* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download RIT Technical Conference Publication - Edge

Survey

Document related concepts

Transcript

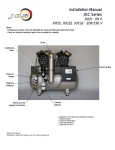

Multi-Disciplinary Engineering Design Conference Kate Gleason College of Engineering Rochester Institute of Technology Rochester, New York 14623 Project Number: 08452 INTEGRATION OF A RECIPROCATING COMPRESSOR WITH A NON-TRADITIONAL RESEARCH ENVIRONMENT Garry Studley Mechanical Engineer Project Manager Christopher Neitz Computer Engineer Interface Design David Rigolo Mechanical Engineer Lead Engineer James Jarvie Industrial Systems Engineer Integration ABSTRACT The objective of this project was to safely install a reciprocating air compressor at a university, which required test bed redesigns and interface development for future compressor research projects. The compressor needed static and dynamic structural support, as well as floor mounts for vibration isolation. Compressor stage removals were designed to reduce the required inputs and resulting outputs of electrical and mechanical power, cooling fluids, and compressed air. An intuitive graphical user interface was developed for use by future engineering student teams. Potential future compressor research projects include fault detection, variable valve timing mechanisms, and auxiliary cooling units. INTRODUCTION In a demanding educational atmosphere, where universities are attempting to differentiate their programs to add value for prospective students, exciting projects need to be offered to give today’s engineers significant real world experience. To provide this, a technical university aligned itself with an industry leader in the field of air compressors to create a variety of unique projects that would highlight multiple facets of the engineering curriculum. With this in mind, an air compressor was chosen that would allow for multiple generations of projects that could include interests in Mechanical, Electrical, Industrial Systems, and Computer Engineering. The selected air compressor was a vertical reciprocating, multiple stage machine with positive displacement that was used onboard navy aircraft carriers during the late 20th century. The main function of the unit was turbine and diesel starting, weapon augmentation, and to deliver liquid oxygen to storage reservoirs that would be used for pilots while in flight. The compressor was originally designed to compress the inlet Kiernan French Mechanical Engineer Safety condition of atmospheric pressure to a desired outlet pressure of 3000 psi (20.68 MPa) through six stages of compression powered by a 75 HP (55.95 kW) electric motor. Designs for the compressor required a compact unit that would be bolted to the ship’s deck and make use of the abundant seawater for cooling of the air in heat exchangers after compression. Although this model of compressor is being removed from use on aircraft carriers, it still provides a valuable test bed that directly relates to products in the air compressor industry. The unit could allow for implementation of various research projects such as variable valve timing and fault detection that are of particular interest to the industry. Value is also seen from the educational standpoint as future engineers involved in these projects explore areas of thermodynamics, vibrations, data acquisition, control systems, and multiple other fields. To effectively use the compressor in a university environment, the machine needed to be transformed into an adequate test bed that could be installed, revamped, and have an interface in place to facilitate future research. Major challenges included minimizing effects of the compressor on the educational atmosphere, and accounting for future projects involving the machine. Safety was the main concern due to the nature of the compressor’s new environment that lacked the mechanical and electrical resources and personnel with technical knowledge of the unit for proper operation and maintenance. The compressor input and outputs had to be modified in the interest of safety while considering future project intentions in all redesigns of parts or systems. The end goal of this project was to successfully provide instructions, part designs, and a functional interface that would create an appropriate test bed for future teams. NOMENCLATURE © 2008 Rochester Institute of Technology Proceedings of the KGCOE Multi-Disciplinary Engineering Design Conference I – Electrical Current (A) n – Number of Stages – Density (lb/ft3) k – Ratio of Specific Heats m - Mass Flow Rate (slugs/s) PT – Mechanical Power (HP) q - Heat Rate (Btu/s)T – Change in Temperature (°F) V – Voltage (V) V – Volumetric Flow Rate (ft3/s) Z – Compressibility rp – Overall Compressor Pressure Ratio Cp – Specific Heat at Constant Pressure (Btu/lb*°F) SAFETY Throughout the project, safety has been a major consideration at all levels. The main documentation for the project, the Operation and Maintenance (O&M) Manual, was developed to ensure that no one was injured while working on or operating the compressor unit. Contained within the O&M Manual were detailed instructions for safety considerations, as well as sections for compressor startup, operation, shutdown, and service. Additionally, a safety training session was developed by the sponsoring company to provide all future teams with a pre-project safety overview. Safety was also a large consideration in the design and layout of the test chamber. Structural, electrical, thermal, environmental, acoustical, vibrational safety and fire hazards were all considered. In order to mitigate electric shock hazards, all electrical components were supplied by panels possessing lock out-tag out points that would ensure the system was fully de-energized when appropriate. Additionally, the electrical system was designed to include two emergency stop buttons, located on opposite ends of the test cell, which would completely disconnect all electricity to the compressor. A clearly marked fire extinguisher was located within the test cell, with additional extinguishers located within the adjoining machine shop. Warnings, cautions, and hazard signs were placed throughout the test cell. These signs included; shock, pinch, pressure, burn, and noise warnings. Ventilation within the cell was checked to ensure that heat and exhaust gasses would not make the room hazardous. In order to ensure personal safety, requirements were developed for all teams working on the compressor. The main requirement was that the compressor be located in a test cell with restricted access. This was achieved by ensuring that the test cell door remained locked, and that anytime it was accessed, a log sheet was signed indicating who was there and what was done with the compressor. Requirements for personal protective equipment were also developed. Safety glasses and hearing protection were provided and are required whenever the compressor is in operation, and the sound reducing doors must be closed. When performing work on the unit, materials such as work gloves, safety glasses, pants, and steel toed boots are required. Additionally, every time a student team member works on the compressor in the test cell, a faculty member or lab supervisor must be informed. INSTALLATION The objective of the installation was to integrate the compressor into its surroundings without adversely affecting the current state of the atmosphere. The ability of the installation area to withstand this type of compressor and resulting loads had to be verified. Static and dynamic loads were a main concern as the compressor would be located in a high traffic area of the university. In addition to handling the loading of the machine, the test cell had to provide the necessary inputs into the machine and withstand the resulting outputs. Proper accessibility and maintenance capabilities were also required to ensure safe operation of the compressor. Every aspect within the installation had to consider the manner in which the compressor would be used in the future to guarantee that the proper test bed was available. Structural: The area that the compressor was scheduled to be installed in was located between two precision machine shops, and it had been previously used as an engine test cell. Although the room was designed to be explosion proof, structural concerns existed within the area. A main source of concern was the presence of a basement located directly underneath the test cell. This resulted in the floor thickness only being 4.75 inches (12.07 cm), which was supported by 12”x17” beams and structural columns that created bays, area on the floor bounded by four columns. Both the columns and beams are made out of concrete with rebar reinforcement. The beams were oriented across the base of the floor with a distance of 8.75 feet (2.64 meters) between the centers of adjacent beams. The overall floor structure in that location of the building was designed for 80 lb/ft2 (3.83 kPa) of live load. Due to the floor condition, the distribution of the 7500 lbs (33.36 kN) for the unit over the 20.49 ft2 (1.90 m2) footprint area of the machine was a concern. Caution had to be used when developing a procedure for the installation and placement of the compressor. To gain an accurate estimate of the floor capabilities, a professional structural engineer was hired to analyze the room under the static and dynamic conditions that were imposed onto it by the compressor. Based on the footprint area and the weight of the compressor, a surface load of 372 lb/ft 2 (17.81 kPa) would be imposed onto the floor. After completion of the analysis, the determination was made that the compressor could only be placed onto the floor slab if the live load was limited to 50 lb/ft2 (2.39 kPa) in the bay location of the compressor. This was based on the original structure’s live load capabilities being exceeded with the placement into the room. With the presence of the machine shop containing heavy manufacturing equipment surrounding the test cell and the original capabilities of the room, the live load could not be limited and the slab would not be capable of supporting the load. Two steel support beams were necessary underneath the footprint of the machine to help the floor support the load from the compressor by adjusting the effective bay size. With the installation of the steel beams underneath the floor as opposed to a raised slab under the footprint of the compressor, trip hazards were Page Number 2 of 8 Proceedings of the KGCOE Multi-Disciplinary Engineering Design Conference avoided. The weight of the compressor should be distributed over 60 ft2 (5.57 m2) to alleviate the load on the floor during transportation of the compressor to the test cell. evenly distribute the weight of the machine for balance and provide only an additional 6 inches (15.24 cm) in height. Vibration Mounts: Placement of the Compressor: The physical characteristics of the compressor posed a difficult scenario for the placement of the compressor into the test cell location. The weight and dimensions of the unit were at the brink of the test cell capabilities. This was due to the transportation process involving the compressor being fully assembled. The university did not have the resources necessary to completely assemble the compressor. Careful examination was necessary to ensure safety was upheld throughout the entire process. Clearance capabilities of the area were also considered due to the compressor’s size relative to the test cell. As was the case in examining the structural capabilities of the test cell, the floor structure and underneath basement were considered while the compressor would be transported into place. Except for the initial drop off location of the compressor at the machine shop loading bay, the transportation route would travel across a floor structure, with basement underneath similar to the test cell setup, for approximately 135 feet (41.15 meters). Under these circumstances, the additional weight from the transportation equipment needs to be kept to a minimum. A forklift could not be used due to this reason. A suitable pallet jack that could safely transport the extensive weight of the compressor was not available. The simultaneous use of two pallet jacks was not a viable option due to safety concerns. Experience and available resources at the university with moving heavy equipment are limited, which led to the requirement to hire a professional rigging company to perform the transportation of the compressor. The use of a professional rigging company provided the experience and tools to also handle clearance and access issues. Upon arrival at the loading bay, the compressor would need to be moved through two doorways until it arrived in the test cell. The clearance that the compressor will have moving through the doorways needed to be determined. The compressor has a width of 68 inches (1.73 meters), depth of 50 inches (1.27 meters), and a height of 79.88 inches (2.03 meters). The width of the doorways did not pose a problem as the minimum dimension, located at the test cell door, was 60 inches (1.52 meter) wide. The compressor could easily be oriented so that the depth would be in that direction. The height clearance was the primary concern, because each doorway to be passed through only has a height of 83.5 inches (2.12 meters). With the need to lift the compressor off the floor while transporting it into location, the top 6 inches (15.24 cm) of the machine have to be removed to reduce the overall height of the unit to 73.88 inches (1.88 meters). This portion of the compressor could be placed back on the machine after it was in the test cell. While extra clearance was added with this action, the rigging company still needed to use the proper equipment to reduce the lift off the floor to about 9 inches (22.86 cm). Based on the weight and clearance issues, the rigging company d ecided that utilization of four roller carts underneath the compressor will In order to reduce the impact of the compressor’s operation on the surrounding machine shop and classroom environment, it will be mounted on a dampening system. This system will reduce the amount of vibrations transmitted to the floor. The dampening system acts to allow the machine a certain level of acceptable motion. The majority of the vibrations produced by the compressor are in the vertical direction, due to the configuration of the pistons. With vibration isolators installed underneath the compressor, the vertical oscillating load will be dissipated by working to compress and depress the mounting system. Essentially the force will be transferred into moving the machine instead of the floor. Caution must be taken when choosing the spring rate of the mounting system, because the machine runs at a fixed level of revolutions per minute (RPM). If the frequency of the vibrations is within about 50 to 150% of the natural frequency of the system as defined in Eq. 1, the vibrations will actually be amplified by the mounting system. The desired ratio between vibration frequency and natural frequency should be at least 1.5. To reach this ratio, the resonant frequency must be briefly passed through as the compressor spins up and stabilizes; it is not expected that this short time period of matching the resonant frequency will cause significant effects. Natural Frequency(rad / s) mount stiffness ( N / m) Machine Weight (kg) (1) Originally four types of mounts were considered. These were: mats of dampening material, sandwich type mounts, air filled type mounts, and spring type mounts. The dampening mats were ruled out early, despite their ease of installation and reduction of points loads, because of their weak dampening and high price. Sandwich type mounts were eliminated because, when coupled with the compressor, they would produce a spring mass system that would too closely resonate with the compressor’s current designed RPM level. Air type mounts were robust, but discovered to be more expensive than originally anticipated. Considering price, deflection and spring rates, and minimization of resonating frequencies, spring type mounts provided the most appropriate solution. Twelve mounts utilizing existing mounting holes around the compressor perimeter would be used. The twelve out of twentytwo available holes were selected to achieve equal weight distribution on the floor. The original in-situ design of the compressor disregarded the machine vibration impact on the surrounding environment, because the compressor was designed to be rigidly mounted to the deck of a ship using twenty-two 1.125 inch (2.86 cm) bolts. To utilize these existing mounting holes on the base of the compressor, some form of adaptation to the mount’s 0.5 inch (1.27 cm) bolts needed to be made. For this purpose 0.25 inch Page Number 3 of 8 Proceedings of the KGCOE Multi-Disciplinary Engineering Design Conference (0.64 cm) thick 3 inch (7.62 cm) squares of steel plate will have holes drilled in them to act as reducing washers. To prevent the compressor from walking across the floor, the mount would be anchored to the concrete floor. For this purpose there is a wide selection of available anchors. Vibration-resistant wedge stud anchors have been chosen due to their healthy balance between high strength, minimal hole depth requirement, and low price. A contracting company will need to be hired to locate the rebar in the concrete floor prior to the drilling of any holes during the mount installation. This will prevent damage to the rebar in the concrete floor during drilling procedures that would physically weaken the floor support structure. motor of the compressor would not be removed while in the test cell. Removal of the motor would only be necessary upon failure and require equipment not available at the university. After subtracting the width of the compressor, the remaining space available in the shorter direction of the room was 5.813 feet (1.77 meters). This space was split to give the operation side of the compressor the maximum amount of space possible. The position of the compressor in the long dimension of the room was determined based on the need for storage and future project uses of the machine. Shelving, a computer with a desk, and workbench were all considered with the test cell layout. The selected configuration of the room can be seen in Fig. 2. Other hardware includes washers and nuts for the anchor studs, and a level adjusting nut on the mount as shown in Fig. 1. Machine Bolt 1/2-13 x7.5" Adaptor plate Compressor frame ½” Anchoring hardware Figure 2: Selected Test Cell Layout ½” Flat washers Nut supplied with mount Spring mount Figure 1: Vibration Mount Bolt Down Diagram Because 0.5 inch (1.27 cm) bolts are being used in the 1.188 inch (3.02 cm) frame holes, a tolerance stack up showed that there is room for up to 0.40 inches (1.02 cm) of error in the placement of the mounts during installation into pre-drilled holes in the floor. Test Cell Layout: Once the professional rigging company maneuvers the compressor into the test cell, precise placement of the unit will be needed to provide ample access area around the machine. The test cell needed to be arranged to provide the proper access area for maintenance capabilities and safe operation. The room dimensions are 9.98 feet (3.04 meters) wide and 24.375 feet (7.43 meters) long. Enough room for spare equipment and storage area is also needed for proper maintenance and future uses of the compressor. To provide ample room for maintenance on both sides of the compressor, the unit should be oriented near the center of the room. Based on the dimensions of the compressor and room, the depth of the machine was oriented to be with the width of the room. This maximized the distance on either side of the compressor. The minimum space needed for access on either side of the machine was 23 inches (58.42 cm), assuming the COMPRESSOR INPUTS AND OUTPUTS With the insertion of the compressor into the university environment, the inputs and outputs of the machine needed to be altered to and verified that an appropriate level was achieved. With the original design of the compressor, the university would not be able to support the unit. Inputs such as electrical supply, mechanical power, and cooling specifications were not readily available due to lack of resources. Vibrations, acoustics, pressure, heat generated, and other various outputs imposed a threat to the general safety of the surrounding environment. With this in mind, the compressor was redesigned to have reduced inputs and outputs by transforming the unit from 6 stages with an exit pressure of 3000 psi (20.68 MPa) into 2 stages that would have a reduced overall discharge pressure of 100 psi (0.69 MPa). With the redesign, the effects on the inputs and outputs were determined to distinguish whether further adjustments to the compressor or room were necessary. Mechanical Power: By redesigning the compressor to operator with 2 stages instead of the original 6 stages, the mechanical power needed by the unit would be less than the 75 HP (55.95 kW) that was originally supplied to the electric motor. Under the assumption of an adiabatic cycle, the mechanical horse power required could be determined based on the pressures and properties for the compressed air as shown in Eq. 2[1]. The mass flow rate, m , through the compressor was considered to be constant. Page Number 4 of 8 k 1 n * p1 *V 1 Z Z2 k PT * *r k * 1 229 k 1 2 * Z1 (2) Proceedings of the KGCOE Multi-Disciplinary Engineering Design Conference Equation 2 is a derivation of adiabatic horsepower using English units. A conversion factor of 229 allows use of a volumetric flow rate in gallons per minute. The input and output conditions are represented by the subscripts 1 and 2, respectively. The subscript T denotes theoretical. The theoretical horse power for the original design was computed with the result from Eq. 2 being divided by the actual measured horse power to estimate the compressor efficiency. Calculations were then preformed, similar to the calculations for the original design, to attain the theoretical horsepower for the redesigned 2 stage compressor configuration. This result was then divided by the compressor efficiency to determine the estimated horse power the new design would require. Numerical values used in the equation can be seen in Table 1 and Table 2. Table 1: Properties of air used in Eq. 2 for each design Table 2: Numerical values used in Eq. 2 for each design The computed impact of the compressor redesign on actual mechanical power was a reduction from 68 HP (50.73 kW) to 25 HP (18.65 kW). Specifications on the electric motor indicated that the motor would be able to handle a reduced load while maintaining a desirable motor efficiency. With reduced power requirements, a safer environment could be maintained and other inputs could also be reduced. Electrical Supply: One of the major advantages of reducing the mechanical horsepower would be the effect on the electrical requirements. The electric motor was determined to be capable of being efficient at a reduced load which in turn would require less electrical current draw by the motor. The original design of the compressor called for 440 V delivered at 90.3 A. While the university had the voltage supply available at the test cell location, the current originally specified would require a customized route to the location from the main electric control panel through thick slabs of concrete. This type of current would also require high capacity wires that would significantly add to the cost. Due to the impact of the redesign on the necessary power drawn by the motor while continuing to use a 440 V supply, the current could be reduced and still provide an ample supply of power. Equation 3[2] was used to compute the new current requirements based on the reduced horse power, compressor efficiency, motor efficiency, and power factor associated with the motor shown in Table 3. V * I * Power Factor HP * Compressor Efficiency * 746 motor efficiency (3) Table 3: Numerical values used for Eq. 2 for each design The motor specifications table provided the necessary information on the motor characteristics and the results from computing the reduced horse power were used to gain the new current requirement of 37 A. This result was verified by examining the load percentage the motor would be at with the new conditions and interpolating the resulting current value from the provided information on the motor drawing. Original startup of the compressor was in an unloaded state and the necessary current used for this process was not a concern. The new current requirement would allow the unit to be supplied with the existing capabilities of the test cell. Heat Generation and Removal: Much like the electrical requirements, the requirements concerning the heat released by the compressor were anticipated to be reduced by the redesign with the reduction of stages. Original specifications considered the compressor’s application on a ship and utilized the vast supply of sea water for an open loop, inner-stage cooling system. With the removal of 4 stages on the high pressure side of the compressor, the heat generated from compression was expected to be reduced. This would result in lower requirements for the open loop cooling system, which was originally designed for 50 gal/min (189.27 liters/min) of sea water to be used in the heat exchangers between stages. In the redesign, the open loop system had to be converted to fresh water, due to its availability and ability to be a suitable alternative. Using an energy balance assuming constant specific heat at constant pressure shown in Eq. 3 and known temperature measurements at the inlet and outlet of stages, the total heat removal of each stage could be computed and summed together. Equation 4[3] could also be used to calculate the actual heat removal being performed by the open loop system with temperature measurements taken at the beginning and end of the system. q m C p T (4) With the assumption that adiabatic inner-stage cooling was occurring by way of the heat exchangers and a constant mass flow rate of cooling water through the machine, theoretical values for heat removal could be computed for the original and redesigned compressor configurations, with 6 and 2 stages respectively. The theoretical heat removal could then be compared to the actual heat removal of the open loop system similar to the method used in calculating compressor efficiency. The inefficiency in the cooling system found from this ratio could be used to predict the actual heat removal for the new system. With the actual heat removal of the redesigned Page Number 5 of 8 Proceedings of the KGCOE Multi-Disciplinary Engineering Design Conference compressor calculated, the required volumetric flow rate of the system could be determined using Eq. 4 and the same temperature difference that was measured for the original design. The new required volumetric flow rate of the open loop system to maintain the same temperature difference was computed to be 18 gal/min (68.14 liters/min). Based on the capabilities of the test cell, the tolerated temperature differential in the system was raised slightly, from 4°F (-15.56°C) to 10°F (-12.22°C), for a required flow rate of 7 gal/min (26.50 liters/min). Another concern was the release of heat from the operation of the compressor into the test cell room. With the doors closed and no air leaving the room, the temperature would rise significantly. To eliminate this effect, ample exhaust was necessary to remove the air from the room. The current setup in the test cell had a gravity inlet vent and two exhaust fans. The total circulation that resulted from the exhaust capabilities was 900 ft3/min (25.49 m3/min) and was more than sufficient for the intended use. and 3rd stage pistons with long shafts. Screwed into the top of these pistons are shafts that lead to another set of pistons for the 4th, 5th, and 6th stages (refer to figure 3 for a visual representation.) This allows the compressor’s reciprocation be modeled the same as a three cylinder engine. This combined with the varying weights of the pistons leads to a considerable amount of unbalanced forces between the farthest and closest pistons. The manufacture has provided us data on the unbalanced inertia forces the machine transfers into the foundation. A silencer will also be used to further alleviate the impact from the acoustics on the environment. The silencer will be placed on the inlet of the machine and oriented in the vertical direction. Due to an existing overhead light and the added height from the silencer, interference issues arose. Options to eliminate interference included moving the light to the side of the compressor or installing an elbow at the inlet to redirect the silencer past the light. The latter was chosen due to its overall ease. 1st piston 2nd piston Acoustics: The reciprocating attribute of the compressor provided concern about the effect it might have on the university environment. Much of this concern was directed at the additional noise related to the compressor’s operation. Verification that the educational atmosphere would be preserved was necessary. Aspects of the room layout, room capabilities, and machine characteristics were considered for this purpose. Features of the test cell, such as being sealed with an acoustic reducing steel door, were anticipated to help the sound issue brought about by the compressor. The test cell capabilities to mitigate any added noise levels were tested by a high volume impulse generating device. Measurements were taken with a decibel meter inside and outside the test cell with the door closed to determine the overall differential. The results from this test describe the capabilities of the room to dissipate sound with an average differential of 64.8 dB. With the measured acoustic levels from the compressor being no more than 90 dB, the acoustic disturbance from the machine was viewed to be minimal. 6th piston 5th piston 4th piston 3rd piston Crossheads Figure 3: Piston configuration The 4th, 5th and 6th stage pistons will be completely removed. Because of this, their weight will have to be compensated for. The 3rd piston will remain in the compressor because there is no benefit of removing it. To counter the removed weight, a donut shaped weight will be bolted to existing holes on each of the crossheads as shown in Fig. 4. Shaft to 3rd and 4th pistons Crosshead REVAMP The pistons act in a vertical arrangement and are of varying weights. The stages are configured such that there are only three rods connected to the crank that then connect to three crossheads. These crossheads are then connected to the 1st, 2nd, Page Number 6 of 8 Support surface 4th stage counterweight Crank Figure 4: Sample Counterweight Assembly Proceedings of the KGCOE Multi-Disciplinary Engineering Design Conference The largest of the three counter weights will be approximately 14 lbs (62.28 N). Figure 4 shows this weight disassembled along with the rod-crosshead assembly. The front and back edges of the crosshead act as a bearing surface. This surface interacts with a cylindrical lining built into the block to support the linear reciprocating motion of the crosshead. This particular counter weight has wings sticking out of the side of it because of clearance issues. The crosshead drops below a side supporting surface (surface of crosshead that interacts with support surface is labeled in Fig. 4) in the block prohibiting material from overhanging over the top of the front and back of the crosshead. Because of limited space above the crosshead, the next feasible place to add mass would be to the sides. The other two counterweights would not need this extra material, because they are only 3 to 4 lbs (13.34 to 17.79 N), and could fit in the foot print on the top of the crosshead. They are lighter because the 5th and 6th stage pistons are very small. The counterweight’s two pieces are designed to interlock to prevent bending loads on the mounting bolts that would lead to failure. With the removal of the 4th, 5th and 6th pistons, their cylinder heads will also be removed. The 4th and 5th stage pistons are connected to the 3rd and 2nd pistons respectively. The 2nd and 3rd stage piston only act to compress gas on the downward stroke. Figure 3 shows each pistons compression volume as a crosshatched area for reference. Because of this and the fact that the 4th and 5th stages are attached to the top of these pistons, plates can be used to block off where the 4 th and 5th cylinder heads and pistons where originally located. The 1st stage piston acts on both the upward and downward stoke. Therefore 1st stage has an upper cylinder head unlike the 2nd and 3rd stages. Because of this, care must be taken to account for the volume of the removed 6th stage components. For this purpose a plate with a length of cylindrical bar will be used as shown in Fig. 5. The bar will extend down slightly past where the seal for the 6th stage piston rod is. This will effectively seal the 1st stage while simulating the majority of the compression volume of the 1st stage taken up by removed 6th stage components. 6th stage block off plate Fake 6th stage Figure 5: 1st Stage Seal and 6th Stage Cover Plate Other components being removed from the compressor included the 3rd, 4th, 5th, and 6th stage air/gas coolers, water separators, air piping, relief values, and coolant piping. None of these items will be utilized since only the 1st and 2nd stages are to remain in operation. The air piping is run in series between the stages. Therefore the air piping after the 2nd stage relief valve will be removed and a new pressure tap will be installed. The open loop coolant piping runs in parallel through the six air/gas to coolant heat exchangers. The 3rd through 6th stage coolant pipes will be replaced with plugs installed in the inlet and outlet coolant manifolds to take their place. All these components will be stored on shelving for possible use in future projects. With only the first two stages in operation, the compressor will compress air to 100 ±20 psi (0.69 ± 0.14 MPa). This is a much safer pressure for an academic environment than 3000 psi (20.68 MPa). Also the removal of stages reduces the required motor power from 68 HP (50.73 kW) to only 25 HP (18.65 kW). This will lead to the electrical current requirement of the motor dropping to 38 Amps from 90 Amps. INTERFACE Because the future goal of the compressor revamp is to allow for users to monitor the state of the compressor during various research projects, a data acquisition (DAQ) system needed to be created. Using LabVIEWTM as a foundation, an interface was created which can be used to build a full data acquisition system once the compressor is installed and converted to a 2stage system. The features of the interface were created with a primary focus on user convenience to view, record, and trend data with ease. The first function of the interface will gather data from sensors to be installed on the compressor. Temperature and pressure are common examples of data collected, but additional data such as water flow and crank angle may be required in order to aide in future research.. Currently, the interface is set to display 25 different sensor indicators, and additional sensors can easily be added. The next important ability of the interface is to store the data being displayed. In the event the user would like to take certain ranges of points and trend them, a single file would need to be created that could be read by data manipulation programs such as Microsoft Excel. For real-time visualization of data trends through the interface, graphs are included for each sensor, which a user could utilize via a set of organized tabs. A threshold line can be adjusted for each graph, so a user can more clearly see how close the data is to an unsafe level. Finally, the interface required a standardized warning system, which could alert the user that a part of the compressor had gone over a safe threshold level. This was accomplished via a number of status diodes, which glow green while the data being reported is under a safe level, but glow red when an unsafe level is reached. Using this mechanism, a user could easily and quickly see where on the compressor a problem was occurring. Usability testing, using both objective and subjective data collection methods, was implemented with a representative set Page Number 7 of 8 Proceedings of the KGCOE Multi-Disciplinary Engineering Design Conference of individuals for the intended user group. While being asked to complete a set of specified tasks with the interface, objective data was collected on the number of errors committed, the number of times help was requested, and the time taken to complete each of the tasks. Individuals repeated the test a second time, and comparisons in the data were made to determine the high degree of learn-ability present in the program. The individuals then completed a brief survey, which was used to capture the quality of subjective aspects such as intuitiveness, aesthetics, and an opportunity to provide written comments. With these features, a simple but robust interface was created which allowed a user to view and record data, monitor trends of past data, and view whether or not the data was within a safe limit. Fig. 6 shows a screenshot of the front panel of the interface. Sensors are grouped together based on their function and location. Graphs for each grouping are accessible with localized buttons, as well as tabs positioned across the top of the interface. Finally, the diode status lights provide a clear indication on the overall health of the system. revamp, and interface design still have valuable processes that can be followed as a reference. Installation: The basic layout of the test cell room can stay the same in most regards depending on size of the new compressor. All supplies and equipment purchased for operation and maintenance can be utilized with the new compressor. The structural analysis that was provided for the room could be used as a benchmark for the capabilities. The recommendations to strengthen the structure with steel beams underneath the floor should be followed with the addition of any new large equipment to the intended location. A rigging company in the intermediate area was specified to be scheduled to perform the installation. Vibration mounts used for isolation have also been identified, and will need to be ordered with a selected quantity as dictated by the new compressor footprint. Revamp: While this portion of the project probably will not directly relate to the new compressor, the basic ideas can be applied to any reciprocating compressor. Theory and proper equations have been documented to compute the resulting changes that the revamp had on the machine, such as the reduced mechanical power, reduced electrical requirements, vibration analysis, the cooling capabilities needed with the inner-stage cooling, and cooling of the room from heat generated during operation. The theoretical calculation process can be followed to address the effect the revamp would have on the new machine. Interface: This section can completely transfer over to the new compressor. A working interface, a user guide, a method for data collection, and a computer have all been provided. Specifications on the DAQ hardware that should be used for the future project’s use have been identified and recommended to be ordered. The quantity of stages that the new compressor will have should be addressed with an adjustment made in ordering and display on the interface. Figure 6: Front Panel of the Interface CONCLUSIONS Although the entire scope of the project was on course to be completed, the compressor was never received by the university due to issues with the International Traffic in Arms Regulation (ITAR) control designation of the machine. This basically meant that non-US citizens could not transport any information regarding the compressor outside the workspace, due to the compressor’s use on government ships. While certain non-US citizens could still work on the compressor, a major liability risk was present with the consequence of large fines if regulations were violated. Extra security measures would have also been required. The legal councils of both parties decided against the donation for these reasons. As a result, another compressor, also reciprocating, will be selected and installed into the same area that the original compressor was to be located. The future purposes of the new compressor will be identical. With these similarities, a great deal of this project can be used in the work intended for the new compressor. The three main subdivisions of installation, ACKNOWLEDGMENTS Dresser-Rand Company, Rochester Institute of Technology Jensen Engineering, Dr. Margaret Bailey, Mr. Mike Bunce, Mr. Scott Delmotte, Mr. Dave Hathaway, Dr. Mark Kempski Mr. Allan Kidd, Mr. Ray McKinney, Mr. Joe Tecza, Mr. Jason Vigil REFERENCES [1] Ingersoll Rand 1981,Gas Properties and Compressor Data, Ingersoll Rand Co. USA., pp. 2-20. [2] Bodine Electric Co. 1993, Small Motor, Gearmotor and Control Handbook, Bodine Electric Co., Chicago, IL. [3] Moran M. and Shapiro, H 2004, Fundamentals of Engineering Thermodynamics, John Wiley & Sons, Inc., Hoboken, NJ. Page Number 8 of 8