The fracture toughness of a cordierite square lattice

... tensile stresses are highest). Struts fail successively forming a crack which propagates parallel to the loading direction, but kinks into a 45° angle before reaching the top layer of cells. For the notched lattice (Fig. 6b), the most heavily loaded struts at the crack tip fail first. The crack then ...

... tensile stresses are highest). Struts fail successively forming a crack which propagates parallel to the loading direction, but kinks into a 45° angle before reaching the top layer of cells. For the notched lattice (Fig. 6b), the most heavily loaded struts at the crack tip fail first. The crack then ...

structure and properties of severe deformed nanocomposite

... mechanism of niobium fibers, is forming of knife-like boundaries that are the result of propagation of powerful disclinations. In that way on the defined stage of drawing structure with 10-20 0 fragment disorientation angle is formed in niobium fibers. At that time strong internal elastic deformatio ...

... mechanism of niobium fibers, is forming of knife-like boundaries that are the result of propagation of powerful disclinations. In that way on the defined stage of drawing structure with 10-20 0 fragment disorientation angle is formed in niobium fibers. At that time strong internal elastic deformatio ...

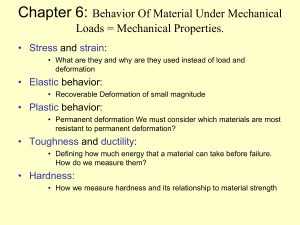

Chapter 6: Mechanical Properties

... measures of load and displacement, respectively. • Elastic behavior: This reversible behavior often shows a linear relation between stress and strain. To minimize deformation, select a material with a large elastic modulus (E or G). • Plastic behavior: This permanent deformation behavior occurs when ...

... measures of load and displacement, respectively. • Elastic behavior: This reversible behavior often shows a linear relation between stress and strain. To minimize deformation, select a material with a large elastic modulus (E or G). • Plastic behavior: This permanent deformation behavior occurs when ...

Ductile fracture

... made up of steel which has low DBT temperature. On the day of sinking, sea temperature was –20 C which made the structure highly brittle and susceptible to more damage Sub: Material Science & Metallurgy (131904) ...

... made up of steel which has low DBT temperature. On the day of sinking, sea temperature was –20 C which made the structure highly brittle and susceptible to more damage Sub: Material Science & Metallurgy (131904) ...

(131904) Topic: Fracture of Metal Temperature Embrittlement

... made up of steel which has low DBT temperature. On the day of sinking, sea temperature was –20 C which made the structure highly brittle and susceptible to more damage Sub: Material Science & Metallurgy (131904) ...

... made up of steel which has low DBT temperature. On the day of sinking, sea temperature was –20 C which made the structure highly brittle and susceptible to more damage Sub: Material Science & Metallurgy (131904) ...

Classes of materials

... is an indication of a material’s ability to resist wear or scratching. This will be an important property if the equipment is being designed to handle abrasive solids, or liquids containing suspended solids which are likely to cause erosion. ...

... is an indication of a material’s ability to resist wear or scratching. This will be an important property if the equipment is being designed to handle abrasive solids, or liquids containing suspended solids which are likely to cause erosion. ...

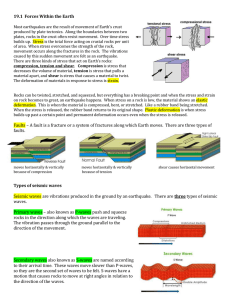

19.1-forces-within-Earth

... plates, rocks in the crust often resist movement. Over time stress builds up. Stress is the total force acting on crustal rocks per unit of area. When stress overcomes the strength of the rock, movement occurs along the fractures in the rock. The vibrations caused by this sudden movement are felt as ...

... plates, rocks in the crust often resist movement. Over time stress builds up. Stress is the total force acting on crustal rocks per unit of area. When stress overcomes the strength of the rock, movement occurs along the fractures in the rock. The vibrations caused by this sudden movement are felt as ...

High Strain Mechanics and Its Importance in Crushing and Grinding

... explosion. Brittle materials behave differently when subjected to high strain rates as opposed to quasistatic strain rates. Quasi-static loading occurs when the stress pulse is slow enough for the system to remain in internal equilibrium. That is, material fracture develops as the stress pulse moves ...

... explosion. Brittle materials behave differently when subjected to high strain rates as opposed to quasistatic strain rates. Quasi-static loading occurs when the stress pulse is slow enough for the system to remain in internal equilibrium. That is, material fracture develops as the stress pulse moves ...

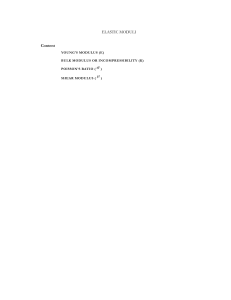

Poisson`s ratio

... decrease. Ph always has positive value and the negative sign in the compensation (R.H.S.) keeps this relation valid. A material that has a large bulk modulus could be imagined to consist of very tightly bound spring and ball materials which will quickly transmit a wave. Ideally, elastic deformation ...

... decrease. Ph always has positive value and the negative sign in the compensation (R.H.S.) keeps this relation valid. A material that has a large bulk modulus could be imagined to consist of very tightly bound spring and ball materials which will quickly transmit a wave. Ideally, elastic deformation ...

Simplified Thermal Stress Analysis

... During manufacturing, small stress concentrations often occur – small cracks when a semiconductor die is sawed, small voids formed. When external stress is applied, these concentrations amplify the stress and may cause a fracture. For an elliptical microcrack with major axis perpendicular to applied ...

... During manufacturing, small stress concentrations often occur – small cracks when a semiconductor die is sawed, small voids formed. When external stress is applied, these concentrations amplify the stress and may cause a fracture. For an elliptical microcrack with major axis perpendicular to applied ...

At what grain diameter will the lower yield point be 310 Mpa?

... 230 MPa (33,000 psi). At a grain diameter of 6 × 10–3 mm, the yield point increases to 275 MPa (40,000 psi). At what grain diameter will the lower yield point be 310 Mpa? ...

... 230 MPa (33,000 psi). At a grain diameter of 6 × 10–3 mm, the yield point increases to 275 MPa (40,000 psi). At what grain diameter will the lower yield point be 310 Mpa? ...

Size reduction

... nanoparticles. These particles consist of pure active pharmaceutical ingredient (API) and are often stabilized with surfactants and/or polymeric stabilizers adsorbed onto their surface. The theoretical strength of crystalline materials can be calculated from interatomic attractive and repulsive forc ...

... nanoparticles. These particles consist of pure active pharmaceutical ingredient (API) and are often stabilized with surfactants and/or polymeric stabilizers adsorbed onto their surface. The theoretical strength of crystalline materials can be calculated from interatomic attractive and repulsive forc ...

a cohesive elements based model to describe fracture and cohesive

... In the model of the tensile test shown in Figure 3-(A), the strength of the cohesive layer was taken by considering the maximum stress obtained in a tensile test on an unnotched specimen. In the first round of analyses, the viscoelastic behaviour of the elastomer was neglected and a bi-linear cohesi ...

... In the model of the tensile test shown in Figure 3-(A), the strength of the cohesive layer was taken by considering the maximum stress obtained in a tensile test on an unnotched specimen. In the first round of analyses, the viscoelastic behaviour of the elastomer was neglected and a bi-linear cohesi ...

Polymers composed of a large number of repeating units. Isomers

... An edge dislocation is a defect where an extra half-plane of atoms is introduced mid way through the crystal, distorting nearby planes of atoms. A screw dislocation is much harder to visualize. Imagine cutting a crystal along a plane and slipping one half across the other by a lattice vector, the h ...

... An edge dislocation is a defect where an extra half-plane of atoms is introduced mid way through the crystal, distorting nearby planes of atoms. A screw dislocation is much harder to visualize. Imagine cutting a crystal along a plane and slipping one half across the other by a lattice vector, the h ...

Identifying Failures and Ensuring Quality of Plastic Materials

... characterization tool which can be used effectively in product design, manufacture, and as demonstrated in this article, failure analysis. In any of these applications areas modern FT-IR systems with diamond ATR sampling can provide rapid analysis of samples with very little effort. Lessons learned ...

... characterization tool which can be used effectively in product design, manufacture, and as demonstrated in this article, failure analysis. In any of these applications areas modern FT-IR systems with diamond ATR sampling can provide rapid analysis of samples with very little effort. Lessons learned ...

Dynamic propagation of a macrocrack interacting with parallel small

... propagation/interaction [5]. Meshfree methods can be a good alternative to finite element method and has been applied to dynamic fracture and fragmentation [6,7]. Moreover, Cracking Particle Method (CPM) [8] was introduced for complex fracture patterns such as crack branching and coalescence. Anothe ...

... propagation/interaction [5]. Meshfree methods can be a good alternative to finite element method and has been applied to dynamic fracture and fragmentation [6,7]. Moreover, Cracking Particle Method (CPM) [8] was introduced for complex fracture patterns such as crack branching and coalescence. Anothe ...

fracture analysis of surface- and through-cracked

... Fracture data on surface-cracked sheet and plate specimens of steel, titanium ahoy, titanium weldment, and aluminum alloy tested at room and cryogenic temperature were analyzed according to equation (9). Wide ranges of crack-depth to crack-half-length ratio (a/c = 0.08 to 1.4) and crack-depth to spe ...

... Fracture data on surface-cracked sheet and plate specimens of steel, titanium ahoy, titanium weldment, and aluminum alloy tested at room and cryogenic temperature were analyzed according to equation (9). Wide ranges of crack-depth to crack-half-length ratio (a/c = 0.08 to 1.4) and crack-depth to spe ...

212_khr.pdf

... One of features of the theory of ideal rigid-plastic body is the possibility of the description of finite strain tensor fields in neighborhood of zones of discontinuity of body shape (angular point of notch, crack tip, etc.), [1]. These regions are strain concentrators and, as a rule, fracture sourc ...

... One of features of the theory of ideal rigid-plastic body is the possibility of the description of finite strain tensor fields in neighborhood of zones of discontinuity of body shape (angular point of notch, crack tip, etc.), [1]. These regions are strain concentrators and, as a rule, fracture sourc ...

MSE 170A Midterm 07

... b. Describe briefly mechanisms related to vacancy and interstitial diffusion and give two reasons why interstitial diffusion is more rapidly than vacancy diffusion. ...

... b. Describe briefly mechanisms related to vacancy and interstitial diffusion and give two reasons why interstitial diffusion is more rapidly than vacancy diffusion. ...

CHAPTER5

... In most engineering materials, however, there will also exist a timedependent elastic strain component. That is, elastic deformation will continue after the stress application, and upon load release some finite time is required for complete recovery. This time-dependent elastic behavior is known as ...

... In most engineering materials, however, there will also exist a timedependent elastic strain component. That is, elastic deformation will continue after the stress application, and upon load release some finite time is required for complete recovery. This time-dependent elastic behavior is known as ...

MATERIALS

... Stress-- σ load per unit area. units: p.s.i. or MegaNewtons/ m . Strain-- ε deformation per unit length units: dimensionless Hooke's Law A. Robert Hooke, 1679 "As the extension, so the force", i.e., stress is proportional to strain B. Hooke's law: an approximation of the relationship between the def ...

... Stress-- σ load per unit area. units: p.s.i. or MegaNewtons/ m . Strain-- ε deformation per unit length units: dimensionless Hooke's Law A. Robert Hooke, 1679 "As the extension, so the force", i.e., stress is proportional to strain B. Hooke's law: an approximation of the relationship between the def ...

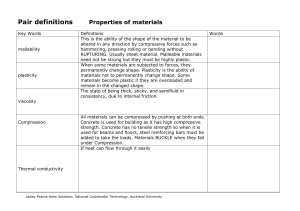

Pair definitions Properties of materials

... Pair definitions Key Words Tensile strength Elasticity ...

... Pair definitions Key Words Tensile strength Elasticity ...

Stress - Delta University!

... Types of stresses 1. Axial stresses Compressive stress Compression results when the body is subjected to two sets of forces directed towards each other in the same straight line. (fig.2) Tensile stress Tension results in a body when it is subjected ...

... Types of stresses 1. Axial stresses Compressive stress Compression results when the body is subjected to two sets of forces directed towards each other in the same straight line. (fig.2) Tensile stress Tension results in a body when it is subjected ...

An energy-based approach for estimates of the stress-strain

... The analysis of stress in notches, needed almost exclusively for fatigue design purposes, is performed with the help of the fatigue stress concentration factor kf . Again the material behavior is assumed to be linear elastic and the little plasticity, if present, is believed to be confined at a pret ...

... The analysis of stress in notches, needed almost exclusively for fatigue design purposes, is performed with the help of the fatigue stress concentration factor kf . Again the material behavior is assumed to be linear elastic and the little plasticity, if present, is believed to be confined at a pret ...

Fracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.In modern materials science, fracture mechanics is an important tool in improving the mechanical performance of mechanical components. It applies the physics of stress and strain, in particular the theories of elasticity and plasticity, to the microscopic crystallographic defects found in real materials in order to predict the macroscopic mechanical failure of bodies. Fractography is widely used with fracture mechanics to understand the causes of failures and also verify the theoretical failure predictions with real life failures. The prediction of crack growth is at the heart of the damage tolerance discipline.There are three ways of applying a force to enable a crack to propagate:Mode I fracture – Opening mode (a tensile stress normal to the plane of the crack),Mode II fracture – Sliding mode (a shear stress acting parallel to the plane of the crack and perpendicular to the crack front), andMode III fracture – Tearing mode (a shear stress acting parallel to the plane of the crack and parallel to the crack front).