* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

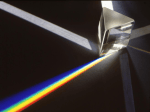

Download 1 Fundamental Optics www.cvimellesgriot.com

Optical rogue waves wikipedia , lookup

Dispersion staining wikipedia , lookup

Atmospheric optics wikipedia , lookup

Ultraviolet–visible spectroscopy wikipedia , lookup

Reflector sight wikipedia , lookup

Fiber-optic communication wikipedia , lookup

Ellipsometry wikipedia , lookup

Optical coherence tomography wikipedia , lookup

Surface plasmon resonance microscopy wikipedia , lookup

3D optical data storage wikipedia , lookup

Silicon photonics wikipedia , lookup

Thomas Young (scientist) wikipedia , lookup

Confocal microscopy wikipedia , lookup

Fourier optics wikipedia , lookup

Magnetic circular dichroism wikipedia , lookup

Birefringence wikipedia , lookup

Interferometry wikipedia , lookup

Optical telescope wikipedia , lookup

Photon scanning microscopy wikipedia , lookup

Schneider Kreuznach wikipedia , lookup

Optical tweezers wikipedia , lookup

Image stabilization wikipedia , lookup

Anti-reflective coating wikipedia , lookup

Lens (optics) wikipedia , lookup

Nonlinear optics wikipedia , lookup

Retroreflector wikipedia , lookup

Nonimaging optics wikipedia , lookup