* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download 6.0 Validation

Electrical substation wikipedia , lookup

Three-phase electric power wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Power inverter wikipedia , lookup

Electrical ballast wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Variable-frequency drive wikipedia , lookup

History of electric power transmission wikipedia , lookup

Current source wikipedia , lookup

Power MOSFET wikipedia , lookup

Portable appliance testing wikipedia , lookup

Distribution management system wikipedia , lookup

Stray voltage wikipedia , lookup

Voltage regulator wikipedia , lookup

Power electronics wikipedia , lookup

Surge protector wikipedia , lookup

Automatic test equipment wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Mains electricity wikipedia , lookup

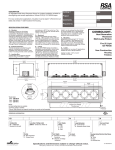

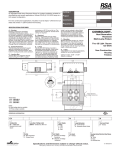

LTR A DESCRIPTION BY Released per CR???????? DATASCOPE 14 PHILIPS PARKWAY MONTVALE, NJ 07645 DATE APPROVED PJB Defib Test Fixture – Specification and Validation FILE NAME. ©DATASCOPE CORP. (UNPUBLISHED) ALL RIGHTS RESERVED This material is the proprietary information of Datascope Corp. and any use, reproduction, or distribution of the material contained herein, unless specifically authorized by Datascope Corp., is expressly forbidden and would violated the rights and interests of Datascope Corp. Datascope Engineering Form E112.5 DIVISION P/M 0454-00-0034 Datascope® PROPRIETARY REVISION A SHEET 1 OF 13 Defib Test Fixture – Specification and Validation TABLE OF CONTENTS 1.0 Introduction .......................................................................................... 3 2.0 Theory of Operation ............................................................................. 3 3.0 Test Fixture Configurations ................................................................ 6 3.1 Defibrillator Load Configuration ...................................................... 6 3.2 Limiting Resistor Configuration ....................................................... 6 3.3 Polarity Configuration ...................................................................... 6 3.4 Inductor Configuration ..................................................................... 7 4.0 Construction Notes ............................................................................... 7 4.1 High Voltage Nodes of Interest ........................................................ 7 4.1.1 Defib configuration Jacks and Jumpers .................................................. 7 4.1.2 Wiring Concerns ............................................................................. 7 4.2 User Safety Concerns........................................................................ 7 5.0 Operating Instructions ......................................................................... 8 6.0 Validation .............................................................................................. 8 5.1 Validation Procedure (AAMI) .......................................................... 8 5.2 Validation Procedure (IEC) ............................................................ 10 APPENDIX A - SCHEMATICS ................................................................ 12 APPENDIX B – ENERGY CALCULATION .......................................... 14 Datascope Proprietary Page 2 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation 1.0 Introduction This document describes the design, construction and validation of the Defib Test Fixture. The Defib Test Fixture is a test device that shall be used to implement the various defibrillator test circuits specified in AAMI and IEC standards. 2.0 Theory of Operation The Defib Test fixture must conform to the following configurations: Figure 1 - EC13 Figure 9A Datascope Proprietary Page 3 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation Figure 2 - EC13 Figure 9B Figure 3 - IEC601-2-27 Figure 106A Datascope Proprietary Page 4 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation Figure 4 - IEC601-2-27 Figure 106B The parameters of the Defib Test Fixture can be configured to conform to a number of different effective circuits shown in the above figures. These different configurations are described in section 3.0 of this document. When attached to the high voltage generator, current will flow through R1 (125k) and initially flow through resistor R2 (125k). Holding down the momentary push button “Charge” switch will cause the normally closed relay, SW2, to open allowing the high voltage capacitor, C1, to charge up with an RC time constant of R1*C1 = 125K*32uF = 4s. (Ignoring the negligible DC resistance of inductor L1) After holding down the charge switch for 4 time constants or 16 seconds, the capacitor (C1) will have charged up to within 1% of 5kV. The timing Relay, TM1, must be configured to allow current to flow through the coil of relay SW1 for 200ms ± 100ms. The timing relay can be configured to produce this effect. The operating mode of the relay must be set to “C002.1”, where the significant digits on the relay must be set to “002”, and the multiplier on the relay must be set to “0.1s”. By configuring TM1 in this manner, in the circuit described in Appendix A of this document, SW 1 will switch from R1 over to R3 for 200ms. Without the inductor, L1, there would simply be a capacitive discharge with an RC time constant of R3*C1=100*32uF=3.2ms. However, due to L1, which will resist the immediate change in current through the circuit, a waveform is obtained similar to that shown in figure 5.1 of this document. Datascope Proprietary Page 5 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation 3.0 Test Fixture Configurations 3.1 Defibrillator Load Configuration The test figure can be configured to deliver the energy across a 100 Ohm load, R3, or the test fixture can be configured to apply the 5KV across a 100k load, R4. To use the test fixture in the first configuration, a high voltage jumper must be places from J1 to J2. To use the test fixture in the second configuration, a high voltage jumper must be placed from J1 to J3 instead. J1, J2 and J3 are labeled as follows inside the test fixture: If there is no jumper in place, the energy will simply be drained by R2 when the charge button is released. J1 J2 J3 COM 100 OHM 100K 3.2 Limiting Resistor Configuration The limiting resistor can be configured to 50 Ohms (R5), 400 Ohms (R5+R6) or 50K (R5+R6+R7, where R5 and R6 are insignificant compared to the tolerance of R7). To configure the test fixture for 50 Ohms, a high voltage jumper is placed between J4 and J6, shorting out R6 and R7, leaving only R5. To configure the test fixture for 400 Ohms, a high voltage jumper is placed between J5 and J6, shorting out R7, leaving R5 and R6. To configure the test fixture for 50K, no high voltage jumper is placed in the circuit. J4, J5, and J6 are labeled inside the test fixture as follows: J4 50 Ohms J5 400 Ohms J6 COM A sticker specifying “50K if open” is also placed inside test fixture. The inductor has to be configured according to the standard the test is going to be carried with. The jumpers JA and JB are used to switch between AAMI and IEC standards respectively. 3.3 Polarity Configuration The test fixture can be configured for either positive or negative polarity. If configured for positive polarity, the positive side of capacitor C1 is applied to the limiting resistor preceding P1 and the negative side of capacitor C1 is applied to P2. If configured to negative polarity, the negative side of the capacitor is applied to the limiting resistor preceding P1, and the positive side of capacitor C1 is applied to P2. This configuration is changed by switch SWXX on the top of the test fixture, labeled “POLARITY”. When configured for positive polarity, this switch is in the open position and no current flows through the coil of high voltage relay SW3. In its normal position, SW3 will create the positive polarity situation described above. When switch SWXX is placed in the Datascope Proprietary Page 6 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation negative position, or closed, current will flow through the coil of relay SW3, and the negative polarity situation, described above, will be created. 3.4 Inductor Configuration The wave-shaping inductor can be configured to whatever is needed for the current test being run. While the AAMI EC-13 test procedure chooses to test with a more realistic defibrillator wave-shape using an inductor on the order of 25mH (this inductor value may be changed so long as the wave-shape still meets requirements defined in the validation section of this document per EC13), the IEC tests use a potentially more destructive wave-shape formed by a 500uH inductor. The 4.0 Construction Notes 4.1 High Voltage Nodes of Interest 4.1.1 Defib configuration Jacks and Jumpers The J1, J2, J3, J4, J5, and J6 jacks are used to configure the test fixture, as needed by various industry standards. Be advised that the jacks, as well as the jumper used to connect them, will reach relatively high voltages as well as relatively high instantaneous current. Throughout the entire test fixture, it is important to place components not rated for greater than 5000V at a distance great enough from one another to prevent arcing. In general, if adequate spacing is observed between high voltage parts of the test fixture, the rated voltage on single conductor component, such as jacks and plugs, can be ignored. 4.1.2 Wiring Concerns All high voltage wiring within the test fixture should be done with a wire rated for greater than 5000V, such as Rowe Industries part number R800-1022-100-9, rated at 10kV. Any open solder points should be kept at a distance great enough to prevent a 5kV arc from any other conductive point. Also, all high voltage nodes should be kept an a great enough distance from any wires carrying low voltage signals, such as relay controls. It may be helpful to route low voltage signals around the sides of the box and high voltage in the center. 4.2 User Safety Concerns User safety must be of primary concern when laying out the defib test fixture. The following guidelines should be followed: User controls should be kept on the opposite end of the test fixture from any points of the test fixture reaching high voltages. Datascope Proprietary Page 7 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation 5.0 “Charge” and “Fire” switches should be kept on opposite sides of the test fixture from one another such that the operator cannot physically operate the unit without both hands being away from the high voltage. Any high voltage monitoring should be kept isolated from low voltages points that may leave the box at unsafe places. For example – by operating the Capacitor charge monitoring circuit shown in Appendix A from a 9 volt battery, there is no worry of high voltages harming the 12v power supply or the operator whom might be in the vicinity of the 12v power supply. Operating Instructions Step 1 – Attached cable marked “HV INPUT” on the Defib Test Fixture to connector J2 labeled “HIGH VOLTAGE” on the high voltage generator. Step 2 – Attach the wires labeled “High Voltage Enable” to screw terminals 14 and 15 on the “TB 1 – I/O INTERFACE” on the back of the high voltage generator. Step 3 – Attach a 12V power supply to the banana plug input labeled “+12V” on the top of the Defib Test Fixture. Step 4 – Attach the device under test to the Defib Test Fixture according to the procedure being followed. Step 5 – Attach a calibrated DVM to the banana plug output labeled “CAP MONITOR”. Step 6 – While holding down both “CHARGE” buttons on the side of the Defib Test Fixture, push the “HV ON” button on the High Voltage power supply and set the output to 5kV. Once the DVM reads 4.95 – 5.05 volts, press the “FIRE” button on the Defib Test Fixture to discharge the Capacitor across the patient load. 6.0 Validation 5.1 Validation Procedure (AAMI) Step 1 – Configure Defibrillator Load in the test fixture to 100 Ohms. Configure the Limiting resistor to 400 Ohms. Plug jumper J to select the inductor for AAMI configuration. Configure the Polarity to Positive. Step 2 – Using a Tektronix 744A 4-channel digitizing oscilloscope and the Tektronix High Voltage Differential Probes, monitor the differential “Output Monitor”. Step 3 – Set up the scope such as to capture an amplitude of approximately 8 volts over a total time of approximately 100ms. Note: These settings are only an approximate starting point, set up the scope, such as to capture the measurements required below. (Table 1) Datascope Proprietary Page 8 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation Step 4 – When the Unit is operated per the operating instructions, capture to following approximate output waveform from the oscilloscope: Figure 5 – Defib Test Fixture Waveform Output Step 5 – Attach a calibrated multimeter to the “capacitor monitor” output. Charge the capacitor to 5000V by holding down the momentary push button “Charge” switch until the multimeter reads 5v. Short out the signal generator by closing the switch (If signal generator is connected). Depress the momentary push “fire” switch to discharge the capacitor. Step 6 – Take the following measurements, as indicated in the figure above, and verify that all measurements are within the specified tolerances. The figure is labeled in current, the table accounts for a test across a 100 Ohm load and is labeled in voltage. Waveform Parameter VP VR V20max tr t50 t10 Minimum Acceptable 2645 volts N/A N/A 0.30 ms 2.30ms 4.00ms Measured Value Maximum Acceptable 4849 volts 0.4 * Vp 0.4 * Vp 1.25ms 6.40ms 19.60ms Pass/Fail Table 1 VP – Peak voltage of the waveform VR – Maximum reverse voltage of the waveform. Note: Test fixture may not result in any reverse voltage at all. V20max – Maximum voltage after 20ms. tr – 10% to 90% rise time of the first lobe of the waveform. Datascope Proprietary Page 9 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation t50 – time between 50% of VP on the rising edge of the first lobe and 50% VP on the falling edge of the first lobe. t10 - time between 10% of VP on the rising edge of the first lobe and 10% VP on the falling edge of the first lobe Step 7 – Save the output of the defib test fixture as seen on the scope into a “.cvs” format and using excel calculate the energy delivered. Integrating V2/R over time will give the energy delivered. Verify that the energy delivered is within 10% of 400J. (See appendix A for a more detailed description of the required calculation) Parameter Energy Minimum Acceptable 360 Joules Measured Value Maximum Acceptable 440 Joules Pass/Fail Table 2 5.2 Validation Procedure (IEC) Step 1 – Configure Defibrillator Load in the test fixture to 100 Ohms. Configure the Limiting resistor to 400 Ohms. Plug jumper J to select the inductor for IEC configuration. Configure the Polarity to Positive. Step 2 – Using a Tektronix 744A 4-channel digitizing oscilloscope and the Tektronix High Voltage Differential Probes, monitor the differential “Output Monitor”. Step 3 – Set up the scope such as to capture an amplitude of approximately 8 volts over a total time of approximately 100ms. Note: These settings are only an approximate starting point. Step 4 – Attach a calibrated multimeter to the “capacitor monitor” output. Charge the capacitor to 5000V by holding down the momentary push button “Charge” switch until the multimeter reads 5v. Short out the signal generator by closing the switch (If signal generator is connected). Depress the momentary push “fire” switch to discharge the capacitor. Step 5 – Save the output of the defib test fixture as seen on the scope into a “.cvs” format and using excel calculate the energy delivered. Integrating V2/R over time will give the energy delivered. Verify that the energy delivered is within 10% of 400J. Parameter Datascope Proprietary Minimum Acceptable Measured Value Page 10 of 14 Maximum Acceptable Pass/Fail 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation Energy 360 Joules 440 Joules Table 3 Datascope Proprietary Page 11 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation APPENDIX A - SCHEMATICS Figure 6 Datascope Proprietary Page 12 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation Figure 7 Datascope Proprietary Page 13 of 14 0454-00-0034 Revision A Defib Test Fixture – Specification and Validation APPENDIX B – ENERGY CALCULATION In order to validate the Defib Test Fixture we must measure the total energy delivered by the output waveform. However, we do not have a direct method by which to measure the energy. Instead we must integrate the output power waveform. Unfortunately, we cannot even measure the output power directly either. The only quantity that we can measure directly is Voltage as a function of time, by hooking up high voltage differential probes to the V+ / V- output monitor on the test fixture. However, we know that this voltage is being applied across a 100-ohm resistor. Knowing voltage and resistance we can easily derive the current and power. Current = Voltage / Resistance Power = Voltage * Current = Voltage^2/Resistance Using a Tektronix 744A oscilloscope, we can Save the waveform to a CSV file. This CSV file can be opened using Excel to do all the necessary calculations. The steps are as follows: 1) Open the CSV file with Excel (or any other spreadsheet application) The first column of data will be the voltages sampled by the scope, the second column will be the time. Since the sampling is linear, we only need the difference between any two adjacent time values. We will refer to this as the Sampling Period. 2) First, since the Output monitor is 1/1000 the actual output voltage, due to the voltage divider in the test fixture, we must multiply column A by 1000. This can be done as B1=A1*1000 and using the Fill Down command. 3) Next, we must calculate the power that each of these voltages corresponds to. This can be calculated by D1 = C1^2/100 and using the Fill Down command. Column D is now instantaneous samples of the power waveform. We can view this waveform by graphing column D if we desire. 4) We want to find the integral of power with respect to time. Because this is defined as the area under the power-time curve. To find this, first we must multiply each instantaneous power measurement by the sampling period. For example, if the sampling period is 20us then we can use E1 = D1*20*10^-6 and use the fill down command. 5) Column E is now our energy contained in each sampling period, to obtain the total power we must sum the column. We can do this using SUM(E1:EXXX) where XXX is the row number of the last used row in the spreadsheet. Datascope Proprietary Page 14 of 14 0454-00-0034 Revision A