* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Training Development Method

Survey

Document related concepts

Transcript

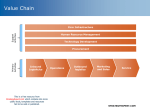

LCM-systems Appendix 4E 4E Training Development Method Training Development Method The Training Development Method is set up in order to support the Training module (section 4.3) according to the following sections: 1. Training Development Structure; 2. Task Analysis; 3. Task Analysis Tables; 4. Team Management Training Module; 5. System Support Engineering Training Module; 6. Process Management Training Module. 4E.1 Training Development Structure To structure the training development a practical and structured training development approach has been selected [Kessels, 1992]. This practical approach is based on Tracey's extended method [1971]. The flow diagram, given in figure 4E-1, illustrates the development steps and their relationship. 1. TRAINING NEED 2. TRAINING GOALS 3. TASK ANALYSIS 4. FORMULATE OBJECTIVES 5. DETERMINE EVALUATION CRITERIA 6. DESIGN AN EVALUATION METHOD 7. DESIGN TRAINING METHODS 8. COMPOSE LECTURE PAPERS 9. PROVIDE TRAINING CONDITIONS 11. SELECT STUDENTS 10. SELECT TRAINERS 12. PERFORM TRAINING 13. EVALUATE TRAINING 14. EVALUATE THE RESULT Figure: 4E-1 Training development flow diagram [Kessels, 1992]. The applied training development approach will be discussed in these 14 steps of the flow diagram. 1. Training need The assessment of skilled actors and their training needs is determined in the problem analysis (section 3.2). Manuscript 4E-1 May, 2002 LCM-systems 2. 4E Training Development Method Training goals Based on the problem synthesis the training goals are defined by the terms of reference for LCM-systems (section 3.3). 3. Task analysis According to Romiszowski [1984], the task analysis is the most important step in the development of a training course. In his opinion the analysis results will determine the content and form of the training course to a large extent. For this research the task analysis has been elaborated in this section. This elaboration is based on the results of the 'Analysis' module. The result is an extensive knowledge and task assessment. 4. Training objectives In this step the results of the task analysis will be translated into training objectives. Because of the fact that, in general, organizations have a functional need and expectation in relation to training courses Kessel recommends formulating the objectives in terms of skills instead of knowledge. For LCM-systems the training objectives will be derived from the knowledge and skills assessment. 5. Evaluation criteria The evaluation criteria are placed directly after the assessment of training objectives because they are the baseline for evaluation. These criteria are essential in assessing the effectiveness of the training courses. 6. Evaluation method assessment The adopted development method recommends tests as the ultimate evaluation method. For this research a combination of tests and practical exercises (hands on) is intended. 7. Training methods It is important to recognize the various training goals such as knowledge transfer, skill improvement and attitude adjustment. To anticipate these preconditions, training courses should be developed with a clearly specified goal and must be in line with the actual work situation as far as possible. 8. Lecture papers Lecture papers should have a clear and structured relation to the training course. When several books are used as reference there must be an outline of the most relevant paragraphs. For this research these conditions have been discussed with the training institutes involved and are their contractual responsibility. In Chapter 5 their contribution will be discussed further 9. Training conditions To avoid an over-academic style Kessels provides the following five suggestions: the training program should contain numerous exercises which force the students to actively participate; teachers and coaches must be trained to support the students in a functionally- oriented manner; when realizing innovation goals (e.g. LCM-systems) it is important to first make sure that the teachers have, themselves, completed the training course successfully; in the case of training courses directly related to the work environment it is essential to prepare an introductory session in order to commit the directors and/or managers involved; appropriate training facilities and equipment must be available. Manuscript 4E-2 May, 2002 LCM-systems 4E Training Development Method These precautions are taken in account during the case study and will be discussed in Chapter 5. 10. Trainer selection To acquire the most suitable candidates a trainer profile must be composed based on the defined training goals, -content and -conditions. For this research trainer selection has been effected for the case study. 11. Student selection For functional-oriented courses Kessel recommends a selection according the actual position and tasks of the person in question. In line with this the selection for this research was based on the analysis of the LPC's and has been performed as part of the case study. 12. Training performance For innovative training courses relevant for LCM-systems, Kessels recommends a flexible approach. Trainers should continuously observe reactions from the environment. When there are signals of problems arising around content or planning it is advisable to adjust the training program as much as possible. This step has been taken during the case study. 13. Training evaluation Training course evaluation is still a poorly developed skill. Kessels argues that this is the reason why education and training departments often have a weak position within the organization. This is caused by the fact that they are unable to prove the contribution training makes to business objectives. For this reason the determination of evaluation criteria is made explicit in this approach (step 5). To measure the effect of training, criteriarelated performance indicators have to be developed and reported periodically. 14. Result evaluation To evaluate the results Kessels recommends making a trend analysis of the actual results compared to the expectations (baseline). Based on such result evaluation reports reasonable readjustments can be considered. 4E.2 Task Analysis In training development literature [Kessels1992], [Romiszowski 1981], et al., a general approach to determining the training requirements is first to work out a task analysis and then determine the training objectives. In a slightly modified way this approach has been applied for the task analysis in this module. For this module the LPC analyses (see Appendix 4D) are taken as starting point. Within the scope of the task analysis an inventory is made of the logistic products and processes according to the System Analysis Method (see Appendix 4D). The task analysis is carried out in the following steps: draw up a table of the discerned processes and products, clustered in the three specified fields of interest (team management, system/logistics engineering, process management); determine the knowledge and skill aspects per process/product record, based on literature references; Manuscript 4E-3 May, 2002 LCM-systems 4E Training Development Method define the knowledge and skills aspects per field of interest by merging these aspects according to the scientifically-recognized logistics and organizational methods and techniques described in literature. The analysis results are incorporated in the tables 4E-1. 4E-2 and 4E-3. Manuscript 4E-4 May, 2002 LCM-systems 4E Training Development Method 4E.3 Task Analysis Tables Processes engineering & logistics management purchasing production construction training operational maintenance intermediate maintenance depot maintenance Table 4E-1: for specification, see tables 4E-2 and 4E-3 LCM Knowledge & Skills Methods and techniques to obtain products and services from specialists, mostly without a hierarchical relation. Field of interests are: contract management management control professional approach organizational learning communication organizing motivation teambuilding. Logistics Commun Organiza 1995] Managin Work, Li True Pro People, Y complete system or installations (system units) spare parts test and support equipment production management complete system or installations (system units) spare parts construction management complete installations (system units) spare parts training courses operational inspections and repairs cost-effectiveness related data intermediate inspections and repairs cost-effectiveness related data depot inspections and repairs modifications and overhaul cost-effectiveness related data Team management related processes and products. Processes systems engineering design engineering Manuscript Products & Services Products & Services LCM Knowledge & Skills operational and system requirements system specifications system design reviews system/installation models or prototypes test and evaluation plan cost projections acceptance standards supportability analysis plan reliability, availability and maintainability plan supply support plan test and support equipment plan personnel and training plan technical data and information systems plan packaging, handling, storage and transportation plan facilities plan system retirement plan acceptance tests Identification of needs to specify the system functionality. Basic knowledge about methods such as the Integrated Cost and Operational Effectiveness Approach and the Quality Function Deployment (Appendix 2B). system design (functional) installation specifications contractor data requirements list feasibility studies design to cost System design criteria [Blanchard, 1998]: performance cost-system effectiveness reliability maintainability human factors safety survivability vulnerability supportability/serviceability producibility reconfiguration ability/flexibility affordability/design to cost disposability/re-use/recycling environmental feasibility. The LCM-team should be aware of these design criteria when estimating the cost-effectiveness of the design process. 4E-5 Life Cycle Analysis to provide the basis for decisions in relation to system functionality versus technical, economical, social and environmental impact. Principles of the use of 'Eco-indicators' (Appendix 2B). Functional logistics, also called sustainability engineering [Jones, 1995], to achieve the logistic plans. System decomposition (functional & physical) May, 2002 Systems Systems The App [PRé Co Integrate Systems Systems LCM-systems Processes detail design engineering systems support engineering maintenance engineering financial engineering commercial engineering utilization feed back Table 4E-2 4E Training Development Method Products & Services detail design documents (technical) installation specifications test and evaluation program functional and technical performance tests requirement analyses design synthesis design evaluation system validation engineering change proposals modifications actual system/installation management information (cost and performance) system retirement program test and evaluation program functional and technical performance tests reliability, availability and maintainability program and adjustments (maintenance plans) actual system/installation management information (cost and performance) shortlist of test and support equipment cost calculations life cycle cost calculations benchmarking contract management trade contracts contract schedule of requirements reference specifications lessons learned database LCM Knowledge & Skills System decomposition (functional & physical) Detail design criteria [Blanchard, 1998]: maintainability human factors safety supportability/serviceability producibility reconfiguration ability/flexibility affordability/design to cost disposability/re-use/recycling environmental feasibility. The smooth change from system design to detail design means that some of the design criteria are valid for both processes. Installation decomposition (functional & physical) Physical logistics to achieve the logistic programs. System decomposition (functional & physical) Logistics support to achieve the required system effectiveness and cost-effectiveness during the utilization phase (Appendix 2B). Physical logistics to achieve the logistic programs. Installation decomposition (functional & physical) Systems Systems Integrate Systems Logistics Integrate Systems For economic evaluations, especially in the acquisition phase, the term Life Cycle Cost Analysis has been adopted for this research. To make cost traceable in the utilization phase with the objective of cost control the Activity Based Costing method has been adopted (Appendix 2B). Trade studies: identifying alternatives determining selection criteria assigning metrics weighing values sensitivity analysis. Contractor selection and validation Contracting, type of contracts Logistics Support Analysis: determining relevant data assigning metrics data acquisition methods data analysis methods. Systems A Capita ment [Ca Systems Integrate Contract STD 680 NATO C Systems Logistics Engineering related processes and products. Processes project/ program management Products & Services project management asset/system management LCM Knowledge & Skills For these processes and products a professional level of project management and asset management will be required [Jones et al.] Basic methods for this field of interest are: Total Quality Management Continuous Improvement (Kaizen) Maintenance management in development Project M Total Qu Global E Guide [D Gemba K Managem Total Qu project/ program planning information man- Manuscript advance system realization planning (technical, economical and organizational) acquisition plan quality assurance plan acquisition planning (technical and organizational) utilization/maintenance plan disposal plan data acquisition and information systems 4E-6 To carry-out the logistics planning processes a professional level in the field of planning methods is necessary. Basic methods for this field of interest are: Material Requirements Planning (MRP) Enterprise Resource Planning (ERP). Beside this, there must also be a basic insight into all logistic products, processes and actors. For the ILS method a Logistics Support Analysis Record May, 2002 Maintena Project M Quality P ERP in b Integrate LCM-systems 4E Training Development Method Processes agement Products & Services up to date system management information (cost and performance) LCM Knowledge & Skills (Appendix 2B) has been developed. Knowledge of the LSAR database is a basic requirement [Jones, 1995]. Besides this mainly asset-related information organizationrelated information, such as productivity, customer satisfaction and possibilities for improvement is also necessary. This field of interest can be covered with the Balanced Score Card method To apply PDM profitably it is essential to be acquainted with modern ICT e.g. Intranet. Methods and techniques must be known and skills available to determine which actor needs which information at which moment. Process management in relation to quality assurance. documentation management product data management (PDM) complete technical data package revisited technical data package quality management quality assurance provisions quality assurance program risk & quality control risk & quality audits risk & quality procedures Process control in relation to risk & quality audits and procedures. product purchase control acceptance tests Process control in relation to acceptance tests. configuration & change management supply/store policy & management configuration management program configuration database Configuration management program development and the setting up and maintenance of the configuration database. maintain and store facilities spare parts supply actual spare part list spare part requirements supply organization education and training program ILS supply/store management principles, related to: supply planning and methods, packaging, handling, storage and transportability. human resource policy & management resource planning & control ILS training and training equipment principles such as: training phases, concepts, programs, materials, support, equipment, etc.. Principles of Human Resource Management (Appendix 2B) such as: resource requirements, acquirement, training/coaching, motivation, productivity, career planning, etc.. Principles of training development and presentation. capacity/cost reservations & overviews based on a degree of Resource planning and control principles such as: resource perfection [Marcelis, 1979] and cost budgeting, planning and control. facility policy & management maintenance establishment providing of test and support equipment Table: 4E-3 Manuscript Facility specification, acquisition, and utilization methods. Process management related processes and products. 4E-7 May, 2002 The Bala mance [K Product D Managem PDM 20 Total Qu Systems Total Qu Systems Systems Logistics Systems Logistics Integrate Logistics Integrate Managin Life, Pro Training Logistics Maintena Integrate LCM-systems 4E.4 4E Training Development Method Team Management Training Module Professional team management is considered the prime factor in creating a successful LCM-team [Blanchard, 1992], [Marcelis, 1984]. The Learning Organization (LO) disciplines of shared vision and mental models are indicated as essential to its achievement. The LO approach is based on the systems thinking concept described by Senge [1990]. In his vision ‘systems thinking’ needs the disciplines of building a shared vision, mental models, team learning, and personal mastery to realize its potential. This method involves breaking a problem into components, studying each part in isolation, and then drawing conclusions about the whole. In relation to Asset Management Control this 'systems thinking' has been elaborated and applied to the logistics process and LCM-team (see figure 3.3). Team learning is defined as the process of aligning and developing the capacity of a team so as to create the results its members really want. It builds on the discipline of developing a shared vision. It also builds on personal mastery. Talented teams are made up of talented individuals. A mental model is one's way of looking at the world. It is a framework for the cognitive processes of our mind. In other words, it determines how we think and act. The shared vision of an organization is built up of the individual visions of its members. Personal mastery is based on the expertise of the individual and has two essential components. First, one must define what one is trying to achieve (a goal). Secondly, one must have an accurate perception of how close one is to the goal. In this LO vision organizations should be skilled in these five main activities: systematic problem solving; experimentation with new approaches; learning from their own experience and past history; learning from the experience and the successful practices of others; transferring knowledge quickly and efficiently throughout the organization. According to Senge and his colleagues, the LO development is motivated by the following higher objectives. If an organization is to be competitive in the long- term, basic issues such as: quality, service and competitive prizes, no longer suffice, these have to be good anyway. In modern business the innovative power of an organization is becoming increasingly important. The philosophy is that the perfect things of today can probably be improved tomorrow. In this context innovation management means inspiring the organization to continuously learn new skills. In their opinion, clear objectives and a company vision are indispensable ingredients in the inspiration of the organization. A learning organization demands more than motivated actors (teams or employees) who do their jobs correctly with loyalty to the organization. It demands actors who are 100% involved with their jobs and who pro-actively participate in improvement processes. To achieve this, it is vital that all concerned are aware of the corporate aim and vision so that they have a mutual target. In addition to the essential corporate objectives, training conditions are seen as an important aspect of a learning organization. According to Senge there is a dynamic reciprocal relation between the development of the organization and the training of the individual actors. The extent to which training takes place, and its effectiveness, depends greatly on the training conditions offered by the organization. A key factor is the influence of the actor's training effort on the development of the organization. When this is not visible the attempts to change things can count on resistance and opposition. The incentive to learn and train should come from questions which appeal to the individual actor, such as: can Manuscript 4E-8 May, 2002 LCM-systems 4E Training Development Method we do it better, smarter, faster, easier, cheaper or more safely ? Senge worked this out in personal mastery (the 'fifth discipline'). In his vision all five disciplines are essential but personal mastery has a special foundational role because of the importance this discipline gives to intrinsic motivation. Senge defined and illustrated personal mastery by relating the story of Antonio Stradivari and his quest for an exceptional musical tone that could be produced by a violin. Stradivari spent his entire life in the pursuit of that sound. He made constant refinements to the violins he crafted and produced instruments that are considered outstanding to this day. No one will ever know if Stradivari was fully satisfied with the last violin he made. Very probably Stradivari was not satisfied because of his devotion to continually trying to improve on the sound. This way of thinking has a lot in common with the LCM vision developed in this research, here too there should be a continuous effort towards improving the cost-effectiveness of the asset to be managed and controlled. In accordance with Garvin [1993] the following training requirements have been defined: team members will be trained to keep an open mind and a non-defensive attitude in communication; they recognize strained relations and are capable of dealing with conflict situations; they know how to increase their commitment to the team values and are respectful of other team members; they can handle stress situations; they can see problems from different angles and are challenged into finding solutions; they can motivate and inspire their environment because they have the skills to negotiate and to advise effectively. The selected training method is a combination of: thematic workshops; training on the job; individual coaching. The reason for this setup is its flexibility in matching the training program with regular business processes. The thematic workshops can be scheduled as an evening program while the training on the job and coaching are scheduled during working hours. In line with the training objectives the following workshop themes have been developed: organizational learning; communication; organizing; motivation; team building; professional approach. The necessary training period depends on various factors e.g. LCM scope, shape of the organization, system complexity, actor quality, etc.. Based on the results of the field survey in the RNLN (refer section 2.5) and the TOR (refer section 3.2) a two-year program has been planned for the actors involved with LCM. This program consists of a monthly workshop plus training on the job combined with coaching for one day a week. In relation to this research 15 employees from the RNLN maintenance establishment have participated. The evaluation criteria are defined as a certain level of improvement in the training objectives seen in relation to the following aspects (derived from the requirements): open communication, conflict management, commitment to team/shared values, stress control, problem solving, motivation and inspiration capabilities. Periodic observations of changes in the work environment are chosen as evaluation method. To establish the point of reference (the baseline) several team meetings have been planned to gather concrete points of improvements that are acceptable to all team members. During the training period regular questionnaires should be planned to measure progress. Manuscript 4E-9 May, 2002 LCM-systems Manuscript 4E Training Development Method 4E-10 May, 2002 LCM-systems 4E.5 4E Training Development Method System Support Engineering Training Module This training module is specifically focused on the technical aspects of asset management in relation to the LO disciplines; shared vision, systems thinking and personal mastery. The pursued approach is based on experiences gained with the development of the RNLN System Support Engineering & Management training course [Delta Consult, 2000]. The target group is defined by studying the analysis short lists (see Appendix D) which results in the following selection: project engineers (primarily responsible for the acquisition phase); operational engineers (primarily responsible for a well-specified operational need and operational support/maintenance); design engineers (primarily responsible for the inherent system- and cost effectiveness); systems engineers (primarily responsible for the overall system- and cost effectiveness); maintenance engineers (primarily responsible for the system maintainability and logistics support). In this context the target group is responsible within system definition and design, production and/or construction, utilization and support and phase-out of the asset. This training cluster gives insight in the relationship between the technical aspects and parameters that determine the system- and cost effectiveness during the system life cycle. For that reason the term System Support Engineering (SSE) is introduced, with the term 'support' underlined, to indicate the 'life cycle' scope. The SSE training courses are linked to the prime AMC performance indicators (refer section 4.5) illustrating the relationship with objectives on a higher level. Based on these starting points the course structure has been designed according to figure 4-13. COST-EFFECTIVENESS SYSTEM EFFECTIVENESS COSTS SYSTEM ANALYSIS LOGISTICS SUPPORT ANALYSIS SYSTEM TEST & EVALUATION SYSTEM SUPPORT System Support Engineering Figure: 4E-2 The System Support Engineering training course structure. System Analysis In line with the elements of the Asset Logistics Cycle, defined in the Analysis module (ref. section 4.2) the systems analysis aspects are discussed according to the following methods and techniques: Integrated Cost and Operational Effectiveness Approach; Design to Cost; Quality Function Deployment; Life Cycle Analysis, composed of: producibility; reconfigurability/flexibility; vulnerability/survivability; Manuscript 4E-11 May, 2002 LCM-systems 4E Training Development Method environmental feasibility; principles of the use of 'Eco-indicators'; disposability/re-use/recycling. Trade studies, composed of: identifying alternatives; determining selection criteria; assigning metrics; weighing values; sensitivity analysis. These methods and techniques are all discussed in Appendix 2B with detailed literature references. These references form the basis of the SSE training course program. Blanchard”s Systems Engineering and Analysis approach [1998] has been selected as program guideline. The aim of this course is to provide a shared vision of the applicability of system analysis methods and techniques. This should lead to a general systems approach in which individuals can develop their personal mastery in this field of study. Logistics Support Analysis Logistics Support Analysis (LSA) is an extensive method aiming to cover all logistic aspects (see Appendix 2B.3). It is considered to be an outstanding method for the definition and planning of all the necessary logistic processes. In accordance with the task analysis the following issues have been given particular attention during this course: determining relevant data; assigning metrics; data acquisition methods; data analysis methods; logistics support planning; contractor selection and validation; contracting, type of contracts. System Test & Evaluation This training course aims at providing the knowledge and skills required in determining the capability according to the cost-effectiveness structure in relation to the Logistics Process Cycle. The ultimate test is to verify that the system is capable of providing the required system functionality to meet the operational need. In this context the system test and evaluation activities start during the conceptual design phase and end when the system is phased out. Different test and evaluation methods are required for each life cycle phase. Based on the four types of tests, as defined by Blanchard [1998], the following have been defined for this course: a conceptual design test; a preliminary system design test; a system prototype (first of class) test; an operational (continuous evaluation) test. The aim of all four tests is to prove that the system is capable of being cost-effective. The test structure and test program are based on the system functionality specifications (see Appendix 4D). To provide the knowledge and skills to set up and perform these tests, the following issues are discussed: defining system functional material part breakdown structure; defining installation block diagrams; system/installation performance modeling; capability assessment; test design method; capability testing & evaluating. Manuscript 4E-12 May, 2002 LCM-systems Manuscript 4E Training Development Method 4E-13 May, 2002 LCM-systems 4E Training Development Method System Support Once a system (e.g. a ship or aircraft) has been equipped and delivered for operational use there is an ongoing need for system support in order to achieve the required availability and reliability [Blanchard, 1992]. This system support course is primarily focused on the engineering activities/products (refer Appendix 4D) required to support the direct logistic processes such as inspection, testing, replacements, repairs, etc.. Based on the installation maintenance plans (adopted from the ILS approach, see Appendix 2B) these activities should lead to optimization of the system cost effectiveness during exploitation. The following methods and techniques are discussed to provide the required insight and the basic knowledge and skills: Total Productive Maintenance [Nakajima, 1988]; Condition Monitoring [Juran, 1999]; Data Collection [Juran, 1999]; Failure Analysis [Juran, 1999]; Modification and Configuration Engineering [Blanchard, 1992]. The training program is based on the system support process elaborated for the RNLN [Stam, 2000], as illustrated in figure 4E-3. MAINTENANCE CONCEPT OPERATIONAL USE EXPERT OPINION ENGINEERING CHANGE PROPOSALS Figure: 4E-3 ANALYSIS LOGISTIC DATA The System Support Process according to Stam [2000]. The practical objectives and performance indicators are elaborated in the 'Representation' module (section 4.5). For the training courses, described above, a 6-month training period is estimated. This period contains 12 group-teaching sessions together with multiple exercises to ensure active participation of the group during this period. Both training courses are completed by a study project which is related to the actual work environment. The evaluation criteria are based on the training course objectives and are incorporated in the class exercises and study project requirements. An evaluation method has been selected whereby the exercises are assessed in combination with the presentation of the project results. To ensure quality and educational standard it is advisable to have the exams checked by a recognized educational institute or academy. It can be assumed here that the LCM-team and prime logistic engineers do, in fact, have a solid base of knowledge and skills of system support engineering to support the 'Program', 'Representation' and 'Control', modules. Manuscript 4E-14 May, 2002 LCM-systems 4E.6 4E Training Development Method Process Management Training Module When developing the process management training module the first step is an analysis of the objectives (refer table 4-4) in relation to the target group, the corporate aim and the work environment. The objective of this analysis is to provide the basic training course design conditions. With reference to the Asset Management aim (see section 1.2) the corporate aim, in this context, is to achieve a (more) cost-effective utilization of capital assets. In relation to this aim, the work environment is the complete Asset Management Control System as defined in a management-, logistics- and technical system (see figure 3-3). In line with this, the LCM-team is considered as the primary target group. Depending on the situation and organizational structure it could be effective to involve the key actors of the logistics process as well. With regard to these design conditions the training course aims at creating an LCM-team as a self-steering team1 of professionals according to the LO methodology. In line with the training objectives the intention is to start with some knowledge transfer courses. The aim of these courses is to provide basic applicable knowledge, as selected in table 4E-3. These results create the preconditions for transforming the LCM-team into a well-trained self-steering team with the following characteristics: process-oriented; a flat hierarchical structure; focused on corporate objectives; learning from their own experiences and past history; learning from the experiences and successful practices of others; operational autonomy. Within this conceptual framework seven training courses have been designated for development. The first two are primarily focused on knowledge transfer, the following five are primarily focused on training skills. The table below gives an overview of the courses together with the literature references used in composing the lecture papers. Training Course Asset/Material Logistics Management (to provide basic knowledge) 2 Information Management (to provide basic knowledge) LCM Need Assessment (to provide applicable skills) Life Cycle Cost Budgeting (to provide applicable skills) Actor Performance Analysis (to provide applicable skills) 3 4 5 Table: 4E-4 Lecture Paper References 1 6 Contract Management (to provide applicable skills) 7 Management Control (to provide applicable skills) Project Management Handbook [Cleland, 1989] Quality Planning and Analysis [Juran, 1999] ERP in business [Koedijk, 1999] Total Quality Management, Global Engineering Documents Guide [Department of Defense, 1990] Process modeling IDEF0 [Marca, 1988] The Balanced Scorecard – Measures that Drive Performance [Kaplan & Norton, 1992] Activity Based Costing [Boons, 1992] Introduction to TPM [Nakjima, 1988] Technical Documenting [Bourgonje, 1995] PDM method (see Appendix 2B, 4C) Quality Planning and Analysis [Juran, 1999] Maintenance management up to the mark [Marcelis, 1979] Logistics Engineering & Management [Blanchard, 1992] Life Cycle Cost Management (see Appendix 2B.5) Logistics Engineering & Management [Blanchard, 1992] Process Modeling IDEF0 [Marca, 1988] Logistic Process Model design (see section 4.4) Contract Management (Doelmatigheidsbeheer met behulp van kerntaakbudgettering) [Janse, 1998] Activity Based Costing (see Appendix 2B) Logistics Process Model design (see section 4.4) LCM modeling & controlling (see section 4.5, 4.6) Process Management training courses. 1 A self-steering team is defined by Senge [1995] as a team of professionals with a maximum of autonomy to achieve their (corporate) objectives. Manuscript 4E-15 May, 2002 LCM-systems 1. 4E Training Development Method Asset/Material Logistics Management This training course is based on the basic management activities as defined by Schieman [1980]. These activities: planning, organizing directing and controlling, have been particularly elaborated regarding the Logistics Process Life Cycles (figure 4-10). Planning the necessary processes: the basics of the project network planning method [Cleland, 1989] are discussed. The relevant quality aspects are discussed according to Juran [1999]. The relation to the organizational control activities is explained along the lines of Enterprise Resource Planning [Koedijk, 1999]. Organizing the logistic processes: the TQM method [Oakland, 1995] has been selected. For this training course the generally applicable TQM method is tailored within the scope of asset management. [Department of Defense, 1990]. In this context the IDEF0 method has been selected as the most suitable process-modeling technique. Directing/managing the processes: the Balanced Score Card [Kaplan & Norton, 1993] and Activity Based Costing principles [Boons, 1992] (see also Appendix 2B) have been selected for use. For the utilization phase especially, with its large amount of different processes over a long span of time, the applicability of Total Productive Maintenance method [Nakjima, 1988] is discussed. To control the logistic processes the Balanced Score Card and Activity Based Costing principles are further elaborated. 2. Information Management This training course is focused on the developed information and communication structure as described in section 4.1. In this context the aim of information management is to keep the LCM data set (figure 4-6) actual and reliable. From this point of view it is a supporting process for System Support Engineering and Material Logistics Management. The approach and setup of Bourgonje [1995] has been adopted to elaborate this training course. In line with this approach the material logistics field of interest is divided in four specific areas: define and design information; production and/or acquisition information; operations and maintenance information; management information. To manage the information processes (get and hold grip on it) the following four specific information management objectives are defined: generating and gathering information; structuring information; document information; transfer information. In this training course the methods and techniques for defining the required information data in cooperation with the primary actors (the logistic engineers and managers) are discussed. This approach is based on a selection of studied methods and techniques which can be customized to the organizations concerned. For asset-related data the approach is in line with the Structuring and Analysis modules (section 4.1, 4.2). Structuring information is defined as a process to structure the data sets (documents) and the data flows. For asset logistics information this process is based on methods and techniques adopted in the ILS/LSA approach (see Appendix 2B) and is further elaborated according to the PDM 2000 approach (Appendix 4C). Document information is defined as the process in which outline/form information is represented. In line with Bourgonje [1995] methods and techniques are discussed for developing or selecting information outlines/forms so as to provide easily-accessible information for all involved actors in a cost-effective way. Manuscript 4E-16 May, 2002 LCM-systems 4E Training Development Method Transfer information is primarily focused on methods of information distribution. Specific attention is given to Internet web technology in combination with the database interface technologies described in the PDM 2000. For the, above-described training courses, a 6-month training period is estimated. This period consists of twelve class sessions plus multiple exercises to ensure active participation of the group. Both training courses are completed with a study project which is related to the actual work environment. The evaluation criteria are based on the training course objectives and incorporated in the classical exercises and study project requirements. Assessment of the tests in combination with the presentation of the project results has been selected as evaluation method. To ensure quality and educational standard it is advisable to have the tests verified by a recognized educational institute or academy. 3. LCM Need Assessment In this context the need assessment is related to the LCM approach in general and the need for relevant LCM information in particular. For this reason two workshops are planned for discussion of this subject. The first workshop session covers the following subjects: general introduction to the Team Based Learning program [Senge, 1995]; need assessment exercise; plenary discussion. The general introduction of the Team Based Learning (TBL) program starts with the introduction of the main asset -management objectives (refer section 3.2) related to the following aspects: insight, vision, policy, objectives, budget, resources, organization, procedures, processes, performance indicators and analysis indicators (refer section 3.4). In line with this introduction the entire TBL program setup is then explained. The need assessment exercise is based on an interview approach with a discussion panel of two interviewers and two interviewees. The applied technique is fairly similar to that used in the field survey (Appendix 2D). The objective is to determine the need of an LCM approach in several 30-minute interview rounds involving different logistic actors selected from the workshop participants. Suitable questions for discussion are: how does, or should, the material logistics system perform in the achievement of the required cost effectiveness? what is the quality and relevancy of the achieved (management) information in the actual situation? why has this set of information been chosen? The workshop leader should make use of his experience to organize interesting combinations of interviewers and interviewees. In the plenary discussion the questions asked, and replies given, will be reviewed. It is expected that the participants will gain real insight into the actual situation, this should form the basis for developing a shared vision. The workshop leader should summarize the results and where possible list improvement features. The second need assessment workshop session focuses specifically on the recognition and identification of information and communication needs. In the scope of this research these aspects are considered essential to continuing the LCM approach in a structured and controlled manner. The objective of this workshop is to achieve an unambiguous understanding of performance and analysis indicators (defined in Appendix 1A) and their use. To prepare the participants and to define the starting points (as illustrated in figure 4E-4) a simple questionnaire is organized prior to the workshop. Manuscript 4E-17 May, 2002 LCM-systems 4E Training Development Method TECHNICAL SYSTEM 1 to N INSTALLATION (funct. package) PRODUCT/ SERVICE LOGISTICS ORGANIZATION (LCM-team) AIM OBJECTIVE LOGISTIC ACTOR (production unit) BASIC ACTIVITY GOAL : responsible for Figure: 4E-4 Level Performance Indicators Analysis Indicators Aim ? ? Objective ? ? Goal ? ? Questionnaire format to get an impression of basic information awareness. The workshop program is then based on the response to the questionnaire. The response should be summarized so that it can be discussed during the workshop. The aim is to achieve a shared vision based on the actual situation in relation to the basic knowledge gained from the previous training sessions. The workshop exercise is to relate the performance and analysis indicators to one another in a simplified information model, based on Juran's cost-effectiveness structure (see figure 1-3). 4. Life Cycle Cost Budgeting Life Cycle Cost Budgeting is considered to be one of the most important asset management activities. This, because it defines the financial baseline throughout the life cycle of an asset. Setting up a reliable LCC estimation requires a professional approach i.e. must be carried out by a team of specialists [Blanchard, 1992]. The LCM-team should be capable of managing this activity. The objective of this workshop is to provide an Integrated Cost Estimation (ICE) to meet the maintenance plan excluding the deprecation costs.” Integrated” because the intended LCC estimation is considered to be an integrated activity of separate actors who estimate their products and services in relation to the various installations (functional packages). Moreover the estimations are differentiated over the life cycle of the asset. The analysis short list (see Appendix 4D) is used to work this out in practical spreadsheets. A conceptual illustration of the developed ICE spreadsheet is given in table 4E. ICE spreadsheet Number: 2315-2000-1 Performance Requirements Life Cycle Period (status) Active Service Active Time (days) Ship/System HNLMS Rotterdam Availability (%) 95 Installation Target Direction Radar Reliability (%) 90 Investment cost 2.000.000,- Euro Capability (%) 100 Actor Product Manuscript Cst./hr. Costs LCM-team Management control 60 50 3.000 Ships Crew Operational maintenance 240 50 12.000 Radar Workshop Intermediate maintenance 160 50 8.000 Warehouse spare part supply - - 15.000 Test Range radar calibration 40 100 4.000 Maintenance Engineering Maintenance plan 80 50 4.000 Technical Data Center Information management 50 40 2.000 Total Maintenance Cost Estimation Table: 4E-5 Hours 120 630 48.000 Example of an Integrated Cost Estimation spreadsheet. 4E-18 May, 2002 LCM-systems 4E Training Development Method The ICE spreadsheet shown above has been composed for the 'active service' period. To set up the overall cost estimation the various life cycle periods should be defined. For HNLMS Rotterdam the following life cycle periods, stipulated as status categories, have been defined: definition and realization; system integration; active service; low-level depot maintenance; high-level depot maintenance; mid-life modernization; phase-out. In one or more workshop sessions the approach is worked out which finally results in a well-structured life cycle cost estimation as illustrated in the figure 4E-5. YEARL Y COST S (M il.Eu ro ) A C Q U IR E M A IN T A IN OVERHAUL D IS P O S E 120 100 80 60 40 20 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 L IF E T IM E (years) Figure: 4E-5 A Life Cycle Cost Estimation based on the ICE spreadsheet data. 5. Actor Performance Analysis As already stated, LCC estimation is recognized as one of the most important activities. However, it should be recognized that this is only a schedule or plan, it requires actors performance to make it realistic and management control to ensure the required results throughout the asset life cycle [Blanchard, 1992]. This workshop introduces a practical approach to qualifying and quantifying the necessary actor performances and their client/performer relationships. The objective is to obtain a logical and effective logistics process structure. The approach is based on the ICE spreadsheet data and the Logistic Process Model (LPM) design as discussed in section 4.4. Within the LPM design the Activity Diagrams are introduced as simplified IDEF0 process modeling sheets, as illustrated in figure 4E-6. Manuscript 4E-19 May, 2002 LCM-systems 4E Training Development Method Actor :…… Product :…… Cost :…… Impact :.… Actor :…… Product :…… Cost :…… Impact :.… Actor :…… Product :…… Cost :…… Impact :100% Actor :…… Product :…… Cost :…… Impact :.… Figure: 4E-6 Installation: …………… Performance: AT.:………… A. :………… R. :………… C. :………… LPM Activity Diagram System :………………. Year :………………. Status :….…………… The basic LPM Activity Diagram. To draw an Activity Diagram the following conventions are determined: the actor directly connected with the installation is primarily responsible for the defined installation performance; an actor connected above the client actor has a control function; an actor connected beside the client actor has a direct delivery function, for example spare parts; an actor connected below the client actor has a support function, for example administration; only primary client/performer relationships are modeled, to keep it short and simple. To model the performance impact of an actor/product combination on a client an impact factor has been introduced. This modeling parameter is defined as a percentage of the impact on the succeeding activity. The impact factor of the 'prime' actor connected to the installation is per definition 100%. In section 4.5 this subject is discussed in more detail. The workshop program starts with the setting up of several Activity Diagrams for an Installation in a specific life cycle period, based on the ICE results. The actor, product and cost data can be copied from the ICE spreadsheet. The intention is to work out the Activity Diagrams in group sessions and then to discuss the considerations and results in plenary sessions. With the experiences obtained in this workshop it should then be possible to structure a complete Logistic Process Model (see section 4.4) which can be used as baseline during the life cycle of an asset. 6. Contract Management Within LCM-systems the contract management principles have been adopted to structure the client/performer relations (see section 4.4). Contract management focuses on the increased autonomy and competence of the actors. This should be achieved by delegating power and reducing central control. When these principles are applied correctly it results in a more effective and efficient organization [Janse, 1989]. Contract management is based on Service Level Agreements (SLA) between the client and performer actors. The SLA is a contract which is accepted by both involved actors (contract partners). It addresses the following issues: the identification of both contract partners; the products or services to be delivered in a measurable manner; the quality and service standard; the cost in relation to the deliveries and quality and service standards; the contract period; the account conditions; the signatures of both contract partners. Manuscript 4E-20 May, 2002 LCM-systems 4E Training Development Method The workshop program is built up as follows: the principles of contract management; an introduction to Service Level Agreements; a brainstorm session on SLA issues and its pros and cons; a plenary discussion to establish the collective conclusions. The result of this workshop should be a shared vision about the applicability of contract management and a set of recommendations to modify the general SLA as defined for this research (ref. section 4.4). 7. Management Control The aim of this workshop is to provide an understanding of the relationship between all the entities involved (systems, functions, installations, products, processes, actors and periods) and of the values of the defined performance indicators (cost/systemeffectiveness, active time, availability, reliability, capability and cost percentages). Based on a realistic LCM model, modeled on the AMICO application 2, several management control situations will be simulated. It is expected that the workshop participants, who represent most of the actors involved, will provide the necessary approaches and report their intended actions to AMICO. Plenary sessions are suggested to discuss the calculated effects on the model. In this context the team approach of the participants is an important aspect (see section 4.6). 2 AMICO stands for Asset Management Information & COmmunication to indicate the developed asset management control system modeler (see section 4.5 & Appendix 4G). Manuscript 4E-21 May, 2002