* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download Item Code Technical Specifications Quantity DL 2125 DC MOTOR

Survey

Document related concepts

Mains electricity wikipedia , lookup

Electrification wikipedia , lookup

Electric motor wikipedia , lookup

Alternating current wikipedia , lookup

Electric machine wikipedia , lookup

Stepper motor wikipedia , lookup

Brushless DC electric motor wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Distributed control system wikipedia , lookup

Potentiometer wikipedia , lookup

Induction motor wikipedia , lookup

Resilient control systems wikipedia , lookup

Brushed DC electric motor wikipedia , lookup

Control theory wikipedia , lookup

Transcript

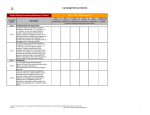

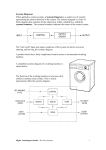

Item Code DL 2125 Technical Specifications DC MOTOR SPEED CONTROL – didactic equipment This system must be suitable for the study of programmable logic control techniques in the control of the speed of a separately excited dc motor. The speed regulation shall include two control loops: hardware current loop with overcurrent limiting and speed loop with external PLC control. Speed measuring with a tachogenerator or with an optoencoder via frequency/voltage converter. Speed reference set by means of potentiometer or selector switches and under PLC control. The PI controller shall modulate the PWM circuit that drives the power stage consisting of switching transistor. Possibility of acceleration and deceleration ramps programming. Pointer meters for motor speed, voltage and armature current; The system shall be supplied with a machine set consisting of a dc permanent magnet motor, a dc tachogenerator, an encoder and a manual brake. Power: 48 Vdc, 5 A. Tachometric signal: 180 V at 3000 rpm. Power supply: single-phase from mains. Complete with connecting cables, teacher's manual and student's work forms. With this system, the student must be able to study the following: Open loop speed control Closed loop speed control Use of the PLC for the speed measuring Acceleration and deceleration ramps programming Duty cycle monitoring With this trainer it must be possible to perform the following exercises: the automatic regulation the block diagram the industrial operations direct current electric motors permanent magnet motors operations for direct current motors Quantity speed transducers operation characteristics of the opto-encoder output characteristics of the tachometric dynamo the plc as tachometric indicator control with the speed set through the keyboard control with the speed adjusted through the potentiometer closed loop control with potentiometer and tachometric dynamo closed loop control with potentiometer and opto-encoder The system must be connectable to PLC through two connectors (37-pin type) placed on the backside of the panel. This system must be supplied with connecting cables, educational manual and PLC control software.