homologous series of n-alkanes into the column and determining their retention characteristics. Dorris and Gray used the incremental amount of free energy of adsorption corresponding to the adsorption of one CH2 D 2) 2 group, GCH A , to determine the value of S : " #2 2 1 GCH A D S ¼ ð6Þ 4CH2 N aCH2 where CH2 is the surface energy of a solid composed solely of -CH2 - groups, i.e., a surface analogous to polyethylene, N Avogadro’s number, and aCH2 the cross sectional area of an adsorbed -CH2 - group (0.06 nm2 ).2) The variation of CH2 with the temperature is given by: where T is the temperature in K. Generally, the logarithm of VN varies linearly with the number of carbon atoms of the injected n-alkanes. Therefore, it becomes possible to define the free energy of adsorption, 2 GCH A , of one methylene group, which no longer depends on the arbitrary choice of the reference state: nþ1 VN 2 GCH ¼ RT ln ð8Þ A VNn where R is the ideal gas constant, T the absolute temperature, and VNnþ1 and VNn the net retention volumes of n-alkanes having n þ 1 and n carbon atoms, respectively. In the IGC experiment, the retention time and volume are associated with the SD of the solid. That is, RT ln VN varies linearly with the number of carbon atoms of the injected nalkanes, as shown in Fig. 2. 2 In Fig. 2, GCH is the slope of the line obtained from A expression (8). Therefore, the SD values of the solid are computed by expression (6). Figures 3 and 4 display the variation of [RT ln VN ] vs. the carbon number of the n-alkanes used to probe the surface properties of the untreated crystalline and fused silica. Figures 5 and 6 display the variation of [RT ln VN ] vs. the carbon number of the n-alkanes used to probe the surface properties of the crystalline and fused silica surface-treated with MTMS. Each line in the above graphs indicates the variation according to the temperature of the IGC measurement. The SD values of the untreated crystalline, fused and surface-treated silicas were computed by the above method for each line. The SD values of the samples were computed at various measuring temperatures between 70 and 180 C. The calculated values of SD are presented in Table 5. The range of temperature used for the IGC measurement was different for each sample, as shown in Table 5. This means that the range of temperature which is suitable for the IGC measurement is 1552 Y.-C. Yang and P.-R. Yoon 8 8 Untreated crystalline silica 70°C 80°C 90°C 100°C 110°C 120°C 130°C 140°C 4 2 -1 2 -1 RT ln VN (kJ·mol ) 4 MTMS−treated crystalline silica 130°C 140°C 150°C 160°C 170°C 180°C 6 RT ln VN (kJ·mol ) 6 0 -2 -4 0 -2 -4 -6 -6 -8 -8 -10 -12 -10 4 5 7 6 9 8 10 5 11 6 7 8 9 10 Carbon number of the probe Carbon number of the probe Fig. 3 Variation of [RT ln VN ] vs. the carbon number of the n-alkanes used as molecular probes for the untreated crystalline silica. Fig. 5 Variation of [RT ln VN ] vs. the carbon number of the n-alkanes used as molecular probes for the crystalline silica surface-treated with MTMS. 8 12 Untreated fused silica 70°C 120°C 80°C 130°C 90°C 140°C 100°C 110°C -1 RT ln VN (kJ·mol ) 6 4 -1 8 MTMS−treated fused silica 130°C 140°C 150°C 160°C 170°C 180°C 6 RT ln VN (kJ·mol ) 10 4 2 0 -2 -4 2 0 -2 -4 -6 -6 -8 -8 -10 5 -10 4 5 6 7 8 9 10 6 7 8 9 10 Carbon number of the probe Carbon number of the probe Fig. 4 Variation of [RT ln VN ] vs. the carbon number of the n-alkanes used as molecular probes for the untreated fused silica. different for each sample because their surface properties are different. The SD values of the crystalline and fused silica are lower than those of the other fillers.11) There have been several papers that presented the SD values for synthetic silica. The SD values of crystalline and fused silica in this paper are similar to those of these previous studies. The SD values of synthetic silica were as follows: 40 4 mJm2 at 80 C,16) 40 mJm2 at 150 C,17) 46 mJm2 at 80 C.18) The SD values of the untreated fused silica shown in Table 5 were slightly higher than those of the untreated crystalline silica at the same measuring temperature. This means that crystalline silica is more stable than fused silica. The SD values of the silicas surface-treated with MTMS were Fig. 6 Variation of [RT ln VN ] vs. the carbon number of the n-alkanes used as molecular probes for the fused silica surface-treated with MTMS. higher than those of the silicas surface-treated with the other silane coupling agents at the same measuring temperature. The MTMS agent is compatible with polyester, having a SD value of 27 3 mJm2 at 290 C.19) The SD values of the silicas surface-treated with GMS were approximately 30 mJm2 at 160 C. It is considered that the GMS agent is suitable for most polymers, because it has a SD value of around 30 mJm2 at 140 C.20) It is estimated that the MCMS agent is also suitable for most polymers, because the SD value of the crystalline silica surface-treated with MCMS was about 30 mJm2 at 150 C. The SD values of the silicas surface-treated with AES were around 30 mJm2 in the relatively low temperature range. Consequently, the AES agent is compatible with epoxy resin, having a SD value of 40 mJm2 at 80 C.21) Determination of Dispersive Properties of Silicas by Inverse Gas Chromatography: Variation with Surface Treatment 1553 Table 5 Dispersive component(SD ) of the surface free energy of untreated and silane coupling agents-treated silicas at various temperatures. Silane none MTMS GMS MCMS AES 4. SD (mJm2 ) Concentration 70 C 80 C 90 C 100 C 110 C 120 C 130 C 140 C Crystalline silica 54.10 49.42 45.59 43.88 41.62 36.92 33.63 31.78 Fused silica 58.93 55.28 53.08 48.20 47.25 44.49 41.33 37.81 Crystalline silica 1.0 g/100 mL 54.69 Fused silica 1.0 g/100 mL Crystalline silica 1.0 g/100 mL 49.65 Fused silica 1.0 g/100 mL 49.07 Crystalline silica Sample 150 C 160 C 170 C 180 C 51.72 46.13 42.75 35.18 29.16 50.78 47.45 44.82 37.32 35.27 28.87 44.36 41.40 35.23 32.31 30.43 45.98 43.87 39.19 38.49 33.54 1.0 g/100 mL 40.22 35.21 33.03 29.99 28.85 Fused silica 1.0 g/100 mL 54.05 48.29 44.69 38.22 34.33 31.3 29.23 Crystalline silica 1.0 g/100 mL 40.12 36.72 32.69 28.61 Fused silica 1.0 g/100 mL 38.60 35.65 32.80 28.32 Conclusions Crystalline and fused silica were subjected to surface treatment with four types of silane coupling agent: MTMS, GMS, MCMS and AES. The treatment of the crystalline and fused silica by these silane coupling agents modified their surface. We examined the number of layers adsorbed on the surface of the silicas by carbon analysis and the surface properties of these silicas according to SD using IGC. The present study produced the following conclusions: (1) By assuming that the molecular possession area of the silane coupling agent is 0.5 to 1 nm2 , it was determined that multilayer adsorption was achieved on the surface of the silicas by carbon analysis. (2) The values of SD decreased with increasing IGC measuring temperature in all cases. Silica is an oxide with a relatively low surface energy. The SD values of the crystalline silica were lower than those of the fused silica at the same measuring temperature. This means that crystalline silica is more stable than fused silica from the surface energetic point of view. (3) The SD values of the silicas surface-treated with MTMS were higher than those of the others, while the SD values of the silicas surface-treated with AES were the lowest at the same measuring temperature. This result indicated that while the AES-surface-treated silica is suitable for polymers such as epoxy resin, the MTMSsurface-treated silica is suitable for polymers such as polyester. The silicas surface-treated with GMS and MCMS are suitable for most polymers, because their SD value is close to that of almost all resins at 160 C(30 mJm2 ). REFERENCES 1) H. S. Katz and J. V. Milewski: Handbook of Fillers and Reinforcements for Plastics (Litton Educational Publishing Inc. 1978) 136. 2) G. M. Dorris and D. G. Gray: J. Colloid and Interface Sci. 77 (1980) 353–362. 3) A. T. James and A. J. P. Martin: The Biochemical J. 50 (1952) 679. 4) J. B. Donnet, S. J. Park and H. Balard: Chromatographia 31 (1991) 434–440. 5) H. Balard, M. Sidqi, E. Papirer, J. B. Donnet, A. Tuel, H. Hommel and A. P. Legrand: Chromatographia 25 (1988) 712–716. 6) E. Papirer, H. Balard, Y. Rahmani, A. P. Legrand, L. Facchini and H. Hommel: Chromatographia 23 (1987) 639–647. 7) M. Sidqi, H. Balard and E. Papirer, A. Tuel, H. Hommel and A. P. Legrand: Chromatographia 27 (1989) 311–315. 8) M. M. Chehimi and E. Pigois-Landureau: J. Mater. Chem. 4 (1994) 741–745. 9) U. Panzer and H. P. Schreiber: Macromolecules 25 (1992) 3633–3637. 10) A. Voelkel, E. Andrzejewska, R. Maga and M. Andrzejewski: Polymer 34 (1993) 3109–3111. 11) Y. C. Yang and P. R. Yoon: Korean J. Chem. Eng. 24 (2007) 165. 12) D. H. Solomon and D. G. Hawthorne: Chemistry of Pigment and Fillers (John Willey & Sons 1983) 108. 13) M. R. Rosen: J. Coatings Technology 50 (1978) 70–82. 14) O. K. Johannson, F. O. Stark, G. E. Vogel and R. M. Fleischmann: J. Composite Materials 1 (1967) 278–292. 15) C. H. Chiang and J. L. Koenig: J. Colloid and Interface Sci. 83 (1981) 361–370. 16) H. Hadjar, H. Balard and E. Papirer: Colloids and Surfaces A: Physicochemical and Engineering Aspects 99 (1995) 45–51. 17) A. Khalfi, E. Papirer, H. Balard, H. Barthel and M. G. Heinemann: J. Colloid and Interface Sci. 184 (1996) 586–593. 18) C. Perruchot, M. M. Chehimi, M. Delamar, S. F. Lascelles and S. P. Armes: J. Colloid and Interface Sci. 193 (1997) 190–199. 19) G. L. Gaines: Polymer Eng. Sci. 12 (1972) 1. 20) S. Wu: J. Macromol. Sci.-Revs. Macromol. Chem. C10 (1974) 1. 21) J. Schultz, L. Lavielle and C. Martin: J. Adhesion 23 (1987) 45–60.