* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Unit.5 Power Quality Monitoring

Power inverter wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Power factor wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Wireless power transfer wikipedia , lookup

Standby power wikipedia , lookup

History of electric power transmission wikipedia , lookup

Electric power system wikipedia , lookup

Voltage optimisation wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Electrification wikipedia , lookup

Audio power wikipedia , lookup

Alternating current wikipedia , lookup

Power over Ethernet wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Mains electricity wikipedia , lookup

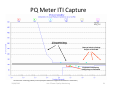

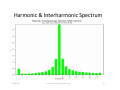

Unit.5 Power Quality Monitoring D.Maharajan Ph.D Assistant Professor, Department of Electrical and Electronics Engg., SRM University, Chennai-203 20/09/2012 Unit.5 Power Quality Monitoring 1 Unit.5 Power Quality Monitoring- syllabus Monitoring considerations: Power line disturbance analyzer, power quality measurement equipment, harmonic analyzer, spectrum analyzer, flicker meters, and disturbance analyzer. 20/09/2012 Unit.5 Power Quality Monitoring 2 Monitoring Considerations The monitoring objectives often determine the choice of monitoring equipment, triggering thresholds, methods for data acquisition and storage, and analysis and interpretation requirements. 20/09/2012 Unit.5 Power Quality Monitoring 3 PQ Monitoring-Introduction • Power quality monitoring is the process of gathering, analyzing, and interpreting raw measurement data into useful information. • The process of gathering data is usually carried out by continuous measurement of voltage and current over an extended period. • The process of analysis and interpretation has been traditionally performed manually, but recent advances in signal processing and artificial intelligence fields have made it possible to design and implement intelligent systems to automatically analyze and interpret raw data into useful information with minimum human intervention. 20/09/2012 Unit.5 Power Quality Monitoring 4 Need for PQ Monitoring • Power quality monitoring programs are often driven by the demand for improving the system wide power quality performance. Many industrial and commercial customers have equipment that is sensitive to power disturbances, and, therefore, it is more important to understand the quality of power being provided. 20/09/2012 Unit.5 Power Quality Monitoring 5 Sensitive to PQ disturbance Examples • computer networking • telecommunication facilities • semiconductor and electronics manufacturing facilities • biotechnology and pharmaceutical laboratories • financial data-processing centers. 20/09/2012 Unit.5 Power Quality Monitoring 6 Common objectives of power quality monitoring • Monitoring to characterize system performanceneed to understand its system performance and then match that system performance with the needs of customers • Monitoring to characterize specific problems- performing short-term monitoring at specific customer sites or at difficult loads. • Monitoring as part of an enhanced power quality service-A provider and customer can together achieve this goal by modifying the power system or by installing equipment within the customer’s premises • Monitoring as part of predictive or just-in-time maintenance-Equipment maintenance can be quickly ordered to avoid catastrophic failure. 20/09/2012 Unit.5 Power Quality Monitoring 7 Monitoring as part of a facility site survey 1. Nature of the problems (data loss, nuisance trips, component failures, control system malfunctions, etc.) 2. Characteristics of the sensitive equipment experiencing problems (equipment design information or at least application guide information) 3. The times at which problems occur 4. Coincident problems or known operations (e.g., capacitor switching)that occur at the same time 5. Possible sources of power quality variations within the facility (motor starting, capacitor switching, power electronic equipment operation, arcing equipment, etc.) 6. Existing power conditioning equipment being used 7. Electrical system data (one-line diagrams, transformer sizes and 20/09/2012 Unit.5 Power Quality Monitoring 8 impedances, load information, capacitor information, cable data, etc.) Power quality monitoring concept with monitoring at the substation and selected customer locations. 20/09/2012 Unit.5 Power Quality Monitoring 9 Some of the categories of equipment that can be incorporated into an overall monitoring system 1. Digital fault recorders (DFRs).- DFR will typically trigger on fault events and record the voltage and current waveforms that characterize the event. 2.Smart relays and other IEDs. 3. Voltage recorders. 4. In-plant power monitors. 5. Special-purpose power quality monitors. 6. Revenue meters. 20/09/2012 Unit.5 Power Quality Monitoring 10 Power line disturbance analyzer • The first generation of power quality monitors began in the mid-1970s when Dranetz Engineering Laboratories (now Dranetz-BMI) introduced the Series 606 PLDA. • This was a microprocessor based monitor-analyzer first manufactured in 1975, and many units are still in service. • The output of these monitors was text-based, printed on a paper tape. • The printout described a disturbance by the event type (sag, interruption, etc.) and voltage magnitude. • These monitors had limited functionalities compared to modern monitors, but the triggering mechanics were already well developed. 20/09/2012 Unit.5 Power Quality Monitoring 11 Power line disturbance analyzer 20/09/2012 Unit.5 Power Quality Monitoring 12 • Second-generation power quality instruments debuted in the mid1980s. • featured full graphic display and digital memory to view and store captured power quality events, including both transients and steady-state events. • Some instruments had a capability of transmitting data from a remote monitoring site to a central location for further analysis. • Second-generation power quality instruments virtually had perfected the basic requirements of the triggering mechanism. Since the occurrence of a power quality disturbance is highly unpredictable, data must be continuously recorded and processed without any dead time 20/09/2012 Unit.5 Power Quality Monitoring 13 • Complex triggering engines determine what data and how much data should be saved to the digital memory. Trigger methods include fixed and floating limits and sensitivities, wave shape changes, and specific event characteristic parameters. These methods optimize the probability that what is important to the user will be captured and stored. • By the mid-1990s, the third-generation power quality instruments 20/09/2012 Unit.5 Power Quality Monitoring 14 • By the mid-1990s, the third-generation power quality instruments emerged. The development of the thirdgeneration power monitors was inspired in part by the EPRI DPQ project. • This generation of monitors was more appropriate as part of a complete power quality monitoring system, and the software systems to collect and manage the data were also developed. • Since the conclusion of the project, substantial field experience gained revealed some of the difficulties in managing a large system of power quality monitors 20/09/2012 Unit.5 Power Quality Monitoring 15 Third Generation PQ Monitoring Eq 1. Managing the large volume of raw measurement data that must be collected, analyzed, and archived becomes a serious challenge as the number of monitoring points grows. 2. The data volume collected at each monitoring point can strain communication mechanisms employed to move that data from monitor to analysis point. 3. As understanding of system performance grows through the feedback provided by the monitoring data, detailed views of certain events, such as normal capacitor switching, become less valuable and would be of more use in a summary or condensed form. 4. The real value of any monitoring system lies in its ability to generate information rather than in collecting and storing volumes of detailed raw data. 20/09/2012 Unit.5 Power Quality Monitoring 16 Types of instruments used for PQ Monitoring A number of different instruments may be used for measuring PQ problems • Wiring and grounding test devices • Multimeters • Oscilloscopes • Disturbance analyzers • Harmonic analyzers and spectrum analyzers • Combination disturbance and harmonic analyzers • Flicker meters • Energy monitors 20/09/2012 Unit.5 Power Quality Monitoring 17 Important factors considered when choosing the instrument Number of channels (voltage and/or current) Temperature specifications of the instrument Ruggedness of the instrument Input voltage range (e.g., 0 to 600 V) Power requirements Ability to measure three-phase voltages Input isolation (isolation between input channels and from each input to ground) • Ability to measure currents • Housing of the instrument (portable, rack-mount, etc.) • Ease of use (user interface, graphics capability, etc.) • Documentation • Communication capability (modem, network interface) 20/09/2012 Unit.5 Power Quality Monitoring 18 • Analysis software • • • • • • • Benefits of Continuous PQ Monitoring • Power Quality monitoring provides a continuous “Health Check” of a facility’s power system … for example: o Harmonic interaction between loads and power conditioning equipment spotted o High Inrush currents from equipment startup detected o Transients from load switching are seen • It provides data to see, diagnose and avert looming problems – “like squeaky brakes on a car” o Trends can be detected o JIT equipment maintenance programs can be established • It acts like a “Black Box” on an airplane to tell you what, when, and where a Power Quality event occurred … to prevent it from reoccurring Continuous PQ Monitoring Detects, Records, and Leads to the 20/09/2012 Unit.5 Power of Quality Prevention PQMonitoring Problems 19 Power Quality Meter – PQM II Features: • All basic electrical parameters • Data logging and waveform • Voltage disturbance analyzer • Analog outputs, digital inputs • Control relays and KYZ pulses • Multiple communication ports • Easy to program and set-up… EnerVista • Replaces multiple analog meters 20/09/2012 Unit.5 Power Quality Monitoring 20 Power Quality Meter – PQM II • Key Features – High accuracy, mid range Power Quality with many advanced features. – Waveform capture using set-points for PQ analysis. Waveform can be triggered by external equipment (motors) through digital inputs for capturing start-up current etc…. – Control Relays can open and close at the pre-programmed (min, max etc) set-points for alarms and notifications. – Analog outputs for power information to PLCs, RTU and other non digital communication devices. – VERY EASY to use , program and set-up – comes with free set-up and monitoring software (launch pad). – Voltage Disturbance Recording for electrical up to 500 sag & swell events – Open Modbus and DNP 3.0 protocol over RS 485 with multi port communication capability Power Quality with Advanced Voltage Disturbance Recorder 20/09/2012 Unit.5 Power Quality Monitoring 21 Target Applications/Industries – Ideal for circuit monitoring for control panels, switchboards, Motor Control Centers, Power Distribution Panels. – Primary Monitoring of low and medium voltage application, requiring full metering with over 100 different electrical parameters with data logging and oscillograph (waveform). – Applications requiring Control Relays with set-point activation, Analog and digital I/Os. – Heavy power users for need of clean power - Data Centers, Pulp and Paper, Oil & Gas……. – OEMs, Electrical Panel Manufacturers, Switchgear manufacturers, Motor Control manufacturers….. 20/09/2012 Unit.5 Power Quality Monitoring 22 Assignment • • • • Features Block Diagram Each Block Explanation Target Applications/Industries 20/09/2012 Unit.5 Power Quality Monitoring 23 PQ Meter ITI Capture ITI Acceptable Power Disturbance Envelope Damage Inducing Voltage Surges as Recorded Equipment Interrupting Voltage Sags as Recorded ITI: Information Technology Industry Council (Computer & Business Equipment Manufacturer’s Association) 20/09/2012 Unit.5 Power Quality Monitoring 24 Instantaneous Sag Event 20/09/2012 Unit.5 Power Quality Monitoring 25 Instantaneous Swell Event 20/09/2012 Unit.5 Power Quality Monitoring 26 Harmonic & Interharmonic Spectrum 20/09/2012 Unit.5 Power Quality Monitoring 27 References 1. Electric Power System Quality – Roger C.Dugan, Mark F. McGranaghan, Mark McGranaghan, Surya Santoso, H. Wayne Beaty, H. Beaty, Tata McGraw-Hill Education. 2. http://www.duke-energy.com/indianabusiness/products/power-quality/power-quality-mitigation strategies.asp 3. http://www.enetics.com/app-PQM.html 4.http://www.esgroundingsolutions.com/electrical-groundingservices/power-quality-monitoring-and-load-analysis.php 5.http://www.gedigitalenergy.com/multilin/catalog/pqmii.htm 20/09/2012 Unit.5 Power Quality Monitoring 28