* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download edms_tmp_1967707_DIQH_procedure - lhc-div-mms

Spectral density wikipedia , lookup

Solar micro-inverter wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Ground (electricity) wikipedia , lookup

Wireless power transfer wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Power factor wikipedia , lookup

Stray voltage wikipedia , lookup

Electrical substation wikipedia , lookup

Three-phase electric power wikipedia , lookup

Power inverter wikipedia , lookup

Power over Ethernet wikipedia , lookup

Power MOSFET wikipedia , lookup

Audio power wikipedia , lookup

Surge protector wikipedia , lookup

Immunity-aware programming wikipedia , lookup

Electric power system wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Electrification wikipedia , lookup

Earthing system wikipedia , lookup

History of electric power transmission wikipedia , lookup

Distribution management system wikipedia , lookup

Amtrak's 25 Hz traction power system wikipedia , lookup

Opto-isolator wikipedia , lookup

Power electronics wikipedia , lookup

Power engineering wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

Power supply wikipedia , lookup

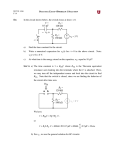

CERN CH-1211 Geneva 23 Switzerland CERN Div./Group or Supplier/Contractor Document No. LHC-MTA-TF/AS/rl the EDMS Document No. Large Hadron Collider 342797 rev. 0.1-draft project Date: 2002/04/22 Technical Manual and Test Procedure THE DIQH TEST SYSTEM Abstract The DIQH tester type HCDQHDS001 is intended for the following application: To test the quench heaters of the pre-series superconducting magnets assembled in industry To validate the integrity of the quench heater circuits The DIQH tester contains: 1) a Macintosh PC instrumented with a National Instruments acquisition card and a dedicated LabView program, 2) a National Instruments connection board for input signals linked to the acquisition card, 3) a trigger box generating 6-0V trigger signal on acquisition card and 12-0V on the quench heater power supply, 4) a quench heater power supply containing the capacitor bank. The DIQH test system is a Low Voltage B device and therefore stringent safety precautions are prevailing. Prepared by : To be checked by : To be approved by : M. Chamiot-Clerc M. Gateau R. Mompo CERN/LHC-MTA K-H. Mess CERN/LHC-ICP A. Siemko CERN/LHC-MTA S. Russenchuck CERN/LHC-ICP F. Szoncso CERN/TIS-GS D. Tommasini CERN/LHC-MMS J. Vlogaert CERN/LHC-MMS C. Charrondière B. Khomenko H. Reymond A. Rijllart CERN/LHC-IAS Distribution List : M. Chamiot-Clerc, C. Charrondière, M. Gateau, B. Khomenko, K-H. Mess, R. Mompo, H. Reymond, A. Rijllart, S. Russenchuck, A. Siemko, F. Szoncso, D. Tommasini, J. Vlogaert. EDMS No. 342797 rev. 0.1-draft Page 2 of 11 History of Changes Rev. No. Date Pages 0.1-draft 2002-04-22 All Description of Changes Document created by M. Gateau. To be checked and approved (see distribution list). Deadline: 26 April 2002. EDMS No. 342797 rev. 0.1-draft Page 3 of 11 Table of Contents 1. INTRODUCTION .......................................................................................4 2. 2.1 2.2 SAFETY PRECAUTIONS ............................................................................4 GENERAL ................................................................................................ 4 SAFETY INSTRUCTIONS ............................................................................ 4 3. 3.1 3.2 3.3 HARDWARE .............................................................................................5 EQUIPMENT ............................................................................................ 5 CABLING ................................................................................................ 5 CAPACITOR BANK CHARGE AND DISCHARGE .............................................. 6 4. SOFTWARE USE .......................................................................................6 5. 5.1 5.2 5.3 5.4 OPERATION PROCEDURE .........................................................................7 TO CONNECT QUENCH HEATER TO THE POWER OUTPUT .............................. 7 FOR 715J ENERGY.................................................................................... 7 FOR MAXIMUM ENERGY (2550J) ................................................................ 7 TO DISCONNECT QUENCH HEATER FROM POWER OUTPUT............................ 7 6. TECHNICAL DESCRIPTION .......................................................................7 6.1 GENERAL DESCRIPTION ........................................................................... 7 6.2 ENVIRONMENTAL CONDITIONS ................................................................. 8 6.3 MAIN PARAMETERS .................................................................................. 8 6.4 CAPACITOR BANK .................................................................................... 8 6.5 TRIGGER CIRCUIT ................................................................................... 9 6.6 CHARGE DETECTOR ................................................................................. 9 6.7 CHARGE MONITOR ................................................................................... 9 6.8 CURRENT MONITOR ............................................................................... 10 6.9 SOFT START CIRCUIT ............................................................................. 10 6.10 INTERNAL POWER SUPPLIES ................................................................... 10 6.11 CONNECTION TO EARTH ......................................................................... 10 7. DIAGRAM ..............................................................................................11 EDMS No. 342797 rev. 0.1-draft Page 4 of 11 1. INTRODUCTION The Dipole Industry Quench Heaters (DIQH) test system has been prepared to verify the proper functioning of quench heaters on pre-series magnets assembled and instrumented with quench heaters in industry. To perform this test an energy from a capacitor bank is dissipated in each quench heater of the magnet at ambient temperature. Safety precautions have been undertaken due to the high energy that would be dangerous for persons. The capacitor bank (7.05mF) is discharged in one quench heater at a time. Firstly 715J (450V) is applied, secondly the nominal value of 2550J (850V) is dissipated. The applied voltage and current are recorded on a labview program. Discharge validity can be evaluated from automatic calculations displayed. The 8 quench heaters of a magnet shall be verified following this procedure. 2. SAFETY PRECAUTIONS 2.1 GENERAL The quench heater power supply is a high energy capacitor bank. It has been designed in such a way that the personal safety shall never be violated. The crate containing the capacitors will never have to be opened which would leave un-accessible the parts under voltage or current carrying conductors under operating conditions. 2.2 SAFETY INSTRUCTIONS This instruction is dedicated to people with a suitable technical training and education, familiar with electrical risks and who can keep the risk for themselves and for others as low as possible. Only authorised personnel shall be allowed to operate the DIQH test system. Before operating the quench heater power supply make sure you have read and understood the operating instructions. Ensure that you observe all the hints and warnings contained within it. If not following the operation instructions, you contravene the safety regulations for operating the DIQH test system. Before operating the quench heater power supply check for any obvious signs of physical damage that may occur during transportation and installation. In case of doubt report immediately to the designers of the quench heater power supplies in CERN/LHC/ICP group. The quench heater power supply must be powered with 230VAC referenced to earth. It is forbidden to disconnect mains cable during whole operation of the apparatus. All cabling connections must be done before powering any hardware equipment. It is forbidden to disconnect any of the connectors under a capacitor bank charge voltage exceeding 50V. The quench heater power supply may only be operated in a clean and dry environment. Ensure that no objects or liquids can get into the crate through the ventilation grids. The quench heater power supply shall not be operated in the vicinity of flammable gases or fumes. The quench heater power supply is air cooled by convection. Therefore, ensure that the ventilation grills are not obstructed and that airflow is available. Once a series of tests is terminated, check the voltage that shall be less than 50V on the labview display. If higher voltage is observed, reset and trigger immediately the power supply again to keep the voltage below 50V. Then switch the power OFF by using the main switch. EDMS No. 342797 rev. 0.1-draft Page 5 of 11 Never leave the quench heater power supply under power and unused for prolonged duration, i.e. during night or without direct supervision. Capacitor bank shall be discharged for transportation and stand by. For troubleshooting consult directly quench heater power supplies designers in CERN/LHC/ICP group. 3. HARDWARE 3.1 EQUIPMENT The DIQH system is composed of: One Macintosh PC instrumented with a National Instruments acquisition card and labview program One National Instruments connection board for input signals linked to the acquisition card One trigger box that generates 6-0V trigger signal on acquisition card and 12-0V on the quench heater power supply One quench heater power supply containing the capacitor bank; power output (Socapex connector) is to be connected to the quench heater strips on sockets 3.2 CABLING All interconnections shall be done before switching on any instrument. Quench heater power supply Trigger Monitor Courant Macintosh with labview program Power output to quench heater Socket Connection board Connection board Monitor Courant Trigger Wire 3 4 1 2 White Blue Socket 33 66, 67 65 31 28 61 Trigger box EDMS No. 342797 rev. 0.1-draft Page 6 of 11 3.3 CAPACITOR BANK CHARGE AND DISCHARGE Once all equipment has been switched ON and connected properly, especially power output connected to quench heater, reset the quench heater power supply with its front panel button to allow the charge of the capacitor bank. To discharge it into the quench heater, press the button on the trigger box that will send the trigger signal. 4. SOFTWARE USE The labview program will be launched automatically when the Macintosh is switched on. View Online ON Then press box. By pressing this button, the user has access to the online values of voltage, current, and trigger level. Voltage charge must be controlled from this window. From this button the user has access to the next window from where the configuration file for DIQH can be loaded (use default configuration). RUN to arm the system that is now waiting for a trigger signal from the trigger Once a trigger is received, the measurement file can be saved under a chosen directory and name. Voltage and current discharge are displayed on the graphs. Automatic calculation of discharge parameters can be visualized by pressing on . The next window is QH TEST then displayed. A particular attention should be taken on initial resistance (~20), time constant (~140ms) and its derivative (-1<’<1), energy (~2550J for 850V, ~715J for 450V), and on minimum reached voltage at the end of discharge (Vmin<10V). EDMS No. 342797 rev. 0.1-draft Page 7 of 11 Previously stored data can be visualised and saved with comments by pressing on View stored data AND Rec Info 5. OPERATION PROCEDURE The 8 quench heater strips of the magnet should be tested one by one in the following way. 5.1 TO CONNECT QUENCH HEATER TO THE POWER OUTPUT The quench heater power supply must show trigger signal on the front panel (trigger led indicator flashing red) Displayed voltage on labview window must be lower than 50V Check whether the SOCAPEX connector is disconnected from the quench heater power supply crate Connect the quench heater leads to the sockets Reconnect the SOCAPEX connector on the quench heater power supply crate 5.2 FOR 715J ENERGY Press reset button on the front panel of the quench heater power supply to charge Control the charge voltage on the labview window Once 450V is reached, arm the acquisition system Send a trigger signal from the trigger box by pressing the button on it Check the discharge parameters to validate the test result 5.3 FOR MAXIMUM ENERGY (2550J) Press reset button on the front panel of the quench heater power supply to charge Control the charge voltage on the labview window Once 850V is reached, arm the acquisition system Send immediately a trigger signal from the trigger box by pressing the button on it Check the discharge parameters to validate the test result 5.4 TO DISCONNECT QUENCH HEATER FROM POWER OUTPUT The quench heater power supply must show trigger signal on the front panel (trigger led indicator flashing red) Displayed voltage on labview window must be lower than 50V Disconnect the SOCAPEX connector from the quench heater power supply crate Disconnect the quench heater leads from the sockets 6. TECHNICAL DESCRIPTION 6.1 GENERAL DESCRIPTION This specification concerns the supply of the heater discharge power supplies for the LHC superconducting magnet protection. In case of a magnet quench these power supplies will energise the heater strips inside the magnet. By these means the propagation of the quench is enhanced in order to prevent damage to the magnet coil. Each power supply contains a capacitor bank with 6 Aluminium electrolytic capacitors (4.7mF/500V) resulting in a total EDMS No. 342797 rev. 0.1-draft Page 8 of 11 capacitance 2x14.1mF/500V which is connected in series. The nominal operating voltage of the capacitors will be Unom=450V giving a maximum stored energy of 2.86kJ. According to LHC-PM-ES-0002.00 each magnet will experience approximately 10 quenches after its installation in the LHC tunnel. In addition there will be approximately two test discharges for diagnostic purposes per year (during LHC shutdown periods). The result is an average of 50 discharges during 20 years of LHC operation. Probably most of the DQHDS remain powered and charged during the shutdown periods, resulting in about 175000 hours of operation within 20 years. This requires long life quality for all parts of the power supply and an industrial grade manufacturing process. 6.2 ENVIRONMENTAL CONDITIONS The power supplies will rely on passive cooling and face the following atmospheric conditions (see also LHC-PM-ES-0002.00 paragraph 6.6). Temperature: 14°C - 26°C Dew point: 12°C 6.3 MAIN PARAMETERS The general electric parameters of the power supply and the specification of all external connectors are summarised in the following tables. Mains power Power consumption Nominal charging voltage Time constant (discharge) Charging time Stored energy Trigger (negative logic) Fuses Temperature range Weight Name Mains power Trigger Charge detector Charge monitor Quench heater 230V 50Hz redundant UPS 15W (35W peak), cos0.88 2x450V 78ms 25min 2.9kJ 12V 0V 1A, 60mA 0°C - 70°C 15kg Ratings 230V 12V/1A DC 12V/1A DC 15V/0.1A DC 1kV/100A surge Type FCI-Burndy UTG0187PVDEX FCI-Burndy UT00104S21T female FCI-Burndy UT00104P21T male Amphenol Socapex SL E F 22 B The power supply follows a modular design and consists of six functional units. 6.4 CAPACITOR BANK Each power supply contains a capacitor bank with 2x3 Aluminium electrolytic capacitors (4.7mF/500V) forming a total capacitance of 2x14.1mF/500V connected in series. The nominal operating voltage of the capacitors will be Unom=450V giving a maximal stored energy of 2.86kJ. The individual capacitors are connected with the help of screwed copper busbars. The centre tap of the capacitor bank is directly connected to the analog ground point of the power supply. A fast freewheeling diode (Schottky type, forward recovery time=0.9µs), mounted in parallel to each sub-circuit containing 3 capacitors, will keep the capacitor bank balanced in case of failures (open circuits, lack of charge). EDMS No. 342797 rev. 0.1-draft Page 9 of 11 6.5 TRIGGER CIRCUIT After receiving the trigger signal (falling ramp 12V 0V) from the quench detector, the trigger circuit provides the firing pulse for both thyristors. At the same time it stops the low voltage B supply for 5 seconds, in order to guarantee a safe turn-off of the thyristors after the capacitor discharge. The heart of the circuit is a NE556 double timer triggered by the falling ramp. It produces the rectangular shape 50ms firing pulse for the thyristors (output 2) and stops at the same time the low voltage B power supply for 5s in order to guarantee a safe turn-off of the thyristors (output 1). The firing pulse is transferred to the thyristors with the help of two current transformers (ratio 2:1). The trigger circuit requires +15V/1A DC stabilised power. 6.6 CHARGE DETECTOR The charge detector circuit signalises to the control system whether the power supply is correctly charged. In case of a power supply failure, this signal will prohibit beam injection. During operation with beam or magnets ramped to current levels above injection, this signal will not cause a beam/power abort, but send a warning to the control system that the specific power supply is no longer available. The “power supply charged” signal will be sent if 90% of the nominal voltage is reached, whereas the “power supply not charged” signal will be given at 80% of the nominal voltage. For the time being the nominal charging voltage is U nom =450V (Uon=405V, Uoff=360V). The capacitor bank of the power supply consists of 2x3 Aluminium electrolytic capacitors (4.7mF/500V) circuited in parallel. In addition each group is protected by a free wheeling diode circuited in parallel to the capacitors. The two groups of 3 capacitors each are connected in series giving a total capacitance of 7.5mF/1000V. The input of the charge detector consists of two voltage dividers across each group of 3 capacitors. The output of these dividers (+10V for the positive branch, -10V for the negative branch for Unom) is connected to two comparators (LM311) wired as Schmitt-triggers. The reference for these comparators is given by 10V reference of the Zener type. In order to use a single reference the negative branch sums the output of the divider and the 10V-reference signal. Both comparator outputs are connected together with diodes forming a logical AND, which is controlling a relay for the output signal. In case the input voltage is smaller than U nom the comparator outputs sink a current of about 15mA to ground. As soon as all capacitors are charged the current drops out. The positive feedback used in the Schmitt-trigger configuration guarantees a fast single transition. The relay has two working contacts one for the output signal and a second one for switching the indicator LED’s mounted on the front panel (GREEN for charged, ORANGE for not charged). The charge detector circuit requires ±15V/1A DC stabilised power. 6.7 CHARGE MONITOR The charge monitor circuit provides a signal for the acquisition and monitoring controller (DQAMC), which is equivalent to 1/100 of the voltage across the capacitor bank. The signal will be used for diagnostic purposes i.e. test discharge of the power supply for verification of the operational status of the capacitor bank and status of the quench heater. The capacitor bank of the power supply consists of 2x3 Aluminium electrolytic capacitors (4.7mF/500V) circuited in parallel. The two groups of 3 capacitors each are connected in series resulting in a total capacitance of 7.5mF/1000V. The output voltages of two dividers (1/100) across each group of 3 capacitors are added and connected to the input of an isolation amplifier (AD210BN). The output signal of this amplifier is then available for further processing in the AMC. The charge detector circuit requires +15V/100mA DC stabilised power. EDMS No. 342797 rev. 0.1-draft Page 10 of 11 6.8 CURRENT MONITOR The current monitor circuit provides a signal for the acquisition and monitoring controller, which of equivalent to 1/25 of the current in the quench heater circuit. The signal will be used for diagnostic purposes i.e. test discharge of the power supply for verification of the operational status of the quench heater. The current monitor circuit is based on LEM HAS 100-S current sensor with a galvanic isolation between the primary circuit (high power) and the secondary circuit (electronic circuit). The current detector circuit requires +5V/12mA DC stabilised power. 6.9 SOFT START CIRCUIT In order to avoid high peak power, the circuit limits the current during the charging of the capacitor banks (Icharge<20mA, Pmax (3 capacitors)10W). As an extra advantage the current limitation makes it possible to reduce the final charging resistance to 1k. The current is limited by a series connection of three resistors (20k, 10k and 1k10W each). Two of these resistors can be short-circuited with the help of relays controlled by a NE556 double timer. The timing sequence is to short-circuit the first resistor after 400s and the second after 1200s leading to a total charging time of about 25 minutes. The trigger for the timer is automatically generated as the circuit is powered. As the operation of components like MOSFET-transistors or photo-triacs is not recommended for circuits exposed to irradiation with high-energy particles, the use of relays is the only feasible solution. The charge detector circuit requires +15V/1A DC stabilised power. 6.10 INTERNAL POWER SUPPLIES Internal voltage levels are produced with two power supplies. One will provide 2x450V DC, as charging voltage of the capacitor banks and a second stabilised power supply with 2x15V DC will feed the electronic sub-circuits. 6.11 CONNECTION TO EARTH The housing of the power supply is directly connected to earth. The analogue ground point of the power supply is connected to earth via a 1M2x500kresistor in parallel with a 63mA slow blowing fuse. EDMS No. 342797 rev. 0.1-draft Page 11 of 11 7. DIAGRAM Control electronic and power circuit diagram