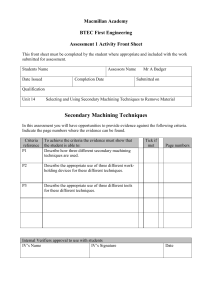

Secondary Machining Techniques

... training you must undergo appreciation courses in the other trades. The following tasks form part of a mechanical fitter’s job description. Tasks 1 You need to write a report for each of the named processes below. The reports must also include diagrams to aid in the description of how the process wo ...

... training you must undergo appreciation courses in the other trades. The following tasks form part of a mechanical fitter’s job description. Tasks 1 You need to write a report for each of the named processes below. The reports must also include diagrams to aid in the description of how the process wo ...

TipTalk June 2011

... pocket design. An innovative clamping design enables significantly more insert indexes. The drill features twisted coolant nozzles with indexable drilling heads, which are available in different head configurations for various material groups. ISCAR’s innovative SUMOCHAM drill line will provide long ...

... pocket design. An innovative clamping design enables significantly more insert indexes. The drill features twisted coolant nozzles with indexable drilling heads, which are available in different head configurations for various material groups. ISCAR’s innovative SUMOCHAM drill line will provide long ...

automatic embossing drilling machine

... Drilling is the process of producing hole on the work piece by using a rotating cutter called drill. The machine used for drilling is known as drilling machine. By a drilling machine holes are drilled. ...

... Drilling is the process of producing hole on the work piece by using a rotating cutter called drill. The machine used for drilling is known as drilling machine. By a drilling machine holes are drilled. ...

The History of Drill and Ceremony

... Military history reveals that armies throughout the world participated in some form of drill. The primary value of drill, historically, is to prepare troops for battle. For the most part, the drill procedures practiced are identical to the tactical maneuvers employed on the battlefield. Drill enable ...

... Military history reveals that armies throughout the world participated in some form of drill. The primary value of drill, historically, is to prepare troops for battle. For the most part, the drill procedures practiced are identical to the tactical maneuvers employed on the battlefield. Drill enable ...

Drill

A drill is a tool fitted with a cutting tool attachment or driving tool attachment, usually a drill bit or driver bit, used for boring holes in various materials or fastening various materials together with the use of fasteners. The attachment is gripped by a chuck at one end of the drill and rotated while pressed against the target material. The tip, and sometimes edges, of the cutting tool does the work of cutting into the target material. This may be slicing off thin shavings (twist drills or auger bits), grinding off small particles (oil drilling), crushing and removing pieces of the workpiece (SDS masonry drill), countersinking, counterboring, or other operations.Drills are commonly used in woodworking, metalworking, construction and do-it-yourself projects. Specially designed drills are also used in medicine, space missions and other applications. Drills are available with a wide variety of performance characteristics, such as power and capacity.