Abstract - 1000kv technologies

... In this project " AUTOMATIC COIL WINDING MACHINE" main objective is to bring out a machine which can implement the idea of automation in Transformer winding or any type of coil windings .Here in real time application let us consider Transformer Manufacturer were the winding is important criterion. A ...

... In this project " AUTOMATIC COIL WINDING MACHINE" main objective is to bring out a machine which can implement the idea of automation in Transformer winding or any type of coil windings .Here in real time application let us consider Transformer Manufacturer were the winding is important criterion. A ...

MOTOR CONTROL STARTER

... Does not have solid poles Instead, it has laminations: numerous flat sheets held together in a package. They are insulated from each other (this reduces Eddy currents) making up the stator The difference between induction and synchronous motors is that the rotor for an induction motor can travel at ...

... Does not have solid poles Instead, it has laminations: numerous flat sheets held together in a package. They are insulated from each other (this reduces Eddy currents) making up the stator The difference between induction and synchronous motors is that the rotor for an induction motor can travel at ...

IM - Module 5

... In order to develop torque in the motor, the rotor position should be determined by sensors so that the excitation timing of the phase windings is precise. Although its construction is one of the simplest possible among electric machines, because of the complexities involved in the control and elect ...

... In order to develop torque in the motor, the rotor position should be determined by sensors so that the excitation timing of the phase windings is precise. Although its construction is one of the simplest possible among electric machines, because of the complexities involved in the control and elect ...

It is the year 2115, and we have successfully discovered

... value 0, which is 0V, then the motor rotates clockwise. Likewise, if the direction signal is logical value 1, which would be 5V, then the motor rotates counter clockwise. Provide details for the transistor used and justify your choices. Identify all currents and voltages in the design as necessary. ...

... value 0, which is 0V, then the motor rotates clockwise. Likewise, if the direction signal is logical value 1, which would be 5V, then the motor rotates counter clockwise. Provide details for the transistor used and justify your choices. Identify all currents and voltages in the design as necessary. ...

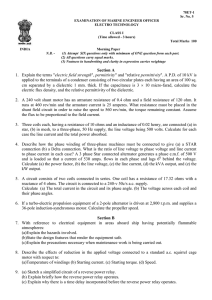

78ET-1 - Marine Engineering Study Materials

... steady current it may carry in order to allow a safe margin of 100 per cent overload if it is known to lose heat at the rate of 0.004 cal/sec/sq cm of surface for each Centigrade degree above the ambient temperature of 17OC. The melting point of the wire material is 327OC and the specific resistance ...

... steady current it may carry in order to allow a safe margin of 100 per cent overload if it is known to lose heat at the rate of 0.004 cal/sec/sq cm of surface for each Centigrade degree above the ambient temperature of 17OC. The melting point of the wire material is 327OC and the specific resistance ...

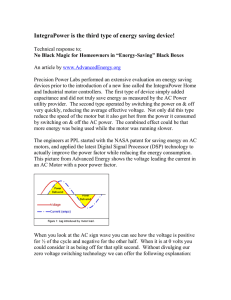

Electronics 3 Class 16 Before the availability of high power

... Timing of the sequence gives frequency of the output signal. - Overall View: ...

... Timing of the sequence gives frequency of the output signal. - Overall View: ...

Document

... • They are designed to operate on 120 V or 240 V. • They range in capacity from fractional horsepower to several horsepower depending on the application. • Voltage is induced in the rotor as a result of magnetic induction, and a magnetic field is produced around the rotor. This field will always be ...

... • They are designed to operate on 120 V or 240 V. • They range in capacity from fractional horsepower to several horsepower depending on the application. • Voltage is induced in the rotor as a result of magnetic induction, and a magnetic field is produced around the rotor. This field will always be ...

Synchronous Motor

... centrifugal stresses inherent in high-speed operation Used for high speed, low inertia loads (low starting torque) ...

... centrifugal stresses inherent in high-speed operation Used for high speed, low inertia loads (low starting torque) ...

Induction motor control

... Electrical power converted into mechanical power (developed power in the rotor). Pm = Total air gap power transferred across the air gap for a three phase induction motor (Pag) – copper loss in the rotor (Pcur) ...

... Electrical power converted into mechanical power (developed power in the rotor). Pm = Total air gap power transferred across the air gap for a three phase induction motor (Pag) – copper loss in the rotor (Pcur) ...

Stepper motor

A stepper motor or step motor or stepping motor is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can then be commanded to move and hold at one of these steps without any feedback sensor (an open-loop controller), as long as the motor is carefully sized to the application in respect to torque and speed.Switched reluctance motors are very large stepping motors with a reduced pole count, and generally are closed-loop commutated.