* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download the* motor of the future

Survey

Document related concepts

Transcript

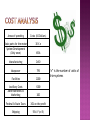

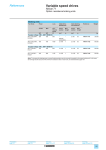

By: Innovators Inc. Morgan Dacy, Maria Ramos Arpita Ghosh & Young Hwang It’s a new company started by four fresh EE graduates from UW. Inspired through Senior Year Capstone Project. First drive system created in the Emerald City i.e. Seattle With the help of the Institute of Engineers Company, our drive systems are manufactured in bulk in Bangalore, India. Most of our employees are the people of India, with the exception of the Safety Certification Committee and Quality Assurance Department, USA. Very high efficiency (>90%) Can run for up to five hours at max load on two 20Ah 12V batteries Utilizes a synchronous H-bridge drive layout Contains brake-accelerator interlock User selectable braking mode Current limiting provided by resistor feedback The system is bi-directional. It starts by just pushing the accelerator. The maximum starting current at full load does not exceed twice the rated current. The motor reaches the rated speed in less than 3 seconds. The speed can be changed by using the accelerating pedals. We are using dynamic, counter current and regenerative braking for our system. The braking current is limited to 3x rated current Forward Command Accel Pedal Command Signals Brake Pedal Reverse Command Control Circuit Selector Circuit Feedback Power Supply Battery Source Power Circuit It can be used in the following machines: Energy efficient a.k.a. hybrid vehicles. Powered wheelchairs Electric go-carts, mopeds, and scooters This electric drive system is designed for DC Motors ONLY. It uses significantly less power as compared to other electric drive systems. It comes with Acceleration and Brake Pedals Most importantly, this drive system is embedded in such a clever way, that all the three kinds of braking: Dynamic, Countercurrent & Regenerative, can be applied. It is very cost-effective. Areas of spending Costs (US Dollars) Basic parts for the motor System Development (Only once) 30 Х n Manufacturing 2410 Manpower 795 Facilities 2000 Ancillary Costs Advertisements & Marketing 1000 Federal & State Taxes 30% on the profit Shipping 55.61 *(n/5) 6536 200 “n” is the number of units of drive systems n (Units) Operating Cost($) Price per Unit($) 500 26,966.00 70.11 7,280.82 600 31,078.20 67.34 8,391.11 700 35,190.40 65.35 9,501.41 800 39,302.60 63.87 10,611.70 Units bought per month Profit ($) SellingPrice of Profit over 10 Unit($) Annual profit($) yrs ($) 500 70.11 80,833.84 808,338.40 600 67.34 94,157.32 941,573.20 700 65.35 107,480.92 1,074,809.20 800 63.87 120,804.40 1,208,044.00 Annual Profit over 10 yrs 12 Profit every year (US Dollars) 10 8 6 4 2 0 1 2 3 4 5 6 Number of years 7 8 9 10 Investors make profit from the very starting month Cost Effective User Friendly One-year *FREE* Consultancy One-year Warranty We promote International Business Our employees are hand-picked from a group of talented and competitive people---- You are in good hands Our system is very simple We are the best!!!!! Think Green, Go Green…… Save the world!!!