* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download full text pdf

Survey

Document related concepts

Transcript

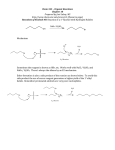

Cent. Eur. J. Chem. • 11(6) • 2013 • 953-959 DOI: 10.2478/s11532-013-0227-2 Central European Journal of Chemistry Preparation of low initial expansion temperature expandable graphite and its flame retardancy for LLDPE Research Article Xiuyan Pang*, Yu Tian, Mingwei Duan, Meng Zhai College of Chemistry and Environmental Science, Hebei University, Baoding 071002, People’ Republic of China Received 25 October 2012; Accepted 23 January 2013 Abstract: To get expandable graphite (EG) flame retardant for Liner Low-Density Polyethylene (LLDPE) with low initial expansion temperature and high dilatability, the effects of various factors on dilatability were investigated including the dosages of oxidant KMnO4, intercalating reagent H2SO4, assistant intercalating reagent acetic acid (HAc) and reaction temperature. Feasible conditions were obtained according to the results of L9 (34) experiments and single factor experiments. EG with an initial expansion temperature of 160°C and expansion volume of 460 mL g-1 could be prepared according to the mass ratio of material graphite C : KMnO4 : 100% H2SO4 : HAc = 1.0 : 0.4 : 5.0 : 1.0 (H2SO4 should be diluted to the mass concentration of 75% before the intercalation reaction); the reaction time was 1.0 hour at 25°C. It was found that reaction temperature and H2SO4 dosage were the most important influence factors for dilatability. The limiting oxygen index could be improved to 28.1% by adding 30% of the prepared EG to LLDPE, and the synergistic anti-flame capability of 20% EG with 10% Ammonium polyphosphate (APP) (I) can reach to 33.9%. According to thermal gravimetric and differential thermal analysis results, 70% LLDPE /10% APP (I) /20% EG synergistic anti-flame system shows higher residual carbon and thermal stability. Keywords: Expandable graphite • Acetic acid • Initial expansion temperature • Expansion volume • Flame retardant © Versita Sp. z o.o. 1. Introduction Graphite is a kind of crystal compound with layer structure. Expandable graphite can be prepared when non-carbonaceous reactants are inserted into graphite layers through chemical or electrochemical reaction. Expandable graphite has many favourable properties: it can be used as a catalyst [1]; and porous expanded graphite can be prepared with expandable graphite expanded instantly at high temperature. Expanded graphite is a kind of adsorption material for heavy oil and dyes wastewater [2-5]. In addtion, expandable graphite is a good intumescent type flame-retardant for its good capability of halogen-free, non-dropping, low-smoke and low pollution potential [6,7]. When exposed to flame, the expandable graphite will form a swollen multicellular char, which can protect materials from the heat of combustion, limit the access of oxygen to the polymer, and reduce the production of smoke. Simultaneously, expandable graphite absorbs huge heat during the process of instant expansion, which can decrease the burning temperature. When it gets oxidized on reaction with H2SO4 at high temperature as shown in Eq. 1, the releasing gases can reduce the concentration of oxygen. C + 2 H 2 SO 4 → CO 2 ↑ +2 SO 2 ↑ +2 H 2O ↑ (1) Due to its outstanding anti-flame capability, expandable graphite has been used widely in the flame retardance of polyolefin blends [8,9], high-density PUF, polyurethane-poly-isocyanurate foam [10-16] and poly(methyl methacrylate) [17]. In these reports, most of the expandable graphites were purchasable goods, and the research was mainly focused on the influences caused by its size or dosage on flame retardance [18]. As a flame retardant, the parameter of initial expansion temperature of expansible graphite is important. According to initial expansion temperature (T0), expandable graphite is classified into three kinds [19]: low initial expansion temperature expandable graphite (T0 is * E-mail: [email protected] 953 Unauthenticated Download Date | 6/16/17 3:49 AM Preparation of low initial expansion temperature expandable graphite and its flame retardancy for LLDPE Table 1. Influence factors and experiment dosages of reactants a. Levels of factors 1 a KMnO4 (g) 100% H2SO4 (g) HAc (g) T (°C) 0.2 3.0 1.0 25 2 0.4 4.0 2.0 40 3 0.6 5.0 3.0 55 Based on 1.0 g material graphite between 80-150°C), middle initial expansion temperature expandable graphite (T0 is between 180-240°C) and high initial expansion temperature expandable graphite (T0 is between 250-300°C). It is well known that the dilatability of expandable graphite is affected by the dosages of oxidation reagent, intercalation reagent, ancillary intercalation reagent and reaction temperature. With KMnO4, HNO3 and HBrO3 used as intercalation system, a kind of expandable graphite with an initial expansion temperature of 130°C and expansion volume (EV) of 350 mL g-1 was prepared [20]. Expandable graphite holding an initial expansion temperature of 310°C and EV of 270 mL g-1 could be prepared with 85% H2SO4, KMnO4 and FeSO4 [21]. Linear Low-Density Polyethylene (LLDPE) possesses low machining temperature (less than 140°C) and it is very flammable. In this research, in order to prepare an expansible graphite (EG) with low initial expansion temperature, high dilatability and fit for LLDPE flame retardancy, KMnO4, H2SO4 and HAc were used as oxidation reagents, intercalating reagent and assistant intercalating reagent, respectively, which is helpful to change product initial expansion temperature and improve its dilatability [22]. The dosages of KMnO4, H2SO4, HAc and reaction temperature were optimized in the intercalation reaction of material graphite. The method to preparing EG fitting for LLDPE was founded, and its anti-flame properties were determined. Thermal gravimetric TG and differential thermal analysis DTA were performed to illuminate its anti-flame mechanism. 2. Experimental procedure 2.1. Instruments and materials SX3-4-13 Muffle furnace (Tientsin, precision of temperature ± 0.1%-0.4%°C); 101-3 Oven (Shanghai, precision of temperature ± 2°C); Muller (Jiangsu); Instrument of limiting oxygen index (LOI) (Chengde); KYKY-2800B scanning electron microscope SEM (Beijing); Y-4Q X-ray diffractometer XRD (Dandong, China); NETZSCH TG209 F3 Thermal gravimetric and Mass Spectrum TG/MS (Germany); STA 449 C Thermal gravimetric TG and Differential Thermal Analysis DTA (Germany) were used in this experiment. Material graphite (C, 5092) was provided by Action Carbon CO. LTD, Baoding, China. HAc, H2SO4 (98%), KMnO4 are all analytical reagents. Ammonium polyphosphate APP (I) was purchased from Sichuan, China. LLDPE 7540 was purchased from Daqing, China. 2.2. Preparation of the EG In the intercalation reaction of material graphite, dosages of KMnO4, H2SO4 and HAc were optimized through L9 (34) orthogonal tests and the masses used in the experiments are listed in Table 1. The reactants were quantified according to a definite mass ratio of material graphite C : H2SO4 (100%) : KMnO4 : HAc, and the H2SO4 used was diluted to a mass concentration of 75%. Then, under a definite reaction temperature, the quantified C was mixed with H2SO4 (75%) and KMnO4 in a 250 mL beaker, and HAc was intermittently instilled under stirring. After 1.0 hour the product was washed with de-ionized water and dipped in water for 2.0 hours until the pH of the waste water reached 6.0-7.0; then filtered and dried at 60-80°C for about 6.0 hours. EG was obtained. 2.3. Character of EG 2.3.1. Detection of initial expansion temperature 0.30 g of the prepared EG was spread on an evaporating dish and heated in an oven for some time, then the sample was removed and its volume was measured. When the detected volume of EG was 1.5 times of its initial volume, the oven temperature was defined as the initial expansion temperature T0. 2.3.2. Detection of EV Ten EG samples with a respective mass of 0.30 g were prepared, and they were heated at different temperatures in the range of 100-1000°C, then EV was detected. Expansion times corresponding to the different expansion temperature are listed in Table 2, and the higher the expansion temperature was, the shorter expansion time was observed. 954 Unauthenticated Download Date | 6/16/17 3:49 AM X. Pang et al. Table 2. Expansion times used corresponding to different expansion temperature. Expansion temperature (°C) 100 200 300 400 500 600 700 800 900 1000 Expansion times 30 min 30 min 5 min 1 min 12S 12S 12S 5S 5S 5S 2.3.3. XRD and TG/MS analysis of EG XRD analysis was performed with a Y-4Q X-ray spectrometer using the Cu Kα 1, 2 radiation in the range of 5° < 2θ< 70°. TG-MS analysis of the prepared EG was carried out under the condition of N2 ambience and a heating rate of 20.0 K min-1. 2.3.4. Measurement of EG anti-flame properties A certain amount of EG was added into melting LLDPE at less than 120°C, the mixtures were pressed at 140°C and 10MPa, and then chopped in sliver. The slivers were used to measure LOI according to Standard of GB/ T2406-1993 with oxygen index instrument. 2.3.5. TG and DTA analysis TG analysis condition: N2 flux was controlled as 25 mL min-1, and about 10.0 mg sample was laid in a porcelain crucible, then it was heated to 900°C at a heating rate of 10 K min-1. Changes of sample weight with temperature were recorded. DTA was carried under N2 ambience with a flux of 25 mL min-1. Al2O3 was used as reference compound, and a heating rate of 10 K min-1 was used. 3. Results and discussion 3.1. Results of the orthogonal test to prepare EG In the oxidation of KMnO4, the EG initial expansion temperature and EV can be influenced by intercalation of H2SO4 and HAc into graphene planes. So orthogonal tests were arranged according to Table 2, and the experiment results are listed in Table 3. Range analysis shows that reaction temperature is the most influential factor; the second factor is the dosage of KMnO4. In the range of the test levels, it is can be seen that the initial expansion temperature decreases with the increase of KMnO4 and H2SO4 dosages, but it increases with the increase of reaction temperature and HAc dosage. 3.2. Influence of H2SO4 dosages on EG initial expansion temperature and EV In order to optimize the condition of H2SO4 dosage, single-factor experiments were carried out by changing H2SO4 dosage in the range of 4.5~7.0 g g-1. Experiments were carried out under the constant mass ratio C: KMnO4: HAc of 1.0 : 0.4 : 1.0 according to orthogonal test results; the reactions lasted 1.0 hour at 25°C, and H2SO4 should be diluted to the mass concentration of 75%. Results listed in Table 4 show that the initial expansion temperature and EV of EG are related to the dosage of H2SO4, and the best mass ratio of H2SO4 to C should be 5.0 g g-1. Under this ratio, the initial expansion temperature and EV can reach 160°C and 460 mL g-1, respectively. 3.3. Influence of reaction temperature on EG initial expansion temperature and EV Single-factor experiments of reaction temperature were carried out under the mass ratio C : KMnO4 : 100% H2SO4 : HAc of 1.0 : 0.4 : 5.0 : 1.0, the reactions lasted 1.0 hour at the controlled temperature, and H2SO4 was diluted to a mass concentration of 75%. As shown in Table 5, when the reaction temperature is controlled at 25°C, EG with an initial expansion temperature of 160°C and an EV of 460 mL g-1 is obtained. Too low or too high reaction temperature can lead to the increase of initial expansion temperature and decrease of EG dilatability. When the temperature is lower than 25°C, the intercalation reaction of H2SO4 and HAc is scant. While, higher temperatures cause the excessive oxidation of EG. Therefore, the feasible reaction temperature is set as 25°C. 3.4. Influence of HAc dosage on EG initial expansion temperature and EV Under the constant mass ratio C : KMnO4 : 100% H2SO4 of 1.0 : 0.4 : 5.0, the dosage of HAc is changed in the range of 0.2-1.0 g g-1 with the reaction lasting 1.0 hour at 25°C. It is found that EG with an initial expansion temperature of 160°C and EV of 460 mL g-1 can be gained at the HAc dosage of 0.2 g g-1. Too high HAc dosage may lead to the relative insufficient KMnO4 dosage, the deficient oxidation and intercalation. On the contrary, too low HAc dosage may lead to the relative excess of KMnO4 dosage and excessive oxidation of EG. All these can lead to the increase of initial expansion temperature and decrease of EV. 3.5. Feasible condition of EG preparation According to the results of orthogonal tests and singlefactor experiments, conditions of preparing EG fitting 955 Unauthenticated Download Date | 6/16/17 3:49 AM Preparation of low initial expansion temperature expandable graphite and its flame retardancy for LLDPE Table 3. L9 (34) orthogonal test results of EG initial expansion temperature b. Factors Samples b KMnO4 (g) H2SO4 (g) HAc (g) Reaction temperature (°C) Initial expansion temperature (°C) 1 0.2 3.0 2.0 55 235 2 0.4 3.0 1.0 25 175 3 0.6 3.0 3.0 40 200 4 0.2 4.0 1.0 40 210 5 0.4 4.0 3.0 55 220 6 0.6 4.0 2.0 25 175 7 0.2 5.0 3.0 25 187 8 0.4 5.0 2.0 40 170 9 0.6 5.0 1.0 55 177 Sumlevel 1 632 610 562 537 Sumlevel 2 565 605 580 580 Sumlevel 3 552 534 607 632 R 82 78 47 93 1749 Based on 1.0 g material graphite Table 4. Influence of H2SO4 dosage on EG initial expansion temperature and EV c. c Dosage of 100% H2SO4 (g g-1) 4.5 5.0 5.5 6.0 7.0 EV (mL g-1) 420 460 440 433 416 Initial expansion temperature (°C) 180 160 180 170 170 Based on 1.0 g material graphite Table 5. Influence of reaction temperature on initial expansion temperature and EV. Temperature (°C) 0 15 25 40 EV (mL g-1) 200 400 460 380 Initial expansion temperature (°C) 240 195 160 160 for retardancy of LLDPE can be set as: mass ratio C : KMnO4 : 100% H2SO4 : HAc are controlled as 1.0 : 0.4 : 5.0 : 1.0; the reaction lasts 1.0 hour at 25°C, and H2SO4 is diluted to a mass concentration of 75%, then EG with an initial expansion temperature of 160°C and EV of 460 mL g-1 can be obtained. The expansion temperature curve of the EG is shown in Fig. 1. When the expansion temperature is between 600-900°C, EV of EG is all above 400 mL g-1. 3.6. Preparation of EG1 with no HAc intercalation Compared with EG, EG1 was prepared under the mass ratio C : KMnO4 : 100% H2SO4 of 1.0 : 0.4 : 5.0; the reaction lasted 1.0 hour at 25°C, and H2SO4 was diluted to a mass concentration of 75%. The initial expansion temperature and EV of EG1 was detected as 170°C and 390 mL g-1, respectively. So that, HAc can affect EG initial expansion temperature and dilatability. 3.7. XRD analysis of EG XRD analysis for material graphite, EG were performed. As shown in Fig. 2a, the two peaks with the interplanar crystal spacing of 3.34 Å and 1.67 Å corresponding to diffraction angle of 26.6°, 54.8° are the characteristic spectrum of material graphite. While, as shown in Fig. 2b, the characteristic peak of EG transfers to a small angle of 26.2°, it corresponds to a big interplanar crystal spacing of 3.40 Å due to intercalation in graphene planes. Material graphite is a crystal compound with graphene planes structure by Van Der Waals force. Under the oxidation of KMnO4 and H2SO4, the plane repellency will increase due to the formation of carbon cations through losing the plane electrons. Then the non-carbonaceous 956 Unauthenticated Download Date | 6/16/17 3:49 AM X. Pang et al. Table 6. LOI Results of samples adding different flame retardants. LLDPE% EG% APP (I) % LOI% 0 0 17.5 70 0 30 20.8 70 10 20 31.7 70 20 10 33.9 70 30 0 28.2 100 reactants can easily insert into the planes, leading to the increase of interplanar crystal spacing, which allows graphite to absorb heat, release volatile gas and expand under the condition of high heat. This makes it suitable as a flame retardant. Figure 1. Expansion temperature curve of EG (EV is the volume of 1.0 g EG after expanding at different oven temperature). 3.8. TG/MS analysis of EG Via chemical or electrochemical oxidation, noncarbonaceous reactants can insert into graphene planes. Under high temperature conditions, the intercalating substances can decompose and give out volatile gases which lead to instant expansion of graphite along C axis and give birth to graphite worm. Under the condition of N2 ambience and a calefactive ratio of 20.0 K min-1, TG/MS analysis of the prepared EG was carried out. As shown in Fig. 3, it can be seen that when the temperature is less than 200°C, the decrease of weight is very small, and only smaller intercalating substances decompose. When the temperature is above 300°C, EG weight decreases rapidly, and its expansion capability rises with the increase of temperature. Additionally, SO2 can be detected at the temperature of 400°C and 700°C, which indicates that SO2 plays a more important role for getting EG with high EV. (a) Material graphite 3.9. Detection of EG anti-flame capability The processing temperature of LLDPE is lower than 140°C, so the prepared EG can be used as flame retardant. Flame retardants were added to LLDPE according to the proportion listed in Table 6. The results show that addition of 30% EG can make LOI improve up to 28.2%. But the addition of the same amount of EG1 or purchasing EG to LLDPE can only make LOI reach 24% and 23% [23], respectively. LOI is only 21% under the condition of single 30% APP (I) as flame retardant, but it can be improved to 33.9% when 20% EG together with 10% APP (I) are applied as flame retardant. After combustion, EG changes to graphite worm on the surface of LLDPE (Fig. 4), and a heat insulation layer is formed by the swollen multicellular char. During the expansion of EG, the existence and decomposition of (b) EG Figure 2. XRD analysis of material graphite and the EG (Cu Kα 1, 2 radiation in the range 5° < 2θ< 70°). APP (II) might cause compact coking charred layers. This char structure can limit heat and mass transfer, which is helpful to retard combustion [18,23]. 957 Unauthenticated Download Date | 6/16/17 3:49 AM Preparation of low initial expansion temperature expandable graphite and its flame retardancy for LLDPE Figure 3. TG/MS analysis of EG (Under the condition of N2 ambience and a calefactive ratio of 20.0 K min-1). samples. Mass loss of these anti-flame systems between 100-400°C is less than 5%, which is caused by incomplete decomposition of APP (I) and EG expansion. The loss of weight is about 13% when temperature increases to 450°C. Additionally, 60% weight loss occurs around 450-520°C, which is in a good agreement with the high dilatability of EG under this temperature (as shown Fig. 1). Compare LLDPE retardance sample of 70% LLDPE/10% APP (I) /20% EG with 70% LLDPE/30% EG, the former gives higher residual carbon of 25.9% than the latter, which testifies the synergistic anti-flame of EG with APP (I) [18,23]. Figure 4. SEM analysis of the burn-out LLDPE with 20% EG and 10% APP (I) as flame retardants. Figure 5. TG analysis of LLDPE retardance samples 1. 70% LLDPE/10% APP/20% EG; mass percent of LLDPE, APP (I) and the EG is 70%, 10% and 20%, respectively 2. 70% LLDPE/30% EG; mass percent of LLDPE and the EG is 70% and 30%, respectively. 3.10. TG analysis of retardance LLDPE samples Fig. 5 shows the TG analysis results of 70% LLDPE/10% APP (I) /20% EG and 70% LLDPE/30% EG retardance 3.11. DTA analysis It is well known that huge heat will be consumed during the decomposition of APP (I) and expansion of EG, which results in the decrease of material temperature. As shown in Fig. 6, the peaks corresponding to 111°C are melting decalescence peak of LLDPE. Peaks corresponding to 483.5°C and 481°C, should be two strong decalescence peaks corresponding to EG expansion containing in LLDPE retardance samples of 70% LLDPE/10% APP/20% EG and 70% LLDPE/30% EG, respectively. The higher decomposing temperature of 483.5°C than 481°C shows that the addition of APP will form compact multicellular char, and improve thermal stability of 70% LLDPE/10% APP/20% EG retardance system. 3.12. Analysis of anti-flame mechanism According to the results of TG and DTA, the anti-flame mechanism of EG was proposed as follows: when touched with flame, the structure of EG will change into a swollen multicellular char, which limits the transfer of heat and mass, as well as oxygen diffusion. Instantaneous expansion of the EG can absorb huge heat and releases 958 Unauthenticated Download Date | 6/16/17 3:49 AM X. Pang et al. Figure 6. DTA analysis of LLDPE retardance samples 1. 70% LLDPE/10% APP/20% EG; mass percent of LLDPE, APP (I) and the EG is 70%, 10% and 20%, respectively 2. 70% LLDPE/30% EG; mass percent of LLDPE and the EG is 70% and 30%, respectively. SO2, CO2, H2O; and the coexistence of EG and APP (I) can give more residual carbon and improve thermal stability of the LLDPE retardance system. 4. Conclusions In this work, EG with different initial expansion temperature and EV can be prepared through adjusting dosages of KMnO4, H2SO4 and HAc. The preparing condition of EG with low initial expansion temperature and high EV is: C : KMnO4 :100% H2SO4 : HAc = 1.0 : 0.4 : 5.0 : 1.0 (mass ratio); the reaction lasts 1.0 h at 25°C, and H2SO4 needs to be diluted to a mass concentration of 75%. Under this condition, EG with an initial expansion temperature of 160°C and EV of 460 mL g-1 can be prepared. Reaction temperature has important influence on EG dilatability. It can affect reaction environment and reactant activity; affect open degree of graphene planes; and influence the inserting dosages of HAc and H2SO4; then influence the expansion capability of EG. The excellent anti-flame capability of EG is contributed by the ability of absorbing huge heat and the formation of swollen multicellular char, which acts as physical barrier for heat and mass transfer. It is can be seen that addition of 30% EG to LLDPE can improve LOI up to 28.2% from 21%. Moreover, addition of 20% EG to LLDPE together with 10% APP (I) leads to a higher LOI of 33.9% because of the synergistic flame retardancy between EG and APP (I). Acknowledgements This study is supported by Undergraduate Scientific and Technological Creation Project (STCP) of Hebei University (2011075) and Doctor Foundation of Hebei province Education Office (China, No.B2004402). We gratefully acknowledge their support during the study. References [1] X.Y. Pang, P. Lv, Y.S. Yang, H.L. Ren, F. Gong, E. J. Chem. 5, 149 (2008) [2] M. Toyoda, M. Inagaki, Carbon. 38, 199 (2000) [3] F.Y. Kang et al., New Carbon Mater. 18, 161 (2003) [4] J.H. Li, Y.Z. Gao, S.F. Liu, L.N. Yang, J. Sichuan Univ. (Nat. Sci.) 44, 399 (2007) [5] X.Y. Pang, R.N. Lin, Asian J. Chem. 22, 4469 (2010) [6] S. Duquesne, M.L. Bras, S. Bourbigot, Fire and Mater. 27, 103 (2003) [7] M. Thirumal, D. Khastgir, N.K. Singha, J. Appl. Polym. Sci. 110, 2586 (2008) [8] R.C. Xie, B.J. Qu, Polym. Degrad. Stab. 71, 375 (2001) [9] R.C. Xie, B.J. Qu, J. Appl. Polym. Sci. 80, 1190 (2001) [10] M. Modesti, A. Lorenzetti, F. Simioni, G. Camino, Polym. Degrad. Stab. 77, 195 (2002) [11] M. Modesti, A. Lorenzetti, Polym. Degrad. Stab. 78, 167 (2002) [12] M. Modesti, A. Lorenzetti, Polym. Degrad. Stab. 78, 341 (2002) [13] M. Modesti, A. Lorenzetti, Eur. Polym. J. 39, 263 (2003) [14] S. Duquesne, R. Delobel, M.L. Bras, G. Camino, Polym. Degrad. Stab. 77, 333 (2002) [15] L. Shi et al., Polym. Int. 55, 862 (2006) [16] X.C. Bian, J.H. Tang, Z.M. Li, Z.Y. Lu, A. Lu, J. Appl. Polym. Sci. 104, 3347 (2007) [17] L. Ye, X.Y. Meng, X. Ji, Z.M. Li, J.H. Tang, Polym. Degrad. Stab. 94, 971 (2009) [18] H.F. Zhu, Q.L. Zhu, J. Li, K. Tao, L.X. Xue, Q. Yan, Polym. Degrad. Stab. 96, 183 (2011) [19] Y. X. Huang, N.L. Zhou, L. Li, Y. Liu, S.H. Wei, J. Liu, J. Nanjing Norm. Univ. (Nat. Sci.). 28, 57 (2005) [20] L. Wang, K.M. Song, S.H. Zhang, Q. Li, Y.P. Li, M. Liu. Bull. Chinese Ceram. Soc. 28, 844 (2009) [21] L. Wang, K.M. Song, M.Y. Zhang, T. Feng, NonMetallic Mines. 31, 19 (2008) [22] X.Y. Pang, S.K. Zhi, Y.J. Su, L. Liu, Fang. Lin, J. Hebei Univ. (Nat. Sci.) 31, 497 (2011) [23] A.H. Yan, Z.Q. Zhou, Z. Wu, Chem. Engineer. 3, 48 (2006) 959 Unauthenticated Download Date | 6/16/17 3:49 AM