* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download AC induction - final notes

Power engineering wikipedia , lookup

Distributed control system wikipedia , lookup

Commutator (electric) wikipedia , lookup

Control theory wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Resilient control systems wikipedia , lookup

Power inverter wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Electrical ballast wikipedia , lookup

Control system wikipedia , lookup

Three-phase electric power wikipedia , lookup

Current source wikipedia , lookup

Dynamometer wikipedia , lookup

Utility frequency wikipedia , lookup

Opto-isolator wikipedia , lookup

Power MOSFET wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Surge protector wikipedia , lookup

Voltage regulator wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Electric motor wikipedia , lookup

Stray voltage wikipedia , lookup

Distribution management system wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Buck converter wikipedia , lookup

Power electronics wikipedia , lookup

Voltage optimisation wikipedia , lookup

Alternating current wikipedia , lookup

Mains electricity wikipedia , lookup

Electric machine wikipedia , lookup

Stepper motor wikipedia , lookup

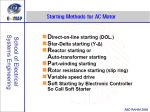

EET421 Power Electronic Drives – Induction Motor & drives Abdul Rahim Abdul Razak 1 ABD RAHIM 2008 INDUCTION MOTORS Per-phase equivalent circuit …. (Rashid) In real world: •Value of Xm is very large (Rm can be omitted) •Xm2 >> (Rs2 + Xs2) Vs ≈Vm •Thus, for circuit simplification, the magnetizing reactance Xm can be moved-out to the stator winding. 2 ABD RAHIM 2008 INDUCTION MOTORS The input impedance of the motor becomes: Power factor angle: 3 ABD RAHIM 2008 INDUCTION MOTORS Rotor current (rms): Previously noted, PAG or Pg=3Ir2Rr /s And developed torque τdev or, Thus , τind =Pdev / ωm = PAG / ωsync --(15-18) 4 ABD RAHIM 2008 INDUCTION MOTORS 5 ABD RAHIM 2008 6 ABD RAHIM 2008 Extended Torque-speed characteristic .. Pullout torque or breakdown torque = max possible handling torque. The curve is nearly linear up to full load (Rr >> Xr, thus Ir,Br and Tind rise ∞ increasing slip). s Plugging = reversing of magnetic field rotation by switching any two stator phases. The reversed Tind will stop the motor rapidly and rotate it to reverse direction. If speed driven faster than ns the Tind reverses and motor becomes generator. 7 ABD RAHIM 2008 Extended Torque-speed characteristic .. Pullout torque or breakdown torque = max possible handling torque. The curve is nearly linear up to full load (Rr >> Xr, thus Ir,Br and Tind rise ∞ increasing slip). If speed driven faster than ns the Tind reverses and motor becomes generator. Plugging = reversing of magnetic field rotation by switching any two stator phases. The reversed8Tind will stop the motor rapidly and ABD RAHIM 2008 rotate it to reverse direction. INDUCTION MOTORS – DRIVES Speed & torque control strategies A) Change nsync 1. Pole changing 2. Line frequency control B) Change slip, s 3. Rotor-resistance control 4. Rotor slip-energy recovery 5. Line/stator voltage control C) Parameters alteration 6. Rotor voltage control 7. Stator current control 8. Stator voltage and frequency control 9. Voltage, current and frequency control 120f e ns P n m ( 1 s )n sync 9 ABD RAHIM 2008 INDUCTION MOTORS – DRIVES With the existence & development of modern solid-state variable-frequency motor drives. • The modern favorable speed and torque controller of induction motors : 1. 2. 3. 4. 5. 6. • Stator voltage control Rotor voltage control Frequency control Stator voltage and frequency control Stator current control Voltage, current, and frequency control To meet the torque-speed duty cycle of a drive, the voltage, current, and frequency control are normally used. 10 ABD RAHIM 2008 INDUCTION MOTORS – Speed Control 11 ABD RAHIM 2008 1. Stator voltage control the torque is proportional to the square of the stator supply voltage, a reduction in stator voltage will produce a reduction in speed. If the terminal voltage is reduced to bVs, where b ≤ 1,Typical torquespeed characteristics for various values of b : 12 ABD RAHIM 2008 1. Stator voltage control In any magnetic circuit, the induced voltage is proportional to flux and frequency, and the rms air-gap flux can be expressed as or (15-31) Where, Km is a constant and depends on the number of turns of the stator winding. As the stator voltage is reduced, the air-gap flux and the torque are also reduced. 13 ABD RAHIM 2008 The stator voltage can be varied by three-phase 1. 2. 3. AC voltage controllers, voltage-fed variable DC-link inverters, or pulse-width modulation (PWM) inverters. However, due to limited speed range requirements, the AC voltage controllers are normally used to provide the voltage control. The ac voltage controllers are very simple. However, the harmonic contents are high and the input PF of the controllers is low. They are used mainly in low-power applications, such as fans, blowers, and centrifugal pumps, where the starting torque is low. They are also used for starting high-power induction motors to limit the in-rush current. 14 ABD RAHIM 2008 1) AC voltage controller & soft start (to apply an adjustable voltage to the motor and increase this voltage gradually over a user-selectable acceleration period) Advantages : •Reduced starting current •Reduced starting torque •Less mechanical stress •Improved control of acceleration and deceleration 15 ABD RAHIM 2008 16 ABD RAHIM 2008 Example 15.2a: A 3-phase 460V, 4-pole Y-connected induction motor has below parameters: Rs = 1.5ohm, Rr = 0.75ohm, Xs = 1.5ohm, Xr = 2.25ohm and Xm = 65ohm. The no-load loss, Pno-load is negligible. The load torque is proportional to the speed squared, is 45Nm at 1740rpm. If the motor speed is 1550rpm, determine : a) Load torque, τL b) The rotor current, IR c) Stator supply voltage , Va d) Motor input current, Ii e) Motor input power , Pi f) The slip for maximum current ,sa g) Maximum rotor current , Ir(max) h) Speed at maximum rotor current, ωa i) Torque at maximum current, τ a 17 ABD RAHIM 2008 2. Rotor voltage control (Rotor resistance control) Wound rotor induction motor. Breakdown torque peak is shifted to zero speed by increasing rotor resistance. 18 ABD RAHIM 2008 2. Rotor voltage control (Rotor resistance control) applicable for a wound-rotor motor type only. an external three-phase resistor may be connected thru slip rings as shown in figure: The method may increase starting torque while limiting starting current. However, this is an inefficient method and there would be imbalance voltages and currents if the resistances in the rotor circuit are not equal. The increase in resistance does not affect the value of maximum torque but increases the slip at maximum torque. The wound-rotor motors are widely used in application which need frequent starting and braking with large motor torque (hoist, crane). 19 ABD RAHIM 2008 -Applicable for wound-rotor induction motors only -The shape of torque-speed curve is altered by inserting extra resistances to the rotor circuit -Inserting extra resistances, will seriously reduce efficiency of the motor -Usually applied for short period only. 20 ABD RAHIM 2008 2. Rotor voltage control (Rotor resistance control) • • The three-phase resistor may be replaced by a three-phase diode rectifier and a dc converter, as shown in Figure, where the gateturn-off thyristor (GTO) or an insulated-gate bipolar transistor (IGBT) operates as a dc converter switch. The inductor Ld acts as a current source Id and the dc converter varies the effective resistance, which can be found from Eq. (14.45): Re = R (l - k) • • (15.41) where k is the duty cycle of the dc converter and the motor speed can be controlled by varying the duty cycle. The portion of the air-gap power, which is not converted into mechanical power, is called slip power. The slip power is dissipated in R. 21 ABD RAHIM 2008 2. Rotor voltage control (Rotor resistance control) 22 ABD RAHIM 2008 2. Rotor voltage control (Rotor resistance control) 23 ABD RAHIM 2008 2. Rotor voltage control (Rotor resistance control) Example 15.3a: Rs = 0.05Ω, Rr =0.055Ω, Xs = 0.31Ω, Xr = 0.35Ω and Xm = 7.1Ω 24 ABD RAHIM 2008 3. • • • • • Frequency control The torque and speed of induction motors can be controlled by changing the supply frequency. We can notice from Eq. (15.31) that at the rated voltage and rated frequency, the flux is the rated value. If the voltage is maintained fixed at its rated value while the frequency is reduced below its rated value, the flux increases. This would cause saturation of the air-gap flux, and the motor parameters would not be valid in determining the torque-speed characteristics. At low frequency, the reactances decrease and the motor current may be too high. This type of frequency control is not normally used. 25 ABD RAHIM 2008 3. • Frequency control If the frequency is increased above its rated value, the flux and torque would decrease. If the synchronous speed corresponding to the rated frequency is called the base speed ω b, the synchronous speed at any other frequency becomes, thus, and 26 ABD RAHIM 2008 3. Frequency control 27 ABD RAHIM 2008 3. Frequency control 28 ABD RAHIM 2008 3. Frequency control - Rotation of magnetic fields nsync will change in direct proportion to change in electrical frequency, fe. so does the no-load point on the torque-speed characteristic curve. -The base speed will change with the same pattern. -Controlling under base speed, terminal voltage level and maximum operating torque MUST be derated accordingly. -Beyond based speed (up to 2p.u), voltage should be maintained to take care on its insulation. -but the maximum operating torque will automatically decreasing. -The motor is now operating in so called “field weakening mode” 29 ABD RAHIM 2008 INDUCTION MOTORS – Speed Control 30 ABD RAHIM 2008 Line frequency Control The important of derating… the stator voltage is not decreased nearly with decreasing of stator frequency, the steel in the core of the induction motor will saturate and excessive magnetization currents will flow in the machine. 31 ABD RAHIM 2008 Line frequency Control 32 ABD RAHIM 2008 33 ABD RAHIM 2008 4. Voltage and frequency control (volt/hertz control ) -From previous equation , flux is direct proportional to stator voltage and inverse proportional with frequency : - thus, if the ratio is kept constant, the flux value will remain constant. - the maximum torque (τm) can be maintained constant as it only depends on base speed (ωb) and β. - Once ωb ↓, β ↓ thus Va need to be ↓ as well in order to maintain the same Tm value. 34 ABD RAHIM 2008 4. Voltage and frequency control (volt/hertz control ) -As the frequency reduced, β decreases, thus the slip at maximum torque increases. 35 ABD RAHIM 2008 4. Voltage and frequency control (volt/hertz control ) - Volt/hertz control usually applied to maintain torque while speed is varied. - voltage supply are obtained from 3-phase inverter or cycloconverters - as for very large power applications (locomotives , cement mills) cycloconverters are used. - As the frequency reduced, β decreases, thus the slip at maximum torque increases. 36 ABD RAHIM 2008 3 possible circuit arrangement for obtaining variable voltage and frequency : - regeneration is not possible and inverter would generate harmonics into the AC supply. - harmonics into the AC supply is reduced. - input power factor is low - Regeneration is possible 37 ABD RAHIM 2008 5. Current control - torque of induction motor can be decreased by reducing rotor current. - but only the accessible input current is varied. - at fixed input current, the rotor current depends on the relative values of magnetizing and rotor circuit impedance. 38 ABD RAHIM 2008 5. Current control - maximum torque depends on squared of current. -starting torque is low due to Xm is large compared to Xs an Xr 39 ABD RAHIM 2008 5. Current control - as the speed increase, slip decrease, stator voltage rises and the torque increase. -Torque is increased due to increasing flux. Magnetizing current also increased and saturation will happen if the input current is not limited. - the constant current can be supplied by 3-phases CSI. 40 ABD RAHIM 2008 2 possible CSI circuit for Current control : -Inductor act as current source - controlled rectifier controlling the current source - input power factor is very low. - the chopper controlling the current source - input power factor is higher. 41 ABD RAHIM 2008 6. Voltage, current and frequency control - In some application or requirement, all the 3 parameters might have to be adjusted. - - 1st region: speed is varied by voltage (or current) control at constant torque. - 2nd region: motor operated at constant current and slip is varied. - 3rd region: speed is controlled by frequency at reduced stator current.42 ABD RAHIM 2008 6. Voltage, current and frequency control 43 ABD RAHIM 2008 44 ABD RAHIM 2008 electric drives control : closed loop : means that some sort of feedback device attached to the motor feed speed information back to the drive for use in correcting any speed discrepancies. Open loop: like most AC Drives, means no such feedback exists, and the drive assumes that what it told the motor to do is actually being done. 45 ABD RAHIM 2008 Modern electric drives (With closed-loop control ) - closed-loop control is required to satisfy the steady-state and transient performance specs of AC drives - control strategies: 1) scalar control: control variable are DC quantities and only magnitude are controlled. 2) Vector control : both magnitude and phase of control variables. 3) Adaptive control: parameters are continuously varied to adapt the output variables variations. 46 ABD RAHIM 2008 Modern electric drives (With closed-loop control ) Input Output 47 ABD RAHIM 2008 Modern electric drives (With closed-loop control ) 48 ABD RAHIM 2008 Choice of Electrical Drives Choice of an electrical drive depends on a number of factors. Some of the important factors are : 1. Steady state operation requirement : nature of speed-torque characteristics, speed regulation, speed range, efficiency, duty cycle, quadrants of operation, speed fluctuations if any, ratings. 2. Transient operation requirement: values of acceleration and deceleration, starting, braking and reversing performance. 3. Requirement related to the source : type of source, and its capacity, magnitude of voltage, voltage fluctuations, power factor, harmonics and their effect on other load, ability to accept regenerated power. 4. Capital and running cost, maintenance needs, lifespan expectation. 5. Space and weight restrictions if any. 6. Environment and location. 7. Reliability. 49 ABD RAHIM 2008