* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download LED Driver Dimming Methods

Transmission line loudspeaker wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electrical substation wikipedia , lookup

Stepper motor wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Control system wikipedia , lookup

Stray voltage wikipedia , lookup

Electrical ballast wikipedia , lookup

Power inverter wikipedia , lookup

Distribution management system wikipedia , lookup

Integrating ADC wikipedia , lookup

Voltage optimisation wikipedia , lookup

Mains electricity wikipedia , lookup

Current source wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Schmitt trigger wikipedia , lookup

Voltage regulator wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Power MOSFET wikipedia , lookup

Three-phase electric power wikipedia , lookup

Alternating current wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Buck converter wikipedia , lookup

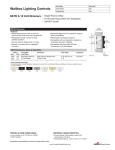

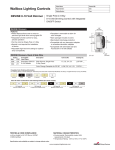

Current mirror wikipedia , lookup

112 DIMMING Application Note: 112 Dimming Methods Application Note LED Driver Dimming Methods Dimming Dimming is the process of controlling the amount of electrical power supplied to a light source. The four most popular methods for dimming LED lights are described below and cover 0-10Volt dimming, PWM (Pulse Width Modulation) dimming, Forward-Phase dimming (sometimes referred to as “Triac” or Incandescent Dimming) and Reverse-Phase dimming (sometimes referred to as an ELV or Electronic Low Voltage Dimming). Dimming Methods 0-10V Dimming - (Add “-RD” to appropriate EPtronics Part Number) This method can use a number of devices to control the dimming. This requires additional low voltage wiring, but is more accurate than AC phase dimming. EPtronics 0-10V Dimmable LED Drivers use CCR (Constant Current Reduction) based on the input signal level to achieve dimming. Dimmer Types ● 0-10V Controller - outputs 0 to 10V using a computerized control device. ● 0-10V Wall Dimmer - uses a passive current sinking dimmer to sink ~5mA off a 0-10V input. ● Potentiometer - For EPtronics drivers, a 50K Ohm 2-terminal connection is recommended. ● Fixed Resistor - A fixed resistor can be used to tune the drivers output. Summary of 0-10V EPtronics Dimming ● Controls current to LED's via CCR method ● Better energy efficacy. ● Color of light could change as LED's are current dependent for color ● Light output is non-linear vs. current to LED Typical 0-10V performance curve: Output Current % Output Current vs. 0-10VDC Dimming Input 100 90 80 70 60 50 40 30 20 10 0 Output Current % 0V 1V 2V 3V 4V 5V 6V 7V 8V 9V 10V Dimming Input VDC PWM (Pulse Width Modulation) - (Add “-PD” to appropriate EPtronics Part Number)) This method can use a number of devices to control the dimming. This requires additional low voltage wiring but is more accurate than AC phase dimming. EPtronics PWM Dimmable LED Drivers use CCR (Constant Current Reduction) based on the duty cycle of the PWM input signal to achieve dimming. EPtronics standard “-PD” products use positive PWM dimming. That is the longer the positive duty cycles the brighter the output. Typical PWM duty cycles are 10-90%. Summary of EPtronics PWM dimming ● Controls current to LED's via CCR method ● Better energy efficacy. ● Color of light could change as LED's are current dependent for color ● Light output is non-linear vs. current to LED ● CCR PWM dimming operates the same as 0-10V CCR dimming as explained above except pulse width controls dim level. 1 EPtronics, EPtronics, Inc. Inc. 1 ◙◙ Los Los Angeles, Angeles, California California ◙◙ T:T: 800 800 643-0688 643-0688 ◙ ◙ E: E: [email protected] [email protected] ◙ www.EPtronics.com ◙ Rev Rev.-08/01/2010 01/09/2012 DIMMING Application Note 112 LED Driver Dimming Methods Application Note: 112 30 Watt - LD30W Series Dimming Methods CONSTANT VOLTAGE OR CONSTANT CURRENT LED DRIVER WITH DIMMING Typical PWM performance curve: Output Current % Output Current vs. Positive Duty Cycle 100 90 80 70 60 50 40 30 20 10 0 Output Current % 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% Positive Duty Cycle AC Line Dimmers Requires a Leading Edge (Triac) or Trailing Edge (ELV) dimmer to change input voltage via phase cut. The resulting chopped wave has less energy than the AC line. Since these types of dimmers connect directly between AC source and AC input of the power source, they are very popular and easy to use. They typically require no additional wiring so are good for retrofit and residential applications Leading Edge - (Add “-LE” to appropriate EPtronics Part Number) Also commonly known as "Triac Dimming", "SCR Dimming", and Forward Phase control dimming, Forward Phase dimming control is the most common form of phase dimming. It uses a silicon device, usually an SCR or a Triac, to turn the mains waveform on part way through its cycle. By varying the point at which the waveform turns on, we can alter the amount of power delivered to the load. The first solid-state phase control dimmers employed SCRs and Triacs for switching. The electrical characteristics of these devices require that the unwanted power be cut from the start or leading edge of each half power cycle as show in figure 3. The very rapid switch-on time of SCRs and Triacs produces very low losses, however the rapid current increase produces unwanted Electromagnetic Interference (EMI), radiated from the load circuits and harmonic distortions in the supply mains. To reduce these problems, a substantial inductor is incorporated into the dimmer circuit to slow the rate of current increase. Typical Leading Edge Performance Waveform: FORWARD PHASE 0 45 90 135 180 225 270 315 360 405 450 495 540 Delayed Turn on FIGURE: 3 2 EPtronics, Inc. ◙ Los Angeles, California ◙ T: 800 643-0688 ◙ E: [email protected] ◙ www.EPtronics.com ◙ Rev - 01/09/2012 112 DIMMING Application Note: 112 Dimming Methods Application Note LED Driver Dimming Methods Trailing Edge (Add “-TE” to appropriate EPtronics Part Number) A trailing edge dimmer is a reverse phase dimmer with a more complex circuit than a forward phase dimmer. The simple leading edge circuit can no longer be used, because most Triac’s cannot be turned off until the wave crosses zero volts. (Gate turn-off (GTO) Triac’s exist, but are far more expensive and less common). To implement a trailing edge dimmer, the switching device turns on as the AC waveform passes through zero, called a zero-crossing detector circuit. After a predetermined time set by the control, the switching device is turned off, and the remaining part of the waveform is not used by the load. Trailing edge dimmers commonly use a MOSFET (metal oxide semiconductor field effect transistor), as these require almost no control current and are rugged and reliable. They are also inexpensive and readily available at voltage ratings suitable for mains operation. Another option is to use an IGBT (insulated gate bipolar transistor), which combines the advantages of both MOSFET and bipolar transistor. These are generally more expensive than MOSFET’s. Reverse Phase Control dimmers employ MOSFET’s or IGBT’s to remove power from the end or trailing edge of each power cycle. The general thought was that a reverse phase control dimmer will produce less EMI and mains distortion than a forward phase control dimmer. Using IGBT’s and MOSFET’s to achieve slow turn-on times has enabled the production of phase control dimmers with acceptable EMI and harmonic distortion, without the need for big, heavy inductors. The drawback is higher heat dissipated in the switching devices necessitating thermal control measures, such as heatsinks. Typical Trailing Edge Performance Waveform: REVERSE PHASE 0 45 90 135 180 225 270 315 360 405 450 495 540 Early Turn Off FIGURE: 4 Summary of Phase Control Dimmers ● ● ● ● ELV (Electronic Low voltage) - Developed for use on electronic transformers & switch mode power supplies. HIGHEST COST - Reverse Phase Dimmer (“-TE”) MLV (Magnetic Low voltage) - Developed for use on magnetics transformers. MEDIUM COST - Forward Phase Dimmer that prevents DC in the output. (“-LE”) Incandescent - Developed for use on Resistive loads & bulb filaments. LOWEST COST - Forward Phase Dimmer (“-LE) DALI = Digital Addressable Lighting Interface - Remote controlled phase dimmer capable of either leading or trailing edge phase cuts dimming of the AC line. 3 EPtronics, EPtronics, Inc. Inc. 3 ◙◙ Los Los Angeles, Angeles, California California ◙◙ T:T: 800 800 643-0688 643-0688 ◙ ◙ E: E: [email protected] [email protected] ◙ www.EPtronics.com ◙ Rev Rev.-08/01/2010 01/09/2012 DIMMING Application Note 112 LED Driver Dimming Methods Application Note: 112 30 Watt - LD30W Series Dimming Methods CONSTANT VOLTAGE OR CONSTANT CURRENT LED DRIVER WITH DIMMING -RD 2-Wire 0-10V CCR Dimming Scheme Parameters Minimum Typical Maximum 0mA -2.0V 0mA ———- 2mA +15V 1.2mA Source Current out of 0-10V Purple Wire Absolute Voltage Range on 0-10V (+) Purple Wire Sink Current into 0-10V Purple Wire Notes 1. 2. 3. 4. -RD 0-10V dimmable version comes with an extra two wires +Purple/-Grey on the output side. -RD2 version is compatible with most 0-10V Wall Slide dimmers and direct 0-10V analog signal. Recommended dimmer is Leviton IP710 or equivalent -RD 0-10V dimmable version is not intended to dim below about 5% @ 0V or 10% @ 1.0V -RD 0-10V dimmable version output will be 100% with Purple/Grey open and minimum with Purple/Grey Shorted. -RD 2-Wire Resistance Dimming Scheme -RD 2-Wire 0-10V Analog Dimming Scheme Dim (+) PURPLE Dim (+) PURPLE IP710 Wall Dimmer LDXXW-XX-CXXXX-RD LDXXW-XX-CXXXX-RD Dim (-) GREY Dim (-) GREY V 0-10V Output Current % Output Current vs. 0-10VDC Dimming Input 100 90 80 70 60 50 40 30 20 10 0 Output Current % 0V 1V 2V 3V 4V 5V 6V 7V 8V 9V 10V Dimming Input VDC 4 EPtronics, Inc. ◙ Los Angeles, California ◙ T: 800 643-0688 ◙ E: [email protected] ◙ www.EPtronics.com ◙ Rev - 01/09/2012 112 DIMMING Application Note: 112 Dimming Methods Application Note LED Driver Dimming Methods -PD 2-Wire CCR PWM Positive Dimming Scheme Parameters Minimum Typical Maximum Absolute Maximum Voltage Range on PWM Input (Purple Wire) Input LOW Level Voltage Range (Purple Wire) Input HIGH Level Voltage Range (Purple Wire) Sink Current into PWM Input (Purple Wire) PWM Input Signal Frequency PWM Input Signal Positive Duty Cycle -2.0V -2.0 +9.0 0mA 200Hz 0% 10V 0V 10V ——10-90% +28V +7.5V 28V 1.2mA 1000Hz 100% Notes -PD PWM Dimmable version comes with an extra 2 wires +Purple/-Grey on the output side. Below 10% Duty cycle proper dimming operation is not assured. Unit is not intended to turn off at <10% Duty Cycle. -PD PWM dimmable version output will be 100% with Purple/Grey open and minimum with Purple/Grey Shorted. -PD 2-Wire PWM Positive Dimming Scheme PWM (+) PURPLE LDXXW-XX-CXXXX-PD PWM IN PWM (-) GREY Output Current vs. Positive Duty Cycle Output Current % 1. 2. 3. 100 90 80 70 60 50 40 30 20 10 0 Output Current % 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% Positive Duty Cycle 5 EPtronics, Inc. ◙ Los Angeles, California ◙ T: 800 643-0688 ◙ E: [email protected] ◙ www.EPtronics.com ◙ Rev - 01/09/2012