basic_CMOS_technology

... • For PMOS transistors the same concepts are valid except that: – All voltages are negative (including Vth) – Were we used bigger than you should use smaller than – The drain current actually flows out of the transistor instead of into the transistor. ...

... • For PMOS transistors the same concepts are valid except that: – All voltages are negative (including Vth) – Were we used bigger than you should use smaller than – The drain current actually flows out of the transistor instead of into the transistor. ...

Lecture 4

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

Electrical Discharge Machining- EDM

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

Laser Beam Machining

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

Document

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

Slides - Agenda INFN

... 3. ZBTSC scan (heating): system brought back to the fundamental equilibrium state. Charge redistribute into the volume and charge injection occurs at the electrodes, giving rise to current detected in the external circuit. Charge relaxation during heating scan can be discussed in terms of motion of ...

... 3. ZBTSC scan (heating): system brought back to the fundamental equilibrium state. Charge redistribute into the volume and charge injection occurs at the electrodes, giving rise to current detected in the external circuit. Charge relaxation during heating scan can be discussed in terms of motion of ...

Dip Coating - University of New Mexico

... At first some general comments to the requirements of precursor solutions with regard to successful dip coating are presented in this section. A trivial but probably most important precondition is that the condensed phase remain dispersed in the fluid medium, that macroscopic gelation be avoided, an ...

... At first some general comments to the requirements of precursor solutions with regard to successful dip coating are presented in this section. A trivial but probably most important precondition is that the condensed phase remain dispersed in the fluid medium, that macroscopic gelation be avoided, an ...

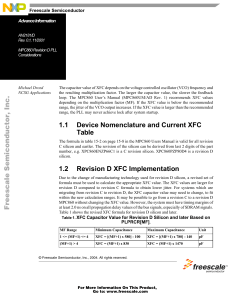

AN2181: MPC860 Revision D PLL Considerations

... any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters which may be provided in Freescale Semiconductor data sheets and/or specifications can and do vary in different applications and actual per ...

... any product or circuit, and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters which may be provided in Freescale Semiconductor data sheets and/or specifications can and do vary in different applications and actual per ...

Abstract - ASU Physics

... young age. His parents claim that he was a handful and always getting into trouble. The problem, however, was that he rarely got punished because he could always end up making his mother laugh. This gift of his was and still is the core of his personality. As a child, the author moved several times ...

... young age. His parents claim that he was a handful and always getting into trouble. The problem, however, was that he rarely got punished because he could always end up making his mother laugh. This gift of his was and still is the core of his personality. As a child, the author moved several times ...

Effects of sputter deposition parameters on stress in tantalum films

... Figure 5: Generic hysteresis curve for voltage vs. reactive gas flow rate ......................... 9 Figure 6: Different process steps in the copper damascene process............................... 10 Figure 7: Schematic representation of typical CMP process ........................................ ...

... Figure 5: Generic hysteresis curve for voltage vs. reactive gas flow rate ......................... 9 Figure 6: Different process steps in the copper damascene process............................... 10 Figure 7: Schematic representation of typical CMP process ........................................ ...

ENG165-265.2017 .4

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

... referred to as the heat-affected zone or HAZ. The heating (and subsequent cooling) waves propagating through the HAZ cause mechanical stress and may create micro cracks (or in some cases, macro cracks) in the surrounding material. These defects are "frozen" in the structure when the material cools, ...

Atomic Force Microscope (AFM)

... ● The Lennard-Jones potential is important for the interaction between neutral atoms or molecules. The electrostatic interaction force becomes important, if the particles are electrically charged and conductive. ...

... ● The Lennard-Jones potential is important for the interaction between neutral atoms or molecules. The electrostatic interaction force becomes important, if the particles are electrically charged and conductive. ...

ppt - CMOS VLSI Design

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

CMOS VLSI Design

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

IU2415411546

... As the conducting polymer is grown out of a solution, the deposited film contains cation sites balanced by anions from the electrolyte and the solvent residue (Wünsche et al., 1995 and Hodgins et al., 1995 and 1997).The cation sites probably consist of polar ions or bipolar ions which are small regi ...

... As the conducting polymer is grown out of a solution, the deposited film contains cation sites balanced by anions from the electrolyte and the solvent residue (Wünsche et al., 1995 and Hodgins et al., 1995 and 1997).The cation sites probably consist of polar ions or bipolar ions which are small regi ...

Lecture 0 - Harvey Mudd College

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

A novel large displacement electrostatic actuator: pre

... the method [17], and causes problems of alignment and gap expansion. Notably, a vertical comb-drive actuator cannot easily achieve a larger deflection angle at a low driving voltage. The advantages of bulk micromachining, a MEMS fabrication technique, are in manufacturing flatter micromirrors, with ...

... the method [17], and causes problems of alignment and gap expansion. Notably, a vertical comb-drive actuator cannot easily achieve a larger deflection angle at a low driving voltage. The advantages of bulk micromachining, a MEMS fabrication technique, are in manufacturing flatter micromirrors, with ...

Deposition, Characterization, and Fabrication of a Zinc Oxide

... creates electricity that can then be stored and used to power other devices. ................................. 4 Figure 3 – The material experiences the direct piezoelectric effect when a pressure is applied, resulting in an electrical potential that can be detected. ................................ ...

... creates electricity that can then be stored and used to power other devices. ................................. 4 Figure 3 – The material experiences the direct piezoelectric effect when a pressure is applied, resulting in an electrical potential that can be detected. ................................ ...

Silica (quartz) Silica, SiO2, is a white or colorless crystalline

... Silicon (Si) has the atomic number 14 and is closely related to carbon. It is a relatively inert metalloid. Silicon is often used for microchips, glass, cement, and pottery. Silica is the most abundant mineral found in the crust of the earth. One of the most common uses of silica quarts is the manuf ...

... Silicon (Si) has the atomic number 14 and is closely related to carbon. It is a relatively inert metalloid. Silicon is often used for microchips, glass, cement, and pottery. Silica is the most abundant mineral found in the crust of the earth. One of the most common uses of silica quarts is the manuf ...

Cellular materials made of stacked tubes : influence of the

... properties of their constitutive material an Inconel 600® here, it has been proposed to perform uniaxial tensile tests at various strain rates on tubular specimens for the three different material configurations. The cellular materials in Figure 1 being possibly subjected to dynamic loads (i.e. fan ...

... properties of their constitutive material an Inconel 600® here, it has been proposed to perform uniaxial tensile tests at various strain rates on tubular specimens for the three different material configurations. The cellular materials in Figure 1 being possibly subjected to dynamic loads (i.e. fan ...

Document

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

634_1.pdf

... In the case of powder samples and highly imperfect single crystals, these assumptions are usually warranted. However, in large, highly perfect semiconductor crystals, one or even all may become invalid. In these cases a more complex theory is needed to describe the diffraction process. In this appro ...

... In the case of powder samples and highly imperfect single crystals, these assumptions are usually warranted. However, in large, highly perfect semiconductor crystals, one or even all may become invalid. In these cases a more complex theory is needed to describe the diffraction process. In this appro ...

Recovery of electronic properties in hydrogen

... forming-gas anneal is performed in the temperature range of about from 400° C. to 450° C. for about 30 minutes, then the ferroelectric and electronic properties of the ferroelectric element are practically fully recovered When an inert-gas recovery anneal is conducted in the temperature range of abo ...

... forming-gas anneal is performed in the temperature range of about from 400° C. to 450° C. for about 30 minutes, then the ferroelectric and electronic properties of the ferroelectric element are practically fully recovered When an inert-gas recovery anneal is conducted in the temperature range of abo ...

CMOS VLSI Design 4th Ed.

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

... n-well n-well is formed with diffusion or ion implantation Diffusion – Place wafer in furnace with arsenic gas – Heat until As atoms diffuse into exposed Si Ion Implanatation – Blast wafer with beam of As ions – Ions blocked by SiO2, only enter exposed Si SiO2 n well ...

IOSR Journal of Applied Physics (IOSR-JAP)

... In this report, gate tunneling electron current and substrate hole current versus gate voltage characteristics of two n+ polysilicon gated n-channel MOSFETs are analyzed to characterize the metal-oxidesemiconductor device structure. The MOSFET data were reported by Eitan and Kolodny in 1983 and Rasr ...

... In this report, gate tunneling electron current and substrate hole current versus gate voltage characteristics of two n+ polysilicon gated n-channel MOSFETs are analyzed to characterize the metal-oxidesemiconductor device structure. The MOSFET data were reported by Eitan and Kolodny in 1983 and Rasr ...

Microelectromechanical systems

Microelectromechanical systems (MEMS) (also written as micro-electro-mechanical, MicroElectroMechanical or microelectronic and microelectromechanical systems and the related micromechatronics) is the technology of very small devices; it merges at the nano-scale into nanoelectromechanical systems (NEMS) and nanotechnology. MEMS are also referred to as micromachines (in Japan), or micro systems technology – MST (in Europe).MEMS are separate and distinct from the hypothetical vision of molecular nanotechnology or molecular electronics. MEMS are made up of components between 1 to 100 micrometres in size (i.e. 0.001 to 0.1 mm), and MEMS devices generally range in size from 20 micrometres to a millimetre (i.e. 0.02 to 1.0 mm). They usually consist of a central unit that processes data (the microprocessor) and several components that interact with the surroundings such as microsensors. At these size scales, the standard constructs of classical physics are not always useful. Because of the large surface area to volume ratio of MEMS, surface effects such as electrostatics and wetting dominate over volume effects such as inertia or thermal mass.The potential of very small machines was appreciated before the technology existed that could make them (see, for example, Richard Feynman's famous 1959 lecture There's Plenty of Room at the Bottom). MEMS became practical once they could be fabricated using modified semiconductor device fabrication technologies, normally used to make electronics. These include molding and plating, wet etching (KOH, TMAH) and dry etching (RIE and DRIE), electro discharge machining (EDM), and other technologies capable of manufacturing small devices. An early example of a MEMS device is the resonistor – an electromechanical monolithic resonator.