* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download fuse theory and operation

Electrification wikipedia , lookup

Power inverter wikipedia , lookup

Electric power system wikipedia , lookup

Ground (electricity) wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Power engineering wikipedia , lookup

Stepper motor wikipedia , lookup

Electrical ballast wikipedia , lookup

Thermal runaway wikipedia , lookup

Three-phase electric power wikipedia , lookup

Voltage regulator wikipedia , lookup

Electrical substation wikipedia , lookup

Switched-mode power supply wikipedia , lookup

History of electric power transmission wikipedia , lookup

Power electronics wikipedia , lookup

Power MOSFET wikipedia , lookup

Resistive opto-isolator wikipedia , lookup

Voltage optimisation wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Stray voltage wikipedia , lookup

Opto-isolator wikipedia , lookup

Current source wikipedia , lookup

Earthing system wikipedia , lookup

Buck converter wikipedia , lookup

Mains electricity wikipedia , lookup

Current mirror wikipedia , lookup

Surge protector wikipedia , lookup

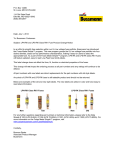

FUSE THEORY AND OPERATION Introduction Terminology ‘Fuse’ does require any introduction. We all know from experience that ‘Fuse’ blows out on short circuits, overcurrents etc. Thus, they limit overcurrent and protect power apparatus. An enormous variety of fuses are available today. Fuses are characterized by ‘thermal’ and interrupting characteristics. Thermal characteristic are quite intuitive and relate to the following. -current rating -melting characteristics Interrupting characteristics refer to -voltage rating -interrupting rating Thermal Characteristics ‘Fuse’ refers to a device that opens a circuit with fusible part, which is heated and severed by current flowing through it. The fusible part is also called the “Element”. When current flows in a fuse, heat is generated and its element temperature rises. If the current within(less or equal to) its continuous rated value, then the new steady state temperature is such that fuse does not melt. However, if the current has sufficient magnitude, the higher current will lead to the fuse element to melt before the steady state temperature conditions are achieved. After melting, the fuse must interrupt the current. It should be obvious that larger magnitude currents will lead to higher power dissipation (I2R) and hence faster rise in temperature. This would imply that melting time of the fuse should be inversely proportional to magnitude of square of current. The relationship between the magnitude of the current that causes melting and the time needed for it to melt is given by the fuse’s melting time current characteristics (TCC).To cover a wide range of currents and operating time, TCC is plotted on a log-log paper. The current is the symmetrical current, fuse carry no initial current and ambient temperature is between 200 C and 300 C(IEEE std 37.41-IS974). Since, the melting time vary in a range, minimum melting time curve is plotted as shown in Fig. As the magnitude of the current increases, melting time reduces. Further, larger the current smaller the melting time. The severity of fuse element is a primary consequence. of thermal effect. It does not depend upon mechanical forces, inertia etc. Thus there is no limit on how short the melting time can be. This extremely small melting (fast operation) of a fuse at very high currents tends to distinguish it from most other protective devices. Very Inverse Melting Characteristic Fuse melting time characteristic is usually sorted to be very inverse. To understand this, we again need to address the physics of the problem. When overcurrents are smaller in magnitude, rate of heat generated in the element is low and only slightly higher than rate of dissipation. As a consequence, temperature of the element increases gradually. As current increases, the melting time reduces at a rate which is more than expected increased rate of heat generation (I2R). This is because, heat which is generated in reduced cross section and/or centre of element, cannot be removed as fast as it is produced. This gives fuse a very inverse characteristics. At very short melting times, no heat is lost from the smaller cross section of the element. Interrupting Characteristics To understand these characteristics, it is important to realize that melting of the fusing element is not sufficient to interrupt the current which continues to flow through the arc. Consequently, there is always some period of arcing before the current is interrupted. During this period, fuse must withstand any immediate transient voltage condition and subsequent steady state recovery voltage. Addition of melting time and this arcing overhead gives total clearing time. Total clearing TCC curve(fig) present this information. For lower currents, melting time can be large and arcing time small. In contrast, for large currents, melting time is small and arcing time large. Hence TCC for melting time and total clearing time diverges as | I | increases. Both these characteristics are required to coordinate back up fuse or overcurrent relay or any other protective devices. Back up devices should give sufficient time to primary fuse to clear the fault. This ensures selectivity which minimizes loss of service. This is a very important consideration in operating electrical energy systems. So far we have broached the subject of voltage rating of a fuse. However, even a fuse has a maximum rated voltage. It is the highest voltage at which fuse is designed to operate and it is important that a fuse not be assigned to interrupt current above this voltage. Sometimes, for a fuse both maximum and minimum interrupting currents are specified. To summarize the fuse behavior or operations, following points should be observed. 1. They are designed to continuous load currents. 2. They are designed to interrupt abnormal overcurrents and thereby isolate circuits. 3. Their melting and interrupting time characteristics should be coordinated with other circuit overcurrent protective devices. 4. Just like circuit breakers, they all interrupt the circuit at a modified or normal current zero, by having a dielectric recovery that is greater than the transient recovery voltage imposed by the power distribution system. 5. Likelihood of thermal breakdown after current zero is reduced by dissipating the arc energy released in the fuse. Classification Of Fuses Fuses can be classified into two types 1. Non-current limiting fuses (Expulsion type). Dielectric medium may be used, vacuum or SF6 The basis for current limiting fuse function at high currents involves inserting a high resistance into the faulted circuit, which forces the power factor of the circuit as a whole closer to unity. Hence, such fuses are insensitive to high X/R ratios. On the other hand, expulsion type fuses do not significantly limit the first of current. Basically, the current limiting fuses attempt to constrict the arc and cooled by sand Fuses can also be classified by their domain of application. Based on this approach they are classified into 1. Power class 2. Distribution class type Power fuses are tested to TRVs and X/R ratio values more likely to be encountered in or near the generating station or substation for three phase circuits. Distribution fuses have specifications more closely matched to distribution system which is further away from source or substation on a single phase or three phase system. We now conclude this lecture, by briefly discussing the physics of arc interruption, both for non current limiting and current limiting fuses. Simplified fault current circuit is shown in Fig. Earc(t) is the arc voltage V(t) the source voltage. Thus, V(t)- Earc(t)=L(di/dt) I(t)=1/L∫(V(t)-Earc(t))dt The equation brings out the following concepts; a) The current is proportional to the area under the difference of source and arc voltage. The inductance provides a stored energy and the necessary voltage to sustain the current even if the instantaneous arc voltage of the fuse momentarily exceeds the source voltage. b) A higher source voltage will adversely affect the interruption of current. c) Conversely, a high fuse arc voltage, sustained over time will helping greater limitation of the fault current. d) If the fuse arc voltage is sustained over time it will have a positive impact on limiting current. e) Lower the inductance, higher the available prospective fault current. Fig 3a and 3b show the function of expulsion type and current limiting fuses. Notice that in expulsion type fuses, arc voltage is low, the peak first cycle current is not limited and current is interrupted after one or two loops at near nominal current zero. In contrast, in current limiting fuse, high arc voltage resulting in substantial current limiting capacity with advanced current zero. This condition is achieved at time ti When ∫V dt= ∫Earc(t)dt