* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Biopharmaceuticals

Pharmacognosy wikipedia , lookup

Drug interaction wikipedia , lookup

Pharmacogenomics wikipedia , lookup

Prescription costs wikipedia , lookup

Pharmaceutical industry wikipedia , lookup

Pharmacokinetics wikipedia , lookup

Neuropsychopharmacology wikipedia , lookup

Drug design wikipedia , lookup

Neuropharmacology wikipedia , lookup

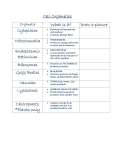

Biopharmaceuticals Protein Therapeutics Andreas Castan DISCLAIMER In order to utilize the ‘Safe Harbor’ provisions of the United States Private Securities Litigation Reform Act of 1995, Biovitrum is providing the following cautionary statement. This presentation contains forward-looking statements with respect to the financial condition, results of operations and businesses of Biovitrum. By their nature, forward-looking statements and forecasts involve risk and uncertainty because they relate to events and depend on circumstances that will occur in the future. There are a number of factors that could cause actual results and developments to differ materially from that expressed or implied by these forward-looking statements. These factors include, among other things, the loss or expiration of patents, marketing exclusivity or trade marks; exchange rate fluctuations; the risk that R&D will not yield new products that achieve commercial success; the impact of competition, price controls and price reductions; taxation risks; the risk of substantial product liability claims; the impact of any failure by third parties to supply materials or services; the risk of delay to new product launches; the difficulties of obtaining and maintaining governmental approvals for products; the risk of failure to observe ongoing regulatory oversight; the risk that new products do not perform as we expect; and the risk of environmental liabilities. 2 1 Outline of the presentation • Basics: Drug development and protein therapeutics • Proteins vs. small molecules • Protein drug discovery • Protein drug development – ReFacto show case 3 Drug development in general • Safety – Acceptable therapeutic window – No side effects • Efficacy – Effect in the chosen indication 4 2 The Process BLA Market Biotech Pharma Pharma Biotech C O S T Pharma Biotech H2L Academia Basic Research Target ID -hypothesis Phase 3 Effect Phase 2 Dose Phase 1 PK/PD Lead Opt Candidate Candidate Drug Drug Screening Validation Discovery Pre-Clinical Clinical RISK 5 Protein Therapeutics • Proteins are fragile i.e. cannot be autoclaved • Normally injected intravenous or subcutaneous – A number o new devices under development • Produced by – Bacteria or mammalian cells – Plasma or other biological sources – Transgenic animals or plants • Replacement therapy or new, engineered proteins 6 3 Outline of the presentation • Basics: Drug development and protein therapeutics • Proteins vs small molecules • Protein drug discovery • Protein drug development – ReFacto show case 7 NBEs versus NCEs inherent differences, but good complementarity's! Therapeutic proteins (NBEs) +• - protein-protein interactions Small molecules (NCEs) +• • secreted natural proteins - high eff./pot./sel, less sideeffects • engineered non-natural proteins • multiple functions via fusion proteins • injectables • non-natural proteins - immunogenicity • extra cellular & mainly peripheral targets oral administration • central & peripheral - intra & extra cellular targets • protein-protein interactions - • toxicity, selectivty, side effects • some “mimetics” hard to develop... 8 4 NBEs versus NCEs differences in development times! ¾ Historically NBEs show • Shorter development times • Replacement therapy • Defined pharmacological action • More successful in clinical development • Orphan drug approval • Treatment of rare, severe diseases • Easier to prove efficacy 9 NBEs versus NCEs convergent trend in development time! 14 12 10 8 6 4 NBEs (n=47) 2 NCEs (n=511) 19 99 19 97 19 95 19 93 19 91 19 89 19 87 0 19 85 Mean development time [years] Mean development times Year of launch 10 5 NBEs versus NCEs convergent trend in development time! Why ? ¾ Nature of NBEs affects the development time • Replacement therapy • Engineered proteins with altered functions • mAbs and antibody fragments • Vaccines ¾ Little difference in FDA mean approval time ¾ NBEs still more successful in Ph I-II but failure increasing in Ph III 11 Outline of the presentation • Basics: Drug development and protein therapheutics • Proteins vs small molecules • Protein drug discovery • Protein drug development – ReFacto show case 12 6 The NBE Discovery Process involves Target ID Lead selection Lead Generation CD Lead Preclinical Phase I Phase II Phase III Optimization Protein Activity Relationship (PAR) Primary sequence • Protein Optimization • Protein Design • Quantification assay - Protein Engineering • Protein Production - Fusion partner for preclinical testing • Pharmacokinetic • Screening funnel – analysis - Stability / half-life in vitro and in vivo Reg Posttranslational modifications GMP process • Optimization/characterization of - PEGylation - Glycosylation • Process development – PI/II studies • GLP-toxicity, immunogenicity • Formulation 13 Outline of the talk • Basics: Drug development and protein therapeutics • Proteins vs small molecules • Protein drug discovery • Protein drug development – General development needs – Monoclonal Antibodies – ReFacto show case 14 7 Documentation to support approval of a new drug • Description of molecule • Mechanism of action • Manufacturing and control – Drug Substance (Active Pharmaceutical Ingredient) – Drug Product • Preclinical data (animal studies) • Clinical data 15 Two stage Process Development Pre clinical Tox batch Phase I batch Phase II batch Phase III batch Manufacturing Minimal process development Focus on few important parameters Focus on in-process controls and analytical methods Focus on impurity profile and impurity characterization Extensive process development Optimization and justification of all parameters and extensive work on critical parameters Focus on yield, stability, reproducibility and scalability Reducing number of in-process control and spec. analyses Phase I/II process Intermediate yield Intermediate purity Limitied # of batches Manufacturing process High yield Low cost High purity Robust 16 8 Additional information required in drug development projects • Market needs (sets scale of manufacturing) • Competitor situation • Intellectual Property (IP, patents) 17 Currently used techniques for Recombinant Biopharmaceuticals • Design of molecules by genetic engineering • Expression in bacterial and mammalian hosts – E.coli – Pichia pastoris – CHO & NS0 • Development of cell lines with high expression levels • Host modification / cell line optimization – Removal of proteases and impurities 18 9 Fed batch cultivation of mammalian cells Glucose + Glutamine + Feed medium 50L 25L 5L 150L 10-11 days 4 days 16 days Cell thaw and expansion Seed train Production 400L Purification 19 Over 300 monoclonal antibodies under development • Design of new molecules • Design of new monoclonal antibodies • Design of antibody fragments • Expression of monoclonal antibodies • Mammalian production 0,5-4g/L • Production scale up to 20 000 L Bioreactors 20 10 MAb heterogeneity Identity N-terminal C-terminal Modifications -Deamidation -Oxidation -Fragmentation Binding Aggregation Sulfhydryl groups Disulphide bridges Glycosylation 21 Product Flow Cell Bank Cultivation Filling/Freeze drying Distribution Purification Labeling Packaging Marketing 22 11 New era in Biotechnology? • 5 out of 20 top products are biologics • Price for yearly treatment with Refacto 75 KUSD • Needs to be decreased to some hundreds/ thousand USD/year • Platform approach upstream and downstream • Demand vs capacity ongoing discussions • Robust processes • Demand for high titers 5 g/L or even 10 g/L 7000 6000 total demand biologics (kg/year) • The biotech industry today: A shift towards antibodies 5000 4000 3000 2000 1000 0 2002 2003 2004 2005 2006 year Source: UBS investment research 23 Upstream productivity increase: Focus on DSP 24 12 Eliminate (DSP) bottlenecks! 25 Challenges for modern downstream process • Technical challenge – Complex and technically demanding with inherent complexity, high initial volume and low product titer – Need for robust and scalable process for the entire DSP – Increasing regulatory focus on DSP and comparability • Financial challenge – Processes are fixed cost driven (investment vs consumables) – Manufacturing cost 15-25 % of total COGs – Costs for DSP up to 75 % of manufacturing costs 26 13 Major process derived contaminants in Mab production FDA PTC 1997 27 28 14 Design of candidate drug • Interacting with target • Known mechanism • Safety • Tolerability • Efficacy • Immunogenicity 29 ReFacto (Recombinant Factor VIII SQ) Gene Construction 90 kDa H2N A1 1 110 kDa A2 80 kDa B A3 740 SQ-link 1649 C1 C2 COOH 2332 SFSQNPPVLKRHQR 741 745 1637 1648 In vivo processing 30 15 ReFacto (Recombinant Factor VIII SQ) Processing of Primary Translation Product 170 kDa A1 A2 SQ-link A3 C1 C2 SFSQNPPVLKRHQR Intracellular Processing 90 kDa A1 80 kDa A2 A3 C1 C2 Me 2+ 31 Structure of Factor VIII and r-VIII SQ Factor VIII full-length r-VIII SQ B-domain deleted Heavy Chain Heavy Chain A2 A3 A3 A1 Light Chain C2 2+ Me Me2+ C1 Light Chain B C1 Me2+ A2 A1 C2 PL-binding site vWF-binding site PL-binding site vWF-binding site 32 16 Development of manufacturing system 33 ReFacto Manufacturing Process CHO Cultivation Continuous Harvesting Primary Capture Ion exchange Downstream Purification Drug Substance Viral inactivatin Immunoaffinity Formulation Ion exchange Lyophilization HIC Buffer exchange Drug Product Packaging 34 17 ReFacto is produced with recombinant gene technology Chinese Hamster Ovary, CHO, cells is used as host cell The human gene for Factor VIII has been incorporated in the CHO cell DNA, and the cell has been cloned Factor VIII gene DNA The CHO cells produce human Factor VIII, ReFacto 35 Cell bank preparation Clone Master Cell Bank MCB Cultivation Process Working Cell Bank WCB Post Production Cell Bank, PPCB 36 18 ReFacto Cell Culture: Production medium 500 L medium / day Well defined 60 components Nutritionally rich Antibiotics free Serum free (Albumin Ph. Eur.) Recombinant insulin 500 L spent medium / day 37 ReFacto Cell Culture: Process Flow Cell bank (WCB) T-Flask Spinner 50L 500L 38 19 ReFacto Purification Process Harvest filtrate Ion Exchange Chromatography Virus Inactivation Immuno Affinity Chromatography Ion Exchange Chromatography Hydrophobic Interaction Chromatography Gel Permeation Chromatography Drug Substance 39 Manufacturing quality • Identify critical parameters – robustness studies (process characterization) • Batch records and Standard Operating Procedures (SOPs) • Cleaning validation • Preventive maintenance programs 40 20 ReFacto, Characterization • Identity • Purity • Structure • Function 41 ReFacto Purity tests • Specific activity • CHO cell protein • SDS-PAGE • Mouse IgG • SEC-HPLC • TNBP • RP-HPLC • Triton X-100 • DNA • Ethylene glycol 42 21 ReFacto Analysis of structure • Amino acid composition • SDS-PAGE/ Western Blot • Amino acid sequence • Tryptic map • Carbohydrate composition • Gel filtration • Carbohydrate sequence • MALDI-MS • RP-HPLC • Circular dichroism 43 ReFacto Analysis of structure • Amino acid composition • SDS-PAGE/ Western Blot • Amino acid sequence • Tryptic map • Carbohydrate composition • Gel filtration • Carbohydrate sequence • MALDI-MS • RP-HPLC • Circular dichroism 44 22 Analytical package • Identify assays • Develop specifications – drug substance and Finish Product • Validation of assays • Transfer to Quality Control, QC, laboratory 45 ReFacto Pharmaceutical Formulation • Stable freeze-dried formulation • No protein stabilizer • Small reconstitution volume • Short dissolution time • High recovery 46 23 Recovery during formulation and freeze-drying 300 Before filtration After filtration Thawed 5 times Freeze-dried VIII:C (IU/ml) 250 200 150 100 50 0 Buffer only Polysorbate 80 PEG 4000 HSA Haemaccel Haes 47 ReFacto Storage Stability • Lyophilized product – 36 months 2 to 8oC – whereof 6 months at room temperature <25oC • Reconstituted product – 3 hours at <25oC – stable for 48 h in syringe system for continuous infusion 48 24 Virus Safety • Cell bank testing • In-process testing • Validation of purification process – model virus studies Virus reduction by filtration: 49 ReFacto virus validation data Log reduction Process step Enveloped MXR yes MCF yes IBR yes PI3 yes SD treatment ≥ 4,6 ≥ 4,1 ≥ 4,9 ≥ 6,2 5,1 5,5 ≥ 7,9 6,3 Immunoaffinity chromatography Gel filtration Overall reduction POL no 3,8 1,8 ≥ 9,7 ≥ 9,6 ≥ 12,8 ≥ 12,5 5,6 MXR, murine xenotropic retrovirus (Retroviridae) MCF, mink cell focus virus (Retroviridae) IBR, infectious bovine rhinotracheitis virus (Herpesviridae) PI3, parainfluenza 3 virus (Paramyxoviridae) POL, polio virus (Picornoviridae) 50 25 Safety and efficacy • Preclinical studies – Rat (Sprague-Dawley) – Hemophilia A dog – Monkey (Cynomolgus) • Clinical trials – PTP, Previously Treated Patients – PUP, Previously Untreated Patients – Surgery – On-demand/prophylaxis 51 Regulatory process • IND, Investigational New Drug • BLA, Biologics License Application – FDA, US • MAA, Market Authorization Application – Centralized procedure, EMEA, EU • Rest of the World Applications • Comparability protocols & variations 52 26 Commercial phase • Ensure manufacturing capacity • Life cycle management programs – Convenient devices • Current GMP • Market support • Regulatory support • Phase IV clinical studies 53 Abbreviations • BLA – Biologics License Application • MAA, Market Authorization Application • CD – Candidate drug • MCB - Master Cell Bank • CTD – Common Technical Document • NBE – new biological entity • EMEA- European Medicinal Evaluation Agency • NCE – new chemical entity • FDA- Food and Drug Administration • PD - Pharmacodynamics • GLP - Good Labboratory Practice • PK- Pharmacokinetics • GMP – Good Manufacturing Practice • PPCB – Post Production Cell Bank • H2L- Hit to lead • SOP – Standard Operation Procedure • IND – Investigational new drug • WCB - Working Cell Bank 54 27 Andreas Castan Biovitrum AB E-mail: [email protected] www.biovitrum.com 55 www.biovitrum.com 28