Chapter 5 Revenue

... The perpetual inventory system consists of a continuous record of inventory movement, usually main tained by computer. This system, in contrast to the periodic inventory system, maintains a constant record of inventory purchased and sold thus providing a balance at any time. Using the same example ...

... The perpetual inventory system consists of a continuous record of inventory movement, usually main tained by computer. This system, in contrast to the periodic inventory system, maintains a constant record of inventory purchased and sold thus providing a balance at any time. Using the same example ...

Solution: AQ#3 (Chp 4, 5, 6)

... ____ 1. Which of the following would represent a “product” cost? a. Merchandise purchased for resale. b. Interest paid to the bank on a note payable. c. Advertising expense. d. Salary for the company president. Use the following information for question #2: BG Supply Co. uses accrual-basis accountin ...

... ____ 1. Which of the following would represent a “product” cost? a. Merchandise purchased for resale. b. Interest paid to the bank on a note payable. c. Advertising expense. d. Salary for the company president. Use the following information for question #2: BG Supply Co. uses accrual-basis accountin ...

FoxMeyer Drug

... • included electronic order entry, invoice preparation, inventory tracking • 1992 began migration of core systems • Benefits not realized until system fully integrated ...

... • included electronic order entry, invoice preparation, inventory tracking • 1992 began migration of core systems • Benefits not realized until system fully integrated ...

1 - Cengage

... Managers want information displayed so that the important problems or issues can be identified quickly. One method of reporting information is the Pareto chart. A Pareto chart is a bar chart that shows the totals of an attribute for a number of ranked ...

... Managers want information displayed so that the important problems or issues can be identified quickly. One method of reporting information is the Pareto chart. A Pareto chart is a bar chart that shows the totals of an attribute for a number of ranked ...

Production-and-Operations-Management

... cycle time • Higher capacity utilization due to line balancing • Manpower is not required for material handling as it is completely automatic • Person with limited skills can be used on the production line • Unit cost is lower due to high volume of production ...

... cycle time • Higher capacity utilization due to line balancing • Manpower is not required for material handling as it is completely automatic • Person with limited skills can be used on the production line • Unit cost is lower due to high volume of production ...

Postponement - Georgia Tech ISyE

... Postponement How to respond to demands for – Customized products – Rapid delivery – Competitive prices ...

... Postponement How to respond to demands for – Customized products – Rapid delivery – Competitive prices ...

In-Class Exercise : Applying the Research Steps

... toy stores and discount retailers. Each grow-a-frog kit contains a small plastic aquarium tank, gravel, a plastic plant, and a coupon redeemable for one live tadpole. A large inventory of tadpoles are kept on hand at all times. To ensure a ready supply of tadpoles, one thousand adult frogs are kept ...

... toy stores and discount retailers. Each grow-a-frog kit contains a small plastic aquarium tank, gravel, a plastic plant, and a coupon redeemable for one live tadpole. A large inventory of tadpoles are kept on hand at all times. To ensure a ready supply of tadpoles, one thousand adult frogs are kept ...

FoxMeyer Drug - Yuan Ze University

... – late orders, incorrect shipment, lost shipments – losses of over $15 million ...

... – late orders, incorrect shipment, lost shipments – losses of over $15 million ...

Manufacturing

... Analyse product requirements by examining sales quotations, orders, deliveries, invoices, job quotations and other production runs to produce recommendations for required work orders. Simplify and speed up the process of purchasing by analysing component demand and taking into account lead times for ...

... Analyse product requirements by examining sales quotations, orders, deliveries, invoices, job quotations and other production runs to produce recommendations for required work orders. Simplify and speed up the process of purchasing by analysing component demand and taking into account lead times for ...

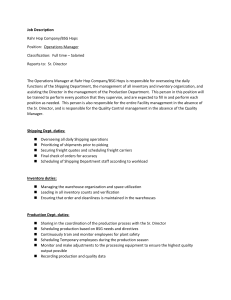

Job Description Rahr Hop Company/BSG Hops Position: Operations

... assisting the Director in the management of the Production Department. This person in this position will be trained to perform every position that they supervise, and are expected to fill in and perform each position as needed. This person is also responsible for the entire Facility management in th ...

... assisting the Director in the management of the Production Department. This person in this position will be trained to perform every position that they supervise, and are expected to fill in and perform each position as needed. This person is also responsible for the entire Facility management in th ...

Chap009

... Chapter 9 Production Cycle “There is one rule for industrialists and that is: Make the best quality of goods possible at the lowest cost possible, paying the highest wages possible.”—Henry Ford ...

... Chapter 9 Production Cycle “There is one rule for industrialists and that is: Make the best quality of goods possible at the lowest cost possible, paying the highest wages possible.”—Henry Ford ...